Professional Documents

Culture Documents

p21078 Quiz Report

p21078 Quiz Report

Uploaded by

Ankit NathOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p21078 Quiz Report

p21078 Quiz Report

Uploaded by

Ankit NathCopyright:

Available Formats

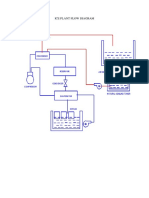

Process A:

Melt

Adamantium(15min

Splash Infuse Reheat(10min) Melting Mold

Mixing(10min) (10min) Transfer(1min)

Melt Vibranium (14

min)

Final Cooling(8min)

Touchup(12min)

Process B:

S-Melt(12min)

B1(6min)

CBM(24min) Mold

L-Boil(12min) Transfer(1min)

Cleaning at Refiltering

MDS (16min) (1min)

Cooling(8min)

B2 Final

Touchup(12min)

Answer:2:

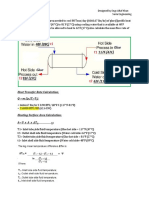

Through put time for process A = 15+10+10+8+8+12+1= 64 mins

Through put time for process B = 12+17+24+8+12+4= 77 mins

If Shuri runs the plant for 8 hrs/day and 5 days/week, therefore, number of production hours in

hand

Total productions hours = 8*5 = 40 hrs= 2400 mins.

Total nu. of batches of knee caps made by process A = 2400/64 = 37.5= 38(approximately)

Total nu. of batches of knee caps made by process B = 2400/77= 31.16= 31(approximately)

Total nu. of batches produced = 31+38=69 batches.

Answer:3:

If the SIM machine is under maintenance, therefore, process B is the sole load bearer for the plant.

All the orders will be processed using process B.

Assuming a constant flow from one station to another (ie. Whenever a station gets free the next

product in line is put into production)

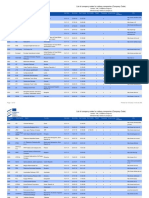

For product coming in at 9:18AM:

Wait Time (WT)= 0

Throughput Time (TPT)= 77 mins

Flow Time (FT) = WT + TPT = 77 mins.

For product coming in at 9:20AM:

Wait Time (WT)= 75+77= 152 mins

Throughput Time (TPT)= 77 mins

Flow Time (FT) = WT + TPT = 229 mins.

For product coming in at 9:52AM:

Wait Time (WT)= 152-32+77= 197 mins

Throughput Time (TPT)= 77 mins

Flow Time (FT) = WT + TPT = 274 mins.

For product coming in at 10:03AM:

Wait Time (WT)= 274-11= 263 mins

Throughput Time (TPT)= 77 mins

Flow Time (FT) = WT + TPT = 340 mins.

If product comes at 10:15 AM:

Wait Time (WT)= 340-12= 328 mins

Throughput Time (TPT)= 77 mins

Flow Time (FT) = WT + TPT = 398 mins= 6hrs 38 min

Hence, it will be delievered by= 4:53 PM

ANSWER:4:

If for process A cooldown time is halved. Hence time taken for cooling is 4 mins.

Also, if final touch up time is halved. Hence, that time in touchups is 6 mins.

Therefore, throughput time of the process = 64-10=54 mins.

Hence, the first order can be delivered after 54 mins of order, if delivered as soon as possible.

ANSWER:5:

Statement A is FALSE.

Statement B is TRUE.

ANSWER:6:

If the plant is starting production at another location, it should take system A there for the following

reasons:

Less throughput time.

Less processes going on in parallel.

Smaller bottleneck.

UNDERTAKING

I Ankit Nath declare that I have not used any unfair means while answering the questions.

You might also like

- Cummins LTA10-G Parts ManualDocument117 pagesCummins LTA10-G Parts ManualMarielis Contreras100% (3)

- Wildfire Entertainment: Case Study Analysis Graphic OrganizerDocument2 pagesWildfire Entertainment: Case Study Analysis Graphic OrganizerAnkit NathNo ratings yet

- ControlDocument44 pagesControlRavi KumarNo ratings yet

- A Report On DrillDocument18 pagesA Report On DrillTITU NATH100% (1)

- Benjamin Sobieck - The Writer's Guide To WeaponsDocument147 pagesBenjamin Sobieck - The Writer's Guide To WeaponsGeorgescu BogdanNo ratings yet

- Answer Key Quiz 2022Document11 pagesAnswer Key Quiz 2022Sounak PaulNo ratings yet

- Assignment 2Document3 pagesAssignment 2Osen GaoNo ratings yet

- Filter PressDocument9 pagesFilter PressEl CoolNo ratings yet

- Assignment 2 PDFDocument2 pagesAssignment 2 PDFNicolas PercianiNo ratings yet

- Chapter 3: Process and Capacity AnalysisDocument15 pagesChapter 3: Process and Capacity AnalysisAnugragha SundarNo ratings yet

- CS101 - Introduction To Computing: Part # 1: Draw The Ready Queue SolutionDocument3 pagesCS101 - Introduction To Computing: Part # 1: Draw The Ready Queue Solutiondc210200041 SHAHEER KHANNo ratings yet

- Solutions Review Questions Session 2Document1 pageSolutions Review Questions Session 2gaurab_khetan789No ratings yet

- Sample Tutorial 2 SolutionDocument7 pagesSample Tutorial 2 SolutionSumit RijalNo ratings yet

- Clocks Problem SolutionsDocument14 pagesClocks Problem SolutionsBsksvdndkskNo ratings yet

- Lecturer Dr. Arkan - Jasim.Hadi Good LuckDocument1 pageLecturer Dr. Arkan - Jasim.Hadi Good Luckکبری ادریس رسولNo ratings yet

- Libro 4 PDFDocument8 pagesLibro 4 PDFCynthia Jazmin Flores CisnerosNo ratings yet

- Chemical Kinetics QUESTION SHEETDocument14 pagesChemical Kinetics QUESTION SHEETzackNo ratings yet

- Stoforos IFTPS SA 2020Document59 pagesStoforos IFTPS SA 2020Balaji MariappanNo ratings yet

- Agricultural ProcessingDocument8 pagesAgricultural ProcessingRexieNo ratings yet

- Heat Exchanger Design CalculationsDocument4 pagesHeat Exchanger Design Calculationssuria qaqcNo ratings yet

- EEV Manual Polar 03-06 PDFDocument16 pagesEEV Manual Polar 03-06 PDFErika JaneNo ratings yet

- PART-3-Blast Freezing - Cold RoomDocument3 pagesPART-3-Blast Freezing - Cold RoomDEEPANSHU KUMAR MISHRANo ratings yet

- Correction Cas KanbanDocument2 pagesCorrection Cas KanbanVan Anh AuNo ratings yet

- Lean Assignment 4Document11 pagesLean Assignment 4Hozefa Ajmerwala100% (1)

- Example 1Document16 pagesExample 105191022No ratings yet

- ReviewerDocument8 pagesReviewermaylynXiXNo ratings yet

- Angricultural ProcessingDocument8 pagesAngricultural ProcessingYendis SamsonNo ratings yet

- Unsteady StateDocument6 pagesUnsteady StateBeben SyaputraNo ratings yet

- Batching: Process Flow Chart of Pre-MordantingDocument2 pagesBatching: Process Flow Chart of Pre-MordantingSales Sodhani BiotechNo ratings yet

- Build-Heat-Exchanger: Compose Your Own Heat Exchanger and Make CalculationsDocument13 pagesBuild-Heat-Exchanger: Compose Your Own Heat Exchanger and Make CalculationsMamoon ShahidNo ratings yet

- Formula AmpulDocument5 pagesFormula AmpulRISNAWATINo ratings yet

- Previous Next Prep FindDocument2 pagesPrevious Next Prep FindStephen Velasco VillaruzNo ratings yet

- Calculation of A 2-4 Oil CoolerDocument45 pagesCalculation of A 2-4 Oil CoolerAndre HenriqueNo ratings yet

- Assignment 2 Q1. Draw The Ready Queue For The Above Given ProcessesDocument3 pagesAssignment 2 Q1. Draw The Ready Queue For The Above Given ProcessesOmar Masood KhanNo ratings yet

- Praktikum HEDocument6 pagesPraktikum HEReza PahleviNo ratings yet

- Value Stream LEANDocument8 pagesValue Stream LEANJoven CastilloNo ratings yet

- Autoclave Temperature and Time Pressure Chart PDFDocument1 pageAutoclave Temperature and Time Pressure Chart PDFSiddarthNo ratings yet

- Autoclave Temperature and Time Pressure ChartDocument1 pageAutoclave Temperature and Time Pressure ChartAli AftabNo ratings yet

- Module 5: Activity No. 1: LengthDocument3 pagesModule 5: Activity No. 1: LengthMELANTHONY QUINITNo ratings yet

- Lab Task # 02 Softening Point of Bitumen: ScopeDocument3 pagesLab Task # 02 Softening Point of Bitumen: ScopeAsif KhanNo ratings yet

- Ice Plant ComputationDocument6 pagesIce Plant ComputationGerk100% (1)

- Activity in Just in Time Problem Solving With AnswersDocument2 pagesActivity in Just in Time Problem Solving With AnswersLucy HeartfiliaNo ratings yet

- 1 Process - Analysis SolutionsDocument6 pages1 Process - Analysis SolutionsHEMANT KUMARNo ratings yet

- KondensorDocument9 pagesKondensorHenrikus Bhanutanaya WNo ratings yet

- BE1401 Business Operations and Processes Answer Key For Exercises On Capacity AnalysisDocument4 pagesBE1401 Business Operations and Processes Answer Key For Exercises On Capacity Analysisgao linxinNo ratings yet

- Boost Predicion Series OneDocument11 pagesBoost Predicion Series Onewinrosenyaboke56No ratings yet

- Ice Plant and Cold Storage Design (60 TONS OF ICE/day: Submitted To: Engr. Renato A. ArriolaDocument24 pagesIce Plant and Cold Storage Design (60 TONS OF ICE/day: Submitted To: Engr. Renato A. ArriolaJonas Dela PeñaNo ratings yet

- Class Example-SolutionDocument4 pagesClass Example-SolutionAslam ChohanNo ratings yet

- Termodinamika IDocument107 pagesTermodinamika ILiyan Fajar Gintara100% (2)

- Exercises+Replacing+Push+Production+ +kopie+Document4 pagesExercises+Replacing+Push+Production+ +kopie+MarlonNo ratings yet

- Trial Long DistanceDocument1 pageTrial Long DistanceMuhammad RidwanNo ratings yet

- LEMBAR DATA Heat ExchangerDocument1 pageLEMBAR DATA Heat Exchangermhd solihinNo ratings yet

- Sayed Ahmed Abdel-Moneim - MSF DesalinationDocument10 pagesSayed Ahmed Abdel-Moneim - MSF DesalinationUnc StappyNo ratings yet

- Calibration of Bomb CalorimeterDocument17 pagesCalibration of Bomb CalorimeterStephen AbeladaNo ratings yet

- Zakoni Termodinamike: Granica SistemaDocument19 pagesZakoni Termodinamike: Granica SistemaGeorge GrossNo ratings yet

- Isobaric Thermodynamics Processes Problems and SolutionsDocument1 pageIsobaric Thermodynamics Processes Problems and SolutionsBasic PhysicsNo ratings yet

- Information QuestionDocument16 pagesInformation QuestionAshif IqubalNo ratings yet

- DF96 18OZ Instructions - CompleteDocument2 pagesDF96 18OZ Instructions - CompleteAndrea J. NasiNo ratings yet

- StepCoolingTestofCr MoSteel PDFDocument4 pagesStepCoolingTestofCr MoSteel PDFvijaya kumarNo ratings yet

- Chapter11 12Document3 pagesChapter11 12Nyan Lynn HtunNo ratings yet

- Process Analysis Batching SolutionDocument1 pageProcess Analysis Batching Solutionaditya162No ratings yet

- Donner Case Operations ManagementDocument3 pagesDonner Case Operations Managementleeladon0% (1)

- Group-4 - Section-B - Shouldice CaseDocument6 pagesGroup-4 - Section-B - Shouldice CaseAnkit NathNo ratings yet

- Group4 SecB MO DonnerCaseSubmissionDocument7 pagesGroup4 SecB MO DonnerCaseSubmissionAnkit NathNo ratings yet

- Operations Management: Mid TermDocument3 pagesOperations Management: Mid TermAnkit NathNo ratings yet

- OM QuizDocument4 pagesOM QuizAnkit NathNo ratings yet

- 10 - Moonka Auto - Growth Strategies of A Honda DealershipDocument14 pages10 - Moonka Auto - Growth Strategies of A Honda DealershipAnkit NathNo ratings yet

- U93090MH2018PTC308253 T dlmbvvm3vg0bh6Document161 pagesU93090MH2018PTC308253 T dlmbvvm3vg0bh6Ankit NathNo ratings yet

- Kyocera Corporation: Case Study Analysis Graphic OrganizerDocument2 pagesKyocera Corporation: Case Study Analysis Graphic OrganizerAnkit NathNo ratings yet

- Tony Heish at Zappos: Case Study Analysis Graphic OrganizerDocument1 pageTony Heish at Zappos: Case Study Analysis Graphic OrganizerAnkit NathNo ratings yet

- SUmmary PT. PAGUN TAKADocument2 pagesSUmmary PT. PAGUN TAKAbill kandyNo ratings yet

- RSRDL Antt, T-600 038. Salary Slip Employee Copy: 038.deczuDocument1 pageRSRDL Antt, T-600 038. Salary Slip Employee Copy: 038.deczurajkamal rNo ratings yet

- VARAOSAKIRJA-Bucket Brush 205,305 - 2.painos - EN-RUDocument23 pagesVARAOSAKIRJA-Bucket Brush 205,305 - 2.painos - EN-RUСветлана ГайдайNo ratings yet

- KPR Price List June 2022Document1 pageKPR Price List June 2022YESWIN SEKSARIANo ratings yet

- Name of The ResortDocument7 pagesName of The ResortJack MathewNo ratings yet

- Float Valves (Drillmax)Document8 pagesFloat Valves (Drillmax)Alexander KlmNo ratings yet

- Grundfosliterature 4609703Document11 pagesGrundfosliterature 4609703GenkimanNo ratings yet

- Saturn NozzlesDocument6 pagesSaturn NozzlesDaniel FuentesNo ratings yet

- Chennai: Hr@bafn ApharmaDocument10 pagesChennai: Hr@bafn Apharmakbogeshwaran100% (1)

- Chemical Supplier Certification UpdateDocument5 pagesChemical Supplier Certification UpdateDyeing DyeingNo ratings yet

- Companies ListDocument3 pagesCompanies ListMj KousalyaNo ratings yet

- Size Chart - BataDocument6 pagesSize Chart - BataindustrialmechatechNo ratings yet

- Dokumen - Tips - Gurgaon FBD DataDocument26 pagesDokumen - Tips - Gurgaon FBD DataSachin RaiNo ratings yet

- Vespa Elegante Limited Edition BrochureDocument4 pagesVespa Elegante Limited Edition BrochureHarshal DhanawadeNo ratings yet

- CompanyCodes 20230404 1004Document87 pagesCompanyCodes 20230404 1004asd fdaNo ratings yet

- HAESG 9006 Humpty Dumpty Sat On A SwingDocument35 pagesHAESG 9006 Humpty Dumpty Sat On A SwingMaria ChievaNo ratings yet

- Stell IndustryDocument4 pagesStell IndustryFortune BuildersNo ratings yet

- Hand Tools: 1) Match The Hand Tools With The Correct Picture. You Have The First One As ExampleDocument2 pagesHand Tools: 1) Match The Hand Tools With The Correct Picture. You Have The First One As ExampleFlorencia ZurbrikggNo ratings yet

- Atk GLC DataDocument7 pagesAtk GLC DataViena SukmawatiNo ratings yet

- 400scale - BAe146-200 - Avro RJ 85 - Pionair AustraliaDocument1 page400scale - BAe146-200 - Avro RJ 85 - Pionair AustraliaMohamed DhiaaNo ratings yet

- Charge 2Document1 pageCharge 2Ibne JobairNo ratings yet

- Chapter4analysis of Clamping ForceDocument10 pagesChapter4analysis of Clamping ForceMohammad umarNo ratings yet

- LKB Spare PartsDocument42 pagesLKB Spare PartsraluntitledNo ratings yet

- Dimensions:: Manufacturer FAG SKF Product 7314-B-XL-MP-UB 7314BECBMDocument1 pageDimensions:: Manufacturer FAG SKF Product 7314-B-XL-MP-UB 7314BECBMriyadh bsisoNo ratings yet

- Brands To Avoid Selling On AmazonDocument4 pagesBrands To Avoid Selling On AmazonFahad KhanNo ratings yet

- Cone BrochureDocument6 pagesCone BrochureJaime I. de la RosaNo ratings yet

- 03 - 17 - 16 - Wireline Type JarsDocument3 pages03 - 17 - 16 - Wireline Type JarsrezaNo ratings yet