Professional Documents

Culture Documents

TDS - Silirub 614 PV

Uploaded by

Souradeep MukherjeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS - Silirub 614 PV

Uploaded by

Souradeep MukherjeeCopyright:

Available Formats

Silirub 614 PV

Revision: 15/02/2019 Page 1 from 2

Technical data

Basis Alkoxy

Consistancy Stable paste

Curing system Moisture curing

Skin formation* (23°C/50% R.H.) Ca. 15 min

Curing speed * (23°C/50% R.H.) Ca. 2,2 mm/24h

Hardness** 45 ± 5 Shore A

Specific Gravity Ca. 1,50 g/ml

Max. tension Ca. 2,0 N/mm²

Maximum allowed distortion 25 %

Max. tension (ISO 37)** 2,1 N/mm²

Elasticity modulus 100% (ISO 37)** 0,65 N/mm²

Elongation at break (ISO 37)** > 500 %

Dielectric strength kV/mm 18

Non Flamability UL94 V-0

Application temperature 5 °C → 45 °C

* These values may vary depending on environmental factors such as temperature, moisture, and type of substrates. ** This

information relates to fully cured product.

Product description Substrates

Silirub 614 PV is a high-quality, neutral, elastic Substrates: a variety of porous and non-porous

one-component silicone based joint sealant. materials

Nature: rigid, clean, dry, free of dust and

Properties grease.

Good adhesion on typical photovoltaic Surface preparation:

module components. There is no adhesion on PE, PP, PTFE

Very easy to apply (Teflon®) and bituminous substrates. We

Color fast and UV resistant recommend a preliminary adhesion test on any

Permanently elastic after curing substrate. This is highly recommended on PVC

Non-corrosive to metals. and other plastics.

Primerless adhesion to many substrates

Excellent electrical insulation properties Application method

Application method: With manual- or

pneumatic caulking gun.

Applications

Cleaning: Clean with White Spirit or Soudal

Bonding and sealing of photovoltaic

Surface Cleaner immediately after use (before

module components.

curing).

Frame sealing and junction box bonding. Finishing: With a soapy solution or Soudal

Finishing Solution before skinning.

Packaging Repair: With the same material

Colour: white

Packaging: Health- and Safety Recommendations

Take the usual labour hygiene into account.

Shelf life Consult the packaging label for more

12 months in unopened packaging in a cool information. Maintain adequate ventilation in

and dry storage place at temperatures the work place at all times.

between +5°C and +25°C.

Remark: This technical data sheet replaces al previous versions. The directives contained in this documentation are the result of

our experiments and of our experience and have been submitted in good faith. Because of the diversity of the materials and

substrates and the great number of possible applications which are out of our control, we cannot accept any responsibility for

the results obtained. Since the design, the quality of the substrate and processing conditions are beyond our control, no liability

under this publication is accepted. In every case it is recommended to carry out preliminary experiments. Soudal reserves the

right to modify products without prior notice.

Soudal NV Everdongenlaan 18 - 20 B-2300 Turnhout, Belgium

Tel: +32 (0)14-42.42.31 Fax: +32 (0)14-42.65.14 www.soudal.com

Silirub 614 PV

Revision: 15/02/2019 Page 2 from 2

Remarks

Given the great diversity of possible

surfaces, it is recommended to perform an

adhesion test on both substrates prior to

application.

In an acid environment or in a dark room, a

white sealant can slightly turn yellow.

Under the influence of sunlight it will turn

back to its initial colour.

When finished with a finishing solution or

soapy solution, make sure that the

surfaces are not touched by this solution.

This will cause the sealant not to adhere to

that surface. Therefore we recommend to

only dip the finishing tool in this solution.

We strongly recommend not to apply the

product in full sunlight as it will dry very

fast.

Adhesion may be less successful on

plastics such as polyethylene,

polypropylene and so on.

This product should not be applied on

surfaces that are continuously immersed in

water.

Environmental clauses

Leed regulation:

Silirub 614 PV conforms to the requirements of

LEED. Low –Emitting Materials: Adhesives and

Sealants. SCAQMD rule 1168. Complies with

USGBC LEED 2009 Credit 4.1: Low-Emitting

Materials – Adhesives & Sealants concerning

the VOC-content.

Liability

The content of this technical data sheet is the result

of tests, monitoring and experience. It is general in

nature and does not constitute any liability. It is the

responsibility of the user to determine by his own

tests whether the product is suitable for the

application.

Remark: This technical data sheet replaces al previous versions. The directives contained in this documentation are the result of

our experiments and of our experience and have been submitted in good faith. Because of the diversity of the materials and

substrates and the great number of possible applications which are out of our control, we cannot accept any responsibility for

the results obtained. Since the design, the quality of the substrate and processing conditions are beyond our control, no liability

under this publication is accepted. In every case it is recommended to carry out preliminary experiments. Soudal reserves the

right to modify products without prior notice.

Soudal NV Everdongenlaan 18 - 20 BE-2300 Turnhout

Tel: +32 (0)14-42.42.31 Fax: +32 (0)14-42.65.14 www.soudal.com

You might also like

- Silicone U - TDSDocument2 pagesSilicone U - TDShadeer youns0% (1)

- ID2920 - Silirub 908Document2 pagesID2920 - Silirub 908hhnp204No ratings yet

- Soudaflex 40FC - DatasheetDocument2 pagesSoudaflex 40FC - DatasheetsouravrobinNo ratings yet

- ID250 - Silirub Cleanroom - Belgium - EnglishDocument2 pagesID250 - Silirub Cleanroom - Belgium - Englishsamira bashirvandNo ratings yet

- Fisa Tehnica Soudal Vapourseal Adeziv Folii ConstructiiDocument2 pagesFisa Tehnica Soudal Vapourseal Adeziv Folii ConstructiiRĂZVANNo ratings yet

- Souda Flex 45 HMDocument2 pagesSouda Flex 45 HM7774R105No ratings yet

- Soudafoam 1KDocument2 pagesSoudafoam 1KCHERIF YAHIANo ratings yet

- Soudaflex Construction FCDocument2 pagesSoudaflex Construction FCAvijitSinharoyNo ratings yet

- DC 688 Technical Data SheetDocument3 pagesDC 688 Technical Data SheetHoang ThiNo ratings yet

- Soudal SpecDocument3 pagesSoudal Specthang TranNo ratings yet

- EasyPro Alkyd Prime 2019Document2 pagesEasyPro Alkyd Prime 2019Raja SNo ratings yet

- Ca1101 TdsDocument2 pagesCa1101 TdsJosevi Jiménez MerinoNo ratings yet

- Battery Size Calculator 22-8-12Document2 pagesBattery Size Calculator 22-8-12hintesarNo ratings yet

- EVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data SheetDocument3 pagesEVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data Sheetsamira bashirvandNo ratings yet

- Bondloc B270 Studlock TDSDocument2 pagesBondloc B270 Studlock TDSsean jukesNo ratings yet

- A11122XG W/B Gloss Coating: Technical Data SheetDocument1 pageA11122XG W/B Gloss Coating: Technical Data SheetYenifer LinaresNo ratings yet

- 6640 SIP-SPLASH 640 June-12Document2 pages6640 SIP-SPLASH 640 June-12ShaikhRizwanNo ratings yet

- Dispercoll U 42 - en - 00418072 17982223 19840529Document3 pagesDispercoll U 42 - en - 00418072 17982223 19840529Yan TengNo ratings yet

- Silicon Dow Corning Ficha TecnicaDocument2 pagesSilicon Dow Corning Ficha TecnicadanieldayettddNo ratings yet

- ENEN Metal Primer PDSDocument4 pagesENEN Metal Primer PDSNovica ĐorđevićNo ratings yet

- DT202B THERMAL TOP P 200 RH01 HONEY GLASSINE 65 UPM Raflatac SPADocument2 pagesDT202B THERMAL TOP P 200 RH01 HONEY GLASSINE 65 UPM Raflatac SPArcNo ratings yet

- Technical Information: Frimpeks UV Curable VarnishesDocument1 pageTechnical Information: Frimpeks UV Curable VarnishesAmbot NimoNo ratings yet

- FU B20 DAT BK620500 Prop GBDocument5 pagesFU B20 DAT BK620500 Prop GBsantosh mhetreNo ratings yet

- RNQxFixALLCrystalBelgiEngels PDFDocument2 pagesRNQxFixALLCrystalBelgiEngels PDFAndres JimenezNo ratings yet

- Colofix Ecolabel Ang 2Document1 pageColofix Ecolabel Ang 2douiissi.pyramideNo ratings yet

- Manual Everbuild Evercryl One Coat 15341Document3 pagesManual Everbuild Evercryl One Coat 15341scribd2162No ratings yet

- TDS - Pool FixDocument3 pagesTDS - Pool FixSeunNo ratings yet

- Vetoflex SS783: High Quality Elastic One Component Moisture Cure Silicone SealantDocument2 pagesVetoflex SS783: High Quality Elastic One Component Moisture Cure Silicone SealantSHAIK ASIMUDDINNo ratings yet

- Flexseal PU425 (K - 27.02.2020)Document2 pagesFlexseal PU425 (K - 27.02.2020)Mohamed RusfanNo ratings yet

- Safeguard Universal ES: Technical Data SheetDocument5 pagesSafeguard Universal ES: Technical Data SheetIsaacNarendraAkbarNo ratings yet

- Powerproof: One Component Polyurethane Dispersion Waterproofing MembraneDocument2 pagesPowerproof: One Component Polyurethane Dispersion Waterproofing MembraneFritz Natividad50% (2)

- 739 Plastic AdhesiveDocument4 pages739 Plastic AdhesivevkmsNo ratings yet

- PP ClearDocument2 pagesPP ClearCris AlexandrescuNo ratings yet

- DOWSIL™ GP Sealant: Features & Benefits ApplicationsDocument2 pagesDOWSIL™ GP Sealant: Features & Benefits ApplicationsSondangNo ratings yet

- Flexseal PU440 TDSDocument2 pagesFlexseal PU440 TDSkumaraguruNo ratings yet

- Novocat EP5720 Ceramic PasteDocument2 pagesNovocat EP5720 Ceramic PasteProveedora de servicios y suministros PSSNo ratings yet

- Don't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiDocument2 pagesDon't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiLion YangNo ratings yet

- Loctite 596™: SurfacesDocument2 pagesLoctite 596™: Surfaces楼淼森No ratings yet

- TDS 429 Conseal Touch-Up Euk GBDocument4 pagesTDS 429 Conseal Touch-Up Euk GBGalih WicaksonoNo ratings yet

- Dow Corning 732Document5 pagesDow Corning 732Imbran SheriffNo ratings yet

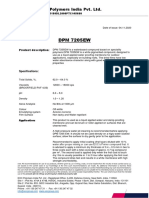

- DPM 7205EW: EOC Polymers India Pvt. LTDDocument2 pagesDPM 7205EW: EOC Polymers India Pvt. LTDsantosh mhetreNo ratings yet

- TDS 356 Antifouling SeaGuardian Euk GBDocument4 pagesTDS 356 Antifouling SeaGuardian Euk GBHarry FebrianzahNo ratings yet

- Jotun Pilot WF PDS Promain 12 09 2022Document6 pagesJotun Pilot WF PDS Promain 12 09 2022Debkov RomanNo ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- VT-231 Heavy Duty Construction AdhesiveDocument2 pagesVT-231 Heavy Duty Construction AdhesivetrinityallianceconsultancyNo ratings yet

- Mining FoamDocument2 pagesMining FoamCesar ZarateNo ratings yet

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocument4 pagesSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNo ratings yet

- TDS 43362 Alkyd High Gloss QD Euk GBDocument4 pagesTDS 43362 Alkyd High Gloss QD Euk GBkominthitsar7474No ratings yet

- Alkyd High Gloss QD TDSDocument4 pagesAlkyd High Gloss QD TDSthar gyiNo ratings yet

- Clarity PHL 4167 C ZP: Technical Data SheetDocument1 pageClarity PHL 4167 C ZP: Technical Data SheetMarvinNo ratings yet

- TDS Sikagard®-PW GCCDocument3 pagesTDS Sikagard®-PW GCCAmar Wadood100% (2)

- TDS Stainless Steel Paint Jotamastic 70Document5 pagesTDS Stainless Steel Paint Jotamastic 70rndsb.aopNo ratings yet

- EasyPro Epoxy Prime 2019Document2 pagesEasyPro Epoxy Prime 2019Raja SNo ratings yet

- Dow Corning 732 Multi-Purpose Sealant: Product InformationDocument2 pagesDow Corning 732 Multi-Purpose Sealant: Product InformationProject Sales CorpNo ratings yet

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049No ratings yet

- Aculon AL-B TDSDocument2 pagesAculon AL-B TDSAlan TanNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- AlphaSeal PU25VLS NGDocument3 pagesAlphaSeal PU25VLS NGMuthukumar JayaveerapandianNo ratings yet

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- Shower: Group Members: Masturah Binti T.Peter@ Mustafa Dianna Binti Maxy Hannah Fairuz Binti HamdanDocument8 pagesShower: Group Members: Masturah Binti T.Peter@ Mustafa Dianna Binti Maxy Hannah Fairuz Binti HamdanNajib TowyNo ratings yet

- First Mock Test (2020-21) PDFDocument2 pagesFirst Mock Test (2020-21) PDFsharique alamNo ratings yet

- Effective Viscosity Prediction of Crude Oil-Water Mixtures With High Water FractionDocument11 pagesEffective Viscosity Prediction of Crude Oil-Water Mixtures With High Water FractionVanessa RiosNo ratings yet

- INSTRUMENTAL METHODS OF ANALYSIS QUESTION BANK FOR B Tech BIOTECH PDFDocument3 pagesINSTRUMENTAL METHODS OF ANALYSIS QUESTION BANK FOR B Tech BIOTECH PDFFabian MataloNo ratings yet

- PHD ThesisDocument163 pagesPHD ThesisONURNo ratings yet

- Buckling AnalysisDocument26 pagesBuckling AnalysisbachNo ratings yet

- Ochsner 2008 Carbon Dioxide Heat Pipe in ConjuncDocument6 pagesOchsner 2008 Carbon Dioxide Heat Pipe in ConjuncHugo PeresNo ratings yet

- JOU - EQ Analysis of Structure by Base Isolation Technique in SAP PDFDocument10 pagesJOU - EQ Analysis of Structure by Base Isolation Technique in SAP PDFIlham Hussein RasyidNo ratings yet

- Api 510 QuizletDocument6 pagesApi 510 QuizletMahmoud Alwasif100% (1)

- Electromagnetic Waves: J.D.Jackson, "Classical Electrodynamics", 2nd Edition, Section 7Document26 pagesElectromagnetic Waves: J.D.Jackson, "Classical Electrodynamics", 2nd Edition, Section 7Armando CajahuaringaNo ratings yet

- Neet Major Test Plan - 2023-2024Document3 pagesNeet Major Test Plan - 2023-2024santhoshsivoNo ratings yet

- 4 Ericsson CycleDocument2 pages4 Ericsson CyclecaptainhassNo ratings yet

- Ws Experiment - ElectrolysisDocument3 pagesWs Experiment - ElectrolysisBrandon LawyNo ratings yet

- Fire Pump CatalogDocument19 pagesFire Pump CatalogFaheem MushtaqNo ratings yet

- Fluid Mechanics Summary Notes PDFDocument322 pagesFluid Mechanics Summary Notes PDFLendo PosaraNo ratings yet

- Reckon Civil Academy Strength of Material Mains PaperDocument4 pagesReckon Civil Academy Strength of Material Mains PaperAbhishek ChoudharyNo ratings yet

- Chapter 2 Heat EffectsDocument27 pagesChapter 2 Heat Effectsprakash_krishnan_2No ratings yet

- UTCHEM Tech Doc PDFDocument256 pagesUTCHEM Tech Doc PDFpasha khanNo ratings yet

- CES CBT Test Questions and Answers About Vessel Structure ConditionDocument27 pagesCES CBT Test Questions and Answers About Vessel Structure ConditionMyo Minn TunNo ratings yet

- Measurement of Horizontal Distances 3Document11 pagesMeasurement of Horizontal Distances 3Joshua50% (2)

- Part-C Defects - Nptel PDFDocument5 pagesPart-C Defects - Nptel PDFLakhwant Singh KhalsaNo ratings yet

- Earth Crust WSDocument2 pagesEarth Crust WSMarc Lawrence FallegaNo ratings yet

- Rev 2 Ducting Spec - ASMErevDocument76 pagesRev 2 Ducting Spec - ASMErevromerobernaNo ratings yet

- Computer Aided Analysis and Design of Multi-Storeyed BuildingsDocument66 pagesComputer Aided Analysis and Design of Multi-Storeyed BuildingsPeter Saxena100% (1)

- DLL Science 7 q1 Week 3Document6 pagesDLL Science 7 q1 Week 3Jayvee EnriquezNo ratings yet

- Requirements For Pressure Relief ValvesDocument1 pageRequirements For Pressure Relief ValvesshuzaoNo ratings yet

- Emx20Clc: General DataDocument3 pagesEmx20Clc: General Dataأبو زينب المهندسNo ratings yet

- Ashrae Duct PDFDocument3 pagesAshrae Duct PDFAnonymous XhkjXCxxsTNo ratings yet

- Session One - Kinematics Part ADocument9 pagesSession One - Kinematics Part ABoaz OtienoNo ratings yet