Professional Documents

Culture Documents

Wps Asme Ix-2019 Template

Uploaded by

Almasrizal AlmasrizalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps Asme Ix-2019 Template

Uploaded by

Almasrizal AlmasrizalCopyright:

Available Formats

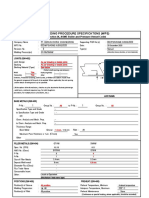

WELDING PROCEDURE SPECIFICATION

(WPS)

ASME IX-2019

Page 1 Of 2

Company Name

Date

Welding Procedure Specification No. Revision No.

------ Date

Supporting PQR No.(s) Revision No.

------

Welding Process(es) Type(s)

(Automatic, Manual, Machin•. or S•mi-Automatlc)

JOINTS (QW·402) Details Joint Details 6(1> 110·

\ )

l--t-----\

Joint Design :

Root Spacing :

Backing Yes : _

Backing Material (Type)

No _ /,2m-m-Ma-x.- l

�ill_

D Metal

D

(Refer to both backing and retainers)

Non Fusing Metal

I

D Non Metallic

D Other Joint Sequence 3mm Max

Sketches, Production Drawings, Weld Symbols, or Written

Description should show the general arrangement of the parts to be

welded. Where applicable, the details of weld groove may be - �- I -'� )�

;.

specified.

[Sketches may be attached to illustrate joint design, weld layers, and

bead sequence (e.g., for notch toughness procedures, for multiple 2mm Max f

process procedures, etc.)]

*BASE METALS (QW·403)

P No. Group No. : to P No. : Group No.

OR

Specification and type/grade or UNS Number :

to Specification and type/grade or UNS Number :

OR

Chem. Analysis and Mech. Prop. : ---------------------------------

to Chem. Analysis and Mech. Prop. : -

Thickness Range: ---------------------------------

Base Metal: Groove

------�-------Fillet

Maximum Pass Thickness: s 1/2 in. (13 mm) (Yes) - (No)

Other

*FILLER METALS (QW-404)

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Filler Metal Product Form

Supplemental Filler Metal

Weld Metal

Deposited Thickness Range:

Groove

Fillet

Electrode-Flux {Class)

Flux Type

Flux Trade Name

Consumable Insert

Consumable Trade Name

•fach base metal-filler metal combination should be recorded individually.

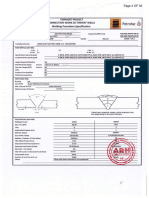

WELDING PROCEDURE SPECIFICATION

(WPS)

ASME IX-2019

Pa1e 2 Of 2 WPS No Rev.

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove Temperature Range

Welding Progression: Up Down Time Range (Holding)

Position(s) of Fillet

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temperature, Minimum Gas(es) (Mixture) Flow Rate

lnterpass Temperature, Maximum Shielding

Preheat Maintenance Tralling

Other . Backing Gas

(Continuous or special heating, where applicable, should be recorded)

ELECTRICAL CHARACTERISTICS (QW-409)

Other

Filler Metal

Current Wire Feed Energy or (e.g., Remarks, Com-

Weld Amps Travel Speed

Process Type and Speed Power Volts (Range) ments, Hot Wire Addition,

Pass(es) Diameter (Range) (Range)

Classification Polarity (Range) (Range) Technique, Torch Angle,

(mm) etc.)

.

Amps and volts, or power or energy range, should be recorded for each electrode size, position, and thickness, etc.

Pulsing Current Heat Input (max.) <j /mm

Tungsten Electrode Size and Type

(Pure I ungsten, 2" lhonated, etc.)

Mode of Metal Transfer for GMAW (FCAW)

(�pray Are, !:liort l'.ircuitmg Are, etc.!

TECHNIQUE (QW-410)

String or Weave Bead

Orifice, Nozzle, or Gas Cup Size

Initial and lnterpass Cleaning (Brushing, Grinding, etc.)

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (per Side)

Multiple or Single Electrodes

Electrode Spacing

Peening

Prepared By, Verified By, Reviewed & Approved By,

······························-· ... ··········

Inspector

-·····' · ·-···' ···-·-·-··

Dlt. Jend. Mips

Date:

Date ....... / ........ / .............. Date: Representative

.......... ./. ... " ..... ./"

You might also like

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- QW-482 WELDING PROCEDURE SPECIFICATIONS (WPSDocument1 pageQW-482 WELDING PROCEDURE SPECIFICATIONS (WPSlinaNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- Report on Welding Procedure Specifications for Single V-Groove JointsDocument15 pagesReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- Welding Procedure Specification for ASME Section IXDocument4 pagesWelding Procedure Specification for ASME Section IXRahul MoottolikandyNo ratings yet

- WPS Format GuideDocument2 pagesWPS Format GuideKhaled bouhlelNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- QW 482Document2 pagesQW 482Ramu NallathambiNo ratings yet

- 04 WPS Atp Asme 2012 (A312 304) (A312 310)Document6 pages04 WPS Atp Asme 2012 (A312 304) (A312 310)lailatul kodriNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- ASME IX - WPS - Register ListDocument1 pageASME IX - WPS - Register ListThe Welding Inspections CommunityNo ratings yet

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Ex Wps Train 01Document2 pagesEx Wps Train 01aidil30No ratings yet

- Pt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Document1 pagePt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Ilham PaneNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps 11Document2 pagesWps 11Avishek GuptaNo ratings yet

- Ii. 5 Tes - WPS Rebabbit Bearing Pltu TembilahanDocument4 pagesIi. 5 Tes - WPS Rebabbit Bearing Pltu TembilahanaddinulichsanNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- Plantilla WPS (SMAW) Junta TDocument1 pagePlantilla WPS (SMAW) Junta Tjhojan garciaNo ratings yet

- Plantilla WPS (SMAW) Junta TDocument1 pagePlantilla WPS (SMAW) Junta Tjhojan garciaNo ratings yet

- Chem-Wps - PQR - WPQ-004 CS-SS 08-08 GtawDocument5 pagesChem-Wps - PQR - WPQ-004 CS-SS 08-08 Gtawvijay padaleNo ratings yet

- WPS Tsila 012Document2 pagesWPS Tsila 012AslaouiNo ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Document2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix TerbarufebriNo ratings yet

- PWPS - 3G FCAWDocument2 pagesPWPS - 3G FCAWasrafiNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Nma App B PDFDocument11 pagesNma App B PDFJesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- FSDH321, FSDL321: Green Mode Fairchild Power Switch (FPS)Document20 pagesFSDH321, FSDL321: Green Mode Fairchild Power Switch (FPS)Ricardo WerlangNo ratings yet

- 2gb19me404 EvtDocument13 pages2gb19me404 EvtB BASAVAPRABHUNo ratings yet

- Liulceb0 00Document20 pagesLiulceb0 00John Fredy Palacio G.No ratings yet

- MPPT Solar Charge Controller ThesisDocument7 pagesMPPT Solar Charge Controller Thesismichellewilsonvirginiabeach100% (2)

- Total Seriola 32 - Product Data SheetDocument3 pagesTotal Seriola 32 - Product Data Sheetjihad jamarei100% (1)

- Resignation LetterDocument3 pagesResignation LetterMD.Habibur RhamanNo ratings yet

- DC to AC Solid State ConvertersDocument59 pagesDC to AC Solid State ConvertersriajulNo ratings yet

- Short Circuit CalculationsDocument15 pagesShort Circuit CalculationsJessica RibeiroNo ratings yet

- Department of The Interior and Local Government Bureau of Fire ProtectionDocument6 pagesDepartment of The Interior and Local Government Bureau of Fire ProtectionRyan SunNo ratings yet

- OASC TDDocument8 pagesOASC TDFati ZoraNo ratings yet

- Technical Seminar Presentation - 2022 - 2023: Advanced Techniques For Earthquake Resistant StructuresDocument18 pagesTechnical Seminar Presentation - 2022 - 2023: Advanced Techniques For Earthquake Resistant StructuresMadan V SNo ratings yet

- Spre 06 255 DSDocument3 pagesSpre 06 255 DSDuverseau Louis MaryNo ratings yet

- Applied Physics Lab Lab 07: DC Circuits (2) : Section: BEE-10A Group: B4 Group MembersDocument9 pagesApplied Physics Lab Lab 07: DC Circuits (2) : Section: BEE-10A Group: B4 Group MembersAli HaiderNo ratings yet

- Electric Vehicle Conductive Charging System: Indian StandardDocument56 pagesElectric Vehicle Conductive Charging System: Indian Standardamit singh100% (1)

- Compressor Handbook Sec 6 ArielDocument32 pagesCompressor Handbook Sec 6 Arielfrana hadiNo ratings yet

- Cement Plant Expansion Feasibility ReportDocument37 pagesCement Plant Expansion Feasibility ReportAkash DasNo ratings yet

- OSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas Safety - Torch AssemblyDocument3 pagesOSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas Safety - Torch AssemblyRa saNo ratings yet

- Solar InstallationDocument2 pagesSolar InstallationgeorgemonageNo ratings yet

- GRADE 12 SAHODAYA PREBOARD -2 PHYSICS (042) MSDocument7 pagesGRADE 12 SAHODAYA PREBOARD -2 PHYSICS (042) MSMohd AdilNo ratings yet

- Principles of Sensing: Definition, Classification and Data AcquisitionDocument13 pagesPrinciples of Sensing: Definition, Classification and Data AcquisitionvanithaNo ratings yet

- P2061 WebDocument124 pagesP2061 WebElias TolentinoNo ratings yet

- Activity 2: College of EngineeringDocument3 pagesActivity 2: College of EngineeringMa.Elizabeth HernandezNo ratings yet

- Alfa Laval Aalborg Os Tci Marine BoilerDocument2 pagesAlfa Laval Aalborg Os Tci Marine Boilera.lobanov2020No ratings yet

- Power Boost BulletinDocument3 pagesPower Boost BulletinBrianHazeNo ratings yet

- A89307 ETDoc PKG Rev 1Document6 pagesA89307 ETDoc PKG Rev 1santhosha rkNo ratings yet

- 09232015123025madhya PradeshDocument14 pages09232015123025madhya Pradeshsameer bakshiNo ratings yet

- Parts List V-480 Engine (Job No-11436) - CWS PropsalDocument4 pagesParts List V-480 Engine (Job No-11436) - CWS PropsalSandeep NikhilNo ratings yet

- PC340 7latestDocument218 pagesPC340 7latestBach Nguyen XuanNo ratings yet

- Product Detail - 700d - English - 2Document2 pagesProduct Detail - 700d - English - 2Athan TheaNo ratings yet

- PART TEST-4 (JM-2022) 25-03-2022 (F22 MDP-Seniors) QPDocument11 pagesPART TEST-4 (JM-2022) 25-03-2022 (F22 MDP-Seniors) QPsunny meenuNo ratings yet