Professional Documents

Culture Documents

Ntegrated Raining Esources Ummary Based On: Unrelated Features

Uploaded by

MBROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ntegrated Raining Esources Ummary Based On: Unrelated Features

Uploaded by

MBRCopyright:

Available Formats

INTEGRATED TRAINING RESOURCESGD&T SUMMARY BASED ON ASME Y14.

5-2009 and ISO 1101 and related standards

Material Condition Material Condition Tolerance Datum Material Condition Material Condition

Type Control Symbol Formulas and Abbreviations

Options ASME Y14.5 Options ISO 1101 Zone Shape Reference on Datum Ref. ASME Y14.5 on Datum Ref. ISO 1101

Form Straightness RFS, MMC, LMC RFS, MMC, LMC 1, 6 Never N/A N/A Bonus Tolerance, MMC Basis:

Unrelated Features Flatness RFS, MMC, LMC RFS Only 2 Never N/A N/A Bonus = MMC – Actual Size

Circularity RFS Only RFS Only 3 Never N/A N/A Datum Shift, MMB Basis:

Cylindricity RFS Only RFS Only 4 Never N/A N/A Shift = Virtual Condition – Actual Size

Profile Profile of a Line RFS Only RFS Only 7 Usually RMB, MMB, LMB RFS, MMC, LMC Virtual Condition, MMC Basis:

Related or Unrelated Profile of a Surface RFS Only RFS Only 2, 5, 8 Usually RMB, MMB, LMB RFS, MMC, LMC Internal Feature = MMC-G-Tol

Orientation Angularity RFS, MMC, LMC RFS, MMC, LMC 1, 2, 6 Always RMB, MMB, LMB RFS, MMC, LMC External Feature = MMC+G-Tol

Related Features Perpendicularity RFS, MMC, LMC RFS, MMC, LMC 1, 2, 6 Always RMB, MMB, LMB RFS, MMC, LMC LMB: Least Material Boundary

Parallelism RFS, MMC, LMC RFS, MMC, LMC 1, 2, 6 Always RMB, MMB, LMB RFS, MMC, LMC LMC: Least Material Condition

Location Position RFS, MMC, LMC RFS, MMC, LMC 1, 2, 6, 9 Always RMB, MMB, LMB RFS, MMC, LMC MMB: Maximum Material Boundary

Related Features

Concentricity RFS Only RFS, MMC, LMC 6 Always Axial Datum RMB RFS, MMC, LMC MMC: Maximum Material Condition

Symmetry RFS Only RFS, MMC, LMC 2 Always RMB Only RFS, MMC, LMC RMB: Regardless of Material Boundary

Runout Circular Runout RFS Only RFS Only 3 Always Axial Datum RMB Axial Datum RFS RFS: Regardless of Feature Size

Related Features

Total Runout RFS Only RFS Only 2, 4, 5 Always Axial Datum RMB Axial Datum RFS www.gdt-tolerancestack.com

Tolerance Zones (not exhaustive): 1-Two Parallel Lines, 2-Two Parallel Planes, 3-Two Concentric Circles, 4-Two Concentric Cylinders, 5-Two Concentric Cones, 6-A Cylinder, 7-Two Lines, 8- Two 3D Limits, 9-A Sphere

Datum Selection Guidelines

• Select datums based on contact with mating parts that establish orientation and location relationships; choose datums by analyzing the part within the context of the assembly when fully seated, fully assembled.

• Establish “mirrored” datum and dimensional schemes between mating parts and/or features. When multiple options are possible, consider manufacturing and inspection practices, and also choose datums with more surface area or that

will provide better repeatability; avoid relatively short or small surface area primary datums that might introduce projected error during inspection.

• Manufacturing datums should dimensionally be tied back to functional datums. Consider datum targets to reflect functional contact or mfg. setups, especially for machined parts.

• Create additional datum schemes when appropriate to better reflect local functional relationships and to open or close tolerances on groups of related features.

Modifier Application Guidelines

On tolerances…

• Per ASME Y14.5 and ISO 1101, RFS is implied for all tolerances and datum references unless otherwise specified. MMC or LMC modifiers can only be used on features of size (typically when controlling axes or center planes).

• MMC should be the first choice on position and perpendicularity tolerances when locating features of size that are primarily concerned with assembly. Use RFS (or both MMC and LMC) only when more precise centering is required.

• Consider LMC when material conservation is a primary consideration; should be considered for pre-machined features of size on cast, forged, or stock size features, and can also be used on o-ring grooves.

On datum references…

• MMB or LMB modifiers (which are the same modifier symbols used after the tolerances, but with a different meaning) are typically used on axis or center plane datums (derived from features of size), and provide datum shift tolerance.

• If the feature of size datum will have an interference or press fit in the assembly, it should be referenced RMB (no modifier); if the feature of size datum will have a clearance, running, or line to line fit in the assembly, it can be

referenced MMB or RMB.

2000-2018 ITR • 2420 WOODLANE DR. • NEW BRAUNFELS, TEXAS 78132 • (915) 867-4500 • FAX • DAN.BAUER@ITR-SA.COM • WWW.GDT-TOLERANCESTACK.COM

You might also like

- Radio Frequency Transistors: Principles and practical applicationsFrom EverandRadio Frequency Transistors: Principles and practical applicationsRating: 4 out of 5 stars4/5 (3)

- Smithells Metals Reference BookFrom EverandSmithells Metals Reference BookE A BrandesNo ratings yet

- ASME and ISO GD&T SummaryTableDocument1 pageASME and ISO GD&T SummaryTableROBERT BAILEYNo ratings yet

- Geometric Tolerancing Reference Chart ASME Y14.5M and ISOTC 213Document3 pagesGeometric Tolerancing Reference Chart ASME Y14.5M and ISOTC 213Anonymous gnbh26No ratings yet

- Chapter 4. ARM Instruction Reference: ARM Developer Suite Assembler GuideDocument13 pagesChapter 4. ARM Instruction Reference: ARM Developer Suite Assembler GuideJavier CarrascoNo ratings yet

- Assessment of Local Metal Loss API 579-1/ASME FFS-1 2007: Quest Integrity October 2015Document40 pagesAssessment of Local Metal Loss API 579-1/ASME FFS-1 2007: Quest Integrity October 2015امينNo ratings yet

- Plegado de PlanosDocument12 pagesPlegado de PlanosPauccar Rhp HpNo ratings yet

- 3.design For Flexure V1Document29 pages3.design For Flexure V1November RainNo ratings yet

- Ddi0439b Errata 01Document5 pagesDdi0439b Errata 01Ahmed TriguiNo ratings yet

- Geometric Dimensioning & TolerancingDocument102 pagesGeometric Dimensioning & Tolerancingcmpatel_0078% (9)

- RCM Moubray - 1 ArabicDocument49 pagesRCM Moubray - 1 ArabicNissan SunnyNo ratings yet

- Counter Surface of Hydraulic Sealing Systems For Heavy-Duty ApplicationsDocument7 pagesCounter Surface of Hydraulic Sealing Systems For Heavy-Duty ApplicationsYaqi HouNo ratings yet

- OSPF Part3 - CheatSheet ATech (Waqas Karim)Document1 pageOSPF Part3 - CheatSheet ATech (Waqas Karim)Waqas Karim100% (1)

- 19 390 Final Settlement Prices For Cash Settled FuturesDocument4 pages19 390 Final Settlement Prices For Cash Settled FuturesAmer ZamanNo ratings yet

- 5-Stage Pipeline CPU HardwareDocument24 pages5-Stage Pipeline CPU HardwareMoksha PatelNo ratings yet

- LTE & Network Architecture: Rajesh Kumar Mobile Faculty Advanced Level Telecom Training CentreDocument40 pagesLTE & Network Architecture: Rajesh Kumar Mobile Faculty Advanced Level Telecom Training CentreRajesh KumarNo ratings yet

- 5-Stage Pipeline CPU HardwareDocument33 pages5-Stage Pipeline CPU HardwarerosestrikesNo ratings yet

- Instruction Summary: Realview Assembler User'S GuideDocument9 pagesInstruction Summary: Realview Assembler User'S GuidePablo RivasNo ratings yet

- Module 1: Terminal Area Fixes and TolerancesDocument12 pagesModule 1: Terminal Area Fixes and Tolerancesjei liNo ratings yet

- Branch Instructions (2) : Refilled. Writing PC-4 Into The LR of The Current BankDocument13 pagesBranch Instructions (2) : Refilled. Writing PC-4 Into The LR of The Current BankGilberto VirgilioNo ratings yet

- PX5004 - MR & RCDocument5 pagesPX5004 - MR & RCNarasimman DonNo ratings yet

- ZTE LTE Radio Link Budget-75Document74 pagesZTE LTE Radio Link Budget-75mountainchNo ratings yet

- TTT Ospf Final Rev5Document35 pagesTTT Ospf Final Rev5felix_kelly_2007No ratings yet

- Retrofit Lehigh University WorkshopDocument45 pagesRetrofit Lehigh University Workshopadnan53No ratings yet

- ANSI Standard Fits.-Tables 3 Through 9 Inclusive Show A Series of Standard Types andDocument11 pagesANSI Standard Fits.-Tables 3 Through 9 Inclusive Show A Series of Standard Types andmohamadelsb3No ratings yet

- Unit 2 ErtsDocument93 pagesUnit 2 ErtsShivanth LenkalapallyNo ratings yet

- Cause Code Vs Eos CodeDocument37 pagesCause Code Vs Eos Codekaijage kishekyaNo ratings yet

- Simple LCC Resonant Half Bridge Converter Solution: NCP160 (2) 2 + NCL30059Document21 pagesSimple LCC Resonant Half Bridge Converter Solution: NCP160 (2) 2 + NCL30059alokNo ratings yet

- RBL RodendsDocument20 pagesRBL RodendsRingball_GusNo ratings yet

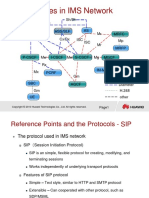

- Ims 8Document8 pagesIms 8Alessandro PazNo ratings yet

- Adaptive Multi Rate - 2G RANDocument73 pagesAdaptive Multi Rate - 2G RANRamane kakaNo ratings yet

- 5-Stage Pipeline CPU HardwareDocument43 pages5-Stage Pipeline CPU HardwareMonu ChouhanNo ratings yet

- Tokico P.D. Oil Flowmeter KatalogDocument6 pagesTokico P.D. Oil Flowmeter KatalogPRIMA UTAMA MULYANo ratings yet

- 2G Feature ListDocument135 pages2G Feature ListPraveen DubeyNo ratings yet

- Chapter 14 GD&TDocument17 pagesChapter 14 GD&Trlnjay2003No ratings yet

- LT B SummaryDocument1 pageLT B SummarycurlyjockeyNo ratings yet

- Mba 15LDocument2 pagesMba 15LlukaseksmurfNo ratings yet

- Protocolo - SDH RADIO 9600LSY ALCATELDocument5 pagesProtocolo - SDH RADIO 9600LSY ALCATELRicardo Ledesma cortijoNo ratings yet

- 美国机械制图标准简介Document82 pages美国机械制图标准简介Han HuangNo ratings yet

- Comparison of OMF IMF and SMFDocument2 pagesComparison of OMF IMF and SMFCarlo Dizon100% (1)

- ARM Instruction Set: ARM7TDMI-S Data SheetDocument60 pagesARM Instruction Set: ARM7TDMI-S Data SheetpavankrishnatNo ratings yet

- Acrónimos Registros HalliburtonDocument60 pagesAcrónimos Registros HalliburtonDidier ChambillaNo ratings yet

- U2U 2018 India - ConfirmationDocument8 pagesU2U 2018 India - ConfirmationAjay Kumar MattupalliNo ratings yet

- Asme 14.5M 2009Document25 pagesAsme 14.5M 2009aguiladezcalza69100% (5)

- CSR Harmonisation: Direct Strength AnalysisDocument13 pagesCSR Harmonisation: Direct Strength AnalysisBorza DorinNo ratings yet

- LensesDocument49 pagesLensesManuel CasanovaNo ratings yet

- Adaptive Multi Rate - 2G RANDocument73 pagesAdaptive Multi Rate - 2G RANMohammad SelimNo ratings yet

- Amr Optimization GuidelinesDocument23 pagesAmr Optimization Guidelinesyus ahmadNo ratings yet

- Reference Frames Reference Frames: ASME Y14.5-2009 Dimensioning & TolerancingDocument51 pagesReference Frames Reference Frames: ASME Y14.5-2009 Dimensioning & TolerancingCaio2101No ratings yet

- Advanced RISC Machines (ARM) : July 11, 2021Document32 pagesAdvanced RISC Machines (ARM) : July 11, 2021Amit Singh GaurNo ratings yet

- Sram Memory CellDocument20 pagesSram Memory CellSathyanarayana RaoNo ratings yet

- Latra LRF BoresightingDocument3 pagesLatra LRF BoresightingNguyễn Văn BìnhNo ratings yet

- Newnes Electronics Engineers Pocket BookFrom EverandNewnes Electronics Engineers Pocket BookRating: 4.5 out of 5 stars4.5/5 (4)

- Examining Stress in Graduate Assistants: Combining Qualitative and Quantitative Survey MethodsDocument14 pagesExamining Stress in Graduate Assistants: Combining Qualitative and Quantitative Survey MethodsMBRNo ratings yet

- Students' Developing Knowledge in A Subject Discipline: Insights From Combining Quantitative and Qualitative MethodsDocument15 pagesStudents' Developing Knowledge in A Subject Discipline: Insights From Combining Quantitative and Qualitative MethodsMBRNo ratings yet

- List of Things Needed Grades 5 6Document1 pageList of Things Needed Grades 5 6MBRNo ratings yet

- Plastic Injection Mold Maintenance Program LinkedInDocument11 pagesPlastic Injection Mold Maintenance Program LinkedInMBRNo ratings yet

- ASRS Damage February 2013 2Document10 pagesASRS Damage February 2013 2MBRNo ratings yet

- ASRS E-Stop BracketDocument1 pageASRS E-Stop BracketMBRNo ratings yet

- Ncert Solutions For Class 11 Maths May22 Chapter 15 StatisticsDocument52 pagesNcert Solutions For Class 11 Maths May22 Chapter 15 StatisticsPriyanshuNo ratings yet

- Spectrometry FinalDocument57 pagesSpectrometry FinalAastha SahuNo ratings yet

- Worksheet 6CDocument2 pagesWorksheet 6CZhang JiangNo ratings yet

- Science8 Q1 MOD4of8 Sound V2Document26 pagesScience8 Q1 MOD4of8 Sound V2Marc Jone ArengaNo ratings yet

- Iso 17485 2006Document13 pagesIso 17485 2006Carlos Jose Sibaja CardozoNo ratings yet

- CBSE Class 12 Maths Chapter 8 Applications of Integrals Important Questions 2022-23Document3 pagesCBSE Class 12 Maths Chapter 8 Applications of Integrals Important Questions 2022-23adarsh awasthiNo ratings yet

- Scope: TIP Category: Data and CalculationsDocument11 pagesScope: TIP Category: Data and CalculationsTomas SalingerNo ratings yet

- Lipson CrystalsX Rays TextDocument110 pagesLipson CrystalsX Rays TextCarolina AlpucheNo ratings yet

- Universidad Nacional de Ingeniería: Sistemas de Control I (EE-647O)Document2 pagesUniversidad Nacional de Ingeniería: Sistemas de Control I (EE-647O)Jhonathan C LNo ratings yet

- Architectural Design of Future Sustainable Primary School in Iran Using Multi-Purpose AtriumDocument4 pagesArchitectural Design of Future Sustainable Primary School in Iran Using Multi-Purpose AtriumThắm PhạmNo ratings yet

- An Automatic Method of Direct Interpretation of Re PDFDocument15 pagesAn Automatic Method of Direct Interpretation of Re PDFIrwansyah RamadhaniNo ratings yet

- Design of Curved Arch Truss With Sections Optimization For Auditorium HallDocument5 pagesDesign of Curved Arch Truss With Sections Optimization For Auditorium Hallsaee pawarNo ratings yet

- Optics Assessment 2019 With AnswersDocument10 pagesOptics Assessment 2019 With AnswersBenjamin NgNo ratings yet

- The Endocrown - A Different Type of All-Ceramic Reconstruction For Molars - JCDA - Essential Dental KnowledgeDocument8 pagesThe Endocrown - A Different Type of All-Ceramic Reconstruction For Molars - JCDA - Essential Dental KnowledgeJoel AlejandroNo ratings yet

- Evsjv ' Ki F Vu e e 'VQ Ms V II Cö Íve: 2021-22 A - ©-Eq II Ev RU KVH© GDocument112 pagesEvsjv ' Ki F Vu e e 'VQ Ms V II Cö Íve: 2021-22 A - ©-Eq II Ev RU KVH© GDaud FaraizyNo ratings yet

- The First Law of Thermodynamics - 040170170000Document50 pagesThe First Law of Thermodynamics - 040170170000xixoNo ratings yet

- Math 9 Q1 Week 1-2Document11 pagesMath 9 Q1 Week 1-2John Nino DoligolNo ratings yet

- Aeb303 Aircraft Structures IiDocument7 pagesAeb303 Aircraft Structures IiradhakrishnanNo ratings yet

- GP2 Q3 Melc-13 Mod-5Document31 pagesGP2 Q3 Melc-13 Mod-5Diana AfableNo ratings yet

- An Investigation of Disc Brake Rotor Using FeaDocument12 pagesAn Investigation of Disc Brake Rotor Using Fearudey18No ratings yet

- A History of Electricity - Park Benjamin PDFDocument628 pagesA History of Electricity - Park Benjamin PDFGavin RuncimanNo ratings yet

- 2.2 Linear Algebra & GeometryDocument16 pages2.2 Linear Algebra & GeometryRajaNo ratings yet

- General Physics 1 Week 12Document56 pagesGeneral Physics 1 Week 12Harold LimboNo ratings yet

- sen (φ) r˙ φ ˆ φ sen (φ) −r˙ φ sen (φ) − 2r ˙ φ ˙ θ cos (φ) r¨ φ + 2 ˙r ˙ φ − r sen (φ) cos (φ) ˙ θ ˆ φDocument3 pagessen (φ) r˙ φ ˆ φ sen (φ) −r˙ φ sen (φ) − 2r ˙ φ ˙ θ cos (φ) r¨ φ + 2 ˙r ˙ φ − r sen (φ) cos (φ) ˙ θ ˆ φnico_1995No ratings yet

- Diploma in Mechanical Engineering LAB 3-2 Law of NewtonDocument6 pagesDiploma in Mechanical Engineering LAB 3-2 Law of NewtonSyafiq AimanNo ratings yet

- Dekton K&B ROADocument24 pagesDekton K&B ROABoraNo ratings yet

- Angular Distortion Structures Pointv Linear GuideDocument13 pagesAngular Distortion Structures Pointv Linear GuideFrancisco Ordoñez MuñozNo ratings yet

- Probability DistributionDocument11 pagesProbability Distributionshakil ahmedNo ratings yet

- MATHS Revision DPP No 5 SolutionsDocument20 pagesMATHS Revision DPP No 5 SolutionsPraphul Pulkit GiriNo ratings yet

- 09-10 Reversible Processes and Open System Energy BalanceDocument42 pages09-10 Reversible Processes and Open System Energy BalanceNomun BatunNo ratings yet