Professional Documents

Culture Documents

P01696-0019-4 - AsBuilt Painting Procedure

Uploaded by

Mahmoud GaberOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P01696-0019-4 - AsBuilt Painting Procedure

Uploaded by

Mahmoud GaberCopyright:

Available Formats

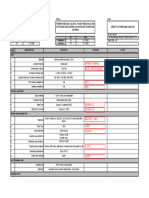

Document Front page

01 14.06.2007 As Built Tst SOS FD

Proj. Issued Date Description Made Chk'd Appr.

Rev. by by by

Acceptance Code 1: Package Title : AC DRILLING DRIVES

Accepted

SDL-code WBS code

Acceptance Code 2: NA

Accepted with

Comments

Incorporated.

Revised and Resubmit Rig Area.: Suppliers reference Sub supplier reference

P01696-0019-4

Acceptance Code 3:

Not accepted. SFI Procurement reference:

Revise and resubmit.

Acceptance Code 4: Department Tag No./Line No.:

For Information Only TE

Acceptance Code Date Reviewer Pages Volume: Encl.

Signature

1 2 3 4 1 of 2

Contractor: Note: Where not applicable use NA

Document title:

SWTS

Painting Procedure

Client:

PPL

Project name: Identification

no.:

PPL Jackup P2017

Rig ID Code. Discipline Drawing No. Sheet No. SFI Group

Code No.

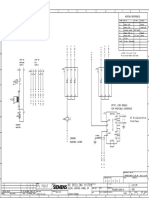

Stig Olav Settemsdal P01696-0007-4 page 1 21.04.2008

Standard lakkering av tavle- og

celleprodukter i PEC, Standard procedure on powder coating of

SIEMENS Trondheim. indoor products in workshop PEC, SIEMENS

Trondheim.

1. Forbehandling

1. Preliminary treatment

1.1 Vasking, avfetting, jernfosfatering og

etterfølgende spyling i rent vann. 1.1 Washing, removal of grease, appliance

Sjiktvekt: 0,3 - 0,9 g/m². of a 0,3 - 0,9 g/m² layer of iron phosphate.

Washing with clean water.

1.2 Varmvalsede profiler er på forhånd

strålerenset. 1.2 Hot rolled profiles are sandblasted before

appliance of iron phosphate.

2. Lakkering

2. Powder coating

Elektrostatisk pulverlakkering.

Electrostatic powder coating

2.1 Materiale: Epoxy-polyester-pulver

2.1 Powder: Epoxy polyester powder

Standardfarge: - Lys grå RAL 7032

- Light Basic 700, SN30920 Standard colors: - Light grey, RAL 7032

- Spesialfarger mulig - Light Basic 700 ,SN30920

Other colors are available.

Overflate: - Finstruktur

- Matt, refleksjon 10-35 Surface: - Fine structure

v / 85º, EN ISO 2813 - Dull, 10-35 v / 85º,

EN ISO 2813

2.2 Tekniske data for belegget:

2.2 Technical specifications:

2.2.1 Tykkelse: 75 +/- 25 µm

2.2.1 Thickness: 75 +/- 25 µm

2.2.2 Salttåkeprøve: 48 timer. EN ISO 7253

2.2.2 Salt fog test: 48 hrs. EN ISO 7253

2.2.3 Gittersnitt: Gt-0. EN ISO 2409

2.2.3 Lattice cut: Gt-0. EN ISO 2409

2.2.4 Bøyeprøve: Ø 12 mm. EN ISO 1519

2.2.4 Bending test: Ø 12 mm. EN ISO 1519

2.2.5 Hardhet: > 80. EN ISO 2815

2.2.5 Hardness: > 80. EN ISO 2815

3. Utbedringsarbeid

3. Repair

Ved utbedring av riper etter transportskade, etc.

benyttes spesiell reparasjonslakk: In case of minor transportation damages, scratches

etc., a special mending lacquer

Pakning 12 ml: SWF 5.3720.1/0882, is to be used:

RAL 7032

Pakning 1 liter: SWF 5.3120.1/0687, 12 ml: SWF 5.3720.1/0882, RAL 7032

RAL 7032

1 liter: SWF 5.3120.1/0687, RAL 7032

Stig Olav Settemsdal P01696-0007-4 page 2 21.04.2008

You might also like

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- 3 Ewp-Elv-Mep-Rfa-Mes-016Document1 page3 Ewp-Elv-Mep-Rfa-Mes-016Tien Duc BanhNo ratings yet

- Jed 021M1Document2 pagesJed 021M1Reginaldo Santos100% (1)

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- Jed-257 008 en LDocument4 pagesJed-257 008 en LcroplaninecNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- Blowers: TMO-O 0000-E Je / 18.08.07 VKIDocument375 pagesBlowers: TMO-O 0000-E Je / 18.08.07 VKIJairoQuirozGomezNo ratings yet

- Rev0 - Repair-Instructions PDFDocument8 pagesRev0 - Repair-Instructions PDFZantar AbdelhaqNo ratings yet

- Liebherr LN 252-1 Zinco AltoDocument6 pagesLiebherr LN 252-1 Zinco AltowiroNo ratings yet

- Further Details On Lead Free Reflow Soldering of LEDsDocument16 pagesFurther Details On Lead Free Reflow Soldering of LEDshuynh thi y viNo ratings yet

- NO18486, System 7 C4 High, 2217059Document9 pagesNO18486, System 7 C4 High, 2217059Mauro CostaNo ratings yet

- Jed-330 008 DDocument4 pagesJed-330 008 DRanjan GnanaoliNo ratings yet

- Specification: FOR 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)Document5 pagesSpecification: FOR 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)Quang LuongNo ratings yet

- Quality System Document 03 Decorative Finishes-Electroplating SpecificationDocument4 pagesQuality System Document 03 Decorative Finishes-Electroplating Specificationocy1212No ratings yet

- Report 14 - Sluice Gates EE-SP2-3-B18 + EE-SP2!3!19Document20 pagesReport 14 - Sluice Gates EE-SP2-3-B18 + EE-SP2!3!19HuthaifahM.DagamsehNo ratings yet

- Assignment #2 Div 06, 07 & 09 SpecDocument1 pageAssignment #2 Div 06, 07 & 09 SpecRio Galan-SuaybaguioNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- PlugDocument2 pagesPlugJalal AlbadriNo ratings yet

- Over All Drawings of PMCC-5 Panel-R0Document24 pagesOver All Drawings of PMCC-5 Panel-R0GreenOlive ControlsNo ratings yet

- Report 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28Document20 pagesReport 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28HuthaifahM.DagamsehNo ratings yet

- Paint Technical Specification PDFDocument3 pagesPaint Technical Specification PDFMoon SzDarkness100% (1)

- 313P Stecind ENGDocument2 pages313P Stecind ENGSophia RoseNo ratings yet

- Over All Drawings of PMCC-4 Panel-R0Document27 pagesOver All Drawings of PMCC-4 Panel-R0GreenOlive ControlsNo ratings yet

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraNo ratings yet

- Rdso SPN TC 97 2012Document13 pagesRdso SPN TC 97 2012Rahul MauryaNo ratings yet

- Standard Direct Buried CableDocument6 pagesStandard Direct Buried CableZeckrey JikurunNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- GraseDocument2 pagesGrasetony mejiaNo ratings yet

- Fontargen A 101Document1 pageFontargen A 101Kara WhiteNo ratings yet

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

- Specification: 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)Document5 pagesSpecification: 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)Quang LuongNo ratings yet

- B 32 - 00 - QjmylvjfraDocument11 pagesB 32 - 00 - QjmylvjfraAndresNo ratings yet

- Report 23 - Sluice Gates EE-SP2-3-B30Document19 pagesReport 23 - Sluice Gates EE-SP2-3-B30HuthaifahM.DagamsehNo ratings yet

- Product Bulletin Corrosion Protection For Fisher Valves en 124040Document12 pagesProduct Bulletin Corrosion Protection For Fisher Valves en 124040Lindsey PatrickNo ratings yet

- Agip OSO: Characteristics (Typical Figures)Document2 pagesAgip OSO: Characteristics (Typical Figures)Luis Carlos Lagos SalinasNo ratings yet

- Approval of Powder Coatings - Quick Guide: Working Group of Technical CommitteeDocument6 pagesApproval of Powder Coatings - Quick Guide: Working Group of Technical CommitteeF.Javier LobeiraNo ratings yet

- 2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument5 pages2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetErkanNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- 7417-16992-TPS-001 Onshore PipesDocument3 pages7417-16992-TPS-001 Onshore PipesFerryNo ratings yet

- Revision No: F1 20-Oct-09 2 of 3 Equipment Data Sheet Pressure Vessel PDRP4220-8430-DS-086-2022Document2 pagesRevision No: F1 20-Oct-09 2 of 3 Equipment Data Sheet Pressure Vessel PDRP4220-8430-DS-086-2022EWTRNo ratings yet

- 4 Binder4Document3 pages4 Binder4EWTRNo ratings yet

- Approval Sheet: Customer ManufacturerDocument7 pagesApproval Sheet: Customer ManufacturerypadillaNo ratings yet

- Baltoflake S2000Document5 pagesBaltoflake S2000Mhd EbalNo ratings yet

- 3289310Document2 pages3289310Philippe VelhaNo ratings yet

- Report 12 - Sluice Gates EE-SP2-3-B16Document18 pagesReport 12 - Sluice Gates EE-SP2-3-B16HuthaifahM.DagamsehNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua SuaNo ratings yet

- Specification For 150kV AL 630sqmm CableDocument4 pagesSpecification For 150kV AL 630sqmm Cablebachtiar ramadhanNo ratings yet

- Technical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingDocument3 pagesTechnical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingNestramiNo ratings yet

- Nepcon: Smart GROUPDocument6 pagesNepcon: Smart GROUPanandsharma9No ratings yet

- s543b - Electrozi Basic 7018 Info ENGDocument2 pagess543b - Electrozi Basic 7018 Info ENGVlad AdrianNo ratings yet

- Wabco: SpecificationDocument4 pagesWabco: Specificationரஞ்சன் ஞானயோளிNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Omn WL 900 Ins Ds 2017 Is Cable DatasheetDocument5 pagesOmn WL 900 Ins Ds 2017 Is Cable DatasheetPranav DubeyNo ratings yet

- West Qurna 1 Building Upgrades & Facilities WorkDocument19 pagesWest Qurna 1 Building Upgrades & Facilities WorkNoor A QasimNo ratings yet

- 01ES00002 - Acabamento de Proteção Contra CorrosãoDocument2 pages01ES00002 - Acabamento de Proteção Contra CorrosãoRafah1212No ratings yet

- Data SheetDocument4 pagesData SheetricedragonNo ratings yet

- AkzoNobel - QN102QF - Interpon ACE 2000Document3 pagesAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukNo ratings yet

- TUNDISH Drawing AND Refractory DATA SHEETDocument14 pagesTUNDISH Drawing AND Refractory DATA SHEETMashiur Rahman100% (1)

- P01696-1008-4 - 02 Internal Test Protocol Incl FAT As BuiltDocument30 pagesP01696-1008-4 - 02 Internal Test Protocol Incl FAT As BuiltMahmoud GaberNo ratings yet

- P01696-2003-4 - AsBuilt Circuit Diagrams MP - LCPDocument37 pagesP01696-2003-4 - AsBuilt Circuit Diagrams MP - LCPMahmoud GaberNo ratings yet

- P01696-1004-4 - 03 As Built Bill of MaterialsDocument15 pagesP01696-1004-4 - 03 As Built Bill of MaterialsMahmoud GaberNo ratings yet

- DatasheetDocument74 pagesDatasheetMahmoud GaberNo ratings yet

- MUST READ-Siemens Control Panel ComponentsDocument24 pagesMUST READ-Siemens Control Panel ComponentspeakfortuneNo ratings yet

- Capacitor Reforming Guide PDFDocument8 pagesCapacitor Reforming Guide PDFpitambervermaNo ratings yet

- En ACS800 07-17-37 Cab Options A ScrresDocument42 pagesEn ACS800 07-17-37 Cab Options A ScrresMaitry ShahNo ratings yet

- Lecture 07Document18 pagesLecture 07zaidNo ratings yet

- W2 - Q1 - Math8B - Basic Geometric ConstructionsDocument4 pagesW2 - Q1 - Math8B - Basic Geometric ConstructionsFNERVEZ, DENISE T.No ratings yet

- Week 4 Combined - AER Feb 24Document19 pagesWeek 4 Combined - AER Feb 24Omkar BhavsarNo ratings yet

- Course OutlineDocument3 pagesCourse OutlineLillian MuwinaNo ratings yet

- Clovis Bray's Personal LogDocument30 pagesClovis Bray's Personal LogBeccaNo ratings yet

- Corning Gorilla Glass 5 - PI SheetDocument2 pagesCorning Gorilla Glass 5 - PI SheetJ. RagaNo ratings yet

- Turning Points of Quadratic Graphs Questions MMEDocument6 pagesTurning Points of Quadratic Graphs Questions MMECCSC124-Soham MaityNo ratings yet

- Example PDFDocument280 pagesExample PDFivoryhornNo ratings yet

- ST-1 2Document8 pagesST-1 2Omar Dr.No ratings yet

- Heat 1Document36 pagesHeat 1ZainabNo ratings yet

- Projectile MotionDocument15 pagesProjectile MotionAlina PetrușNo ratings yet

- MMP 2 Mansoor Sultan: First PortionDocument6 pagesMMP 2 Mansoor Sultan: First PortionMansoor AslamNo ratings yet

- Magneto-Hydro Dynamic Generator: Hannes AlfvénDocument34 pagesMagneto-Hydro Dynamic Generator: Hannes AlfvénHuzaifa WasimNo ratings yet

- PHD Thesis Structures and Publications - Rasyid (2022!11!18)Document4 pagesPHD Thesis Structures and Publications - Rasyid (2022!11!18)m_abdur_rasyidNo ratings yet

- ITR HV CablesDocument2 pagesITR HV CablesYulianti Rahmi PurnamawatiNo ratings yet

- Introverted SensingDocument7 pagesIntroverted Sensinganand__08100% (1)

- Basic Aerodynamics BasicsDocument86 pagesBasic Aerodynamics BasicsElvis ParvoiNo ratings yet

- Data Sheet 6ES7297-0AX30-0XA0: General InformationDocument2 pagesData Sheet 6ES7297-0AX30-0XA0: General InformationsebouelletNo ratings yet

- Matheng Skript 1213Document227 pagesMatheng Skript 1213Jayson Jonson AraojoNo ratings yet

- Nuclear and Particle Physics QuestionsDocument41 pagesNuclear and Particle Physics QuestionsSid KNo ratings yet

- 1.3 Atomic Mass Atomic Number and Isotopes PDFDocument23 pages1.3 Atomic Mass Atomic Number and Isotopes PDFMARVIN DELA CRUZNo ratings yet

- Grade 5 - Arts ActivitiesDocument7 pagesGrade 5 - Arts ActivitiesMarcus Sayson DabonNo ratings yet

- Saturated and Unsaturated FlowDocument48 pagesSaturated and Unsaturated FlowJulio César ChávezNo ratings yet

- Gen Chem 2 Q2 Module 7Document29 pagesGen Chem 2 Q2 Module 7Sou MeiNo ratings yet

- Problem 5 - Shear Force and Bending Moment Diagram of BeamDocument3 pagesProblem 5 - Shear Force and Bending Moment Diagram of BeamShreya PatilNo ratings yet

- NG Flow Meters Why Calibrate Terry GrimleyDocument59 pagesNG Flow Meters Why Calibrate Terry GrimleyPrayogo WibisonoNo ratings yet

- DRD Rescue: Double Rope Descender With Two Jamming PositionsDocument3 pagesDRD Rescue: Double Rope Descender With Two Jamming PositionsferreiraNo ratings yet

- FM 1 Unit Test 6 Elastic Collisions in Two DimensionsDocument4 pagesFM 1 Unit Test 6 Elastic Collisions in Two Dimensions张婧雯No ratings yet

- (Class 5th) Area and Perimeter 2Document6 pages(Class 5th) Area and Perimeter 2Snigdha Goel100% (1)

- Dam Deformation-2Document20 pagesDam Deformation-2Fajar A KurniawanNo ratings yet