Professional Documents

Culture Documents

Procedure For Plant and Machinery Breakdowns and Maintanance

Procedure For Plant and Machinery Breakdowns and Maintanance

Uploaded by

Walay AllanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Plant and Machinery Breakdowns and Maintanance

Procedure For Plant and Machinery Breakdowns and Maintanance

Uploaded by

Walay AllanCopyright:

Available Formats

PROCEDURE FOR PLANT AND MACHINERY BREAKDOWNS AND MAINTANANCE

The Engineering Manager, Plant Manager, Fitters, Mining supervisors, line supervisors shall be

responsible for break downs and the maintenance of the plant and machinery at the mine site.

Call out log book shall work as the job card for communication between supervisors, fitters and

the Engineering manager.

Small breakdowns shall be communicated up to HOD level but bigger break downs which may

stop operations shall be reported immediately to the Technical director and the CEO.

There shall be a standby vehicle in place which shall ferry maintenance team to attendant

breakdowns and this vehicle shall not be used for other tasks other than standby duties.

No breakdown or maintenance shall take place without logging such information in the

maintenance log book and the breakdowns log book.

The call out book shall clearly indicate time a breakdown has occurred, time the call out was

done, time the break down was attended to and time the break down was fixed with time of

release for operations.

The standby truck shall not be allowed to delay even with 10 minutes to pick the fitter or parts

required to fix the problem.

The plant operator or the machine operators shall not leave site of where the fitters are fixing

the breakdown so as to allow assistance with some information of problems faced.

In completion the fitter and the driver shall test together the machines for a period of about 30

minutes to be sure everything has been sorted in case of major breakdowns.

Break downs shall be sorted on site unless if there is need to get technical assistance from other

hired engineers if the situation worsens.

On daily bases drivers shall do machine inspections using the checklist and any possible

stoppages shall be reported immediately.

During inspections if the breakdown is predicted of causing harm the operations may be

suspended with the plant manager, mining supervisors and the technical director and such

stoppage shall be reported immediately in the office of the CEO.

In every 3 working days fitters should stop machines each for a time of about 10-20 minutes for

maintenance checks.

Major maintenance shall be done according to set working hours, mileages and weekly

maintenances.

Radios and phones shall be used to communicate in case of breakdowns and call outs.

Communication log books namely maintenance book, inspections book, plant examination book

and the checklists shall be filled and shall be readily available for inspection by other managers.

END…………….

You might also like

- Sop For Maintenance DepartmentDocument38 pagesSop For Maintenance DepartmentKanjeng Nasuha Gumat87% (23)

- Batching Plant Operation Manual-Compressed (1) New PDFDocument296 pagesBatching Plant Operation Manual-Compressed (1) New PDFGanesh Pipude75% (4)

- U&M ARM550 E01Document165 pagesU&M ARM550 E01Augusto Oliveira100% (2)

- Chief Engineers Standing OrdersDocument8 pagesChief Engineers Standing Ordersoffshorearmada100% (3)

- Dumarent-manUSM Manitou 180ATJ - enDocument131 pagesDumarent-manUSM Manitou 180ATJ - enSomeUser0% (2)

- Watchkeeping AnswersDocument10 pagesWatchkeeping AnswersAshok Kumar100% (1)

- Dokumen - Tips - Bomag-Bw-120-Ad-Drum-Roller-Service-Repair-Manual-1629905308 BomagDocument19 pagesDokumen - Tips - Bomag-Bw-120-Ad-Drum-Roller-Service-Repair-Manual-1629905308 BomagSergio Hernandez0% (2)

- Clark 175b LoaderDocument595 pagesClark 175b LoaderPats Peças Tornearia SilveiraNo ratings yet

- Anura Trading House: Item Wise Price ListDocument25 pagesAnura Trading House: Item Wise Price ListNuwan Dias100% (1)

- Komatsu PC360LC-10Document95 pagesKomatsu PC360LC-10blaktion100% (3)

- SOP 02 Chief Engineers Standing OrdersDocument6 pagesSOP 02 Chief Engineers Standing OrdersJohn StierNo ratings yet

- Emergency Response Procedures (ERP)Document9 pagesEmergency Response Procedures (ERP)Mickey Ch100% (1)

- Sirio Manual 0101Document44 pagesSirio Manual 0101Veselin Karisic100% (1)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Prince Valves PDFDocument82 pagesPrince Valves PDFMauricio Ariel H. OrellanaNo ratings yet

- Traffic Engineering and Management PDFDocument11 pagesTraffic Engineering and Management PDFjeya50% (2)

- CHF Eng. Standing-OrdersDocument4 pagesCHF Eng. Standing-OrdersGökhan Ulukuz100% (1)

- Chief Engineer's Standing Instructions.Document3 pagesChief Engineer's Standing Instructions.prashant manhasNo ratings yet

- ISM Ship Management SMS Manual - SOM CH 09 Engine Room Operations-Ver03Document48 pagesISM Ship Management SMS Manual - SOM CH 09 Engine Room Operations-Ver03Burak YıldırımNo ratings yet

- Exhibit B - Scope of WorksDocument3 pagesExhibit B - Scope of WorksAhmet EpozhanNo ratings yet

- Standard Operating Procedure For The Greenbelt Farms (LTD) WorkshopDocument4 pagesStandard Operating Procedure For The Greenbelt Farms (LTD) WorkshopJames100% (1)

- WatchkeepingDocument90 pagesWatchkeepingAbdul Hafiz0% (1)

- Neral & Technical SpecificationsDocument8 pagesNeral & Technical SpecificationsPritam VanaraseNo ratings yet

- Manual Sy80uDocument300 pagesManual Sy80uAdministración Movitrans100% (1)

- 2E Mentoring 41770 PDFDocument92 pages2E Mentoring 41770 PDFAvinash Sheel100% (1)

- Unmanned Machinery Space Operations On Board Cargo ShipDocument11 pagesUnmanned Machinery Space Operations On Board Cargo ShipSwarg VibhaNo ratings yet

- Engineroom Manual2Document13 pagesEngineroom Manual2Sarm1s100% (1)

- Handling An Maintenance of Construction Machineries, Equipments and InstrumentsDocument13 pagesHandling An Maintenance of Construction Machineries, Equipments and InstrumentsVelmurugan BalasubramanianNo ratings yet

- Revision Record Sheet: TitleDocument4 pagesRevision Record Sheet: TitleSanjay MalhotraNo ratings yet

- JSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesDocument5 pagesJSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesslmLSU100% (3)

- .Section-1 GeneralDocument59 pages.Section-1 GeneralShyam KumarNo ratings yet

- Terms 12052011Document6 pagesTerms 1205201177matiahNo ratings yet

- Indian Railways: Track Machine ManualDocument41 pagesIndian Railways: Track Machine Manualram lochan sahuNo ratings yet

- Construction Machinery Operators InstructionDocument9 pagesConstruction Machinery Operators Instructionmiraç burak navruzNo ratings yet

- Truck Loading Machine Model TLM 1016 JDocument63 pagesTruck Loading Machine Model TLM 1016 Jzain140100% (1)

- t19 (Scope of Work) 1436846899Document4 pagest19 (Scope of Work) 1436846899Mohammad Safdar SadatNo ratings yet

- A Operator's Manual Beam Creel BC - ADocument23 pagesA Operator's Manual Beam Creel BC - AvikiNo ratings yet

- WatchDocument1 pageWatchRohit MishraNo ratings yet

- Без вахтове обслуговування МКВDocument4 pagesБез вахтове обслуговування МКВВалерий РыбалкаNo ratings yet

- Safety Precautions and Practices in Operation and MaintenanceDocument8 pagesSafety Precautions and Practices in Operation and MaintenanceQwe AsdfNo ratings yet

- Gem EscortingDocument7 pagesGem Escortingsuman sutharNo ratings yet

- 2954 2980 00 - QAS 250 John Deere - ENDocument52 pages2954 2980 00 - QAS 250 John Deere - ENIlarion CiobanuNo ratings yet

- CPA - SPOA Site Operating Procedures - Plant Supplement V5 January 2021Document5 pagesCPA - SPOA Site Operating Procedures - Plant Supplement V5 January 2021VeeraNo ratings yet

- Housekeeping ProcedureDocument5 pagesHousekeeping Proceduremondiali89No ratings yet

- CE Standing OrdersDocument4 pagesCE Standing OrdersGaurav MaithilNo ratings yet

- CP6 Chain FeederDocument119 pagesCP6 Chain Feederdeddy ariyantoNo ratings yet

- Presentation For EngineersDocument116 pagesPresentation For EngineersChalana UshanNo ratings yet

- Preliminary Erection Manual DDocument266 pagesPreliminary Erection Manual Dganesan 0011No ratings yet

- Methodology, O&M PhylosophyDocument11 pagesMethodology, O&M PhylosophyVuthpalachaitanya KrishnaNo ratings yet

- Pertemuan 12 Dinas JagaDocument3 pagesPertemuan 12 Dinas JagaGery Febrian PratamaNo ratings yet

- DH08 B2操保手册英文版 林德系统V1.1 2020.02Document184 pagesDH08 B2操保手册英文版 林德系统V1.1 2020.02Aris TacheazyNo ratings yet

- U&M - Merlo P72.10 - ENDocument258 pagesU&M - Merlo P72.10 - ENAndrea RiannaNo ratings yet

- Standing Orders Chief EngineerDocument3 pagesStanding Orders Chief EngineerarnaudvarraineNo ratings yet

- System of Maintenance SOP (19372)Document3 pagesSystem of Maintenance SOP (19372)Salma TariqNo ratings yet

- Fan TV425Document87 pagesFan TV425Khaled RabeaNo ratings yet

- 4-14 Brake Testing SystemDocument3 pages4-14 Brake Testing SystemOlubi FemiNo ratings yet

- Operating Manual: Grader Py180HDocument80 pagesOperating Manual: Grader Py180Hjechbolt1989No ratings yet

- DO - 005 - s2018 - Preventive Maintenance Manual For DPWH Equipment and Service VehiclesDocument231 pagesDO - 005 - s2018 - Preventive Maintenance Manual For DPWH Equipment and Service Vehiclesalterego1225100% (3)

- Part 15 - Temporary ControlsDocument3 pagesPart 15 - Temporary ControlsmhaydockNo ratings yet

- Cyclone Inst SignedDocument2 pagesCyclone Inst SignedSatish KumarNo ratings yet

- Dpu 2950Document32 pagesDpu 2950Dawn HallNo ratings yet

- What Industrial Machinery Workers DoDocument2 pagesWhat Industrial Machinery Workers DoDJ-NONO-88 emilioNo ratings yet

- Innovation and Entrepreneurship-DEG-04Document17 pagesInnovation and Entrepreneurship-DEG-04Walay AllanNo ratings yet

- Some LiteratureDocument5 pagesSome LiteratureWalay AllanNo ratings yet

- Procedure For Oxygen Acetylene Gas Bottles UsageDocument1 pageProcedure For Oxygen Acetylene Gas Bottles UsageWalay AllanNo ratings yet

- Procedure For Small Vehicles and Big TrucksDocument2 pagesProcedure For Small Vehicles and Big TrucksWalay AllanNo ratings yet

- A Proposed TerminalDocument3 pagesA Proposed TerminalGlennson BalacanaoNo ratings yet

- Catalogos de Filtros HLC: JR. MARISCAL CACERES #928 Int. 3 CHILCA - HUANCAYO TELEFAX: 064-231065/CAL:964668456Document3 pagesCatalogos de Filtros HLC: JR. MARISCAL CACERES #928 Int. 3 CHILCA - HUANCAYO TELEFAX: 064-231065/CAL:964668456neptasimon_1995No ratings yet

- Biggin HillDocument2 pagesBiggin HillHalesNo ratings yet

- HJSR0E03BC00ENGDocument1 pageHJSR0E03BC00ENGchrisNo ratings yet

- Seat Belt Recall FAQsDocument2 pagesSeat Belt Recall FAQsNational Content DeskNo ratings yet

- Bajaj Pulsur MBADocument78 pagesBajaj Pulsur MBArahulsogani123No ratings yet

- 60F RCP 03BR0Document14 pages60F RCP 03BR0bayu.agungnugroho96No ratings yet

- Joint Inspection SummaryDocument6 pagesJoint Inspection SummaryRifki Hamdani TanjungNo ratings yet

- Edmo Js5: DescriptionDocument3 pagesEdmo Js5: DescriptionanasamierNo ratings yet

- Brand Architecture PresentationDocument15 pagesBrand Architecture PresentationSuphi Sarigollu100% (1)

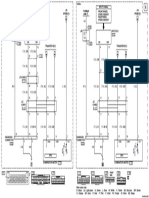

- COMPUTER DATA LINES - Saturn Vue Green Line 2008 - SYSTEM WIRING DIAGRAMSDocument2 pagesCOMPUTER DATA LINES - Saturn Vue Green Line 2008 - SYSTEM WIRING DIAGRAMSFredyNo ratings yet

- Reading Practice 1+keyDocument9 pagesReading Practice 1+keyTrần Huy100% (1)

- Spec Sheet Scania R730la4x2mnaDocument4 pagesSpec Sheet Scania R730la4x2mnaRoman PopulikNo ratings yet

- Manual UF115Document72 pagesManual UF115Juan Carlos Maguiña L.No ratings yet

- Walking in HW Country PDFDocument44 pagesWalking in HW Country PDFDiego Loza FolkloreNo ratings yet

- 2 Tamiya Hull Tweak List Ver. 1Document37 pages2 Tamiya Hull Tweak List Ver. 1692265100% (1)

- A350-43518-Spare Parts PDFDocument293 pagesA350-43518-Spare Parts PDFWaleed LemsilkhiNo ratings yet

- 4 21 4 Concrete Pump TrucksDocument8 pages4 21 4 Concrete Pump TrucksjorlinNo ratings yet

- MTS Testing Solutions For Materials & ComponentsDocument34 pagesMTS Testing Solutions For Materials & ComponentskarthegreNo ratings yet

- Aero Digest 8410 Un SeDocument456 pagesAero Digest 8410 Un SeBuican GeorgeNo ratings yet

- Installation, Use and Maintenance GearlessDocument32 pagesInstallation, Use and Maintenance GearlessNguyễn ThànhNo ratings yet

- Highway and Railway Engineering IntroductionDocument19 pagesHighway and Railway Engineering IntroductionMichael Martinez MercolitaNo ratings yet

- ECM INPUT AUTOLearnerDocument1 pageECM INPUT AUTOLearnerDhashana MoorthyNo ratings yet

- Jacking The Aircraft - Jacking - HoistingDocument4 pagesJacking The Aircraft - Jacking - Hoistingrama AmeesNo ratings yet

- Preet 949 Track Combine HarvesterDocument2 pagesPreet 949 Track Combine Harvesterwaris babaNo ratings yet