Professional Documents

Culture Documents

Hse Manual: Rehabilitation of Corroded Infrastructure in Units 4300/4500/4600 & PROVISION OF SECURED ACID Handling System

Uploaded by

dozzi chuckzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hse Manual: Rehabilitation of Corroded Infrastructure in Units 4300/4500/4600 & PROVISION OF SECURED ACID Handling System

Uploaded by

dozzi chuckzCopyright:

Available Formats

NIGERIA LNG

CAPEX PROJECTS

NLNG REVIEW COMMENTS AND / OR APPROVAL SHALL NOT BE ASSUMED TO

INDICATE EITHER RESPONSIBILITY OR LIABILITY FOR ACCURACY AND

COMPLETENESS OF THIS DOCUMENT OR TO ALTER ANY CONTRACT TERMS

AND CONDITIONS. LIMITED CONDITION ONLY TO PROCEED AS APPLICABLE.

CONTRACTOR SHALL BE RESPONSIBLE TO CORRECT ALL RELATED DOCUMENTS

OR DRAWINGS. OUTSTANDING COMMENTS / ISSUES OF NOTE SHALL BE

ADDRESSED AND DOCUMENTS RE-PRESENTED FOR FINAL APPROVAL.

COMMENTS AS

NOTED

NAME: Joseph Jackson DATE: Nov 29, 2019 TIME: 9:35 am

HSE MANUAL

REHABILITATION OF CORRODED INFRASTRUCTURE IN UNITS

4300/4500/4600 & PROVISION OF SECURED ACID

HANDLING SYSTEM

Liaise with

13/MOC/PDR/039P HSE to update

and align with

CONTRACT NO: B170030TPP NLNG

requirements

Rejected. Doc does not align with

NLNG requirement for HSE Plan

O 18 NOV 19 C. Umeoke M. Aguh H. Enechukwu Issued for Comment

ISSUE DATE BY CHKD APPD DESCRIPTION

WHEN REVISION HAVE BEEN MADE TO THIS DOCUMENT THE INDEX OF ISSUE SHALL BE INDICATED IN A TRIANGLE

NEAR THE PART(S) CONCERNED

CLASSIFICATION: MOST CONFIDENTIAL CONFIDENTIAL RESTRICTED UNRESTRICTED

This document is confidential. The copyright therein is vested in Nigeria

LNG Ltd. Recipients must obtain the written authority of the said company Drinking, Demineralized &

before wholly or partly duplicating these contents or disclosing the same

to others.

Service Water Plants Upgrade

Project

All rights reserved.

DISCIPLINE: HSE PROJECT NO: 13/MOC/PDR/039P

LOCATION: BONNY ISLAND,

NIGERIA

PLANT: LNG COMPLEX PAGE 1 OF 19

UNIT: NIGERIA LNG LTD DOC NO: B-57.006 REV O

4300/4500/

4600 HSE MANUAL CONTR. DOC. NO: B170030TPP

REVISION LOG

REVISION PAGES REMARKS

O First Issue

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 2 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

TABLE OF CONTENTS

1 SAFETY, HEALTH & ENVIRONMENT OBJECTIVES.......................................................................... 6

2 BASIC SAFETY RULES ......................................................................................................................... 7

3 GENERAL SAFETY RULES ................................................................................................................... 8

3.1 HOUSEKEEPING .............................................................................................................. 8

3.2 PERSONAL PROTECTIVE EQUIPMENT ............................................................................... 8

3.3 STACKING MATERIALS ..................................................................................................... 8

3.4 DEFECTIVE TOOLS .......................................................................................................... 8

3.5 GUARDS ......................................................................................................................... 8

3.6 CLEARANCE CERTIFICATE................................................................................................ 8

3.7 STARTING AND REPAIRING MACHINERY .......................................................................... 9

3.8 ELECTRICITY .................................................................................................................... 9

3.9 LADDERS ......................................................................................................................... 9

4 HANDLING AND STORAGE OF GAS CYLINDERS....................................................................... 10

4.1 THE FOLLOWING PRECAUTIONS ARE MANDATORY ...................................................... 10

5 OUR AIM–ZERO ACCIDENTS ......................................................................................................... 11

5.1 TRUCKS ........................................................................................................................ 11

5.2 SMOKING ..................................................................................................................... 11

5.3 FIRST-AID BOXES ........................................................................................................... 11

5.4 HEALTH......................................................................................................................... 11

5.5 HORSEPLAY................................................................................................................... 11

6 REPORTING OF ACCIDENTS .......................................................................................................... 12

6.1 INVESTIGATION OF ACCIDENTS ................................................................................... 12

6.1.1 UNUSUAL OCCURRENCE............................................................................................................... 12

7 EMERGENCIES ................................................................................................................................. 13

7.1 EMERGENCY INSTRUCTION .......................................................................................... 13

7.1.1 IN THE CASE OF AN EMERGENCY LIKE FIRE, GAS LEAK ETC / ON HEARING THE ALARM . 13

7.1.2 EMERGENCY ACTION IN FIRE INCIDENT .................................................................................... 13

7.2 FIRE PROTECTION SYSTEM ............................................................................................ 13

7.2.1 FIRE EXTINGUISHMENT IS BASED ON THE FOLLOWING FOUR METHODS .......................... 14

7.2.2 FIRES ARE CLASSIFIED INTO FIVE CATEGORIES.......................................................................... 14

7.2.3 VARIOUS FIRE EXTINGUISHING AGENTS ARE............................................................................. 14

8 PERSONAL PROTECTIVE EQUIPMENT ........................................................................................... 16

9 ENVIRONMENTAL – POLLUTION .................................................................................................. 17

9.1 AIR POLLUTION ............................................................................................................ 17

9.2 WATER POLLUTION ....................................................................................................... 17

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 3 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

9.3 SOIL POLLUTION .......................................................................................................... 17

9.4 OZONE DEPLETION ...................................................................................................... 17

10 OUR GOALS...................................................................................................................................... 19

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 4 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

HSE POLICY STATEMENT

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 5 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

1 SAFETY, HEALTH & ENVIRONMENT OBJECTIVES

Strive to reduce the probability of the accidents which have the potential to cause

injury, disablement, loss of life & property.

Take measure to minimize health impairment of people.

To minimized degradation of the general environment in & around the location, by

controlling probable situations which have the potential to adversely affect the

environment.

To minimize undue wastage of the material resources including water and other

solvents, which help in preventing environment pollution.

To educate the employees so that they can be aware of their own safety, health &

wellbeing as well as their responsibility towards the environment.

To train, retrain & thereby motivate the employees so that they are able to identify

& eliminate prevailing unsafe practices as well as we able to improve, upgrade &

mention their workplace free of unsafe action & condition.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 6 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

2 BASIC SAFETY RULES

All workers are must to wear coverall uniform, helmet and hand gloves while on

duty.

Smoking is strictly prohibited outside smoking designated area.

For handling chemicals, workers must use face mask and goggles.

Keep the barricades in front of the trucks while on loading.

Do not enter any vessel or equipment, without proper permit.

No hot work in plant without a fire permit.

For doing any maintenance work, the work permission is necessary.

Do not use any fire alarm or fire extinguisher when there is no emergency situation.

Do not start any work without a proper PPE.

Job safety analysis to be followed.

Work as per instructions only, know the instruction is to be followed in case of

emergency

Keep PPE in clean and suitable condition.

Report any abnormal conditions, sound or vibration to your HSE officer.

When you hear the fire alarm siren. Leave the building/area immediately and

proceed to designated assembly area.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 7 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

3 GENERAL SAFETY RULES

3.1 HOUSEKEEPING

Workplace and surrounding area shall be kept clean and free from obstructions.

On job completion all tools, equipment and leftover material shall be stored/kept at

designated storage place.

Waste material and other intermediate material shall be removed and kept in covered

containers.

Slippery substances such as grease or oil spilled on floor, shall be wiped and cleaned

immediately.

Wearing apron, no person working on or near moving vehicles shall be wearing loose

clothing.

The worker who involved in loading or unloading shall put-on tight-fitting apron, shoes,

boots must be tightly lashed.

Casual clothes should not wear by the worker at the time of work.

3.2 PERSONAL PROTECTIVE EQUIPMENT

PPE like goggles, face mask, apron, gloves, safety shoes, helmet etc. are issued for

personnel protection for jobs where special Hazard exist and it is mandatory by the

personnel while engaged on such work

3.3 STACKING MATERIALS

a) All material shall be stacked tightly and up to safe height to prevent them from falling

or causing some other piles to fall.

b) No material shall be stacked in passages and emergency exit.

3.4 DEFECTIVE TOOLS

All defective tools like chisels with irregular heads, spanner with worn jaws, broken

hammers shall be brought to the notice of the HSE officer and discard it.

3.5 GUARDS

Machine guard and other safety devices shall not be removed except for making repairs

lubricating or cleaning by authorized person. These must be replaced before starting

machines.

3.6 CLEARANCE CERTIFICATE

Incidents often occurs when maintenance work or project work is carried out in a half

hazard way. Before taking any maintenance work each job should be analyzed in detail to

find out what are possible hazards involved in the executing job and identifying methods

to be adopted to prevent incidents.

Type of certificate/Permit used in the plant clearance system:

1) Work request and standard certificate

2) Vessel entry permit

3) Hot work permit

4) Temporary electrical connection permit

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 8 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

5) Work on height permit

3.7 STARTING AND REPAIRING MACHINERY

a) No person shall attempt to operate or certain motion or equipment unauthorized.

b) Oiling, cleaning and repairing of machinery shall not be normally carried without first

stopping machinery completely

c) No person switches on electricity, turns on gas, air or acid or certain motion and

machinery without first making sure that no one is in position to be injured.

d) All exposed moving parts of machinery such as pulleys, belts, couplings, chains,

flywheels, rotating collars with projecting shield etc, shall be properly guarded.

3.8 ELECTRICITY

a) No work shall be done near electricity supply lines and operations without the approval

of components authority.

b) The use of defective plugs, socket and flexible cable shall be avoided.

c) No one except a person duly authorized by electrical shall operate any switch gear or

other electric equipment except for routine starting and stopping motors and switching

on or switching off lights, fans etc.

3.9 LADDERS

a) Ladders with broken and missing rings or split side rails or otherwise defective shall not

be used.

b) No metallic ladders shall be used for electrical work or any work to be executed near

the electric supply lines or apparatus unless it has rubber shoes.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 9 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

4 HANDLING AND STORAGE OF GAS CYLINDERS

Cylinders of compressed gas either flammable or otherwise can be lethal if they are mishandled

or misused. Care must be taken in all aspects of their use, particular attention must be paid to

the care of valves or regulator, and these are perhaps a cylinder’s most vulnerable parts. If,

during careless handling, damage occurs to the valve or regulator, gas cylinder can turn into

a deadly missile. The vast store of energy contained in a gas cylinder can culminate into a

powerful jet propulsion unit if there is nothing to control its release.

Flammable gases and oxygen cause particular problems especially if leakage occurs and

instant recognition of cylinders is vital for the course of action to be followed.

4.1 THE FOLLOWING PRECAUTIONS ARE MANDATORY

a) The oxygen and acetylene cylinders shall not be stored together except during use.

b) Gas cylinder shall be stored upright.

c) Full and empty cylinders shall be kept apart to prevent confusion and mistake.

d) No valve or lading on a gas cylinder shall be lubricated.

e) The cylinders shall be kept away from oil and grease during storage and handling.

f) The LPG cylinder shall be stored undercover. Away from the direct rays of the sun and

the storeroom shall be properly ventilated.

g) Filled gas cylinders shall not be rolled on the ground. These shall be moved on cylinder

cars or trolleys.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 10 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

5 OUR AIM–ZERO ACCIDENTS

5.1 TRUCKS

a. All vehicles shall comply with traffic regulations within the site and they shall not exceed

the speed limit.

b. Stop the engine while loading or unloading.

c. Don’t start the engine until loading man takes the barricades away.

d. Riding on a running vehicle or any part of the vehicle except on a proper seat is strictly

prohibited.

e. Sitting on the side laps or standing in a truck while in motion is strictly prohibited.

f. Driver’s shouldn’t go on the top of the loading area it’s highly forbidden.

5.2 SMOKING

Smoking is strictly prohibited in the site premises and any location; it shall be a punishable

offence. All the personnel shall deposit the match boxes and lighters at the front office in

case of visitors. It is the person/section visited, who shall ensure that the visitors do not have

smoking related items.

5.3 FIRST-AID BOXES

First-aid boxes shall be provided in suitable places in the site and office.

5.4 HEALTH

Any contagious or communicable disease suffered by the employee shall be intimated to

the management by the individual. Food, water and beverages shall be taken at designated

places only.

5.5 HORSEPLAY

Horse play of any kind is prohibited inside the site. Do not distract the attention of others

at work.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 11 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

6 REPORTING OF ACCIDENTS

Whenever an injured person is required to be sent to the hospital for treatment, the executive

on duty should prepare the copies of accident form as per the procedure and give to the HSE

officer. In case of serious accident information should be passed at once to location head.

6.1 INVESTIGATION OF ACCIDENTS

The essential requirements of successful accidents prevention practice are:

a) Every accident is investigated expeditiously and causes are analyzed critically.

b) Remedy for avoiding recurrence is recommended and applied.

6.1.1 UNUSUAL OCCURRENCE

These are learning incidents which have the potential of accidents/mishaps/spillages.

These shall be reported, investigated and remedial actions there of shall be expeditiously

implemented to prevent recurrence.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 12 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

7 EMERGENCIES

An emergency shall be declared if an unwanted incident (fire, major solvent/inflammable

material spill or major injury accidents) occurs and requires the mobilization of all possible

resources to arrest it. Regular drills shall be conducted to familiarize everybody on their roles

in the event of such emergency. Participation in these drills is mandatory as per procedure.

7.1 EMERGENCY INSTRUCTION

7.1.1 IN THE CASE OF AN EMERGENCY LIKE FIRE, GAS LEAK ETC / ON HEARING

THE ALARM

Stop work if any, switch off all equipment.

Leave the room/ store/ office etc, with visitors if any.

Close door behind you.

Report to assembly point/muster point.

Do not enter the room/ store/ office etc, before emergency rescue team gives you

permission.

Check and ensure that all occupants have been vacated.

If all have been vacated proceed to assembly point /muster point and report to

emergency response team.

Perform roll call/ head count.

Do not allow occupants and visitors to return to the room/ store/ office etc, until

advised by the emergency response team.

Contact HSE officer.

7.1.2 EMERGENCY ACTION IN FIRE INCIDENT

In the event of a fire follow the following general rules:

After discovering the fire:

Assess the situation to determine if on site resources are adequate to respond. If YES,

initiate response.

Shout FIRE, FIRE…….!!

Sound the bell/alarm…….!!

Attack the fire with appropriate fire extinguisher if possible.

Report to the assembly point/ muster point

If you have visitors you must take them with you.

Do not re-enter the room before the emergency response team gives you permission.

Contact HOECHY HSE officer.

7.2 FIRE PROTECTION SYSTEM

Fire remains a threat to the plant and property, particularly as we use a number of

flammable chemicals; all big fires are initially small and are best prevented if detected &

extinguished in the incipient stage. Hence each one of us should be alert about fire and

know how to extinguish it.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 13 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

A fire takes places if a flammable material gets heated up to its ignition point in the

presence of air. The fire further propagates due to the chain reaction taking place between

the molecules of the fuel & oxygen. The energy released as a result of the chemical reaction

is in the form of heat, light and flames.

Thus, a fire will start if all the three elements Heat, Fuel and Oxygen come together in right

proportions. This is also known as fire triangle.

Fire can be prevented if the three sides of fire triangle are never allowed to meet together.

7.2.1 FIRE EXTINGUISHMENT IS BASED ON THE FOLLOWING FOUR METHODS

1. Cooling - Removal of heat.

2. Starving - Removal of Fuel.

3. Blanketing/smothering - Cutting of oxygen supply.

4. Breaking the chain reaction - Introduction of chemicals which interfere & break the

chain reaction.

7.2.2 FIRES ARE CLASSIFIED INTO FIVE CATEGORIES

Class A – Solid fires (wood, paper, cloth etc.)

Class B – Liquid fires (petrol, methanol, IPA etc.)

Class C – Gas fires (hydrogen, LPG, Acetylene etc.)

Class D – Metal fires (Na, K, aluminum, zinc etc.)

Class E – Electrical fires (panel, motors, cable etc.)

7.2.3 VARIOUS FIRE EXTINGUISHING AGENTS ARE

1. Water

2. Foam

3. Co2

4. Dry chemical powder (DCP)

Water:

We can use water to extinguish fires of class A. Water extinguishes a fire by cooling.

Water spray gives better cooling; water jet is used to extinguish fire from a distance.

Foam:

It is used to extinguish fires of class B i.e. Fires in solvent/chemicals which are lighter

than water. Foam being lighter, floats on solvent surface and extinguishes the fire by

cooling and smothering. Foams are of two kind’s chemicals foam & mechanical foam.

Chemical foam is produced by their action of two chemicals solutions. Mechanical foam

is produced by mechanical impact on a solution of foam compound in water.

CO2:

It is used to extinguish fires of class E, electrical fires. It may also be used to extinguish

class B fires in containers.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 14 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

DCP:

Dry chemical powder extinguishes fires of class A, D & E. it extinguishes by blanketing/

smothering action.

At HOECHY, we have portable fire extinguishers and a fire alarm system.

At least one 6kg dry powder extinguisher must be provided.

Extinguishers should be housed in suitable weather-proof boxes ability at all times.

Extinguishers must be inspected regularly and a permanent record maintained.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 15 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

8 PERSONAL PROTECTIVE EQUIPMENT

Personal protective equipment protects the human being from exposure against various kinds

of hazards. PPE themselves do not eliminate accidents or the hazard, but protect against the

effects there of.

The best of engineering provisions at one time or another can fail, hence the use of PPE is a

must.

PPE are available for protection of various parts of body against each type of hazard. PPE

should be usable, reliable, economical and maintainable in a clean hygienic condition. It

should be borne in mind that PPE add to the cost of production. If these are not used

appropriately, it would affect the availability of PPE.

a. PPE must be in good condition and fit for purpose.

b. PPE must be provided by the hauler for all drivers whilst inside the site.

c. All PPE should be regularly checked and cleaned or replaced whenever their function

to protect personnel cannot be judged as fit for purpose anymore.

d. Responsibility lies with the user as well as with the company providing the PPE.

These protect against physical injury to the external parts of the body as well as absorption into

the skin causing systemic effects.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 16 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

9 ENVIRONMENTAL – POLLUTION

The surroundings in which we live is called environment. It is basically constituted of the air we

breathe, the water we drink and the soil from which we get our food. The heat and rays of the

sun also have a bearing on the environment.

Due to various human activities and over population our environment is being adversely

affected. This is called Pollution. It is a serious threat to the very existence of human life on the

earth.

In order to tackle pollution, each one of us should know how actually pollution takes place and

what can be done to prevent it.

9.1 AIR POLLUTION

Emissions from industries, automobiles etc, pollutes the air, we get sick if we breathe

polluted air.

9.2 WATER POLLUTION

Effluents and discharges from industries, domestic sewage etc. mixes with the natural &

ground water causing water pollution. If we drink water without proper treatment, we would

fall sick.

9.3 SOIL POLLUTION

Waste from industries, human consumption etc. contain materials like plastic, metals, glass,

chemicals etc. when the waste is disposed ruthlessly it damages the soil. This causes loss of

vegetation. The food product growing on such oil would harm our health if we eat them.

9.4 OZONE DEPLETION

There is a protective layer of ozone at the upper most portion of our atmosphere. This

protects the entry of harmful ultraviolet rays from coming to the earth. Due to increase of

chlorinated Hydrocarbon gases in the atmosphere, this ozone layer is getting damaged.

Ultraviolet rays kill living beings. This is a serious threat to the life on earth.

Various forms of pollution listed above if not checked will increase human sufferings and

our future generation will have a miserable life. We can help in preventing further pollution

by contributing in the following ways

Avoid wastage of water, energy, chemicals & usable.

Grow more and more trees, plant etc.

Avoid over consumption of materials.

Use everything to the maximum extent possible.

Use only environment friendly goods & materials.

Follow all pollution controls rules and regulations in a systematic manner.

Air emissions, water discharges & solid wastes should be minimized as far

as possible. Before throwing away, these

Should be treated and made in nocuous.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 17 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

As far as possible recycle & reuse water, waste & natural resources. Share environmental

awareness & manage for pollution prevention with all and one, as far as possible.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 18 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

10 OUR GOALS

Through effective and transparent HSE management, we aim to protect our employees, be the

preferred contractor for customers and the favored employer in the oil and gas sector.

Our HSE Management System helps us achieve these goals by providing the frame work and

processes to examine the risks to our employees, the public, our property, and the environment

in which we operate and determine what actions we need to take to control these risks.

Our promise to our employees and who are all associated with our concern is that we will strive

for continuous improvement in every area of our HSE efforts. This means continuous

improvement of our standards, systems, programs, safety performance, management

leadership, and employees’ awareness, knowledge, commitment, and involvement.

HOECHY has engaged in numerous initiatives to build and reinforce our health and safety

culture, and we expect our employees to achieve year- over-year improvement in safety

performance.

We are aiming for a destination called “zero”—zero safety incidents, zero injuries and zero

days off work due to injury; in other words, a perfect HSE record.

Our Driving to Zero vision means accepting that every incident is preventable, and it has helped

us achieve improvements in our safety performance.

DRINKING, DEMINERALIZED & SERVICE WATER PLANTS UPGRADE PROJECT

(CONTRACT NO: B170030TPP)

LOCATION: BONNY ISLAND,

PLANT: LNG COMPLEX PROJECT NO: 13/MOC/PDR/039P

NIGERIA

UNIT: NIGERIA LNG LTD PAGE 19 of 19

4300/4500/ DOC NO: B-57.006 Rev O

HSE MANUAL

4600 CONTR. DOC NO: B170030TPP

You might also like

- Ninja® Foodi™ Smart XL 6-In-1 Indoor Grill Quick Start GuideDocument2 pagesNinja® Foodi™ Smart XL 6-In-1 Indoor Grill Quick Start GuidehawkjohnNo ratings yet

- Financial Analysis and Decision Making PowerpointDocument28 pagesFinancial Analysis and Decision Making Powerpointashvina321No ratings yet

- Virgil Donati Feature Drumscene Magazine 2010Document10 pagesVirgil Donati Feature Drumscene Magazine 2010Clint Hopkins100% (1)

- 1 Weekly Environment ChecklistDocument3 pages1 Weekly Environment ChecklistibrahimNo ratings yet

- Method Statement For Crane InstallationDocument16 pagesMethod Statement For Crane Installationadetola leke100% (1)

- Microsoft Office 365 Customer Decision FrameworkDocument14 pagesMicrosoft Office 365 Customer Decision FrameworkthinkofdevilNo ratings yet

- Method Statement: Plumbing & Ug Piping WorksDocument17 pagesMethod Statement: Plumbing & Ug Piping WorksMuhammad Sami ParvezNo ratings yet

- Hydraulic Study Report Rev.1 Dated 31-3-2019Document54 pagesHydraulic Study Report Rev.1 Dated 31-3-2019MechanicalEngineNo ratings yet

- JSA For Cathodic Protection Installation For PipelineDocument15 pagesJSA For Cathodic Protection Installation For PipelineAmeerHamzaWarraich100% (1)

- Sure Track SystemDocument2 pagesSure Track SystemIcal AgamNo ratings yet

- Method Statement of Hydro TestDocument15 pagesMethod Statement of Hydro Testmuslim100% (3)

- RFQ For Waste Water Treatment Package (Internal) R.0Document18 pagesRFQ For Waste Water Treatment Package (Internal) R.0roronoa_zorro11100% (1)

- General Instruction Manual: ScopeDocument14 pagesGeneral Instruction Manual: ScopeJithuRajNo ratings yet

- Lesson Plan ABRACADABRADocument9 pagesLesson Plan ABRACADABRAAdelina HasasNo ratings yet

- DH PEP PPS PR 001 Process DescriptionDocument6 pagesDH PEP PPS PR 001 Process Descriptionfadli arsyadaNo ratings yet

- Bài Tập Kỹ Thuật Điện TửDocument13 pagesBài Tập Kỹ Thuật Điện TửNguyenCanhBaoNo ratings yet

- Work Method Statement For X-A T#31 To 34Document8 pagesWork Method Statement For X-A T#31 To 34Twin Bulls100% (1)

- Confined SpaceRescue Plan - Asad HSEDocument16 pagesConfined SpaceRescue Plan - Asad HSEAsad RazaNo ratings yet

- B-63.888 - B - Operational Test Procedure For Lifting Stations (Ls 1-5)Document39 pagesB-63.888 - B - Operational Test Procedure For Lifting Stations (Ls 1-5)onome ohwerhiNo ratings yet

- NS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5Document46 pagesNS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5namdq-10% (1)

- B-57.481 - B - Plumbing Design CalculationDocument14 pagesB-57.481 - B - Plumbing Design CalculationChimex KenNo ratings yet

- 725SSM Boiler Operation and Maintenance ManualDocument30 pages725SSM Boiler Operation and Maintenance Manualmochamad umarNo ratings yet

- Hse PlanDocument69 pagesHse PlanshafiqhaikalNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Pck7a Id PCK Pa Ibp 7011004 - MWP A Flushing Procedure - Rev.c1Document6 pagesPck7a Id PCK Pa Ibp 7011004 - MWP A Flushing Procedure - Rev.c1IsaalexNo ratings yet

- Spec. Safety and Fire Protection - SJBDocument16 pagesSpec. Safety and Fire Protection - SJBRizaldi Riz100% (2)

- Crochet Pattern "Doll-Chamomile": TanaticrochetDocument9 pagesCrochet Pattern "Doll-Chamomile": TanaticrochetElene Lomidze100% (1)

- Method Statement Civil WorksDocument12 pagesMethod Statement Civil WorksDaniel Offiong100% (1)

- LPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetDocument4 pagesLPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetNyssaMaurillaNo ratings yet

- Amine PKGDocument18 pagesAmine PKGRathinavel PerumalNo ratings yet

- Refrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsFrom EverandRefrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsRating: 3 out of 5 stars3/5 (2)

- Laporan Topografi Rev 01Document16 pagesLaporan Topografi Rev 01risal100% (1)

- Global hydrogen trade to meet the 1.5°C climate goal: Part III – Green hydrogen cost and potentialFrom EverandGlobal hydrogen trade to meet the 1.5°C climate goal: Part III – Green hydrogen cost and potentialNo ratings yet

- IP MS 03 General FillDocument5 pagesIP MS 03 General FillZubair Ahmed KhaskheliNo ratings yet

- Reviewed: by Nadiera at 11:45 Am, 5/17/22Document16 pagesReviewed: by Nadiera at 11:45 Am, 5/17/22carlos farinaNo ratings yet

- Planned Enhancements, Northeast Natural Gas Pipeline SystemsDocument5 pagesPlanned Enhancements, Northeast Natural Gas Pipeline SystemsTodd SullivanNo ratings yet

- S-900-1242-022 - 6a - 008 - A7 (Permit To Use Aerial Work Platforms)Document1 pageS-900-1242-022 - 6a - 008 - A7 (Permit To Use Aerial Work Platforms)umar saidNo ratings yet

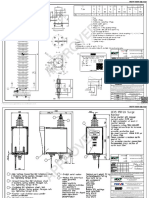

- 145kV SA Outline DrawingDocument3 pages145kV SA Outline Drawingrey pamelo navarroNo ratings yet

- 3006 500a DGB12003Document13 pages3006 500a DGB12003AnaNo ratings yet

- Nuclear Power Corporation of India LimitedDocument11 pagesNuclear Power Corporation of India Limitedkevin desaiNo ratings yet

- JW 13859 Ohs Environmental DocumentDocument130 pagesJW 13859 Ohs Environmental Documentkamogelo MolalaNo ratings yet

- 15.1.4 Fi800237 Int VND BD 10Document14 pages15.1.4 Fi800237 Int VND BD 10sathyanand tkNo ratings yet

- Recommended Procedures For Laying Up BoilerDocument11 pagesRecommended Procedures For Laying Up BoilerRamy OmarNo ratings yet

- B-36.021 - Rev A-HVAC Cooling Load Calculation Report-Ground FloorDocument11 pagesB-36.021 - Rev A-HVAC Cooling Load Calculation Report-Ground Floorchukudi oguneNo ratings yet

- B-45.276 - C - Specification For Control ValvesDocument22 pagesB-45.276 - C - Specification For Control ValvesUbong P. EffiongNo ratings yet

- KGP2301 FLTC PPLA CON MST 0003-R01 METHOD STATEMENT - OF Pipe StringingDocument12 pagesKGP2301 FLTC PPLA CON MST 0003-R01 METHOD STATEMENT - OF Pipe StringingAvak NishanNo ratings yet

- OBS1Document1 pageOBS1younas khanNo ratings yet

- Pre - HydroDocument5 pagesPre - HydroMECON BACHELINo ratings yet

- 3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Document40 pages3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Jonathan MartinezNo ratings yet

- Ksccs Gen Exe AP 99 Pip RPT 0001 0Document173 pagesKsccs Gen Exe AP 99 Pip RPT 0001 0Ahmad AqilNo ratings yet

- Orange County Planning MinisinkDocument7 pagesOrange County Planning Minisink2rQiTPh4KnNo ratings yet

- Platso WatDocument37 pagesPlatso WatAshoka NarayananNo ratings yet

- 9876 155 CHP PVM W 155 01Document62 pages9876 155 CHP PVM W 155 01Caspian DattaNo ratings yet

- Fire Fighting Design Basis Report: Client: M/SDocument12 pagesFire Fighting Design Basis Report: Client: M/SMustafizur SaounNo ratings yet

- Precipitador Electrostatico 2Document499 pagesPrecipitador Electrostatico 2Roberto Carlos Sandoval RuvalcabaNo ratings yet

- SPCC C SH PR 0032 Environmental Management Plan F1Document37 pagesSPCC C SH PR 0032 Environmental Management Plan F1ismayil AdishovNo ratings yet

- Epcon Ms 12 001mechanical Equipment PreservationDocument19 pagesEpcon Ms 12 001mechanical Equipment PreservationSaber MagdyNo ratings yet

- Spesification For Earth Work (IFD Rev 1) SWS BalonganDocument11 pagesSpesification For Earth Work (IFD Rev 1) SWS BalonganEndiarto Budi RaharjoNo ratings yet

- Erection Completion CertificateDocument1 pageErection Completion CertificateBalakrishnan Krishnan0% (1)

- Comentarios Mencionar/Confirmar en El Documento Si El Recipiente Viene Con Protección de Nitrógeno y Manómetros para Su PreservaciónDocument7 pagesComentarios Mencionar/Confirmar en El Documento Si El Recipiente Viene Con Protección de Nitrógeno y Manómetros para Su Preservacióncarlos farinaNo ratings yet

- AFM-IMP-OKL-G10-00078-R01 Overpressure Protection of AP Condensate Flash Drum From Fuel Gas SystemDocument18 pagesAFM-IMP-OKL-G10-00078-R01 Overpressure Protection of AP Condensate Flash Drum From Fuel Gas SystemYousuf Nasser ALAbriNo ratings yet

- PrismaticDocument15 pagesPrismatica.agila03No ratings yet

- BGR Energy Systems Limited Power Projects Division Comments Reply Sheet (CRS) - ClientDocument2 pagesBGR Energy Systems Limited Power Projects Division Comments Reply Sheet (CRS) - ClientKIRANKUMARREDDY KOTLANo ratings yet

- DBR-Complressed Air System-12.08.2019Document13 pagesDBR-Complressed Air System-12.08.2019raaj bharathNo ratings yet

- JKT05 SHD ELC 519 REV D Electrical Service External Power ReviewedDocument8 pagesJKT05 SHD ELC 519 REV D Electrical Service External Power Reviewed2018 Mahendra Alvan RosandyNo ratings yet

- Fdocuments - in DBR For Water TreatmentDocument28 pagesFdocuments - in DBR For Water TreatmentRavi ChandranNo ratings yet

- Word 2016, Using Mail MergeDocument6 pagesWord 2016, Using Mail MergePelah Wowen DanielNo ratings yet

- Chapt 22Document9 pagesChapt 22Rebecca EsNo ratings yet

- RTI Online Submit Request FormDocument1 pageRTI Online Submit Request FormRinky SharmaNo ratings yet

- MISSISSIPPI Chanery ClerksDocument7 pagesMISSISSIPPI Chanery Clerks2PlusNo ratings yet

- Herniated Nucleus PulposusDocument12 pagesHerniated Nucleus PulposusshezarNo ratings yet

- Josef Suk-BagatellaDocument6 pagesJosef Suk-BagatellaAlessandro CaspaniNo ratings yet

- The Marine WorkoutDocument7 pagesThe Marine WorkoutAndres Eco AldeanoNo ratings yet

- 2.2 Crime Scene Investigation andDocument1 page2.2 Crime Scene Investigation andFatima Sarpina HinayNo ratings yet

- Strategy SolutionsDocument2 pagesStrategy SolutionsIbrahim OsmanNo ratings yet

- P.E 12 AquaticsDocument5 pagesP.E 12 Aquaticsabrenicaraniel05No ratings yet

- Liquid FuelsDocument8 pagesLiquid FuelsCharles Bonn Kirby MayoNo ratings yet

- API Ne - Con.prvt - CD Ds2 en Excel v2 5455687Document94 pagesAPI Ne - Con.prvt - CD Ds2 en Excel v2 5455687aaaNo ratings yet

- Choose The Best Answer From The Four Options (Marked A, B, C, or D) To Complete The Sentences. Exercise 1Document6 pagesChoose The Best Answer From The Four Options (Marked A, B, C, or D) To Complete The Sentences. Exercise 1Van AnhNo ratings yet

- Tom MCQ UNIT 2Document14 pagesTom MCQ UNIT 2Kumar PachareNo ratings yet

- Stroke - Wikipedia, The Free EncyclopediaDocument31 pagesStroke - Wikipedia, The Free EncyclopediaRhonskiiNo ratings yet

- 01-PPS SMOI User Manual BodyDocument93 pages01-PPS SMOI User Manual BodyGuelahourou Joel SossieNo ratings yet

- Cirminal Behavior and Cognitive ProcessingDocument9 pagesCirminal Behavior and Cognitive ProcessingAdriana Ornelas AguirreNo ratings yet

- Ch. 30 Basic MacroeconomicsDocument38 pagesCh. 30 Basic MacroeconomicsFatmahNo ratings yet

- Luxury Salon and SpaDocument10 pagesLuxury Salon and Spalucullan studioNo ratings yet

- GIS and Regional Economic Development Planning: Chen Fei Du Daosheng Jiang JingtongDocument8 pagesGIS and Regional Economic Development Planning: Chen Fei Du Daosheng Jiang JingtongJuragan MudaNo ratings yet

- PD78F0138ADocument558 pagesPD78F0138APoon Electronic Training CentreNo ratings yet

- Issue 14Document20 pagesIssue 14The Muse is radNo ratings yet

- E38 Closed Circuit Current TestDocument4 pagesE38 Closed Circuit Current TestCezaryCezasNo ratings yet