Professional Documents

Culture Documents

Service Guide SMC and TSMC 100 Mk1, 2, 3 and 4

Uploaded by

juan leyyonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Guide SMC and TSMC 100 Mk1, 2, 3 and 4

Uploaded by

juan leyyonCopyright:

Available Formats

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

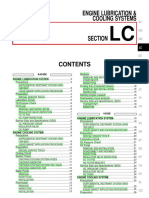

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Inspection of thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inspection of thermopump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inspection of shaft seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inspection of safety controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inspection of heating rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inspection of compressor stop valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inspection of coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inspection of crank main bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspection of connecting rod bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

How to determine usability of cylinder liners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inspection of connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inspection of safety springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Inspection of piston pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Inspection of pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SeviceGuide_0178_948TOC.fm

Inspection of valve seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Inspection of unloading mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

0178-948 - ENG 1/30

Rev. 04.04

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

2/30 0178-948 - ENG

Rev. 04.04

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Service intervals

The service interval for a reciprocating compres- Fig. 1.3 R717 - TSMC 100 S-L

sor should be determined in the following way: E-type: Multiply by 0.75

1. Choose the appropriate diagram corre- TC

sponding to refrigerant and compressor qF qC

type. 14060

12250

Service interval diagrams 5,000

Condensing temperature

Fig. 1.1 R717 - SMC 100 S-L 10440

6,000

E-type: Multiply by 0.75 86 30 8,000

10,000

TC 68 20

11,000

qF qC

50 10 12,000

140 60

32 0

122 50 5,000 --60 --50 --40 --30 --20 --10 0 qC

--76 --58 --40 --22 --4 14 32 TE

104 40

qF

6,000 Evaporating temperature

T0113098_0

Condensing temperature

86 30 8,000

10,000

68 20 Fig. 1.4 HCFC/HFC/R290 - TSMC 100 S-L

50 10

01 introduction.fm

11,000

32 0

TC

14 --10 12,000 qF qC

13,000

--4 --20 140 60

--22 --30

122 50

5,000

Condensing temperature

--60 --50 --40 --30 --20 --10 0 10 20 30 40 qC

TE 6,000

--76 --58 --40 --22 --4 14 32 50 68 86 104 qF

104 40

T0113097_0 Evaporating temperature 8,000

86 30

10,000

Fig. 1.2 HCFC/HFC/R290 - SMC 100 S-L 68 20

11,000

50 10

TC

12,000

qF qC 32 0

--60 --50 --40 --30 --20 --10 0 qC

158 70 TE

--76 --58 --40 --22 --4 14 32 qF

140 60 Evaporating temperature

5,000

T0113100_0

122 50

Condensing temperature

6,000

104 40

8,000 2. Read the service interval from the curves in

86 30 10,000

the diagram.

68 20

50 10

11,000

If the compressor operates at another speed than

32 0 1460 rpm, correct the service interval according to

12,000

14 --10 table.

--4 --20

--22 --30 13,000

--60 --50 --40 --30 --20 --10 0 10 20 30 40 qC

TE

--76 --58 --40 --22 --4 14 32 50 68 86 104 qF

T0113099_0 Evaporating temperature

0178-948 - ENG 3/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Table 1.1 Note: The oil filter must always be replaced when

Rpm 970 1,170 1,460 1,760 changing oil or if indicated by control lamp or

UNISAB II.

Correction

1.5 1.25 1.00 0.83

factor The scope of the overhaul must follow the scheme

below:

Correction may also be calculated according to

• 1 x service interval: Use service set “A”

the formula below:

• 2 x service interval: Use service set “B”

1460

Correction = • 3 x service interval: Use service set “A”

Rpm

• 4 x service interval: Use service set “C”

Example The service sets include parts which must always

A compressor has a service interval of 10,000 be replaced regardless of appearance when com-

hours according to the diagram. pressor is opened. The above cycle is repeated as

If the compressor runs at 970 rpm, the service in- long as the compressor is in operation. The con-

terval will be 1.5 x 10,000 = 15,000h. tent of the individual service set is shown in the

annex.

Diagrams After the first 200 hours of operation, use the com-

The entire reciprocating compressor program will missioning set supplied with the compressor.

be covered by 7 diagrams: Inspection parts

SMC-CMO/R717 Besides the predetermined replacement accord-

ing to above service sets, an inspection of certain

SMC-CMO/R22-R134a-R404a

parts is prescribed. Parts for inspection are shown

TCMO-TSMC/R717 in the annex. Criteria for replacement of inspected

TCMO-TSMC/R22-R134a-R404a parts are shown in separate instruction.

HPC-HPO/R410A Nice-to-have-parts

HPC-HPO/R744 A list of recommended parts supporting the parts

inspection is available. The list contains all parts

HPC-HPO/R717 necessary if the inspected parts must be replaced.

In other words, these lists tell the service techni-

cian what to bring to the inspection.

4/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Table 1.2

Service A Service B Service C

Oil filter Oil filter Oil filter

Ring plates Ring plates Ring plates

Valve springs Valve springs Valve springs

Lock nut for discharge valve Lock nut for discharge valve Lock nut for discharge valve

Piston rings Piston rings Piston rings

O-rings for shaft seal Half section bearings Half section bearings

(+ needed gaskets) Bolt for connecting rod / lock nut Bolt for connecting rod / lock nut

Parts for unloading frame Parts for unloading frame

Shaft seal Shaft seal

(+ needed gaskets) Piston pin

Small end bearings

Main bearings

Discharge valve seat / bolt

01 introduction.fm

(+ needed gaskets)

TSMC 100 TSMC 100 TSMC 100

Needle bearing + piston pin HP´ Needle bearing + piston pin HP Needle bearing + piston pin HP

0178-948 - ENG 5/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Table 1.3 Additional “nice to have” parts

Additional / Nice to have

Change: Change: Change:

V-belts V-belts V-belts

Rocker for unloading Rocker for unloading

Oil pump

(Change based on inspection) (Change based on inspection) (Change based on inspection)

Half section bearings Discharge valve seat / bolt Piston complete

Lock nut conrod screws Oil analysis kit Cylinder liner

Discharge valve seat / bolt Coils solenoid valves Discharge valve complete

Oil analysis kit Control equipment: Suction valve retaining plate

Shaft seal pressostat Coils solenoid valves

Coils solenoid valves thermostat Oil analysis kit

Control equipment: Control equipment:

transducers

pressostat pressostat

Heating element

thermostat Coupling parts

thermostat

transducers Oil return system parts transducers

Heating element Valve seats Heating element

Coupling parts Safety springs Coupling parts

Oil return system parts Stop valve gaskets Oil return system parts

Valve seats Cylinder liners Valve seats

Safety springs Pistons Safety springs

Bearing half sections Piston pins

Stop valve gaskets Piston pin bushings

6/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

If the service interval exceeds one year, an annual inspect crankshaft journal and the big end of the

service and inspection is recommended. Oil and connection rods.

gas suction filters should be changed, one top While service sets A, B and C are intended for ac-

cover should be dismantled and the discharge tual service, the recommended annual service

valve and cylinder liner should be inspected. is intended to ensure that the compressor is in-

Further a side cover must be removed and one spected each year.

connection rod bearing half should be removed to

Table 1.4

Recommended annual service

Oil filter

Gas suction filter

Bolt and nut for one connecting rod

Gaskets for two top covers

Additional / nice to have:

(Change based on inspection)

01 introduction.fm

Gaskets for shaft seal

Oil analysis kit

0178-948 - ENG 7/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of thermostats

Depending on temperature range, thermostats Filling and evacuation of the pump vessel is con-

are checked as follows: trolled by the two level sensors pos. 98C. By

• Low temperature range, by means of ice means of the control box, pos. 98B, the sensors

water ( +/-0ºC ). control the solenoid valves pos. 98G and pos.

98H. The solenoids open and close simultaneous-

• High temperature range, by means of boil- ly – open during filling of the pump vessel and

ing water ( +100ºC ). closed during emptying of the pump vessel.

• Actual temperature setting is checked by Check the function of the thermostat pos. 98X.

slowly increasing or decreasing the setting The thermostat is factory set to start operation

while monitoring temperature cut off. once the discharge gas temperature is above

After checking, reset to actual condition. 80°C.

If the above inspection reveals malfunctioning:

Inspection of thermopump

• Clean the filter pos. 80 and possibly the noz-

Check the general function of the thermopump by

zles pos. 98M.

checking the pumping cycle – monitored by the

light diodes inside the control box. • Check the function of the non-return valves

pos. 98K and 98Z by blowing compressed

The pumping cycle of the thermopump, i.e. a filling

air opposite the normal flow direction.

and an evacuation period, lasts between 4 and 8

minutes depending on the oil temperature, operat- • Check the level sensors and the control box

ing conditions and number of cylinders of the com- according to instructions in the Service

pressor. The filling period takes about 45 sec. manual.

8/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of shaft seal

During operation a small amount of oil leaks from If a shaft seal for any reason has been dismantled,

the shaft seal. The oil forms a lubricating film be- always replace O-rings before assembling. Check

tween the rotating and the static face and thus that the sealing faces are clean, smooth and free

performs the sealing effect. Due to the differential of scratches and wear marks.

pressure, a certain flow out of the shaft seal can-

not be avoided. Inspection of safety controls

Usually the amount of leaked oil is fairly small but If equipped with mechanical controls

even when there is no mechanical fault, the shaft 1. Low suction pressure cut out, KP1(A) or

seal leak rate may vary considerably. This may be KP15(A):

the result of different operating conditions as well

a. Check the correct setting of the pressure

as the actual vibration condition and also the state

cut out – Service manual, section 4.

of the oil as temperature, viscosity, purity and re-

frigerant content will influence the sealing effect. b. Slowly close the suction stop valve while

monitoring the suction pressure gauge.

The leak may be somewhat more extensive at the

initial start-up of the compressor as the sliding sur- c. Note the pressure where compressor

faces have to a adapt to each other. cuts off.

01 introduction.fm

The actual leak rate must be checked according to d. If necessary, adjust setting and repeat

the compressor logbook by comparing it with the above process.

table below. e. Open suction stop valve and - check au-

tomatic reset on low pressure cut out.

Litres per 24 hours 2. High discharge pressure cut out, KP5(A) or

KP15(A) or KP7(A)BS:

Good below 0.2

a. Check the correct setting of the pressure

Worn 0.2 – 0.6

cut out – Service manual, section 4.

Defect above 0.6

b. Slowly close the discharge stop valve

“Good”: leave the shaft seal as it is unless per- while monitoring the discharge pressure

forming service “B” or “C”. At these services the gauge.

shaft seal must always be replaced. c. Note the pressure where compressor

“Worn” or “Defect”: replace the shaft seal. In cuts off – NB! KP7(A)BS dual high pres-

some cases the replacement of a “Worn” shaft sure control.

seal may be postponed to the next scheduled d. If necessary adjust setting and repeat

service. above process.

It is recommended to exercise great care with the e. Open discharge stop valve and check

lapped slide surfaces as even the slightest scratch manual reset (pressure diff. 4 bar.) on

or other damage to the slide surfaces will result in high pressure cut out.

leaks.

3. Oil pressure cut out, MP55(A):

0178-948 - ENG 9/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

a. Check the correct setting of the pressure a. Check the correct setting of the high dis-

cut out – Service manual section 4. charge pressure warning/alarm – UNIS-

b. Slowly and stepwise open the oil pres- AB manual section 5.

sure regulating valve while monitoring b. Slowly and stepwise close the discharge

the oil pressure. stop valve while monitoring the dis-

c. Allow reaction time of 60 seconds for charge pressure.

each step. c. Allow reaction time of 5 seconds for

d. Note the oil pressure where compressor each step.

cuts off and check manual reset (after 2 d. Note the discharge pressure where

min.). warning/alarm appears and compressor

e. If necessary, adjust setting and repeat cuts off.

above process. e. If necessary, adjust setting and repeat

f. Adjust oil pressure (on regulating valve) above process.

to 4.5 bar. f. Open discharge stop valve and check

4. Oil and discharge pipe thermostat, KP98: manual reset on high pressure alarm.

a. Check the correct setting of the thermo- 3. Oil pressure warning/alarm:

stat – Service manual, section 4. a. Check the correct setting of the low oil

b. Slowly decrease temperature settings pressure warning/alarm – UNISAB man-

while monitoring temperatures cut off. ual section 5.

c. Adjust actual settings and check manual b. Slowly and stepwise open the oil pres-

reset (temp. diff. oil/HT = 14/25 K). sure regulating valve while monitoring

the oil pressure.

If equipped with UNISAB control

c. Allow reaction time of 60 seconds for

1. Low suction pressure warning/alarm.

each step.

a. Check the correct setting of the low suc-

d. Note the oil pressure where warn-

tion pressure warning/alarm – UNISAB

ing/alarm appears and compressor cuts

manual section 5.

off and check manual reset.

b. Slowly close the suction stop valve while

e. If necessary, adjust setting and repeat

monitoring the suction pressure.

above process.

c. Note the pressure where warning/alarm

f. Adjust oil pressure (on regulating valve)

appears and compressor cuts off.

to 4.5 bar.

d. If necessary, adjust setting and repeat

4. Temperature warnings/alarms – discharge

above process.

gas, oil, suction superheat and discharge

e. Open suction stop valve and check auto- superheat.

matic reset on low pressure alarm.

a. Check the correct settings of above

2. High discharge pressure warning/alarm: warnings/alarms – UNISAB manual sec-

tion 5.

10/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

b. Slowly increase/decrease temperature If equipped with UNISAB control and high

settings while monitoring warn- pressure safety cut out,

ings/alarms. KP 7(A)BS

1. First, do the test procedures for the me-

c. Adjust actual settings and check manual

chanical safety cut out as described above.

reset.

• Set the UNISAB high discharge pres-

5. Emergency stop:

sure alarm a little higher than the me-

a. Activate the emergency stop by a light chanical cut off.

pressure when compressor is in opera-

2. Second, do the test procedures for the UN-

tion.

ISAB control as described above.

b. Before restarting, reset the alarm and re-

• Set the UNISAB high discharge pres-

lease the emergency stop by turning it

sure alarm a little lower than the me-

clockwise.

chanical cut off.

Note: Local rules and standards are mandatory

and overrule the above recommendations if in

conflict.

01 introduction.fm

0178-948 - ENG 11/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of heating rod Inspection of compressor stop valves

When the compressor is stopped, the heating rod Check the tightness of the gland at the valve spin-

must be activated and the oil temperature during dle by appropriate leak detection while turning the

standstill must be clearly ( 10K or more ) above valve spindle.

ambient temperature. In case of leak, the packing gland pos. 25M and

Check if the power supply is switched on and the gasket for bonnet pos. 25J must be changed.

check the resistance of the heating cartridge by Check the tightness of the valve seat by appropri-

using a multi-meter. If the heating circuit is cut off, ate leak detection inside the compressor.

the resistance is infinitely great.

In case of leak, the sealing ring pos. 25H and the

gasket for bonnet pos. 25J must be changed.

When changing sealing rings and gaskets, the

sealing surfaces have to be clean and free from

scratches and wear marks.

12/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of coupling

For coupling of the lamella type, see if there are

any signs of cracks in lamella (disc) package.

(To be inspected in-place).

Fig. 1.5

01 introduction.fm

0178-948 - ENG 13/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Fig. 1.6

Apply lever bar to

load joints

No cracks allowed

between rubber and

steel bushes.

For coupling of rubber type, check if vulcanization Check and adjust coupling alignment as de-

between rubber and steel bush is intact. Apply a scribed in manual.

lever bar to load joint.

Apply lever bar to load joints.

14/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of crank main bearings

1. Make sure the journals are not seized up 3. The diameter of the intermediate bearing

(picture). journals on long blocks (112 and 116)

2. The diameter of the crankshaft journals should not be less than 79.87 mm.

should not be less than 79.81 mm.

01 introduction.fm

0178-948 - ENG 15/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of connecting rod bearings

1. Check the connecting rod bearings with no scratches. The bearing surfaces be-

your fingertips and make sure that you feel tween the individual stages must be even.

Fig. 1.7

Scratches are not acceptable.

Transitions between bearing sur-

faces must be even.

2. The diameter on the journals should not be 3. Check the axial clearance of the crank.

less than 79.89 mm.

(T)SMC 100 (T)SMC 100

CMO Mk1 & 2

4-10 cyl. 12-16 cyl.

minimum 0.30 0.40 0.75

maximum 0.55 0.64 1.0

16/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

4. Check appearance of thrust bearing.

Fig. 1.8

Scratches and material dis-

placement are unacceptable.

01 introduction.fm

0178-948 - ENG 17/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

How to determine usability of cylinder liners

• See if there are any visible lengthwise

scratches on the running face:

Fig. 1.9

Visible lengthwise

scratches that you can

feel with your fingertips

are not acceptable.

18/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

• See if the suction valve seats are damaged.

Fig. 1.10

01 introduction.fm

0178-948 - ENG 19/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

• See if valve seats are worn, i.e. has rounded

shoulders:

Fig. 1.11

Edges of valve seat

surfaces should be

sharp and not rounded

• Measure the inside diameter of the cylinder 2. Secondly, move the piston ring to approxi-

liner at the top and bottom of the running mately 10 mm below the top of the sleeve.

face. Again, measure the gab between the ends

Perform the measurement with a micrometer of the ring.

gauge. The diameter should not exceed 100.25 3. Finally, move piston ring to the lower part of

mm anywhere. the worn area, approximately 10 mm above

If a measuring gauge is not at hand, wear may be the transition between worn and non-worn

measured indirectly by a piston ring and a feeler area. Measure the gab.

gauge (oil must be wiped away before measur- 4. Compare the measurements. The maxi-

ing): mum difference between measurements in

1. Insert a piston ring (preferably a new one) in non-worn and worn area (running face)

the lower non-worn part of the cylinder should not exceed 0.6 mm.

sleeve. Measure the gab between the ends If a cylinder sleeve shows any of the above de-

of the ring with a feeler gauge. fects, it must be replaced.

20/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of connecting rod

1. Small end: Must be free from distinct Shiny areas are acceptable.

scratches (material displacement) on the

bearing surface.

Fig. 1.12

01 introduction.fm

Distinct scratches and

material displacement

are not acceptable

The picture shows a useless connecting rod bush- If the connecting rod and the piston are not sepa-

ing with scratches. rated a check can be made as follows:

2. The bushing diameter must not exceed

40.08 mm.

Can be measured with a good digital slide

gauge.

0178-948 - ENG 21/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Fig. 1.13

Press small end towards

one side of the piston.

3. Hold the piston steady against a level sur- Try to move the big end of the connecting

face. Press the small end of the connecting rod sideways. The big end should not move

rod towards one side of the piston. more than 1 mm sideways.

22/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Fig. 1.14

Shiny areas are acceptable

- material displacement is

not.

01 introduction.fm

The picture shows a bushing after

normal operation.

0178-948 - ENG 23/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of safety springs

The safety springs on the discharge valves must

be intact and have the following minimum heights

in unloaded condition:

Table 1.5

(T)SMC (T)SMC Mk2&3 (T)SMC Mk4 S&L (T)SMC Mk4 E

Mk2&3 9.5 mm wire 12 mm wire 10.5 mm wire

9.0 mm wire

Minimum height 62 mm 58 mm 73 mm 69 mm

24/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of piston pin

1. At normal workshop temperature, you gers. The hotter the piston gets, the more

should be able to just slightly rotate and the fitting will loosen. There should be no

move sideways the piston pin with your fin- clearance in the fitting.

Fig. 1.15

01 introduction.fm

2. The diameter of the piston pin should not be 3. Feel the bearing surfaces on the piston pin

less than 39.96 mm. with your fingertips and make sure that they

are even.

0178-948 - ENG 25/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of pistons

1. Make sure there are no deep scratches in 2. The width of a worn area must not exceed

the piston skirt. 30 mm.

Fig. 1.16

Worn area. Scratches are

visible and you can feel

them with your fingertips.

max. 30 mm

The picture shows a useless piston.

In order for a piston to be reused, it must be in a considerably better condition than this one.

3. The diameter of the piston should not be 5. Check the axial clearance between the pis-

less than 99.7 mm. ton and the ring using a feeler gauge. It must

4. Check that the piston rings can be turned not exceed 0.2 mm with a new piston ring.

freely in the piston groove.

26/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of valve seats

The valve seats must not be damaged...

Fig. 1.17

01 introduction.fm

0178-948 - ENG 27/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

or corroded...

Fig. 1.18

28/30 0178-948 - ENG

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

or have rounded shoulders.

Fig. 1.19

The valve seat edges

must not be rounded.

01 introduction.fm

0178-948 - ENG 29/30

Rev. 04.05

Service guide SMC and TSMC 100 Mk1, 2, 3 and 4

Inspection of unloading mechanism

Make sure that wear has not made oval holes in that the unloading frame moves between extreme

the spring eye fittings. positions when the pressure is activated and re-

Connect the prelubrication pump to each unload- moved.

ing cylinder. Press the pump handle with a con- Check for broken springs and wear on rocker

stant pressure of approx. 20 kp. The handle must arms and the bushing in the unloading system.

not sink more than 5 cm in 60 seconds. Observe

30/30 0178-948 - ENG

Rev. 04.05

You might also like

- SABROE Guia de Servicio SMC-100 TSMC-100 Mk1,2,3 y 4Document30 pagesSABROE Guia de Servicio SMC-100 TSMC-100 Mk1,2,3 y 4eduardomanuel3100% (2)

- Manual Sabroe SMC - 104-106-108 - EN PDFDocument179 pagesManual Sabroe SMC - 104-106-108 - EN PDFPablo Ruiz86% (7)

- Esab LTN 255 Aristo-Tig 255Document50 pagesEsab LTN 255 Aristo-Tig 255federicoNo ratings yet

- Power Tig 160/200: Service ManualDocument46 pagesPower Tig 160/200: Service Manualsamasca_serbanNo ratings yet

- Tractor Case Series JX PDFDocument85 pagesTractor Case Series JX PDFLeonardo MedinaNo ratings yet

- Manuali Bosch I Instalimit Te Pom Pave Termike GjeotermaleDocument46 pagesManuali Bosch I Instalimit Te Pom Pave Termike GjeotermaleLavdërim SalihuNo ratings yet

- New Red BookDocument100 pagesNew Red BookIan McDaniel (Mc)No ratings yet

- Operating Instruction SRP 1515 FPDocument40 pagesOperating Instruction SRP 1515 FPlacoth100% (1)

- Schneider RM6Document82 pagesSchneider RM6boris100% (1)

- VM405 PBBD2 52317 PDFDocument51 pagesVM405 PBBD2 52317 PDFpechnicNo ratings yet

- Circuit Breaker SF1Document58 pagesCircuit Breaker SF1Alejandra Toro VelasquezNo ratings yet

- Qts ManualDocument57 pagesQts ManualCLARA CARMONANo ratings yet

- Service Manual: Lift TrucksDocument9 pagesService Manual: Lift TrucksChristian Bedoya25% (4)

- Caterpillar Traxcavator Service Manual CT S Trax931Document24 pagesCaterpillar Traxcavator Service Manual CT S Trax931baracuss323iNo ratings yet

- Voltage Regulator Equipment: InstructionsDocument28 pagesVoltage Regulator Equipment: Instructionslxd.hepNo ratings yet

- Manual de Interruptores Sf6 MabeDocument46 pagesManual de Interruptores Sf6 MabeantonioNo ratings yet

- CVT Juke Re0f10bDocument253 pagesCVT Juke Re0f10bAndika SetiyawanNo ratings yet

- VW Amarok 8 Speed Automatic Gearbox 0dr EngDocument89 pagesVW Amarok 8 Speed Automatic Gearbox 0dr Engjose reirizNo ratings yet

- 8 Speed Automatic Gearbox 09p EngDocument105 pages8 Speed Automatic Gearbox 09p EngVladyslav100% (1)

- Maintain Your Vehicle Safely: Precautions for Supplemental Restraint SystemsDocument32 pagesMaintain Your Vehicle Safely: Precautions for Supplemental Restraint SystemsDonnell FrancisNo ratings yet

- Instr Use Rollarc Withdrawable in MCsetDocument38 pagesInstr Use Rollarc Withdrawable in MCsetcatalinccNo ratings yet

- 50 Manual Nissan Sentra 2013Document276 pages50 Manual Nissan Sentra 2013DavidNo ratings yet

- Maxitorque Transmissions t313-t318 (L) (LR) (21) (l21) (Lr21) Service ManualDocument268 pagesMaxitorque Transmissions t313-t318 (L) (LR) (21) (l21) (Lr21) Service ManualHenry Castillo Hidalgo100% (1)

- Tana Gseries Ho C110304enDocument65 pagesTana Gseries Ho C110304enNguyen Ngoc100% (1)

- Oil Gas Ratings Guide February 2020 LECW2462 27Document92 pagesOil Gas Ratings Guide February 2020 LECW2462 27Zaka ZaheeriNo ratings yet

- Directional Control Valves CatalogueDocument31 pagesDirectional Control Valves Cataloguegurivi201100% (1)

- Engine Cooling System: SectionDocument85 pagesEngine Cooling System: SectionАндрей НадточийNo ratings yet

- Engine-CAHA-TDI Injection and Glow Plug System (4-Cyl 2 0 LTR 4-ValveDocument78 pagesEngine-CAHA-TDI Injection and Glow Plug System (4-Cyl 2 0 LTR 4-ValveCatalin UrsachiNo ratings yet

- Engine Cooling System: SectionDocument87 pagesEngine Cooling System: SectionLuis BarriosNo ratings yet

- Engine Lubrication & Cooling SystemsDocument36 pagesEngine Lubrication & Cooling SystemsarbutacNo ratings yet

- 1 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page1 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- Samand: Cooling, Manifold and Exhaust Система охлаждения двигателя Система выпуска отработавших газовDocument40 pagesSamand: Cooling, Manifold and Exhaust Система охлаждения двигателя Система выпуска отработавших газовДмитрий ДимкаNo ratings yet

- Mig 4002cwDocument64 pagesMig 4002cwdpwtNo ratings yet

- 9pa Group 0 GeneralDocument154 pages9pa Group 0 GeneralSebastian MunteanNo ratings yet

- Danfoss Scroll Compressors in Parallel Installation SMSYSZDocument48 pagesDanfoss Scroll Compressors in Parallel Installation SMSYSZNikolas Chionas100% (1)

- SW 9 XRDocument68 pagesSW 9 XRJuniorz R. Huaylinos CruzNo ratings yet

- Perkins 4006-23TAG3A User's HandbookDocument42 pagesPerkins 4006-23TAG3A User's HandbookMr Morgan100% (1)

- Ariel JGE JGH JGK JGT Manual - 231029 - 233805Document203 pagesAriel JGE JGH JGK JGT Manual - 231029 - 233805Daniel LatorreNo ratings yet

- CHINT Industrial Catalogue 2022Document80 pagesCHINT Industrial Catalogue 2022bahaaNo ratings yet

- 10 Fan DrycoolerDocument36 pages10 Fan DrycoolersamersibaniNo ratings yet

- Manual CompressorDocument84 pagesManual CompressorDi Leo Jr.86% (7)

- Workshop Manual - Perkins 4000 Series 4016 - E61trs 16 Cylinder - Turbocharged - Gas Engines PDFDocument116 pagesWorkshop Manual - Perkins 4000 Series 4016 - E61trs 16 Cylinder - Turbocharged - Gas Engines PDFVery Pambudi100% (4)

- MVC 9028 PDFDocument32 pagesMVC 9028 PDFAnonymous u0wETydFNo ratings yet

- En ACS800-67LC System Descr B ScreenresDocument132 pagesEn ACS800-67LC System Descr B ScreenresReda DjatouNo ratings yet

- Aristofeed 30 4 Aristofeed 48 4: Service ManualDocument30 pagesAristofeed 30 4 Aristofeed 48 4: Service Manualatual manutencaoNo ratings yet

- Maintaining your vehicle effectivelyDocument50 pagesMaintaining your vehicle effectivelyluis enrique arriz rodriguezNo ratings yet

- Compresor TMDocument62 pagesCompresor TMFernando Pérez SarriaNo ratings yet

- TDI Injection and Glow Plug System 4-Cyl 2 0 LTR 4-Valve Common RailDocument77 pagesTDI Injection and Glow Plug System 4-Cyl 2 0 LTR 4-Valve Common RailergdegNo ratings yet

- Allison Transmissions Operating Manual 2002 SmallDocument42 pagesAllison Transmissions Operating Manual 2002 SmallleoscazNo ratings yet

- Transaxle & Transmission: SectionDocument37 pagesTransaxle & Transmission: SectionNestor RosalesNo ratings yet

- Engine Lubrication & Cooling SystemsDocument36 pagesEngine Lubrication & Cooling SystemsRached DouahchuaNo ratings yet

- Engine Cooling System: SectionDocument76 pagesEngine Cooling System: SectionH. Yusmira (Kang Otto)No ratings yet

- EA3501SR ManualDocument40 pagesEA3501SR ManualterradyneamgNo ratings yet

- Engine Adr Aeb Anb Apt Apu Arg Atw Afy Repair Manual EngDocument187 pagesEngine Adr Aeb Anb Apt Apu Arg Atw Afy Repair Manual Engnikitobg13No ratings yet

- Micra k13 TransmissionDocument49 pagesMicra k13 Transmissionlukasz_b7No ratings yet

- Transaxle & Transmission: SectionDocument274 pagesTransaxle & Transmission: SectionRuhu royNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- Anw SB17 01 PDFDocument2 pagesAnw SB17 01 PDFEnzo Solis PerezNo ratings yet

- Refrigeración Por AsbsorciónDocument12 pagesRefrigeración Por Asbsorciónjuan leyyonNo ratings yet

- 03 Condenser NOV21Document36 pages03 Condenser NOV21juan leyyonNo ratings yet

- TBW - FC Acoplamiento FrickDocument88 pagesTBW - FC Acoplamiento Frickjuan leyyonNo ratings yet

- Polygon-D60 X h90 6-Sided 6e0ww05fDocument1 pagePolygon-D60 X h90 6-Sided 6e0ww05fjuan leyyonNo ratings yet

- Unisab II Ver 202.04 - Engineering Manual - 0178-511 - ENGDocument230 pagesUnisab II Ver 202.04 - Engineering Manual - 0178-511 - ENGjuan leyyon88% (8)

- Water/dirt and oil purifier type WDO G principle diagramDocument1 pageWater/dirt and oil purifier type WDO G principle diagramjuan leyyonNo ratings yet

- 10 9Document20 pages10 9limlianpengNo ratings yet

- Access Webinar Audio RecordingDocument34 pagesAccess Webinar Audio Recordingjuan leyyonNo ratings yet

- Klein Illapel EPSL PreprintDocument28 pagesKlein Illapel EPSL PreprintRafael RoqueNo ratings yet

- I N T e R N A T I o N A LDocument36 pagesI N T e R N A T I o N A Ljuan leyyonNo ratings yet

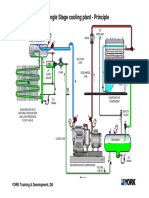

- Single Stage Cooling Plant - PrincipleDocument1 pageSingle Stage Cooling Plant - Principlejuan leyyonNo ratings yet

- Water contamination causes issues in ammonia refrigerationDocument3 pagesWater contamination causes issues in ammonia refrigerationjuan leyyonNo ratings yet

- Phillips DangersWater PDFDocument37 pagesPhillips DangersWater PDFjuan leyyonNo ratings yet

- Ammonia Gauge: Description & FeaturesDocument3 pagesAmmonia Gauge: Description & Featuresjuan leyyonNo ratings yet

- BuildingDocument12 pagesBuildingjuan leyyonNo ratings yet

- Phillips DangersWater PDFDocument37 pagesPhillips DangersWater PDFjuan leyyonNo ratings yet

- Application Supplement: Manufacturing, IncDocument50 pagesApplication Supplement: Manufacturing, Incjuan leyyonNo ratings yet

- Controles Automáticos para Refrigeración Industrial.Document862 pagesControles Automáticos para Refrigeración Industrial.juan leyyonNo ratings yet

- Application Supplement: Manufacturing, IncDocument50 pagesApplication Supplement: Manufacturing, Incjuan leyyonNo ratings yet

- Understanding and Verifying Compressor SafetiesDocument48 pagesUnderstanding and Verifying Compressor SafetiesJuan Pablo NavasNo ratings yet

- Compr Oil Analysis E20-10 SPC May00Document1 pageCompr Oil Analysis E20-10 SPC May00juan leyyonNo ratings yet

- Sulfur Sticks SDS 05-2016 IRPLLC Rev3 PDFDocument3 pagesSulfur Sticks SDS 05-2016 IRPLLC Rev3 PDFjuan leyyonNo ratings yet

- Datasheet Schuetz Ecobulk MX enDocument1 pageDatasheet Schuetz Ecobulk MX enjuan leyyonNo ratings yet

- Sulfur Sticks SDS 05-2016 IRPLLC Rev3Document3 pagesSulfur Sticks SDS 05-2016 IRPLLC Rev3juan leyyonNo ratings yet

- Man d2842 630 730 KvaDocument4 pagesMan d2842 630 730 KvaSatria TrianaNo ratings yet

- Wilson Livestock BrochureDocument9 pagesWilson Livestock BrochureBaw BawNo ratings yet

- Detroit V71 Service Manual Parte 1Document322 pagesDetroit V71 Service Manual Parte 1Elisio Marques100% (3)

- CPC Fault Code ListDocument6 pagesCPC Fault Code Listcristian picadoNo ratings yet

- Diagram 1 AIR CONDITIONING (A..Document1 pageDiagram 1 AIR CONDITIONING (A..AugustoCamachoNo ratings yet

- Catalogue BremenDocument7 pagesCatalogue BremenRizki Heru HermawanNo ratings yet

- Core Acceptance - Injection PumpDocument9 pagesCore Acceptance - Injection PumpGersonNo ratings yet

- Damage To Idle Gear of Drive LO Pump For Diesel GeneratorDocument2 pagesDamage To Idle Gear of Drive LO Pump For Diesel GeneratorRani NoumanNo ratings yet

- 500 Se Ries Speed Om e Ters and Tachometers: Fea TuresDocument2 pages500 Se Ries Speed Om e Ters and Tachometers: Fea Turesanthony corsiNo ratings yet

- Seat Belt Warning System OperationDocument2 pagesSeat Belt Warning System OperationMaxi SardiNo ratings yet

- 1964 Plymouth Barracuda Landau (Factory Prototype W/ Targa Top) - Photos & CorrespondenceDocument12 pages1964 Plymouth Barracuda Landau (Factory Prototype W/ Targa Top) - Photos & CorrespondenceAndrew MikelsonNo ratings yet

- WWW - Incar.tw-How To Build Cobra Kit Cars Buying Used Performance ProjectsDocument6 pagesWWW - Incar.tw-How To Build Cobra Kit Cars Buying Used Performance Projectsshylen sadienNo ratings yet

- United India Insurance Company LimitedDocument11 pagesUnited India Insurance Company LimitedVivalta ModellingNo ratings yet

- Gajra GearsDocument17 pagesGajra GearsJuhi Yadav100% (2)

- Airplane Engine Encyclopedia (En) Part 1Document282 pagesAirplane Engine Encyclopedia (En) Part 1Bea100% (1)

- Panda 8000i ManualDocument176 pagesPanda 8000i Manualeeswaran2000No ratings yet

- Truck trailer refrigerator design planDocument4 pagesTruck trailer refrigerator design planAmir MohammedNo ratings yet

- SD313-2 MFI Control System (G4FC-GSL 1.6L)Document1 pageSD313-2 MFI Control System (G4FC-GSL 1.6L)Luis GarcíaNo ratings yet

- Technical Specifi Cati OnsDocument24 pagesTechnical Specifi Cati OnsRaguramNo ratings yet

- Introduction To Industrial Technology Midterm ReviewerDocument7 pagesIntroduction To Industrial Technology Midterm ReviewerRenz Moyo ManzanillaNo ratings yet

- CDI4Document4 pagesCDI4Xperience LegoNo ratings yet

- Thesis 2011 Turner PDFDocument386 pagesThesis 2011 Turner PDFPetar PavićNo ratings yet

- Special cables for hybrid vehiclesDocument1 pageSpecial cables for hybrid vehiclesVlado PetkovskiNo ratings yet

- Msa15 - Edc15Document4 pagesMsa15 - Edc15Giedrius Zasas80% (5)

- Toyota Kijang Innova Service Manual PdfDocument2 pagesToyota Kijang Innova Service Manual PdfWijoyo Kusumo58% (24)

- GB 1533 2002 S Service Manual Mini Crosser X2 Ver 100rDocument114 pagesGB 1533 2002 S Service Manual Mini Crosser X2 Ver 100rToine LimbeekNo ratings yet

- Fire Fighting Pupms Data SheetDocument18 pagesFire Fighting Pupms Data SheetnourfarmajidNo ratings yet

- Toyota Production System PDFDocument7 pagesToyota Production System PDFZaib RehmanNo ratings yet

- Solved Problems - Design of Cam Clutches and BrakesDocument9 pagesSolved Problems - Design of Cam Clutches and BrakesSashankNiroulaNo ratings yet

- SOP - Incoming Raw Material Unloading in Plant - 2020Document7 pagesSOP - Incoming Raw Material Unloading in Plant - 2020manavNo ratings yet