Professional Documents

Culture Documents

276 Install Rail

Uploaded by

Bashir MtwaklCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

276 Install Rail

Uploaded by

Bashir MtwaklCopyright:

Available Formats

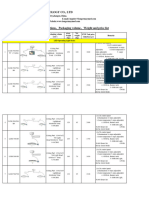

AR07.03-P-1010EL Remove/install rail 21.04.

2017

Engine 276 in model 212, 218

Modification notes

24.09.2014 Union nut, fuel line to high-pressure pump BA07.03-P-1002-01D

24.09.2014 Union nut, fuel line to fuel distributor BA07.03-P-1001-01D

Shown on model 212.080

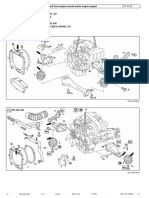

78 Center section of the bulkhead

P00.00-4697-11

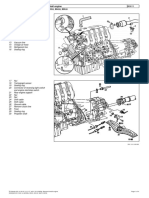

Shown on model 212.080

1 Rail

1s Screw/bolt

2 Seal

3 Hold-down tool

Y76 Fuel injectors

P07.03-2293-12

© Daimler AG, 12/18/18, X/11/18, ar07.03-p-1010el, Remove/install rail Page 1 of 5

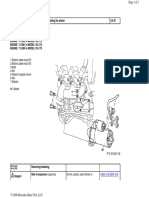

Engine 276 in model 212, 218

Shown on model 212.080

1 Rail

1s Screw/bolt

4 Support

B4/25 Fuel pressure and temperature

sensor

B6/7 Right exhaust camshaft Hall

sensor

P07.03-2297-06

Warning Risk of injury caused by fingers being No parts of the body or limbs should be within AS00.00-Z-0011-01A

jammed or pinched when removing, installing the operating area when the components are

or aligning hoods, doors, trunk lid/rear-end moving.

door or sliding roof.

Danger Risk of explosion caused by fuel igniting, risk No fires, sparks, open flames or smoking. AS47.00-Z-0001-01A

of poisoning caused by inhaling and Pour fuels into suitable and appropriately

swallowing fuel as well as risk of injury to eyes marked containers only.

and skin caused by contactwith fuel. Wear protective clothing when handling fuel.

General information on work on gasoline direct AH07.00-P-2000-01A

injection system

Remove

1 Detach ground line from battery AR54.10-P-0003EW

Topical note Notes on battery AH54.10-P-0001-01A

2 Remove center section of the bulkhead (78) Engine 276 in model 212, 218

Engine 276.8 in model 212 AR61.25-P-6600EW

Engine 276.9 in model 212.095/195

3.1 Remove air filter housing Engine 276.9 in model 212, 218

When removing the right rail (1)

Screw/bolt, air filter to air intake pipe *BA09.10-P-1002-01M

support brace

Screw/bolt, air filter to cylinder head cover *BA09.10-P-1001-01M

3.2 Remove both air filter housings Engine 276.8 in model 212, 218

When removing the left or right rail (1)

AR09.10-P-1150ELS

4 Remove connecting flange of the intake Engine 276.9 in model 212, 218 AR09.20-P-1961EL

manifold

5 Remove crash plate and insulation on the AR07.02-P-1020EL

high-pressure pump

6 Relieve fuel pressure over diagnostic socket AR07.03-P-1460-01VA

Cap on service connection *BA07.03-P-1007-01D

Pressure hose *119589046300

7 Remove fuel pressure in fuel high-pressure AR07.03-P-1460-02MM

circuit

8 Detach high-pressure line between rail (1) and

high-pressure pump

9 Detach fuel line (low pressure) at high-

pressure pump

10 Disconnect electrical connection on RH Engine 276.9 in model 212

exhaust camshaft Hall sensor (B6/7) Engine 276.9 in model 218

11 Disconnect electrical connection on fuel

pressure and temperature sensor (B4/25)

12 Detach engine wiring harness on the rail (1). Engine 276.9 in model 212, 218 AR01.00-P-2410-02EL

Engine 276.8 in model 212, 218 AR01.00-P-2410-02ELS

13 Remove support (4) for the intake manifold Engine 276.9 in model 212, 218

© Daimler AG, 12/18/18, X/11/18, ar07.03-p-1010el, Remove/install rail Page 2 of 5

Engine 276 in model 212, 218

14 Remove screws/bolts (1s)

Unscrew screw/bolts (1s) alternately each by

half a revolution. Begin in the center of the rail

(1) and work outwards.

Damage to the rail (1) can occur otherwise.

15 Remove hold-down tool (3) between rail (1)

and fuel injectors (Y76)

16 Mark fuel injectors (Y76) relative to the When reusing the fuel injectors (Y76) they

respective cylinder must be inserted into the cylinder in which it

was previously installed.

17 Detach rail (1) from fuel injectors (Y76)

18 Remove fuel injectors (Y76) AR07.03-P-0004EL

Oil which comes out during disassembly of

the rail (1) or from the fuel injectors (Y76) is

safe. The rail (1) or the fuel injectors (Y76) can

be re-used.

All fuel injectors (Y76) must be pulled out

since the rail (1) may only jointly be installed

with the fuel injectors (Y76).

In case of jammed fuel injectors (Y76):

Remove fuel injectors (Y76).

AR07.03-P-0004-03MM

Puller *278589003300

Clean

19 Clean fuel connections on fuel injectors (Y76)

During cleaning the fuel connections must be

held downwards.

This ensures that no dirt gets into the

openings.

Assembly cleaner *BR00.45-Z-1028-04A

Check

20 Check high-pressure line and replace if AR07.03-P-1010-03MM

necessary

The sealing cone for high-pressure lines must

be checked before assembly.

Do this to avoid leaks and damage.

Assembly cleaner *BR00.45-Z-1028-04A

Install

21 Replace sealing packages for the fuel injectors AR07.03-P-0004-02MM

(Y76) on rail (1)

Assembly cleaner *BR00.45-Z-1028-04A

Drift *278589011500

22 Replace sealing rings and seals (2) on the fuel AR07.03-P-0004-01MM

injectors (Y76)

Assembly cleaner *BR00.45-Z-1028-04A

Assembly tool *272589004300

23 Replace seal (2) on spilling of the rail (1)

24 Insert fuel injectors (Y76) into rail (1) and When reusing the fuel injectors (Y76) they

fasten in place using the hold-down tools (3) must be inserted into the cylinder in which it

was previously installed.

Fuel injectors (Y76) may only be installed

again in combination with the rail (1) (as a

whole).

Replace hold-down tool (3).

25 Insert rail (1) with fuel injectors (Y76) into the

cylinder head

26 Screw in screw/bolts (1s)

Screw in screw/bolts (1s) alternately each by

half a revolution. Begin in the center of the rail

(1) and work outwards.

Damage to the rail (1) can occur otherwise.

Screw/bolt, fuel distributor to cylinder *BA07.52-P-1001-01G

head cover

27 Install support (4) for the intake manifold Engine 276.9 in model 212, 218

28 Mount engine wiring harness on rail (1) and Engine 276.9 in model 212, 218 AR01.00-P-2410-02EL

fuel injectors (Y76)

Engine 276.8 in model 212, 218 AR01.00-P-2410-02ELS

29 Connect electrical connection on fuel pressure When installing left rail (1)

and temperature sensor (B4/25)

30 Connect electrical connection on RH exhaust Engine 276 (except 276.8) in model 212

camshaft Hall sensor (B6/7) Engine 276 (except 276.8) in model 218

When installing right rail (1)

© Daimler AG, 12/18/18, X/11/18, ar07.03-p-1010el, Remove/install rail Page 3 of 5

Engine 276 in model 212, 218

31 Mount low-pressure line at high-pressure Union nut, fuel line to fuel distributor *BA07.03-P-1001-01D

pump

32 Mount high-pressure line on rail (1) and high- AR07.03-P-1010-02MMA

pressure pump

Do not kink or bend high-pressure line and

low-pressure line .

Do this to avoid leaks and damage.

The work instructions absolutely must be

observed for assembly work.

Union nut, fuel line to fuel distributor *BA07.03-P-1001-01D

Union nut, fuel line to high-pressure pump *BA07.03-P-1002-01D

33 Install crash plate and insulation on the high- AR07.02-P-1020EL

pressure pump

34 Install connecting flange of the intake manifold AR09.20-P-1961EL

35.1 Install air filter housing Engine 276.9 in model 212, 218

When installing right rail (1)

Screw/bolt, air filter to air intake pipe *BA09.10-P-1002-01M

support brace

Screw/bolt, air filter to cylinder head cover *BA09.10-P-1001-01M

35.2 Install both air filter housing Engine 276.8 in model 212, 218

When installing the left or right rail (1)

AR09.10-P-1150ELS

36 Install center section of the bulkhead (78) Engine 276.8 in model 212, 218

Engine 276.9 in model 212.095/195

Engine 276.8 in model 212 AR61.25-P-6600EW

Engine 276.9 in model 212.095/195

Ensure correct seating of the center

section of the bulkhead (78).

37 Mount ground line on battery AR54.10-P-0003EW

38 Read out fault memory using the diagnostic

system and clear if necessary

AD00.00-P-2000-04A

Check

39 Check fuel high-pressure circuit for AR07.03-P-1010-04MM

leaktightness

Warning Risk of accident from vehicle starting off by Secure vehicle to prevent it from starting off by AS00.00-Z-0005-01A

itself when engine running. Risk of injury itself. Wear buttoned-up and snug-fitting work

(bruises and burns) resulting from working on clothes. Do not touch hot or rotating parts.

the engine while it is being started or when it is

running.

40 Carry out an engine test run, checking the

engine for proper operation and leaktightness

Injection nozzles, injection valves, lines

Number Designation Engine 276

BA07.03-P-1001-01D Union nut, fuel line to fuel distributor Stage 1 Nm 15

Stage 2 ° 90

Injection nozzles, injection valves, lines

Number Designation Engine 276

BA07.03-P-1002-01D Union nut, fuel line to high-pressure pump Stage 1 Nm 15

Stage 2 ° 90

Injection nozzles, injection valves, lines

Number Designation Engine 276

BA07.03-P-1007-01D Cap on service connection Plastic Nm 2

Metal Nm 15

Fuel distributor

Number Designation Engine 276

BA07.52-P-1001-01G Screw/bolt, fuel distributor to cylinder head cover Nm 9

© Daimler AG, 12/18/18, X/11/18, ar07.03-p-1010el, Remove/install rail Page 4 of 5

Engine 276 in model 212, 218

Air filter

Number Designation Engine 276.9

BA09.10-P-1001-01M Screw/bolt, air filter to cylinder head cover Nm 9

Air filter

Number Designation Engine 276.9

BA09.10-P-1002-01M Screw/bolt, air filter to air intake pipe support brace Nm 9

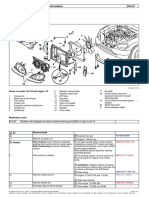

278 589 01 15 00 119 589 04 63 00 278 589 00 33 00 272 589 00 43 00

Drift Pressure hose Puller Assembly tool

Repair materials

Number Designation Order number

BR00.45-Z-1028-04A Assembly cleaner Adolf Würth GmbH & Co. KG

Reinhold-Würth-Str. 12-17

74653 Künzelsau-Gaisbach

Germany

Tel. +49 7940 15-0

Fax +49 7940 15-1000

http://www.wuerth.de

© Daimler AG, 12/18/18, X/11/18, ar07.03-p-1010el, Remove/install rail Page 5 of 5

Engine 276 in model 212, 218

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Radspeed Preventive MaintenanceDocument4 pagesRadspeed Preventive MaintenanceBashir MtwaklNo ratings yet

- m112 Remove Install Cylinder HeadDocument10 pagesm112 Remove Install Cylinder Headarmando aguirre100% (1)

- Rear Window Shade Wiring DiagramDocument1 pageRear Window Shade Wiring DiagramBashir Mtwakl100% (2)

- Remove Install Timing Case 963 OM470Document6 pagesRemove Install Timing Case 963 OM470nietzscheean558950% (2)

- Vacon NXP System Drive Hardware Manual DPD01365A UDocument72 pagesVacon NXP System Drive Hardware Manual DPD01365A UTanuTiganu100% (3)

- Application Note - Measuring KVP On An Amx 4 or 4plus-2013!10!30 1Document2 pagesApplication Note - Measuring KVP On An Amx 4 or 4plus-2013!10!30 1Bashir MtwaklNo ratings yet

- Hifu 3DDocument13 pagesHifu 3DBashir MtwaklNo ratings yet

- IWGIA Book The Indigenous World 2021 ENGDocument824 pagesIWGIA Book The Indigenous World 2021 ENGREy FOxNo ratings yet

- Planets in NakshatrasDocument6 pagesPlanets in Nakshatrasmurthyy55% (11)

- Static Var CompensatorDocument12 pagesStatic Var CompensatorBengal Gaming100% (1)

- Buoyancy Calculation Report For 10INCH PipelineDocument7 pagesBuoyancy Calculation Report For 10INCH PipelineEmmanuel LawrenceNo ratings yet

- Reading ComprehensionDocument9 pagesReading Comprehensionxifres i lletres xifres i lletres100% (1)

- Ranitidine + OndansetronDocument7 pagesRanitidine + OndansetronAllicia PutriNo ratings yet

- MODEL 212, 218 Install Complete Rear AxleDocument5 pagesMODEL 212, 218 Install Complete Rear AxlePedro Rivera ValenciaNo ratings yet

- Remove - Install Charge Air ManifoldDocument4 pagesRemove - Install Charge Air ManifoldAlex AndreiNo ratings yet

- w211 m156 ThermostatDocument2 pagesw211 m156 ThermostatAdrian NazareNo ratings yet

- R&I Oil Pump 186 Eng. #2Document4 pagesR&I Oil Pump 186 Eng. #2basheer almetwakelNo ratings yet

- Transmission 722.6 in Model 212: AR27.10-P-0500EW Remove/install Transmission With Torque Converter 09.09.2019Document6 pagesTransmission 722.6 in Model 212: AR27.10-P-0500EW Remove/install Transmission With Torque Converter 09.09.2019novanNo ratings yet

- AR15.40-P-5032TA Remove/install Alternator 4.2.09 Engine 648.961 in MODEL 211.023 /223 /026 /226Document2 pagesAR15.40-P-5032TA Remove/install Alternator 4.2.09 Engine 648.961 in MODEL 211.023 /223 /026 /226Stefan AdrianNo ratings yet

- 276 CentrifugeDocument2 pages276 CentrifugeBashir MtwaklNo ratings yet

- R&I Oil Pan Bottom 272 & 273 Eng.Document4 pagesR&I Oil Pan Bottom 272 & 273 Eng.Dr. Mousa AlhaddadNo ratings yet

- Intake ManifoldDocument3 pagesIntake ManifoldLudmila CroitoruNo ratings yet

- R&I Timing Case Cover 156 Eng. #5aDocument2 pagesR&I Timing Case Cover 156 Eng. #5aArt ArevshatianNo ratings yet

- Remove Install Rear-Axle Brake CaliperDocument5 pagesRemove Install Rear-Axle Brake CaliperJulian SeetoNo ratings yet

- Fuel Pump ModuleDocument1 pageFuel Pump ModuleFareedNo ratings yet

- Amg Remove - Install Camshaft AdjustersDocument5 pagesAmg Remove - Install Camshaft AdjustersRoland HendriksNo ratings yet

- R&I Intake ManifoldDocument4 pagesR&I Intake ManifoldmagetszNo ratings yet

- Remove - Install TurbochargerDocument5 pagesRemove - Install Turbochargerparasol2115No ratings yet

- Caliper Remove-ReplaceDocument4 pagesCaliper Remove-ReplacePablo ØdegaardNo ratings yet

- C63 - Remove - Install Resonance Intake ManifoldDocument3 pagesC63 - Remove - Install Resonance Intake ManifoldMargarit Nicolae100% (1)

- Remove-Install Front Engine Mounts Andor Engine SupportDocument3 pagesRemove-Install Front Engine Mounts Andor Engine SupportCarlos MurilloNo ratings yet

- Remove Install Cylinder Head PDFDocument4 pagesRemove Install Cylinder Head PDFSubkhan Maulana YusufNo ratings yet

- Shown On Engine 271.940Document2 pagesShown On Engine 271.940Ludmila Croitoru100% (1)

- 276 Intake ManifoldDocument4 pages276 Intake ManifoldBashir MtwaklNo ratings yet

- Condenizator MB w211Document3 pagesCondenizator MB w211Tomica TišljarićNo ratings yet

- R&I Timing Case Cover 156 Eng. #6Document2 pagesR&I Timing Case Cover 156 Eng. #6Art Arevshatian0% (1)

- C63 - Remove - Install Transmission With Torque ConverterDocument10 pagesC63 - Remove - Install Transmission With Torque Converterjose luis BenitoNo ratings yet

- Install Intelligent Servo ModuleDocument4 pagesInstall Intelligent Servo Modulemarcelo ustarezNo ratings yet

- AMG156 Remove - Install Timing Case CoverDocument4 pagesAMG156 Remove - Install Timing Case CoverRoland HendriksNo ratings yet

- AR88.20-P-2250GZ - Install Carrier For Rear BumperDocument4 pagesAR88.20-P-2250GZ - Install Carrier For Rear Bumpernigel maistryNo ratings yet

- Remove-Install Oil-Water Heat ExchangerDocument2 pagesRemove-Install Oil-Water Heat ExchangerBogdan SeciuNo ratings yet

- Install Control ValveDocument2 pagesInstall Control ValveprasNo ratings yet

- Radiator Remove&installDocument3 pagesRadiator Remove&installHermes VacaNo ratings yet

- Remove Install EngineDocument4 pagesRemove Install EngineAnonymous d8ermLyF3No ratings yet

- 722.6 Transmisson Flush1 PDFDocument3 pages722.6 Transmisson Flush1 PDFDan BotezatuNo ratings yet

- Remove - Install Charge Air Cooler, Water-CooledDocument2 pagesRemove - Install Charge Air Cooler, Water-CooledRicardo Santo AntonioNo ratings yet

- R&I Oil Cooler Eng. 642 #2Document3 pagesR&I Oil Cooler Eng. 642 #2Hilal HazaaNo ratings yet

- 12. Tháo Đĩa Phanh Để Bảo DưỡngDocument3 pages12. Tháo Đĩa Phanh Để Bảo Dưỡngl98519171No ratings yet

- R&I StarterDocument3 pagesR&I StarterFab Faby FabienNo ratings yet

- 6 Intake Air Duct: Remove/installDocument2 pages6 Intake Air Duct: Remove/installLudmila CroitoruNo ratings yet

- Remove - Install Electrohydraulic Controller Unit (Transmission Installed) PDFDocument5 pagesRemove - Install Electrohydraulic Controller Unit (Transmission Installed) PDFGKNo ratings yet

- Remove - Install Intelligent Servo ModuleDocument3 pagesRemove - Install Intelligent Servo ModuleJosephNo ratings yet

- W211 Fan Shroud RemovalDocument2 pagesW211 Fan Shroud Removalniladam2002No ratings yet

- 211 642 Engine MountDocument2 pages211 642 Engine MountgzgwzdxggyNo ratings yet

- R&I Rear Engine MountDocument2 pagesR&I Rear Engine MountgzgwzdxggyNo ratings yet

- Remove - Install Camshaft AdjustersDocument2 pagesRemove - Install Camshaft AdjustersBAO ANH LÊNo ratings yet

- GLA45AMG 156 133 Replace Brake FluidDocument4 pagesGLA45AMG 156 133 Replace Brake FluidNhật Anh TrầnNo ratings yet

- AR42.10-P-0070CMG - R&R Front Axle Brake CaliperDocument2 pagesAR42.10-P-0070CMG - R&R Front Axle Brake Calipervonevef926No ratings yet

- Shown On Model 163.154 With Engine 112: AS20.00-Z-0001-01ADocument3 pagesShown On Model 163.154 With Engine 112: AS20.00-Z-0001-01AHermes VacaNo ratings yet

- AR20.20-P-3865NKB Remove/install Radiator 17.7.13Document2 pagesAR20.20-P-3865NKB Remove/install Radiator 17.7.13Hidayat KassimNo ratings yet

- Remove Install Front Prefuse Box f32Document3 pagesRemove Install Front Prefuse Box f32valenNo ratings yet

- Remove - Install Engine Wiring HarnessDocument3 pagesRemove - Install Engine Wiring Harnessمحمد يونسNo ratings yet

- 2010-04!02!044302 Removing and Installing Evaporator Temperature SensorDocument1 page2010-04!02!044302 Removing and Installing Evaporator Temperature SensorYang W OngNo ratings yet

- Remove-Install Glow Plugs Om651Document2 pagesRemove-Install Glow Plugs Om651Lukas DerkaczNo ratings yet

- Remove Upper DashDocument3 pagesRemove Upper DashOsama Ben DawNo ratings yet

- R&I Timing Case Cover 156 Eng. #2Document3 pagesR&I Timing Case Cover 156 Eng. #2Art ArevshatianNo ratings yet

- Remove-Install Exhaust Gas Recirculation PositionerDocument2 pagesRemove-Install Exhaust Gas Recirculation PositionerMedic Billy NyamboNo ratings yet

- Set Basic Position of CamshaftsDocument2 pagesSet Basic Position of CamshaftsAntonio OgNo ratings yet

- W169 WIS Remove - Install Oil Pressure SwitchDocument1 pageW169 WIS Remove - Install Oil Pressure Switchhessian123100% (1)

- NTC8D 11datasheetDocument4 pagesNTC8D 11datasheetfourfingerxNo ratings yet

- LED OT Light OT Table Pendants-20221208Document13 pagesLED OT Light OT Table Pendants-20221208Bashir MtwaklNo ratings yet

- FabiusGSSpecSheet 1Document1 pageFabiusGSSpecSheet 1Bashir MtwaklNo ratings yet

- Bavt-401-B, Bavt-02-B, Bavt-403-BDocument45 pagesBavt-401-B, Bavt-02-B, Bavt-403-BBashir MtwaklNo ratings yet

- Medmont-Studio-7 2 9Document1 pageMedmont-Studio-7 2 9Bashir MtwaklNo ratings yet

- Medmont Studio 7.2.9 Release Notes ٢Document8 pagesMedmont Studio 7.2.9 Release Notes ٢Bashir MtwaklNo ratings yet

- Frequent Buyer Program: Temporarily SuspendedDocument1 pageFrequent Buyer Program: Temporarily SuspendedBashir MtwaklNo ratings yet

- Airshields C450Document2 pagesAirshields C450Bashir MtwaklNo ratings yet

- 276 Intake ManifoldDocument4 pages276 Intake ManifoldBashir MtwaklNo ratings yet

- June 8, 2009 S-B-01.30/28: Complaint Process Guidelines (Pages 2-4)Document4 pagesJune 8, 2009 S-B-01.30/28: Complaint Process Guidelines (Pages 2-4)Bashir MtwaklNo ratings yet

- Serial Number ChartDocument1 pageSerial Number ChartBashir MtwaklNo ratings yet

- 276 CentrifugeDocument2 pages276 CentrifugeBashir MtwaklNo ratings yet

- Serial Number ChartDocument1 pageSerial Number ChartBashir MtwaklNo ratings yet

- Rear Shelf Load Through BlindDocument2 pagesRear Shelf Load Through BlindBashir MtwaklNo ratings yet

- RHRP1540, RHRP1560: 15A, 400V - 600V Hyperfast Diodes FeaturesDocument5 pagesRHRP1540, RHRP1560: 15A, 400V - 600V Hyperfast Diodes FeaturesBashir MtwaklNo ratings yet

- 06 Oil Injected Screw GAR 11-37-2Document2 pages06 Oil Injected Screw GAR 11-37-2RUN GONo ratings yet

- Adjustable Flow Regulators: For Noncorrosive ServiceDocument1 pageAdjustable Flow Regulators: For Noncorrosive ServiceBashir MtwaklNo ratings yet

- SBN-CPS-2018-012: Field Safety NoticeDocument4 pagesSBN-CPS-2018-012: Field Safety NoticeBashir MtwaklNo ratings yet

- 4 Q GJ WHRKLFWC ZJ JWDocument2 pages4 Q GJ WHRKLFWC ZJ JWBashir MtwaklNo ratings yet

- 7Chmh FD KH L@GLHKDocument2 pages7Chmh FD KH L@GLHKBashir MtwaklNo ratings yet

- PSA Oxygen Generator AmcareMedDocument6 pagesPSA Oxygen Generator AmcareMedBashir MtwaklNo ratings yet

- PSA Oxygen Generator AmcareMedDocument6 pagesPSA Oxygen Generator AmcareMedBashir MtwaklNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Mixture and of The Company/UndertakingDocument16 pagesSafety Data Sheet: 1. Identification of The Substance/Mixture and of The Company/UndertakingBashir MtwaklNo ratings yet

- Use of The Fluke 105B Scopemeter On The Farm: SafetyDocument7 pagesUse of The Fluke 105B Scopemeter On The Farm: SafetyBashir MtwaklNo ratings yet

- Dr. Mach M2 - Mounting InstructionDocument20 pagesDr. Mach M2 - Mounting InstructionBashir MtwaklNo ratings yet

- v4n3 PDFDocument168 pagesv4n3 PDFJorge RodriguezNo ratings yet

- 1often Wonder About My Future As I Am About To Finish Secondary SchoolDocument2 pages1often Wonder About My Future As I Am About To Finish Secondary SchoolMidz Santayana100% (1)

- New Approaches To Cryopreservation of Cells, Tissues, and OrgansDocument19 pagesNew Approaches To Cryopreservation of Cells, Tissues, and OrgansLaura CursaruNo ratings yet

- Hydraulic Seat Puller KitDocument2 pagesHydraulic Seat Puller KitPurwanto ritzaNo ratings yet

- Jeremiah's Law, Introduced by Assemblywoman Rodneyse BichotteDocument2 pagesJeremiah's Law, Introduced by Assemblywoman Rodneyse BichotteCity & State NYNo ratings yet

- Executive Compensation: A Presentation OnDocument9 pagesExecutive Compensation: A Presentation On9986212378No ratings yet

- Offshore Drilling Operation in East Indonesia Oil and Gas FieldsDocument3 pagesOffshore Drilling Operation in East Indonesia Oil and Gas FieldsMuhammad Galih Eko SaputroNo ratings yet

- Hitec 8888Z Atf C4 & To4 - TDSDocument2 pagesHitec 8888Z Atf C4 & To4 - TDSPranit More Arabian Petroleum LimitedNo ratings yet

- Oedipus SummaryDocument1 pageOedipus SummaryReynold FrancoNo ratings yet

- SAVULESCU, Julian - A Simple Solution To The Puzzles of End of LifeDocument5 pagesSAVULESCU, Julian - A Simple Solution To The Puzzles of End of Lifediradosta_1992No ratings yet

- PGS 504 Notes Part IIDocument3 pagesPGS 504 Notes Part IISejal PriyaNo ratings yet

- Kaye Olson Cude Celebration of Life by Pat JohnsonDocument3 pagesKaye Olson Cude Celebration of Life by Pat JohnsonJB PetersonNo ratings yet

- Personal and Social AdjustmentDocument10 pagesPersonal and Social AdjustmentMobin AlamNo ratings yet

- SCIENTIFIC BASIS OF HUMAN MOVEMENT EFFECTS OF EXERCISE ON RESPIRATORY SYSTEM - Wbshce PDFDocument9 pagesSCIENTIFIC BASIS OF HUMAN MOVEMENT EFFECTS OF EXERCISE ON RESPIRATORY SYSTEM - Wbshce PDFlancetNo ratings yet

- Metrel Mi 3290 Earth AnalyserDocument4 pagesMetrel Mi 3290 Earth AnalyserMarijan MustačNo ratings yet

- ASME Single Certification MarkDocument3 pagesASME Single Certification MarkahmadghasusNo ratings yet

- Ryder Funeral Home Ex Parte MotionDocument22 pagesRyder Funeral Home Ex Parte MotionJim KinneyNo ratings yet

- PBL 3 - Toothache Drugs and MedicationsDocument10 pagesPBL 3 - Toothache Drugs and MedicationsAlbert LawNo ratings yet

- Pressure Relief Valve, Poppet-Type, Direct-Acting: M28x1.5 - Q 50 L/min (13 GPM) - P 320 Bar (4600 PSI)Document2 pagesPressure Relief Valve, Poppet-Type, Direct-Acting: M28x1.5 - Q 50 L/min (13 GPM) - P 320 Bar (4600 PSI)Richam HamzeNo ratings yet

- Brown Wolf ExerciseDocument8 pagesBrown Wolf ExerciseAarnav kumar0% (1)

- Quality Control Argex 0032/32.50.15.08 4/10 MM EN 13055: EN 15732 NL BSB K73820/01 (1/01/2004)Document1 pageQuality Control Argex 0032/32.50.15.08 4/10 MM EN 13055: EN 15732 NL BSB K73820/01 (1/01/2004)joe briffaNo ratings yet

- iSF EClassRecord - NewNormal AdviserDocument254 pagesiSF EClassRecord - NewNormal AdviserYanara Delarama DayapNo ratings yet

- QTR-2 2023 Meeting Format Nov.23Document45 pagesQTR-2 2023 Meeting Format Nov.23skumar31397No ratings yet