Professional Documents

Culture Documents

Hdpe TR 144 Film Polymer SM

Uploaded by

Akram.yishakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hdpe TR 144 Film Polymer SM

Uploaded by

Akram.yishakCopyright:

Available Formats

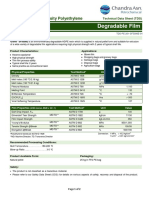

Polyethylene HDPE TR-144

DESCRIPTION:

HDPE TR-144, copolymer of ethylene and hexene is tailored for blown film production.

Extraordinary melt toughness made possible to get film down to 0.006 mm thickness. Extruded

film has high impact resistance, good tear strength, excellent antiblock and good barrier properties,

low gel content and excellent sealing and printing properties.

PROCESSING RECOMMENDATIONS:

Processing temperature: 195 – 220 oC

Blow-up ratio: 3.5–5:1

Neck height: 6 -10 times die diameter

PROPERTIES:

NOMINAL

PROPERTY TEST METHOD UNIT

VALUE

EN ISO 1133-1

MELT FLOW RATE 190°C / 2.16 kg g/10 0.18

min

DENSITY EN ISO 1183-2 kg/m3 947

EN ISO 527-2 32

TENSILE STRENGTH AT BREAK EN ISO 527-3 MPa 40/32**

EN ISO 527-2 21

TENSILE STRENGTH AT YIELD EN ISO 527-3 MPa 24/19**

EN ISO 527-2 900

ELONGATION AT BREAK EN ISO 527-3 % 550/690**

14

IZOD IMPACT STRENGTH EN ISO 180 kJ/m2 no fracture

SHORE D HARDNESS EN ISO 868 Shore D 69

EN ISO

ESC RESISTANCE , F50 22088-3 h > 1000

method B

ASTM D

1693

ASTM D 1709

DART DROP g 80*

EN ISO 7765-1

TEAR STRENGHT (ELMENDORF) ASTM D 1922 g/mil 25/550**

*Result s obtained on film of 25 µm; blow-up ratio: 1:4

**Results obtained on film sample in MD/TD direction (MD - machine direction; TD – transversal direction) SRPS –

national standard

The values in this review are characteristic and are provided for guidance purposes only.

APPLICATION:

HDPE TR-144 is suitable for production of composite films, carrier bags and other kinds

of packaging. It is also recommended for blow moulding of small and medium size

containers.

HDPE TR-144 has Health Certificate issued by Institute for Health Protection of country

of origin. Also, HDPE TR-144 has Statement of Conformity, which declares product’s

conformity with the European norms for materials intended to come into contact with

foodstuffs.

STORAGE:

Polymer pellets are packed in LDPE bags, each bag weighs 25 kg. Bags are arranged on

pallets and wrapped in stretch foil. One pallet has total polymer weight of 1250 kg.

Polyethylene is combustible material, therefore fire prevention measures in warehouses

should be applied. Keep the polymer protected from harmful influences of heat, direct

sunlight and high atmosferic humidity during storage.

If resin is stored under unfavourable conditions of large fluctuation in ambient temperature

and atmospheric humidity, atmospheric moisture can condense inside the packaging. In

such case, it is recommended to dry pellets before use.

The producer has no responsibility for any damage caused with the inappropriate storage.

REACH:

The applying of the existing standards ISO 9001:2008, ISO 14001:2004, OHSAS

18001:2007 and ISO 50001:2011, follows completely the highest standards by which there

are regulated environmental protection and human health and safety protection and herewith

it expresses its intention to meet all the requirements which are prescribed by REACH

regulation.

Registration of all the substances of potential export interest has been made with European

Agency for Chemicals in Helsinki, in accordance with the prescribed deadlines, therefore

in this way it enables further undisturbed placement and sale products without any limits at

EU Market.

RECYCLING:

Polyethylene is a material suitable for recycling.

The waste, that could appear during processing, should be kept clean before new usage

through direct recycling.

CONTACT:

Sale:

Tel: +7 (925) 598-56-05

Tel: +7 (911) 763-83-83

E-mail: polymersm@mail.ru

You might also like

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayNo ratings yet

- Hdpe MPC - Ex5Document1 pageHdpe MPC - Ex5govindNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- Zytel® 73G15L NC010-gbDocument12 pagesZytel® 73G15L NC010-gbzoxxxnNo ratings yet

- Technical Data Sheet - RIBLENE - FL 34 F - ITDocument2 pagesTechnical Data Sheet - RIBLENE - FL 34 F - ITEmanuele GizziNo ratings yet

- Tds Tasnee HD f0455Document2 pagesTds Tasnee HD f0455أبو أميرNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Riblene FC 30Document2 pagesRiblene FC 30Josevi Jiménez MerinoNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Hdpe Bl3-MarunDocument1 pageHdpe Bl3-MarunChetan PandyaNo ratings yet

- TDS Pe 002 Uf1810t 03Document2 pagesTDS Pe 002 Uf1810t 03qc jrpNo ratings yet

- Arkema Rilsan MB 3000 NAT TDSDocument5 pagesArkema Rilsan MB 3000 NAT TDSstartionlilNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- TDS Pe 010 Uf1820t 04Document2 pagesTDS Pe 010 Uf1820t 04Lenggana SukriaNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- Low Density Polyethylene Resin: Physical Properties (Based On Pellets and Press-Molded Sheet)Document1 pageLow Density Polyethylene Resin: Physical Properties (Based On Pellets and Press-Molded Sheet)Akram.yishakNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- Polypropylene Properties - VinidexDocument2 pagesPolypropylene Properties - VinidexalexNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- TDS Pe 003 Uf1810s1 03Document2 pagesTDS Pe 003 Uf1810s1 03qc jrpNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- Utek PYJ9114 SMC SHEETDocument2 pagesUtek PYJ9114 SMC SHEETFrederik TjonnelandNo ratings yet

- Qatofin Lotrene Q2018Document2 pagesQatofin Lotrene Q2018HichamSalamaNo ratings yet

- Hdpe F1 Film Qamar SPDC SpecsDocument1 pageHdpe F1 Film Qamar SPDC SpecsakshayNo ratings yet

- Zytel® 101 NC010-gbDocument11 pagesZytel® 101 NC010-gbalejandrocharlescollNo ratings yet

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 pagesLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúNo ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- Altis em 2Document1 pageAltis em 2Pedro DuqueNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- RADILON A CP300K 333 BK Product InfoDocument4 pagesRADILON A CP300K 333 BK Product InfomuthuNo ratings yet

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- tds-hd5403pdfDocument2 pagestds-hd5403pdfAthonioMourinhoNo ratings yet

- ALTECH PE-HD A 2010/550 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/550 GF10: Technical Data SheetPhung LucNo ratings yet

- PP HOMO 3.2 Spec - T30SDocument1 pagePP HOMO 3.2 Spec - T30SLuis LOZANONo ratings yet

- RilsamidAesnoMed TDS 201811Document2 pagesRilsamidAesnoMed TDS 201811Satish KumarNo ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- Lotrene LLDPE Datasheet PDFDocument6 pagesLotrene LLDPE Datasheet PDFThụy Thảo LinhNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- Muehlstein Certene HWF-852BDocument1 pageMuehlstein Certene HWF-852BManuel martinezNo ratings yet

- HPB-0354 Technical Data Sheet for Blow Molding HDPEDocument1 pageHPB-0354 Technical Data Sheet for Blow Molding HDPEHichamSalamaNo ratings yet

- Hfi5110 300516Document2 pagesHfi5110 300516李万福No ratings yet

- Altis Mv2: ApplicationsDocument1 pageAltis Mv2: ApplicationsM.TayyabNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Mea Polybit Tds Polybit Bituboard en MeaDocument2 pagesMea Polybit Tds Polybit Bituboard en MeaMuhammad hussainNo ratings yet

- Easy Flow Polystyrene Material DatasheetDocument3 pagesEasy Flow Polystyrene Material DatasheetAlbert FortunatoNo ratings yet

- Qdrain C15 65 14F Eng 1Document1 pageQdrain C15 65 14F Eng 1Thameem SharaafNo ratings yet

- BL7 - HM 6255Document1 pageBL7 - HM 6255ShahryarNo ratings yet

- Document Description 65Ϭ,Dͳd,E/>D^,D: Property Units Value Test MethodDocument1 pageDocument Description 65Ϭ,Dͳd,E/>D^,D: Property Units Value Test Methodray9699No ratings yet

- LLDPE Film Product Data SheetDocument2 pagesLLDPE Film Product Data SheetManufaktur Sinar JoyoboyoNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Low Density Polyethylene Resin: Physical Properties (Based On Pellets and Press-Molded Sheet)Document1 pageLow Density Polyethylene Resin: Physical Properties (Based On Pellets and Press-Molded Sheet)Akram.yishakNo ratings yet

- Polyethylene HHM TR-144 MSDS All EnglishDocument10 pagesPolyethylene HHM TR-144 MSDS All EnglishAkram.yishakNo ratings yet

- NJ No9030ul enDocument2 pagesNJ No9030ul enAkram.yishakNo ratings yet

- Neonatal ConjunctivitisDocument10 pagesNeonatal ConjunctivitisAkram.yishakNo ratings yet

- Hikvision How To Reset Password Quick Guide A1securitycamerasDocument9 pagesHikvision How To Reset Password Quick Guide A1securitycamerasAkram.yishakNo ratings yet

- 8 Fob 0 N 3 C 7 DoqjonwDocument1 page8 Fob 0 N 3 C 7 DoqjonwAkram.yishakNo ratings yet

- Manufacturer color masterbatches IndiaDocument4 pagesManufacturer color masterbatches IndiaAkram.yishakNo ratings yet

- Dell Optiplex 9010 Spec Sheet PDFDocument3 pagesDell Optiplex 9010 Spec Sheet PDFAkram.yishakNo ratings yet

- LDPE Datasheet 2017Document1 pageLDPE Datasheet 2017Akram.yishakNo ratings yet

- DubaiCalendar 2019 EnglishDocument1 pageDubaiCalendar 2019 EnglishAkram.yishakNo ratings yet

- Marlex® - Optical Haze Blow FlimsDocument8 pagesMarlex® - Optical Haze Blow FlimsAkram.yishakNo ratings yet

- Microsurfacing EmulsionDocument4 pagesMicrosurfacing EmulsionTarak PatelNo ratings yet

- Amran Et Al. 2022 - 3D-Printable Alkali-Activated Concretes For Building Applications-A Critical ReviewDocument24 pagesAmran Et Al. 2022 - 3D-Printable Alkali-Activated Concretes For Building Applications-A Critical Review孟嫣然No ratings yet

- CementDocument15 pagesCementSuTtA OPNo ratings yet

- Standards List for Road Construction SpecificationDocument19 pagesStandards List for Road Construction SpecificationNana Kwame Osei AsareNo ratings yet

- Boracay Drainage Improvement Project Design PlanDocument34 pagesBoracay Drainage Improvement Project Design PlanDaryl J. S. BadajosNo ratings yet

- Catalog Appleton WSR Interlocked Receptacle Cover en Us 178392Document3 pagesCatalog Appleton WSR Interlocked Receptacle Cover en Us 178392Eecol phone ParedesNo ratings yet

- Evaluating The Effect of Laboratory Aging On Fatigue Behavior of Asphalt Mixtures Containing Hydrated LimeDocument8 pagesEvaluating The Effect of Laboratory Aging On Fatigue Behavior of Asphalt Mixtures Containing Hydrated LimeEizu YangNo ratings yet

- Plastic HingesDocument10 pagesPlastic HingesBala SubramanianNo ratings yet

- Allowable StressDocument12 pagesAllowable StressChristian RigonNo ratings yet

- Safest Versatile Liquid Paint MarkerDocument2 pagesSafest Versatile Liquid Paint MarkerPubcrawlNo ratings yet

- A Fatigue Failure Criterion for Fiber Reinforced MaterialsDocument17 pagesA Fatigue Failure Criterion for Fiber Reinforced MaterialsHussain ZaranwalaNo ratings yet

- Research PaperDocument4 pagesResearch PaperJhon Car Matin-aoNo ratings yet

- Eed 313 4Document8 pagesEed 313 4arangatelgie217No ratings yet

- Damage Modelling of Adhesive Joints Using The Cohesive Zone ModelDocument6 pagesDamage Modelling of Adhesive Joints Using The Cohesive Zone ModelGogyNo ratings yet

- Thursday 04 To Perform The Rockwell Hardness Test and Determine The Hardness of The Given SpecimenDocument6 pagesThursday 04 To Perform The Rockwell Hardness Test and Determine The Hardness of The Given SpecimenFatima ImamNo ratings yet

- Sikafloor®-94: Product Data SheetDocument2 pagesSikafloor®-94: Product Data SheetLONG LASTNo ratings yet

- Technical Data Sheet: Easicoat Professional Refinish SystemDocument24 pagesTechnical Data Sheet: Easicoat Professional Refinish System'Jeiami Verano CaramayNo ratings yet

- 2) Data Sheet VDek-703 Standard 2021 FTDocument1 page2) Data Sheet VDek-703 Standard 2021 FTJean CausilNo ratings yet

- Lab 9 Fatigue TestingDocument2 pagesLab 9 Fatigue TestingTommy MilesNo ratings yet

- TDS 140N - TipicosDocument2 pagesTDS 140N - TipicosCris AranzNo ratings yet

- Efka+PX+4780 TDS 30688721 ENDocument2 pagesEfka+PX+4780 TDS 30688721 ENrndsb.aopNo ratings yet

- Technology of Cement Production: Bottlenecks and SolutionsDocument256 pagesTechnology of Cement Production: Bottlenecks and SolutionsShashwat OmarNo ratings yet

- BMSE D 22 02382 ReviewerDocument28 pagesBMSE D 22 02382 ReviewerHEMANTH KUMAR CNo ratings yet

- ACSR/MZ 400/51 specificationDocument3 pagesACSR/MZ 400/51 specificationDuy TiếnNo ratings yet

- Technical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketDocument2 pagesTechnical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketMohamed KhaledNo ratings yet

- Hilti D16Document1 pageHilti D16Ina RoseNo ratings yet

- ENGN.2060 Assignment 06 SolutionDocument3 pagesENGN.2060 Assignment 06 SolutionSandeep PetwalNo ratings yet

- Nptel: Introduction To Crystallographic Texture and Related Phenomenon - Web CourseDocument2 pagesNptel: Introduction To Crystallographic Texture and Related Phenomenon - Web CourseAnisur RahamanNo ratings yet

- Determinación de La Viabilidad Del Uso de Botellas de PET Como Material de Construcción en Contexto UrbanoDocument10 pagesDeterminación de La Viabilidad Del Uso de Botellas de PET Como Material de Construcción en Contexto UrbanoAlex Percy Antonio Manriquez PaisigNo ratings yet

- EN PDS Scooter Moto 4Document2 pagesEN PDS Scooter Moto 4rizkyram347No ratings yet