Professional Documents

Culture Documents

Specification: FOR 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)

Uploaded by

Quang LuongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification: FOR 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)

Uploaded by

Quang LuongCopyright:

Available Formats

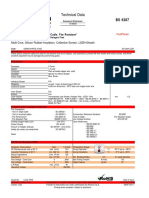

SPEC.NO.

: SP2-160037

REV. NO. : D

PAGE : 1 of 5

ISO-9001-2008

Specification

FOR

12.7/22(24)kV CXV-DATA

(Cu/XLPE/CTS/PVC/DATA/PVC)

12.7/22(24)kV COPPER CONDUCTOR, XLPE INSULATED, COPPER TAPE SCREEN,

PVC SEPARATION SHEATH, ALUMINUM TAPE ARMOURED,

PVC OUTER SHEATH POWER CABLE

D Jun 4th, 2021 Add more technical

L.T.Quang T.T.H.My Kim Do Young

C Mar 8th, 2018 Change company logo

T.T.H.My V.T.Phuc Kim Do Young

B Jul 4th, 2016 Change cable marking

T.T.H.My V.T.Phuc Kim Dong Po

A Mar 22th, 2015 First issue

V.T.Phuc T.T.H.My Kim Dong Po

Rev. Date Revision description Prepared by Reviewed by Approved by

Code: QP – ENG – 02/BM03 Revision: 01 Effective date: 01/03/2012 Issue: 01

SPEC.NO. : SP2-160037

REV. NO. : D

PAGE : 2 of 5

1. DESCRIPTION

NO DESCRIPTION PARTICULAR

1. Origin Vietnam

2. Manufacturer TAIHAN CABLE VINA (TAIHAN)

3. Quality management system ISO 9001:2008

4. CODE & STANDARD IEC 60228, IEC 60502-2

5. CONSTRUCTION

5.1) Conductor Material Plain annealed copper , class 2 (IEC 60228)

Shape Circular compacted strand.

5.2) Conductor screen Material Semi conductive compound

Min. thickness 0.3mm

5.3) Insulation Material XLPE Compound (IEC 60502-2)

Min. thickness at ≥ Nominal value (Data sheet) x 90%- 0.1mm

any point

5.4) Insulation screen Material Semi conductive compound

Min. thickness 0.3mm

5.5) Metallic screen Material Annealed copper tape

Nominal thickness 0.05mm

No. of tape 1 sheet

5.6) Separation sheath Material PVC compound

Min. thickness at ≥ Nominal value (Data sheet) x 80%- 0.2mm

any point

5.7) Armour Material Aluminum tape

Steel tape thickness Nominal value (Data sheet)

5.8) Outer sheath Material PVC compound

Min. thickness at ≥ Nominal value (Data sheet) x 80%- 0.2mm

any point

Color Black

6. MARKING

6.1) Cable Printed on the surface of the outer sheath at regular interval not

greater than one meter: Voltage rating, Cable type, No. core &

Size, Manufacturer’s name, Year of manufacture

Ex:12.7/22(24)kV CXV-DATA 1Cx240mm2TAIHAN CABLE VINA

2016

6.2) Length Printed on the surface of the outer sheath per one meter interval

6.3) Drum Stencil marked

Code: QP – ENG – 02/BM03 Revision: 01 Effective date: 01/03/2012 Issue: 01

SPEC.NO. : SP2-160037

REV. NO. : D

PAGE : 3 of 5

NO DESCRIPTION PARTICULAR

8. TEST Routine test - Conductor resistance (IEC 60228)

- Voltage test (IEC 60502-2)

- Partial discharge test (IEC 60502-2)

9. PACKING Wooden drum Sealed the both ends of cable by means of a

suitable method.

Code: QP – ENG – 02/BM03 Revision: 01 Effective date: 01/03/2012 Issue: 01

SPEC.NO. : SP2-160037

REV. NO. : D

PAGE : 4 of 5

CABLE SECTION DRAWING

No. Description Material Method Remarks

1 Conductor Annealed copper Stranded (compacted) Class 2, IEC 60228

2 Conductor screen Semi-conductive compound Extruded

3 Insulation XLPE compound Extruded Simultaneous

processing

4 Insulation screen Semi-conductive compound Extruded

5 Metallic screen Annealed copper tape Overlapped

Non-woven fabric tape

6 Binder tape Overlapped

( or equivalent tape)

7 Separation sheath PVC compound Extruded

8 Armouring Aluminum tape Overlapped

9 Outer sheath PVC compound Extruded Color : Black

Code: QP – ENG – 02/BM03 Revision: 01 Effective date: 01/03/2012 Issue: 01

SPEC.NO. : SP2-160037

REV. NO. : D

PAGE : 5 of 5

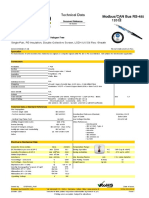

2. CONSTRUCTION DATA:

No. Conductor Nominal Nominal Nominal Nominal Approx. Approx. Max. DC AC Standard Current

of Nominal Construction Nominal insulation separation armour outer Overall weight resistance Voltage length carrying

Core area diameter thickness sheath thickness sheath diamater of at 200C test capacity

thickness thickness cable (in air)

- mm2 - mm mm mm mm mm mm kg/km Ω/km kV/5min m A

35 C.C 6.9 5.5 1.2 0.5 1.9 29.5 1,175 0.524 198

50 C.C 8.1 5.5 1.2 0.5 1.9 30.5 1,340 0.387 238

70 C.C 9.8 5.5 1.2 0.5 2.0 32.5 1,610 0.268 296

95 C.C 11.4 5.5 1.2 0.5 2.0 34.0 1,915 0.193 361

1,000

120 C.C 12.9 5.5 1.2 0.5 2.1 36.0 2,220 0.153 417

150 C.C 14.4 5.5 1.2 0.5 2.1 37.5 2,530 0.124 473

1 44.5

185 C.C 15.9 5.5 1.2 0.5 2.2 39.0 2,940 0.0991 543

240 C.C 18.4 5.5 1.2 0.5 2.3 41.5 3,585 0.0754 641

300 C.C 20.5 5.5 1.3 0.5 2.4 44.5 4,265 0.0601 735

400 C.C 23.4 5.5 1.3 0.5 2.5 48.0 5,180 0.0470 500 845

500 C.C 26.5 5.5 1.4 0.5 2.6 52.0 6,345 0.0366 1040

630 C.C 30.2 5.5 1.5 0.5 2.7 56.0 7,860 0.0283 250 1160

Note: C.C: Circular compacted strand

Code: QP – ENG – 02/BM03 Revision: 01 Effective date: 01/03/2012 Issue: 01

You might also like

- Specification: 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)Document5 pagesSpecification: 12.7/22 (24) KV CXV-DATA (Cu/Xlpe/Cts/Pvc/Data/Pvc)Quang LuongNo ratings yet

- Specification Specification Specification SpecificationDocument9 pagesSpecification Specification Specification SpecificationKhanh Nguyen DuyNo ratings yet

- TS-1PRX1.5MM, 2PRX1.5MM - Blue (New)Document2 pagesTS-1PRX1.5MM, 2PRX1.5MM - Blue (New)mohd darusNo ratings yet

- TS-1C X 25MM - Gy (New)Document2 pagesTS-1C X 25MM - Gy (New)mohd darusNo ratings yet

- DDK 2011 00005 - Technical Datasheet - 13115-2TDocument6 pagesDDK 2011 00005 - Technical Datasheet - 13115-2TMehedi HasanNo ratings yet

- 1 - Specification 18th May 2021Document4 pages1 - Specification 18th May 2021JR DadisNo ratings yet

- Ts-Po15094-1tr X 1.5MMDocument2 pagesTs-Po15094-1tr X 1.5MMmohd darusNo ratings yet

- 24x16AWG RAMCRODocument1 page24x16AWG RAMCROederNo ratings yet

- Phoenix Contact 3073186 enDocument3 pagesPhoenix Contact 3073186 enDGNo ratings yet

- Specification For 150kV AL 630sqmm CableDocument4 pagesSpecification For 150kV AL 630sqmm Cablebachtiar ramadhanNo ratings yet

- SDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 BeaconDocument1 pageSDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 Beaconchandrahai hrangkhawlNo ratings yet

- Feed-Through Plug - DFK-MSTB 2,5/24-STF-5,08-LR - 1230719: Key Commercial DataDocument8 pagesFeed-Through Plug - DFK-MSTB 2,5/24-STF-5,08-LR - 1230719: Key Commercial DatasaurabhNo ratings yet

- Phoenix Contact 5431563 enDocument5 pagesPhoenix Contact 5431563 enDGNo ratings yet

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNo ratings yet

- Phoenix Contact 1733152 en PDFDocument9 pagesPhoenix Contact 1733152 en PDFDGNo ratings yet

- Phoenix Contact 3073186 enDocument4 pagesPhoenix Contact 3073186 enDGNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Bahra CableDocument2 pagesBahra CableMaya HafqNo ratings yet

- 120 Ω Modbus/CAN Bus RS-485 Technical DataDocument1 page120 Ω Modbus/CAN Bus RS-485 Technical DataJoel Marchena GrandaNo ratings yet

- Master Cable DatasheetDocument4 pagesMaster Cable Datasheetmajegu2010No ratings yet

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- Phoenix Contact 5452027 enDocument7 pagesPhoenix Contact 5452027 enDGNo ratings yet

- RC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)Document2 pagesRC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)HaikalNo ratings yet

- Omn WL 900 Ins Ds 2017 Is Cable DatasheetDocument5 pagesOmn WL 900 Ins Ds 2017 Is Cable DatasheetPranav DubeyNo ratings yet

- Printed-Circuit Board Connector - MC 1,5/ 3-ST-3,81 - 1803581Document15 pagesPrinted-Circuit Board Connector - MC 1,5/ 3-ST-3,81 - 1803581Evandro PavesiNo ratings yet

- Datasheet m12 4 PiinesDocument2 pagesDatasheet m12 4 PiinesLuis Yefferson Tica QuispeNo ratings yet

- 3x25mm FCU-PVC-PVC 1 KV (TD)Document2 pages3x25mm FCU-PVC-PVC 1 KV (TD)HaikalNo ratings yet

- 3x25mm FCU-PVC-PVC 1 KV (TD) 2Document2 pages3x25mm FCU-PVC-PVC 1 KV (TD) 2HaikalNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- 4x10mm NCU-XLPE-PVC 1 KV (TD)Document2 pages4x10mm NCU-XLPE-PVC 1 KV (TD)nadeem UddinNo ratings yet

- 3x120 MM CU-XLPE-CUT-SWA-PVC 15 KV (TD)Document2 pages3x120 MM CU-XLPE-CUT-SWA-PVC 15 KV (TD)HaikalNo ratings yet

- Phoenix Contact 1859548 enDocument5 pagesPhoenix Contact 1859548 enDGNo ratings yet

- PCB Terminal Block - MKDS 5/ 2-9,5 - 1714971: Key Commercial DataDocument8 pagesPCB Terminal Block - MKDS 5/ 2-9,5 - 1714971: Key Commercial DataSergioCandiottiNo ratings yet

- PCB Terminal Block - GMKDS 1,5/ 2 - 1717020: Key Commercial DataDocument8 pagesPCB Terminal Block - GMKDS 1,5/ 2 - 1717020: Key Commercial DatalukaNo ratings yet

- Cable Cross LayoutDocument4 pagesCable Cross LayoutWong Chung MengNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- CCSI Buried DoubleJacket 12 G 652 D DGK Rev0Document2 pagesCCSI Buried DoubleJacket 12 G 652 D DGK Rev0Bilal AlifNo ratings yet

- NA2XS (F) 2Y 12-20 KV 1x400Document2 pagesNA2XS (F) 2Y 12-20 KV 1x400plavi10No ratings yet

- Ground Modular Terminal Block - USLKG 10: Jul 7, 2022, 7:41 PM Page 1Document25 pagesGround Modular Terminal Block - USLKG 10: Jul 7, 2022, 7:41 PM Page 1javierNo ratings yet

- Phoenix Contact 3000562 en PDFDocument5 pagesPhoenix Contact 3000562 en PDFDGNo ratings yet

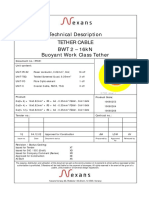

- Technical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherDocument6 pagesTechnical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherRich ManNo ratings yet

- Data Sheet2102-5301 21.07.2020Document17 pagesData Sheet2102-5301 21.07.2020sanyi75No ratings yet

- Cable ControlDocument1 pageCable ControlMisi KeiterNo ratings yet

- IEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONDocument7 pagesIEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONmedazzNo ratings yet

- Specification: 0.6/1kV XLPE CableDocument4 pagesSpecification: 0.6/1kV XLPE CableChrysthyan HitachiNo ratings yet

- Phoenix Contact 1714765 enDocument5 pagesPhoenix Contact 1714765 enDGNo ratings yet

- 2202-3258 Eng TdsDocument4 pages2202-3258 Eng TdsAPNo ratings yet

- Phoenix Contact 1915246 enDocument4 pagesPhoenix Contact 1915246 enDGNo ratings yet

- 189ET INSTRUM RE-vY (ST) Y 6X1 MM2 BK-JJlap HitamDocument1 page189ET INSTRUM RE-vY (ST) Y 6X1 MM2 BK-JJlap Hitamchakrapani vagish chandra pandeyNo ratings yet

- 490NAA271XXDocument2 pages490NAA271XXLeonardoAcevedoNo ratings yet

- Claa185wa03 ChunghwapicturetubesDocument22 pagesClaa185wa03 ChunghwapicturetubesWings Techno ServicesNo ratings yet

- Item 2: Installation Ground Terminal Block - STI 2,5-PE/L/NTB - 3038642Document3 pagesItem 2: Installation Ground Terminal Block - STI 2,5-PE/L/NTB - 3038642HashemAliHashemNo ratings yet

- Datasheet Kabel Power Prysmian N2RXY E22 PCI 002 Issue3 CSI 19.05.22 Halaman 7 8Document2 pagesDatasheet Kabel Power Prysmian N2RXY E22 PCI 002 Issue3 CSI 19.05.22 Halaman 7 8Joko SchumacherNo ratings yet

- An DL001Document12 pagesAn DL001maggamNo ratings yet

- Phoenix Contact 3070613 enDocument29 pagesPhoenix Contact 3070613 enBibhu Ranjan MohantyNo ratings yet

- Sc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Document1 pageSc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Nader AhmedNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Phoenix Contact 1803581 enDocument13 pagesPhoenix Contact 1803581 enDGNo ratings yet

- Phoenix Contact 3211757 enDocument7 pagesPhoenix Contact 3211757 enDGNo ratings yet

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresNo ratings yet

- Flowcharts and Design Equations - Eurocode 2Document7 pagesFlowcharts and Design Equations - Eurocode 2ChineseAssassinNo ratings yet

- Surge Counter Catalog RAW DD 4mbDocument5 pagesSurge Counter Catalog RAW DD 4mbkarthik achudhanNo ratings yet

- Assessment of Electrical Conductivity of A Salt-Water Solution Using Makey MakeyDocument7 pagesAssessment of Electrical Conductivity of A Salt-Water Solution Using Makey MakeyAlex Raymon BinasNo ratings yet

- Welding Variables WeldersDocument5 pagesWelding Variables WeldersAkhilesh KumarNo ratings yet

- Top Civil Engineering Interview QuestionsDocument6 pagesTop Civil Engineering Interview QuestionsSaddaqatNo ratings yet

- Dept. Library B.tech, M.tech, PHD ProjectsDocument9 pagesDept. Library B.tech, M.tech, PHD ProjectsAkhilesh B.MNo ratings yet

- MODEL 7705 Flexible CouplingDocument2 pagesMODEL 7705 Flexible CouplingKalagan YadaNo ratings yet

- JS1020 X P07 1501Document26 pagesJS1020 X P07 1501Anonymous tWOsIcNo ratings yet

- 1,1,1,2 - Tetrafluoroethane. (R134a) : Material Safety Data Sheet (MSDS)Document3 pages1,1,1,2 - Tetrafluoroethane. (R134a) : Material Safety Data Sheet (MSDS)Syed FirozNo ratings yet

- HG ASTM ThermometersDocument4 pagesHG ASTM ThermometersmegacobNo ratings yet

- Vitalograph Alpha Service ManualDocument23 pagesVitalograph Alpha Service ManualaliNo ratings yet

- Sewer Pipe & Chamber Systems: Pipelife Jet Stream IncDocument4 pagesSewer Pipe & Chamber Systems: Pipelife Jet Stream IncParthiban KandhasamyNo ratings yet

- Casting Defects: Seminar - 7Document17 pagesCasting Defects: Seminar - 7Vishal MalusareNo ratings yet

- Id LubeDocument1 pageId LubeWael El EssawyNo ratings yet

- Characterization of MaterialsDocument1 pageCharacterization of MaterialsSalem GarrabNo ratings yet

- Ash in Fatty Quaternary Ammonium Chlorides: Standard Test Method ForDocument1 pageAsh in Fatty Quaternary Ammonium Chlorides: Standard Test Method ForShaker QaidiNo ratings yet

- Bentonite, Kaolin, and Selected Clay Minerals: Environmental Health Criteria 231Document196 pagesBentonite, Kaolin, and Selected Clay Minerals: Environmental Health Criteria 231Atif AhmedNo ratings yet

- Chapter 1 - Stress and StrainDocument72 pagesChapter 1 - Stress and StrainNazhan HaziqNo ratings yet

- Reformulated SoR For The Year 2015-16Document434 pagesReformulated SoR For The Year 2015-16Srinivasarao Ramisetti100% (4)

- Tyre Creep: Refractory Engineering and Kiln Maintenance in Cement PlantsDocument4 pagesTyre Creep: Refractory Engineering and Kiln Maintenance in Cement PlantsMedical LafargeNo ratings yet

- Organochloride Contamination in A Refinery Naphtha Hydrotreater UnitDocument5 pagesOrganochloride Contamination in A Refinery Naphtha Hydrotreater UnitMarwa ElsherifNo ratings yet

- Standard Specification For: Designation: B 6 - 06Document4 pagesStandard Specification For: Designation: B 6 - 06Thaiminh VoNo ratings yet

- Fosroc Concure WB: Water Based Concrete Curing CompoundDocument2 pagesFosroc Concure WB: Water Based Concrete Curing CompoundShaik QutubuddinNo ratings yet

- Balancing Chemical EquationsDocument25 pagesBalancing Chemical EquationsEya JonesNo ratings yet

- 2004 CT AnuarDocument36 pages2004 CT Anuargabi_xyzNo ratings yet

- Mai and Kantzas - 2002 - An Evaluation of The Application of Low Field NMR in The Characterization of Carbonate ReservoirsDocument9 pagesMai and Kantzas - 2002 - An Evaluation of The Application of Low Field NMR in The Characterization of Carbonate ReservoirsLorena Pastana MartinsNo ratings yet

- Techniques To Separate and Identify Contaminants in Recycled PlasticsDocument6 pagesTechniques To Separate and Identify Contaminants in Recycled Plasticssameh100% (1)

- Desiccant Wheel Dehumidification 2Document19 pagesDesiccant Wheel Dehumidification 2ovidiu73No ratings yet