Professional Documents

Culture Documents

3 - Monotube Burner - CPT - 2004

Uploaded by

safwat hassanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 - Monotube Burner - CPT - 2004

Uploaded by

safwat hassanCopyright:

Available Formats

User Tips and Instructions

Note : The OFT (Optimum Flame Theory) burner spreadsheet based on the OFT theory

(from Tom Lowes report released in 1995 (Blue Circle)

The burner 's jet momentum needs to be adequate to entrain sufficient secondary air to

be able to mix the coal on a macro scale before

the plug flow zone in the kiln.

Only for an axial flame ( no swirl)

1

2 Inputs

3 Enter burner elevation , cell F5 and verify

4 Enter the type of burner, cell E14

5 Enter the burner inlet diameter (D1), cell K17 or K29

6 Enter the burner outlet (tip) diameter (D2), cell D18 or D30& D32

7 Enter production at which you are evaluating cell K43

8 Enter SHC , cell D54 (solid fuel flowrate)

9 enter back-end O2 %, cell K54

10 Enter kiln diameter, cell K50

11 Enter brick thickness in the burning zone, cell K52

12 Q50)

13 Enter burner inlet temperature, cell K20 or cell K32

14 Enter the actual primary air flow measured, cell K22 or K34

Check that other statistics and dimensions are correct

Back Pressure at the burner

If the iteration doesn't work , type "0" in cell D63 and after type"1"

You should be able to find out the back pressure needed at the burner with a subsonic

type of flow

and compare with the existing pressure measured, cell D87

Optimum flame theory

rows 96 to 105

This theory will predict an optimal momentum and an optimal velocity at the burner inlet

and at the burner tip

You can compare with your actual numbers, rows 103 to 105

the

inlet diameter ( no bluff body, no tip reduction), this momentum is calculated with the kiln

production rate (tph) , the kiln diameter and the gross fuel consumption (kcal/kg)

burner

momentum decreases below that specified number , reducing conditions begin to occur,

once less

than 85 % of the optimal momentum is reached. Cell D23 or D37

A shorter flame could be achieved by increasing primary air at constant velocity

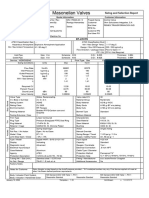

OPTIMAL FLAME THEORY (Monotube burner)

Plant Westbury K1 Existing Legend

Date : 2/24/2004 Very High

Name Olivier BERNARD High

Language 2 Burner elevation: 100 m, ASL OK

English, type "1" 10210.45 mm WG Low

Comments

For standard pipe type "1", for bluff body type "2" 1

1. Standard Monotube Burner Pipe

438.15 D1 - Inlet ID, mm

D2 - exit ID, mm 361.95 17.25 Inlet ID, inches

exit ID, inches 14.25 33 Velocity m/s

area, mm2 102,893 125 Back pressure, mm WG

Velocity m/s 50.6 4.9 Back pressure, inches WG

Impulse N*m/GJ 0.96 13,921 Measured Flow, Nm3/h

% of Optimu 59% 85.0 Inlet temperature, deg C

Optimum velocity m/s 86.11 17.7% % Primary Air

MAP/MAS 1.02

2. Monotube with Bluff Body

438.15 D1 - Inlet ID, mm

D2 - exit ID, mm 438.2 17.25 Inlet ID, inches

exit ID, inches 17.25 33 Velocity m/s

D3 - Bluff body OD, mm 10.0 57 Back pressure, mm WG

Bluff body OD inches 0.39 2.2 Back pressure, inches WG

area, mm2 150,699 13,921 Measured Flow, Nm3/h

Velocity m/s 34.6 85.0 Inlet temperature, deg C

Impulse N*m/GJ 0.66 17.7% % Primary Air

% of Optimu 40%

Optimum velocity m/s 86.11

MAP/MAS 1.02

Production KK (tpd) 1080

Production KK (tph) 45

\

Total combustion air Nm3/kg kk 1.74 Fuel characteristics (dry basis)

0

% fuel in pre-calciner 0 Coal Coke

Kiln shell diameter 4.40 m % 100% 0%

Heat consumption to the main burner Flow Heat value Therm energy brick thickness 0.2 m % volatiles 25 1

kg/h Kcal/kg Gcal/h Kiln ID (BZ) 4 m

COAL 10000 6300 63.00 Back end O2 % 1.5

1400 kcal/kg CK %C 55 1

5862 MJ/T %S 1 1

%H 9 1

%O 1 1

Thermal load (kcal/h/m2) 6123 Nm3/kg fuel 7.28 0.35

Notes and Comments

> valid for dry air LHV (BTU/lb) 11340 0

Burner Design > does not account for energy transferred LHV(Kcal/kg) 6300 0

Iteration Reset 1 to ground fuel carried LHV(kJ/kg) 26377 1

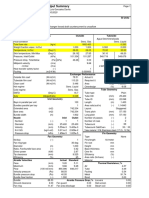

Pipe Dimensions Standard Bluff Nm3/cal

Burner inlet ID (D1) mm 438.15 438.15 ACN

Burner exit ID (D2) mm 361.95 438.2 Nm3/T CK

Bluff body OD (D3) mm 10.0

inlet area mm2 150,777 150,777

outlet area mm2 102,893 150,699

ratio outlet/inlet % 0.68 1.00

Gas/Air Calculations Std Bluff

atmospheric pressure @ elev mmWG 10,210

Normal density kg/m3 1.293

R J/kg K 287.00

k Cp/Cv 1.40

Measured primary air flow Nm3/h 13,921 13,921

Inlet Air temperature Celcius 85.0 85.0

Barrel air density kg/m3 1.00 0.99

Exit air density kg/m3 0.99 0.99

Barrel air flow Am3/h 18,033 18,152

Exit air flow Am3/h 18,194 18,228

Barrel Inlet Velocity m/s 33.2 33.4

Tip Exit Velocity m/s 50.6 34.6

Barrel Inlet Mach Number 0.09 0.09

Tip Exit Mach Number 0.13 0.09

Calculated req'd back pressu mmWG 125 57

Back Pressure mmWG 125 57

inches WG 4.92 2.23

Pa 1224.61 556.01

psig 0.18 0.08

Add Impulse and velocity guidelines

0.96883127

Optimum Flame Theory and Impulse Calculations 7.03694444

Std. Bluff 5

Primary Air Mass flow kg/s 5.00 5.00

Axial Impulsion (air only) N 253.2 173.2

Impulse N.h/Gcal 4.02 2.75

N.h/GJ 0.96 0.66

Total Impulse (air+fuel) N 393.8 269.4

Actual tip velocity m/s 50.6 34.6

Optimum Momentum (G opt) N 669.8 669.8

Optimum tip velocity m/s 86.1 86.1

Ratio momemtun (actual/opt) 0.59 0.40

2.03694444

7333

Energy Balance

Energy gas inlet kJ/s 1776.90

Kinetic energy fuel inlet kJ/s 1.53

Energy gas exit kJ/s 1770.59

Kinetic energy fuel exit kJ/s 3.56

IN minus OUT 4.28

0.24%

MAP/MAS determination

Kiln production,tpd 1080 0.5 1.0 1.5 2.0 2.5 3.0 m

Kiln diam.,m 4.40 primary Nm3/h 13,921 1000 1300 1500 1600 1650 1700 DegC

Coating thickness,m 0.2 m/s 8.4 10.4 11.7 12.4 12.7 13.0

primary% 17.75 Moment,N 195 241 271 286 294 302

kcal/kg CK 1400

Coal kcal/kg 6300

0 Spe.Impuls 3.09 3.82 4.30 4.55 4.67 4.79

Back end O2% 1.5

Approx. Sec air, Nm3/h 64,525 248 N Sec.air

combus air Nm3/cal 1.156 253 N Axial component of burner

Gcal/h through main burner 63.0 Difference 5N

614841745.xls

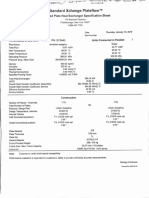

SWIRL AND MOMENTUM DETERMINATION

Original: CLV / S.THIERS Apr-95 PLANT : BATH

Update: CTS / W.Oliveira Sep-99 Date : 9/24/2022

(Inputs are in bold characters) Name : W. Oliveira

COMMENTS :

Modifications on Bath's burner - Increase the axial hole dimension (from 25 to 28.3) and reduce the swirl angle (from 35 to 20

degree).

Goal is to increase the turbulence at the tip, and then reducing the buildups.

TIP CROSS SECTION AREAS Diameters : % cross section reduction Dext : 609.6

(mm) thk : 17.475

AXIAL AIR 545.3 2900 mmWG

Holes 1, Vanes 2 : 1 226 m/s 488.7 72.6% 24 m/s 7806 Nm3/h

12580 mm2 Dext : 457.2

428.7 thk : 14.275

TRANSPORT AIR 0 m/s 327.9 0 m/s Dext : 323.9

0 mm2 thk : 9.5

298.9 2500 mmWG

SWIRL AIR 203 m/s 267.5 62.5% 24 m/s 2957 Nm3/h

4915 mm2 Dext : 219

thk : 8.2

DETAILS OF THE TIP Swirler Number slots groove width radial gap radius

angle (o) of vanes width(mm) (mm) vanes(mm) raccord.

Swirl 20 20 15.697 14.750 0.5 1

Axial (if vanes) -

Axial (if holes) Number of holes : 20 Diameter : 28.30

GENERAL DATA

Kiln TYPE : LD PRODUCTION (T CK /d) : 2950.00

NP : no preca, AT : air through, AS : air seperat. Specific heat consumpt.kJ/kg CK : 3590.00

FUEL ANALYSIS, AS FIRED (DRY BASIS) Swirl Air: F=Fan; B=Blower B

%C #REF! %O #REF! Percent of heat at back-end : 0.00

%S #REF! NCA

%H #REF! Nm3/kg fuel #REF! Shell internal diameter (m) : 5.80

Total combust. air (Nm3/hr) : #VALUE!

SPECIFIC HEAT CONSUMPTION Throughput L.H.V. Therm.power

AT THE BLAST PIPE kg/h KJ/kg GJ/h

COKE/COAL 40/60 #VALUE! #REF! #VALUE!

0.00

0.00

0.00 Recalculated SHC :

Total (GJ/h) : #VALUE! #VALUE! kJ/kg CK

GAS FLOW MEASUREMENTS Axial Swirl Transport

Static pressure in the tip 2900 2500 -

Temperature in the pipe (deg C) 100 70 100

Theoretical flow rate (Nm3/h) 7806 2957 - Fuel to air ratio:

Bias coefficient : 1.00 1.00

Accepted flowrate (Nm3/h) 7806 2957 4200 #VALUE! kg/m3

Axial / Swirl distribution 73% 27%

RESULTS

FLOW VELOCITIES Axial Swirl Transport Is Swirl

Nature of flow subsonic subsonic velocity N.h/GJ

Release tip velocity (m/s) 226 203 0 ### 0.08

Primary air rate, axial : #VALUE! Targets: Fuel-Oil 1.2 0.15

swirl : #VALUE! Coal 1.5 0.15

transport : #VALUE! Coke 1.8 0.15

Axial + Transport: #VALUE!

Primary air rate #VALUE! THERMAL LOAD (MW/m2) : #VALUE!

Pipe

Size O.D. 5 10 20 30 40 STD 60 80 XH

in 6.625 0.109 0.134 0.280 0.280 0.432 0.432

6 mm 168.275 2.769 3.404 7.112 7.112 10.973 10.973

lbs/ft 7.585 9.289 18.970 18.970 28.570 28.570

in 7.625 0.301 0.500

7 mm 193.675 7.645 12.700

lbs/ft 23.570 38.050

in 8.625 0.109 0.148 0.250 0.277 0.322 0.322 0.406 0.500 0.500

8 mm 219.075 2.769 3.759 6.350 7.036 8.179 8.179 10.312 12.700 12.700

lbs/ft 9.914 22.360 22.360 24.700 28.550 28.550 35.640 43.490 43.490

in 9.625 0.342 0.500

9 mm 244.475 8.687 12.700

lbs/ft 33.900 48.720

in 10.750 0.134 0.165 0.250 0.307 0.365 0.365 0.500 0.593 0.500

10 mm 273.050 3.404 4.191 6.350 7.798 9.271 9.271 12.700 15.062 12.700

lbs/ft 15.190 18.700 28.040 34.240 54.740 54.740 54.740 64.330 54.740

in 11.750 0.375 0.500

11 mm 298.450 9.525 12.700

lbs/ft 45.550 60.070

in 12.750 0.165 0.180 0.250 0.330 0.406 0.375 0.562 0.687 0.500

12 mm 323.850 4.191 4.572 6.350 8.382 10.312 9.525 14.275 17.450 12.700

lbs/ft 22.180 24.200 43.770 43.770 53.530 49.560 73.160 88.510 65.420

I.D. mm ### ### 311.150 307.086 303.225 304.800 295.300 288.950 298.450

in 14.000 0.250 0.312 0.375 0.437 0.375 0.593 0.750 0.500

14 mm 355.600 6.350 7.925 9.525 11.100 9.525 15.062 19.050 12.700

lbs/ft 36.710 45.680 54.570 63.370 54.470 84.910 106.100 72.090

I.D. mm ### 339.750 336.550 333.400 336.550 325.476 317.500 330.200

in 15.000 0.250 0.312 0.375 0.375 0.500

15 mm 381.000 6.350 7.925 9.525 0.000 9.525 0.000 0.000 12.700

lbs/ft 36.710 45.680 54.570 63.370 54.470 84.910 106.100 72.090

I.D. mm ### 365.150 361.950 381.000 361.950 381.000 381.000 355.600

in 16.000 0.250 0.312 0.375 0.500 0.375 0.656 0.843 0.500

16 mm 406.400 6.350 7.925 9.525 12.700 9.525 16.662 21.412 12.700

lbs/ft 42.050 52.360 62.580 82.770 62.580 107.500 136.500 82.770

I.D. mm ### 390.550 387.350 381.000 387.350 373.075 363.576 381.000

in 18.000 0.250 0.312 0.437 0.562 0.375 0.750 0.937 0.500

18 mm 457.200 6.350 7.925 11.100 14.275 9.525 19.050 23.800 12.700

lbs/ft 47.390 59.030 82.060 104.800 70.590 138.200 170.800 93.450

I.D. mm ### 441.350 435.000 428.650 438.150 419.100 409.600 431.800

in 20.000 0.250 0.375 0.500 0.593 0.375 0.812 1.031 0.500

20 mm 508.000 6.350 9.525 12.700 15.062 9.525 20.625 26.187 12.700

lbs/ft 52.730 78.600 104.100 122.900 78.600 166.400 208.900 104.100

in 22.000 0.250 0.375 0.500 0.375 0.875 1.125 0.500

22 mm 558.800 6.350 9.525 12.700 9.525 22.225 28.575 12.700

lbs/ft 58.070 86.610 114.800 86.610 197.400 250.800 114.800

in 24.000 0.250 0.375 0.562 0.687 0.375 0.968 1.218 0.500

24 mm 609.600 6.350 9.525 14.275 17.450 9.525 24.587 30.937 12.700

lbs/ft 63.410 94.620 140.800 171.200 94.620 238.100 296.400 125.200

in 26.000 0.312 0.500 0.375 0.500

26 mm 660.400 7.925 12.700 9.525 12.700

lbs/ft 85.600 136.200 102.600 136.200

100 120 140 160 XXH

0.562 0.718 0.864

14.275 18.237 21.946

36.390 45.300 53.160

0.875

22.225

63.080

0.593 0.718 0.812 0.906 0.875

15.062 18.237 20.625 23.012 22.225

50.870 60.630 67.760 74.690 72.420

0.718 0.843 1.000 1.125

18.237 21.412 25.400 28.575

76.930 89.200 104.100 115.700

0.843 1.000 1.125 1.312

21.412 25.400 28.575 33.325

125.500 125.500 139.700 160.300

281.026 273.050 266.700 257.200

0.937 1.093 1.250 1.406

23.800 27.762 31.750 35.712

130.700 130.700 170.200 189.100

308.000 300.076 292.100 284.175

0.000 0.000 0.000 0.000

130.700 130.700 170.200 189.100

381.000 381.000 381.000 381.000

1.031 1.218 1.437 1.593

26.187 30.937 36.500 40.462

164.800 192.300 223.500 245.100

354.025 344.526 333.400 325.476

1.156 1.375 1.562 1.718

29.362 34.925 39.675 43.637

208.000 244.100 274.200 308.500

398.475 387.350 377.850 369.926

1.280 1.500 1.750 1.968

32.512 38.100 44.450 49.987

256.100 256.100 341.100 379.000

1.375 1.625 1.875 2.125

34.925 41.275 47.625 53.975

302.900 353.600 403.000 451.100

1.531 1.812 2.062 2.343

38.887 46.025 52.375 59.512

367.400 429.400 483.100 541.900

You might also like

- Customer Service Metrics CalculatorDocument28 pagesCustomer Service Metrics CalculatorSelma Regita MahardiniNo ratings yet

- Transfer Pump Set Head Loss Calculation - Basement 3rd PDFDocument2 pagesTransfer Pump Set Head Loss Calculation - Basement 3rd PDFMUBASHIRNo ratings yet

- NGCP - Procedures and Requirements For Energy ProjectsDocument17 pagesNGCP - Procedures and Requirements For Energy ProjectspurplebasketNo ratings yet

- Nozzle 1Document25 pagesNozzle 1Sasikumar JothiNo ratings yet

- Performacen Dl250aDocument22 pagesPerformacen Dl250aRoger FederNo ratings yet

- Powerplant QuestionsDocument19 pagesPowerplant QuestionsAshok KumarNo ratings yet

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDocument10 pagesTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNo ratings yet

- Storage Tanks Overfill Prevention Better PracticesDocument2 pagesStorage Tanks Overfill Prevention Better PracticesRicardo Bec100% (1)

- Surge Protection Devices CatalogueDocument134 pagesSurge Protection Devices CatalogueNguyen Doan QuyetNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Tromp Curve v2Document4 pagesTromp Curve v2safwat hassanNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- The Role of Gypsum in CementDocument30 pagesThe Role of Gypsum in Cementsafwat hassanNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- Rosin-Rammler Slope v2Document5 pagesRosin-Rammler Slope v2safwat hassan100% (1)

- Bottom & Annular Plate Design: We Will Use Bottom Witout AnularDocument25 pagesBottom & Annular Plate Design: We Will Use Bottom Witout AnularhgagNo ratings yet

- How To Conduct A Ball Mill AuditDocument7 pagesHow To Conduct A Ball Mill Auditsafwat hassan100% (1)

- Cement Cooler EffDocument1 pageCement Cooler Effsafwat hassanNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- TEMA Spec SheetDocument1 pageTEMA Spec SheetvikzefgNo ratings yet

- Piaggio MP3 300 Ibrido LT MY 2010 (En)Document412 pagesPiaggio MP3 300 Ibrido LT MY 2010 (En)Manualles100% (3)

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- How To Remove Scrap Materials From A Ball Mill CircuitDocument5 pagesHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- LPH Data Sheet For 660 MWDocument7 pagesLPH Data Sheet For 660 MWproloy biswasNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Career Orientation QuestionnaireDocument5 pagesCareer Orientation QuestionnaireApple May100% (1)

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- WO Work Order 111-GeorgiaDocument16 pagesWO Work Order 111-GeorgiaDivyansh Singh ChauhanNo ratings yet

- Heat Exchanger Plate TypeDocument1 pageHeat Exchanger Plate TypeDeepak jainNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- 6 Inch NB Nozzle Calulation For TankDocument12 pages6 Inch NB Nozzle Calulation For TankSACHIN PATELNo ratings yet

- CondenserDocument7 pagesCondenserJade Carlo AntonioNo ratings yet

- Quotation Proposal For Cotton Club LTD 20-12-18Document5 pagesQuotation Proposal For Cotton Club LTD 20-12-18fakir mohammadNo ratings yet

- RTS Size89 Arr8 79width 970rpm 0.652kgm3Document3 pagesRTS Size89 Arr8 79width 970rpm 0.652kgm3hardik033No ratings yet

- E-101, Precalentador de PropanoDocument1 pageE-101, Precalentador de PropanoIsaac RodriguezNo ratings yet

- CONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Document2 pagesCONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Goran PanticNo ratings yet

- Drill Pipe Tool JointDocument1 pageDrill Pipe Tool JointJosh SabimanNo ratings yet

- MN 176323 24Document3 pagesMN 176323 24nawaz.ahmed.spnutra.comNo ratings yet

- WeldcalculatorDocument36 pagesWeldcalculatorDeerendra KaranthNo ratings yet

- Installation Conditions: Fan DescriptionDocument6 pagesInstallation Conditions: Fan DescriptionkingNo ratings yet

- Техническая спецификация S21-IG10-33-TK-SteamDocument1 pageТехническая спецификация S21-IG10-33-TK-SteamArtur AsaturyanNo ratings yet

- 130326-Especificacion SP342CEDocument2 pages130326-Especificacion SP342CELesly LandazabalNo ratings yet

- Diseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesDocument25 pagesDiseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesLuis AlexanderNo ratings yet

- 2019 CP Range Guide LR - PDDocument16 pages2019 CP Range Guide LR - PDmoisesNo ratings yet

- Hơi cần cho trao đổi nhiệtDocument1 pageHơi cần cho trao đổi nhiệtvtdNo ratings yet

- 3216 B TVHDocument1 page3216 B TVHQuản Lê ĐìnhNo ratings yet

- 4m3 - Design Data SheetDocument2 pages4m3 - Design Data SheetUsman NadeemNo ratings yet

- Pressure Loss Calculation Ariobimo Project MGS 2300R & 3100RDocument4 pagesPressure Loss Calculation Ariobimo Project MGS 2300R & 3100RRangga SetaNo ratings yet

- Medidor Chorro Unico Kk-29 Baylan - r200Document2 pagesMedidor Chorro Unico Kk-29 Baylan - r200Carlos Kevin Salame MeléndezNo ratings yet

- Tensile Test CertificateDocument1 pageTensile Test CertificateinfoNo ratings yet

- Htri PDFDocument1 pageHtri PDFLuigy L-aNo ratings yet

- Bit & Pressure Loss CalculationsDocument2 pagesBit & Pressure Loss CalculationsnjileoNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEnokarajuNo ratings yet

- ASU24CL1 AOU24CL1: Split Type Room Air Conditioner Wall Wounted TypeDocument21 pagesASU24CL1 AOU24CL1: Split Type Room Air Conditioner Wall Wounted TypeAndrey RicardoNo ratings yet

- Spec-Sheet DL420ADocument22 pagesSpec-Sheet DL420AAhmed SayedNo ratings yet

- GGB DU BearingsDocument52 pagesGGB DU BearingsMSc Kostic MilosNo ratings yet

- Actuated Ball Valve 357 A - BDKDocument4 pagesActuated Ball Valve 357 A - BDKfarhanakhtar ansariNo ratings yet

- Inter Cambiado RDocument2 pagesInter Cambiado RmilenarixNo ratings yet

- Fe-103, Fe-104 8''Document2 pagesFe-103, Fe-104 8''Vikram JitNo ratings yet

- Api 650 RF Pad CalculationDocument1 pageApi 650 RF Pad Calculationfauzy2504No ratings yet

- Ceiling & Floor Type Air Conditioner: Service ManualDocument43 pagesCeiling & Floor Type Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- 30 TR IG Tube PDFDocument1 page30 TR IG Tube PDFshree awateNo ratings yet

- Dwg. No.04 - 42 22 NS014 - FI 2 BARUUU-ModelDocument1 pageDwg. No.04 - 42 22 NS014 - FI 2 BARUUU-ModelMuhammad Alfin Mulya QotadaNo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- PASES, AIRE 448308 LB - HR REVaa1.SEGDocument1 pagePASES, AIRE 448308 LB - HR REVaa1.SEGTIPAZONo ratings yet

- HE Rating Data Sheet v6Document1 pageHE Rating Data Sheet v6dhaNo ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- 203 MTD 420 JT001 - 1Document3 pages203 MTD 420 JT001 - 1Suparerk SirivedinNo ratings yet

- ProcessTap Temperature - Dualam - AC Plastic PipeDocument2 pagesProcessTap Temperature - Dualam - AC Plastic PipeXarly Polite Jr.No ratings yet

- Holcim Comp and Benefits-1Document1 pageHolcim Comp and Benefits-1safwat hassanNo ratings yet

- Measurement and Estimation of The Particle Size Distribution by The Buoyancy Weighing-Bar Method and The Rosin-Rammler EquationDocument6 pagesMeasurement and Estimation of The Particle Size Distribution by The Buoyancy Weighing-Bar Method and The Rosin-Rammler Equationsafwat hassanNo ratings yet

- Mill Performance CalculationsDocument9 pagesMill Performance Calculationssafwat hassanNo ratings yet

- Average Piece WeightDocument4 pagesAverage Piece Weightsafwat hassanNo ratings yet

- Power Consumption - How To Address Power Cost - March05Document10 pagesPower Consumption - How To Address Power Cost - March05safwat hassanNo ratings yet

- 6 - Cooler Characteristics - CPT - TCEA - 2006Document7 pages6 - Cooler Characteristics - CPT - TCEA - 2006safwat hassanNo ratings yet

- Zener Tester: by MedhatkoDocument6 pagesZener Tester: by Medhatkosaran gulNo ratings yet

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDocument2 pagesElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiNo ratings yet

- Modular Heavy Duty Truck TransmissionDocument6 pagesModular Heavy Duty Truck Transmissionphucdc095041No ratings yet

- KSP Solutibilty Practice ProblemsDocument22 pagesKSP Solutibilty Practice ProblemsRohan BhatiaNo ratings yet

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDocument8 pagesPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoNo ratings yet

- Natal Chart Report PDFDocument17 pagesNatal Chart Report PDFAnastasiaNo ratings yet

- Diltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486Document5 pagesDiltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486sinirsistemiNo ratings yet

- S25580 MSDS Corn Starch FisherchiDocument6 pagesS25580 MSDS Corn Starch FisherchiProcurement ProlineNo ratings yet

- ALTS150-12P Datasheet1Document2 pagesALTS150-12P Datasheet1mamloveNo ratings yet

- Aectp 300 3Document284 pagesAectp 300 3AlexNo ratings yet

- Reviewer in PE&H 1st Quarter 18-19Document7 pagesReviewer in PE&H 1st Quarter 18-19rhex minasNo ratings yet

- Hexoloy SP Sic TdsDocument4 pagesHexoloy SP Sic TdsAnonymous r3MoX2ZMTNo ratings yet

- Sensor de Temperatura e Umidade CarelDocument1 pageSensor de Temperatura e Umidade CarelMayconLimaNo ratings yet

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugNo ratings yet

- Classroom Management PlanDocument14 pagesClassroom Management PlancowlesmathNo ratings yet

- Brp-Rotax Chassis Approval FormDocument3 pagesBrp-Rotax Chassis Approval Formdelta compNo ratings yet

- The Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesDocument456 pagesThe Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesAnna D.No ratings yet

- Analyst - Finance, John Lewis John Lewis PartnershipDocument2 pagesAnalyst - Finance, John Lewis John Lewis Partnershipsecret_1992No ratings yet

- SQL and Hand BookDocument4 pagesSQL and Hand BookNaveen VuppalaNo ratings yet

- Human Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test BankDocument4 pagesHuman Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test Bankanne100% (28)

- Concept of Lokmitra Kendra in Himachal PradeshDocument2 pagesConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaNo ratings yet

- National Pension System (NPS) - Subscriber Registration FormDocument3 pagesNational Pension System (NPS) - Subscriber Registration FormPratikJagtapNo ratings yet

- Er6f Abs 2013Document134 pagesEr6f Abs 2013Calibmatic JobNo ratings yet