Professional Documents

Culture Documents

Method Statement - HOLI SUPERMARKET DMCC

Uploaded by

ak technicalservicesestOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement - HOLI SUPERMARKET DMCC

Uploaded by

ak technicalservicesestCopyright:

Available Formats

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg,

Bur Dubai, Dubai, UAE

P.O Box 80744

+97150 5789060 / 04 26970620 / adeel@aktechservices.com

PROJECT : PROPOSED SUPERMARKET –

HOLI SUPERMARKET DMCC

CLIENT NAME : MR. IVAN CATALAN

PLOT : PL – 22

LOCATION: LAKE TOWER, CLUSTER B, JLT, DXB, UAE

MSRA No: Akts2022|28901

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 1 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

CONTENT

NO METHOD STATEMENT

01 General Details

02 Lake View FM: request to access

03 Contact numbers

04 Scope of Works

05 Management & Work Force

06 Work Permits & Approvals

07 Reference

08 Safety & Emergency Procedures

09 Sequence of Work

10 Insurance

11 Attachments

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 2 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

METHOD STATEMENT

GENERAL DETAILS

Project Name: Project No.

SUPERMARKET RENOVATION & MAINTENANCE akt2022/1413R1|064

WORK

Client: Location:

H O L I Supermarkets DMCC PLOT NO 22, LAKE VIEW, CLUSTER B, JLT, DUBAI, UAE

Contractor: Trade License No:

ABDULHANNAN KARIM TECHNICAL SERVICES EST. 860400

License Activities:

MEP Works | Technical Services & Maintenance Works

Job Type: Work Permit:

NON-CRITICAL COLD WORK

Task / Activity: MSRA No.: Revision No.:

Supply & Installation of MEP & Fitout Works Akts2022|28901 R0

Please find Method Statement & Risk Assessment herewith for the above works.

A copy of this document will be available on site with the AKTS Supervisor at all times.

This Method Statement ensures that all necessary action accompanied the job of MEP & maintenance work as per the

above-mentioned project name & project location.

If there are any risks that AKTS has not covered then please let us know as soon as feasibly possible to eliminate all

potential hazards.

(Note: NOC issued from DMCC & Landlord to proceed MEP/Fitout pertained).

Best Regards,

Manager - AKTS

I confirm our acceptance of this Method Statement & Risk Assessment and that we will undertake our

responsibilities as listed.

Signature Name ADEEL CHIRAGH

On behalf of(Company) ABDULHANNAN KARIM TECHNICAL Designation MANAGER

SERVICES EST.

Date: 28/09/2022

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 3 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

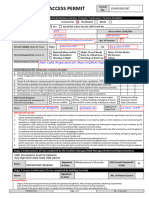

2. Lake View FM : request to access

Please confirm that the following are/will be in place to avoid delays / aborted visits and consequential additional costs

Request # Request details To be completed when?

1 Provision of 110V or 240v power supply adjacent or Prior to AKTS arrival at the site

within 10M of the work area.

2 Provide all access/keys that are required Prior to AKTS arrival at the site

3 Allocation of suitable on-site welfare facilities like Prior to AKTS arrival at the site

washroom & prayer room

4 Provision parking for loading & unloading materials Prior to AKTS arrival at the site

5 Materials to be kept at site for the duration of works will Prior to AKTS arrival at the site

be safely stored as directed by Building Management

personnel, ensuring no access/egress or other route is

obstructed

3. Contact numbers

– for use in the event of a problem or emergency on-site at any time outside of normal office hours.

Contact Person Designation Contact Number

Adeel Chiragh Manager +971507037024

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 4 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

4. Scope of Work

The work scope of this method statement is various of technical services and

maintenance works, as follows;

S/N SCOPE OF WORKS

1 Wall Demolition; Cartaway of Existing Debris / Garbage

Supply & installation of Flooring painting works with 10cm screeding; 1-coat

2

concrete cement paint

3 Wall Works: Plastering & Painting

4 Ceiling Works: Plastering & Painting

5 Supply & installation of Store Room Door - 80x210cm

6 Supply & installation of Tiling Works in Storeroom: Wall and Flooring

7 Supply & installation of New Glass Door

8 Supply & installation of Shop Front Glass

9 MEP works: FAFFS maintenance works

14 MEP works: Mechanical - AC ducting works

MEP works: Electrical Works - Lighting & Fixtures | Switches & Plugs/Outlets |

15

DB Dressing

16 Interior Works: Decorations & Logo

17 SHOP SIGNBOARD - HOLI Supermarkets

18 Furniture: Display & Racks Shelves | Cashier Counter

19 Demobilization: Clearing & Cartaway

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 5 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

5. Management & Work Force

Site Manager|Engr. Adeel Chiragh

Contact Number +971507037024

Rules & Responsible for obtaining of work permit, conducting toll box

Responsibilities meetings for the site crew

Responsible for the overall management of all activities on site.

Responsible to check work safety & unsafety conditions.

Ensure all safety requirements has been adequately addressed

and the work is carried out in accordance to United Arab

Emirates safety procedures.

HSE Requirements Our team members and crews are well trained to manage and

will comply the safety conditions and approved Risk Assessment.

6. Work Permits & Approvals

Work Permits Requirements:

Landlord NOC - Fitout Approved See attachments

Lake View NOC - Fitout Approved See attachments

Lake View NOC - Signage Approved See attachments

DMCC Approved Layout Approved See attachments

Approvals:

DCD Approved Layout: application ongoing process

7. References

akt2022/1413R1|064

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 6 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

8. SAFETY AND EMERGENCY PROCEDURES

Minimum PPE requirements will consist of the following list:

PPE Checklist Usage

Safety Footwear EN ISO 20345 Safety Shoes

Vest/Jacket While working; high visibility to identify workers

Gloves to EN388 When handling materials, removing boilers, cutting, drilling or

grinding

Safety goggles or glasses to BS EN When cutting, drilling, grinding

166 1B349 CE2

Anti-splash safety goggles to CE When painting, dealing with gas-associated services before

EN166-1B349 CE0196 the system has been drained

Hard Hat helmet As required, mandatory

Ear Plugs For Noise

Tools

Tools will be standard engineering hand tools 110V Grinder with disc cutting blades, 110v mag drill,

110v reciprocating saw, and Soldering equipment for brazing of copper/aluminum work.

110v impact wrenches, 110V corded power drills, battery-powered cordless tools, with transformer,

leads, and electrical testing equipment with associated plugs and sockets.

Equipment will consist of GRP steps, aluminum access ladder and scaffolding

Materials will be building materials, paints, brushes, paint gun, calorifier, valves, tiling work, fixings,

vice grips, pliers, cutters, rivet & silicon gun, spanners, associated fittings, nuts, bolt, switches, lights,

outlets etc..

Hazards

Fire / Explosion Dust

Heat Deep Excavation

Fumes / Gas Flying Particles / Objects

Traffic Falling Debris / Materials / Objects

Buried Service Demolition

Nose & Vibrations Manual Handling

Soft Ground Mobile Plant & Vehicles

Leaking Adverse Weather

Precautions

All the risks are assessed in Risk Assessment Document will be submitted separately.

Prior to the work commencement hoarding and proper signages will be placed.

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 7 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

9. SEQUENCE OF WORK

Wall Demolition (manual method)

Checking & assessing on the wall to demolish

Remove all unsafety debris or blockage of the area; remove electrical wires and switches if any;

Start cutting of wall panel by panel using manual jackhammer by separating the compound wall from each other.

Breaking the wall inside the proposed area to avoid damage to the other installed sides.

Ensure that the demolished wall should be cut into pieces as per required weight for the cartaway to the approved

designated disposal area.

Remove all demolished wall bricks at the workplace area to have better access.

Wall & Flooring Tiling Works: Store Room (General)

Apply tile adhesive to the wall and flooring as per the required thickness.

Tiles shall be placed according to the level shown in the drawing and shall be placed firmly with the help of rubber

mallet.

Remove and reset for solid bearing tiles that give a hollow sound when tapped with a steel rod, after installation

Particular care shall be taken in wet areas to prevent loss spot and pooling of water.

The tiles shall be neatly cut, grind rough on exposed edges and cornering.

When the installation has hardened sufficiently (after 48 hours) a thick grout of cement mixed with minimum

amount of water/approved grout shall be prepared and brushed over the floor until all the joints are thoroughly

filled.

Surplus materials shall be removed with dry cloth.

Aluminium Door: Store Room (General)

Wooden frame and architrave; Aluminium Door shutter will be measured and fabricated. Once fabricated, to

attached to the opening profile of the storeroom

Frame & architrave and all associated components will be then attached to this profile.

Aluminium Door shutter will be attached and secured by hinges to the profile.

All exposed edges and rough cornering will be neatly cut and grind; if any

Surplus materials shall be removed for cartaway.

Glass Work: Shop Front Glass (General)

Set out the U channel track around the perimeter of the Shop Front as per size requirement by with a hack saw or

chop saw.

Drill holes into the U channel and fix it to the floor, walls and ceiling with screws.

Counter sink the screws into the U channel so there are no proud screw heads which might damage the glass

Once the U channel is in place, the glass can be lifted into the U channel or slid into the U channel through the door

opening. The glass panels should be levelled using packers in the base of the U channel to ensure the glass panels

are standing vertically and the joins between them are vertical.

Once the glass panels are in place they can be joined together vertically using self-adhesive partition joints (dry

joints) or a bead of clear silicon (wet joints).

When the Glass panels are in place and joined vertically, the rubber gasket is used to fix the glass panels into the U

channel. Push the rubber gasket into the U channel on both sides of the glass to wedge it into the U channel. It is

best to push the rubber gasket into the U channel on both sides simultaneously so that an equal amount of gasket

is pushed in either side of the glass

Surplus materials shall be removed for cartaway.

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 8 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

Hinged Glass Door: Entrance Door (General)

Need to fix a floor plate onto the floor with the bolts supplied.

Insert and fix the U channel pivot point directly above the floor plate

Next, fit the metal patches supplied to the top and bottom of the door. (NB the door should be first installed in the

closed position) Now lift the door up and sit it on the floor plate, slotting the square hole on the metal patch into

the square pin poking up from the floor plate.

Then lean the door up to the U channel pivot point. Unscrew the Alan key bolt which holds the circular hole in the

top patch and then swivel this out and around the circular U channel pivot point that is pointing downward from the

U channel.

Once the circular pivot point is in the circular hole, tighten the Alan bolts. The door should now open. To adjust the

speed that the door closes, adjust the 2-speed adjustment screws on the bottom metal patch.

Surplus materials shall be removed for cartaway.

Industrial Painting: Flooring (General)

Surface preparation: The concrete substrate must be dry, sound, clean, dry and free from dust, oil, grease and

laitance and other contaminants. Molding compounds and release agents must be removed from the surface.

Substrate to be cleaned using encapsulated abrasive blasting method, diamond grinding, high-pressure jetting or

acid etching.

Touch Up Floor Putty (for repair): Using floor putty fill in blow holes that are apparent in the substrate. All cracks

should be a ground out back to the sound substrate using a suitable tool and after a thorough cleaning to remove

all dust and other impurities followed by filling using floor putty. The excessive floor putty should remove ensuring

that it falls level with the substrate. Leave to cure/dry for 24hrs prior to applying the epoxy paint.

Application of Primer Coat: After the surface preparation is complete all dust should be removed by vacuum

ensuring that all dust is removed from the substrate. Thoroughly mix the base and curing agent in accordance

with the product technical data sheet using a mechanical stirrer for 2 to 3 minutes. Epoxy sealer can be thinned

up to a maximum of 50% using Epoxy Thinner. Leave to stand (induction time) for 10 minutes before applying to

the substrate. Apply Epoxy Sealer uniformly by using spray, roller or brush to achieve the required dry film

thickness. Leave to cure/dry for 8hrs prior to applying next coat. The primer must be tack free before top coating.

If pin holes or porosities are evident after initial cure of primer, repriming may be necessary especially on very

porous concrete.

Application of First Coat of Epoxy Flooring: Thoroughly mix the base and catalyst separately, then mixed together

thoroughly in accordance with the product technical data sheet using a mechanical stirrer for at least 6 minutes.

Epoxy Flooring can be thinned up to maximum of 15% using Epoxy Thinner. Apply first coat of Epoxy Flooring

uniformly by using spray, roller or brush to give a uniform film thickness as required. Leave to cure/dry 12hrs

prior to applying final coat. Apply final coat of Epoxy Flooring as mentioned above. Allow to dry fully.

MEP: Electrical Works (General)

Site Engineer (Electrical) has to ensure that all wiring is completed and tested and site is cleared from civil section

to install light fittings and all cement works and coloring of wall is completed and cleared for installation of wiring

accessories. Prior to start installation, Site Engineer (Electrical) should ensure that approved shop drawings

related to the installation area are referred and that required materials are available at site as per approved

material submittals.

DB Dressing: DB already installed

Ensure that the Distribution Board installation is complete and all mechanical & electrical comments on installation

ITRs are completed & approved.

Ensure that no damage has occurred between mechanical completion & precommissioning.

Repair / replace damaged components, if any.

Ensure that the DB are properly tagged & identified location wise and service wise.

Check & record insulation resistance values of all outgoing circuits.

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 9 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

Ensure that the wiring termination to the Distribution Board are complete & are tight & secure.

Ensure that the outgoing cables from the power DB are terminated in the respective equipment, power socket,

spur outlets etc.

Ensure the polarity & the ring circuits are tested for proper installation.

Ensure that the outgoing cables from the lighting DB are terminated in all light fittings.

Ensure that the earthing of the DB has been completed.

Check for proper location & mounting height of the DBs for proper access

Ensure that the incoming cables to the DBs are properly installed and terminated.

Ensure that the cables to the DB are properly tagged & identified.

Ensure that the rating of the incoming & outgoing breakers (MCBs, ELCBs) are as per approved shop drawings &

schedules.

Check the manual operation of all the breakers in the DB.

Light & Light Fixtures:

Installation works shall be carried out only with respect to approved shop drawings of latest revision. Site

Engineer (Electrical) has to ensure that all the lighting fixtures are received at site of latest revision.

Site Engineer (Electrical) has to ensure that all the lighting fixtures are received at site as per approved material

submittal and as per approval.

Ensure all finishing works in all related areas are completed for the area of installation and released / cleared by

civil section to proceed on with the installation of lighting fixtures.

Type of lighting fixtures are to be selected as per the approved schedule of lighting and approved shop drawing.

Lighting fixtures installed in exposed external areas shall be of weatherproof type. Lighting fixtures are to be

installed in line and parallel with other line of fixtures as per approved shop drawings, and false ceiling drawing.

Lighting fixtures which are heavy shall be supported from the ceiling using galvanized caddy clip and heavy gauge

G.I. wire.

Lighting fixtures fixed in service areas, where there is no false ceiling, fittings are to be fixed firmly using anchor

bolts. minimum 6mm bolt and metal expansion anchor rods. Fixing of lighting fixtures above ducts,

pipes, trays and trunkings shall be avoided.

Connection between lighting fixtures and ceiling roses are to be made only using heat resistance 3 core, 2.5 sqm

or 1.5 sqm flexibles wires. wires. Ceiling rose location shall be easily accessible and should be avoided

Installing above AC ducts and cable trays. All lighting fixtures shall be connected with earthing cables. Before

fixing lamps all lighting fixtures are to be cleaned. Gloves shall be used in works. Correct lamps are to be fixed in

lighting fixtures.

Before installation all wires should be tested, mergered and schedules should be submitted to Engineers for

approval and records shall be maintained. GI boxes, round PVC boxes in concrete must be treated after plaster

and the edges shall be finished good and clean. Wall finish shall be done uniformly around the box edges

Test results should be submitted to the consultant for the records. Ensure that where luminaries are fixed

direct to conduit boxes the final circuit connections are adequately protected against the heat transfer from the

luminaries

Fix a label at each luminaries which is connected to more than one circuit to read. This luminaries is connected to

‘X’ number of circuits and is supplied from distribution board Ref.’Y’. Isolate each circuit prior to working on the

luminaire. Agree label location and format on site.

Wall & Ceiling Painting (General)

Preparation:

Operatives will be inductive before working at the site. Pre-start meeting would be conducted before the start of

painting activities and toolbox meetings would be regularly conducted by safety officers for all concerned

operatives.

Hardware materials that are already fixed and not to be painted shall be removed. Removal if not possible, shall

be covered/protected appropriately before surface preparation and painting will commence.

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 10 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

Clean and prepare concrete or cement plaster surfaces to be painted. Efflorescence, chalk, dust, dirt, grease, and

oils shall be removed.

The surface of the area to be painted would be prepared by removing loose particles, blemishes, and deleterious

materials by way of sanding.

Application:

The paint system would be emulsion paint for internal but to be approved by the Engineer. The surface to be

painted when prepared one coat of paint to be applied as primer. Curing would be made by drying until 4 hours is

attained prior to the succeeding coat to be applied. Application of the second coat stucco sanding would be done for

cleaning and removing splattered, blemishes, and stains on the painted surface

Then two coats of final paint would be applied as per the approved RAL color

For working at height, fixed and movable scaffolding would be erected as per area requirements. Scaffolding

when erected shall be inspected with the Safety officer prior to usage.

All materials must be collected and returned to the designated storage area after working hours and properly

secured and locked.

MEP: Mechanical - FAFFS – maintenance (General) | FAFFS already existing

Site Engineer surveys & checks to ensure all components and parts are existing, functional and to checklist which

are to replace or maintenance only. Check Dampers(fused & links), sprinklers, alarms and sensors.

Once checklist is made replace all nonfunctional components.

Fire cylinders shall be replaced with new ones & calibrated

Test and commission all fire alarms and sensors.

Fire Blankets will be replaced with new ones.

Once checked, replaced and calibrated; label & tags, record logsheet to monitor timely PPM purposes

MEP: Mechanical – AC Ducting only (General)

Single-Layer shall be installed tight and snug. Two-Layer shall be installed in separate layers arranged as single

layer with second layer staggered to the first so as to preclude coincident seams.

Insulation impaled on pins to be retained by speed washers. The pins are then to be bent over against the

washers (do not cut pins). Pin standard length is 38mm beyond face of insulation.

Insulation on plate work or burial vault lath to be impaled on pins spaced at approximately 305mm x 305mm

centers.

for valves and fittings of 4’’ and larger size, the insulation shall consist of either (a) preformed insulation

manufactured to fit the specific fitting or valve or (b) preformed pipe insulation mitered or cut as required to

fit the specific fitting or valve. In either case the insulation thickness and type shall be the same as the

adjacent pipe insulation.

Flanged connections on insulated pipelines shall not be covered until the pipeline has been satisfactorily

hydrotested.

Insulation on pipe adjacent to flanges shall be sufficiently tapered back to allow for future removal of flange bolts.

Flanges are to be covered with oversized insulation of the same type and thickness as adjacent pipe insulation

and shall lap the pipe insulation by at least 51mm.

The annular space between the flange and pipe covering shall be filled with loose insulating wool.

Insulation covering the flanges shall be installed to permit removal without damage to adjacent pipe covering.

Surplus materials shall be removed for cartaway

Test & Commissioning.

Interior Works: Furniture(shelves & racks), Decorations and Logo

Decorations: Pre-made wooden panels to be attached in the designated wall as per the approved drawing design

using silicon adhesive and screws. Leave all adhesive to dry.

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 11 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

Logo: Pre-made logo to be attached behind cashier wall and cashier counter frontside by safely fastening silicon

adhesive and screws. Leave all adhesive to dry.

Furniture: Fabricated furniture like display shelves, display racks, cashier counter and tables will be arranged

accordingly as per Client approval before securing.

Surplus materials shall be removed for cartaway

Shop Signage: HOLI Supermakets (General)

Authority Approval & Permits will be secured prior to the installation.

Yellow tape(on-going work) will be placed outside of the shop to avoid accidents.

Fabricated & customized signage will be using scaffolding and drillers in utmost care.

Step-by-step components will be fixed and installed, securely and supervised.

Electrical wiring & LED lights will be fixed and installed as luminaries.

Test & commissioning.

Surplus materials shall be removed for cartaway

10. INSURANCE

Notification to Insurance Department (YES/NO) YES

Insurance Covered (YES/NO) YES

11. ATTACHMENTS

- Company Trade License

Review Status: 1 – Accepted | 2 – Rejected, revision required

ABDULHANNAN KARIM TECHNICAL SERVICES EST.

Office No.22, SAI Business Center, 1st Floor. Al Makhawi Bldg, Bur Dubai, Dubai, UAE P.O Box 80744 Page 12 - MSRA

Mobile: +97150 5789060 / Email: adeel@aktechservices.com

You might also like

- Managing Successful Projects with PRINCE2 2009 EditionFrom EverandManaging Successful Projects with PRINCE2 2009 EditionRating: 4 out of 5 stars4/5 (3)

- 330.2R-17 - Guide For Concrete Site Paving For Industrial and Trucking Facilities PDFDocument7 pages330.2R-17 - Guide For Concrete Site Paving For Industrial and Trucking Facilities PDFRobert BarnesNo ratings yet

- Approval QuoteDocument12 pagesApproval Quotemariyamgarade7No ratings yet

- Basf Masterrheobuild 858 TdsDocument2 pagesBasf Masterrheobuild 858 TdsHassan SyedNo ratings yet

- Orc - Layout DrawingDocument1 pageOrc - Layout DrawingON ROADING CONTRACTING LLCNo ratings yet

- Al AMAL COMPANY PROFILE 2022-2023Document31 pagesAl AMAL COMPANY PROFILE 2022-2023Anas sabbaghNo ratings yet

- 10-TEC-BFM-F24 - Access Permit - R7 Dec 5 2020Document1 page10-TEC-BFM-F24 - Access Permit - R7 Dec 5 2020Design Xess EventsNo ratings yet

- Time Sheet T218Document3 pagesTime Sheet T218RanjithNo ratings yet

- (Cedsr-89721) S11008 - 8Document3 pages(Cedsr-89721) S11008 - 8Ujjwal DubeyNo ratings yet

- Reactive Maintenance: ABHA Gosi Office 6th FloorDocument1 pageReactive Maintenance: ABHA Gosi Office 6th Flooramershareef337No ratings yet

- 02 MAO Monthly Report Apr 20 PDFDocument80 pages02 MAO Monthly Report Apr 20 PDFjonesNo ratings yet

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDocument23 pages835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911No ratings yet

- TDM Acp WSP Com Stat B Msra Sas Na 002Document31 pagesTDM Acp WSP Com Stat B Msra Sas Na 002jithu surendranNo ratings yet

- Sample Work Completion CertificateDocument3 pagesSample Work Completion CertificateSkylink Estimation TeamNo ratings yet

- Method Statement For Installation of Temporary ServicesDocument22 pagesMethod Statement For Installation of Temporary Servicesfaizan khanNo ratings yet

- PreviewDocument2 pagesPreviewСохиб ХаитовNo ratings yet

- Method Statement For Aluminium Works 11Document28 pagesMethod Statement For Aluminium Works 11vairavan deekNo ratings yet

- Wrok Completion ReportDocument2 pagesWrok Completion ReportShiju TajNo ratings yet

- Excellent Technical Services LLC: Maintenance ContractDocument1 pageExcellent Technical Services LLC: Maintenance ContractAmila KumaraNo ratings yet

- TKS Noc MP 51281 2023 15424Document3 pagesTKS Noc MP 51281 2023 15424layaljamal2No ratings yet

- Method Statement AREA 4 KAFDDocument82 pagesMethod Statement AREA 4 KAFDAmeen AseefNo ratings yet

- Building Permit: Permit Type Permit Number Plot Number Initial Issue Date Current Issue Date Expiry DateDocument2 pagesBuilding Permit: Permit Type Permit Number Plot Number Initial Issue Date Current Issue Date Expiry Dateraj vaddiNo ratings yet

- SeifDeira BW InspectionDocument2 pagesSeifDeira BW Inspectionraj vaddiNo ratings yet

- 01.MS For Access Control Testing & CommissioningDocument10 pages01.MS For Access Control Testing & CommissioningrocknNo ratings yet

- Company ProfileDocument36 pagesCompany ProfileShahzad Nasir SayyedNo ratings yet

- O&m Manual For Landscapeing LightDocument104 pagesO&m Manual For Landscapeing Lightmukilanarul12No ratings yet

- 01 - PVC Conduits InstallationDocument11 pages01 - PVC Conduits InstallationRaju ManojNo ratings yet

- Maintenance FormDocument2 pagesMaintenance FormPetronas KkipNo ratings yet

- Purchase OrderDocument2 pagesPurchase Ordershakeel ahmedNo ratings yet

- Technical Report 1Document2 pagesTechnical Report 1atef ghazyNo ratings yet

- (Cedsr-92074) Jvt07iohr001 - 83Document2 pages(Cedsr-92074) Jvt07iohr001 - 83Mohammed AyeshNo ratings yet

- PMX PTWDocument11 pagesPMX PTWAkila SarkunanNo ratings yet

- Constrution of SubstationDocument24 pagesConstrution of SubstationHassan100% (1)

- Ho 87Document1 pageHo 87Shanmugam AnnamalaiNo ratings yet

- Report Ktadvance (Denso Service Verbal)Document2 pagesReport Ktadvance (Denso Service Verbal)azimsabudinNo ratings yet

- Major, Minor Renovation FormDocument12 pagesMajor, Minor Renovation FormRafaee RomenorNo ratings yet

- O 14166 R716 ILF UEW OC 5493 - Sewerage Connection Shop Drawing For Approval Plot RBW7 18 FDocument31 pagesO 14166 R716 ILF UEW OC 5493 - Sewerage Connection Shop Drawing For Approval Plot RBW7 18 FJubair PmNo ratings yet

- DAFZ Auditors List - 06 02 23Document5 pagesDAFZ Auditors List - 06 02 23Muhammed JabbidNo ratings yet

- DAFZ Auditors List - 24 03 22Document4 pagesDAFZ Auditors List - 24 03 22TehseenNo ratings yet

- Technical Inspection Report Pranfood-1Document1 pageTechnical Inspection Report Pranfood-1Mimma afrinNo ratings yet

- Volume 02 Architecture SpecificationsDocument240 pagesVolume 02 Architecture SpecificationsAnish MohanNo ratings yet

- Ho 94Document2 pagesHo 94Shanmugam AnnamalaiNo ratings yet

- Amc ContractDocument4 pagesAmc Contractlany.domusplusNo ratings yet

- Service Report - Valeo US (SCADA Modification)Document1 pageService Report - Valeo US (SCADA Modification)Velmurugan (TEAL AS)No ratings yet

- CCTV-01 Setting Out Plan PDFDocument1 pageCCTV-01 Setting Out Plan PDFAsser MaroufNo ratings yet

- Zia Uddin Khan: Curriculam VittaeDocument5 pagesZia Uddin Khan: Curriculam VittaeZohairzaara KhanNo ratings yet

- Site Work Completion CertificateDocument1 pageSite Work Completion CertificateVISHAL TELANGNo ratings yet

- DAFZA Auditors ListDocument5 pagesDAFZA Auditors ListJ Vamsi ChandraNo ratings yet

- Business Profile MEDocument27 pagesBusiness Profile MEmukeshahir08No ratings yet

- Callout: #E-Docket: QA126956Document2 pagesCallout: #E-Docket: QA126956Chaima Ben AliNo ratings yet

- Architecture&Civil SpecificationDocument616 pagesArchitecture&Civil SpecificationxyzhynNo ratings yet

- 02.01.03 Jobddgd Start Agreement CEM Form 1.0Document2 pages02.01.03 Jobddgd Start Agreement CEM Form 1.0Mohamed BadrNo ratings yet

- CIVILCO - ZIMA Company InformationDocument5 pagesCIVILCO - ZIMA Company InformationSikder MizanNo ratings yet

- HDKC Certificate of Completion - ROYAL CANIN ADDITIONAL WORKSDocument1 pageHDKC Certificate of Completion - ROYAL CANIN ADDITIONAL WORKSerabandoNo ratings yet

- Stars - K RahejaDocument12 pagesStars - K RahejaAlankar Nana Ambwade/Infrastructure Solutions-MEP/MUMBAINo ratings yet

- E&e and 3eg Prequalification PDFDocument44 pagesE&e and 3eg Prequalification PDFraviNo ratings yet

- Mas-Rtcf-Ms-El-001-Cable TrayDocument10 pagesMas-Rtcf-Ms-El-001-Cable TrayASHIQUE ZAFARNo ratings yet

- Qualiconsult Report-Pile Test N-82 (Test N-04)Document13 pagesQualiconsult Report-Pile Test N-82 (Test N-04)mahmoudNo ratings yet

- MZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalDocument59 pagesMZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalFaiyazsulthanNo ratings yet

- CVJ 6375290 20221101174039Document5 pagesCVJ 6375290 20221101174039asdج asdNo ratings yet

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringFrom EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- ProcessDocument30 pagesProcesssmdtsinoyNo ratings yet

- Wool Textile Processing ProductsDocument4 pagesWool Textile Processing ProductsKetan GandhiNo ratings yet

- Technical Data Sheet R410A ENGLISH PDFDocument4 pagesTechnical Data Sheet R410A ENGLISH PDFjane.yuchen8283No ratings yet

- Specification For Carbon and Alloy Steel Nuts For Bolts For High-Pressure or High-Temperature Service, or BothDocument18 pagesSpecification For Carbon and Alloy Steel Nuts For Bolts For High-Pressure or High-Temperature Service, or BothPaulo SantosNo ratings yet

- Wrinkles Silk: Characteristics of Organdy FabricDocument6 pagesWrinkles Silk: Characteristics of Organdy FabricShivendu BhadauriaNo ratings yet

- MTBEDocument34 pagesMTBEruben ordoñezNo ratings yet

- Mesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Document17 pagesMesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Dwayne YiiNo ratings yet

- Corrosion-Related Failure Analysis: Standard Guide ForDocument5 pagesCorrosion-Related Failure Analysis: Standard Guide Foralucard375No ratings yet

- Cast Iron Production & ClassificationDocument34 pagesCast Iron Production & ClassificationTanzir Musa100% (1)

- Chem Question BankDocument71 pagesChem Question BankSai SriramNo ratings yet

- Quakebond J333Sr: The Infrastructure InnovatorsDocument2 pagesQuakebond J333Sr: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- Chapter 13, 14 - Metals PDFDocument9 pagesChapter 13, 14 - Metals PDFAarush SharmaNo ratings yet

- Solution: Characteristics TypesDocument5 pagesSolution: Characteristics TypesMuhammad AsifNo ratings yet

- SCC LV Cable - Thermal SC RatingDocument1 pageSCC LV Cable - Thermal SC RatingRenato AbalosNo ratings yet

- ASTM D 790 - 17 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating MaterialsDocument1 pageASTM D 790 - 17 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating MaterialsGustavoNo ratings yet

- Tanques Hidroneumaticos ProsourceDocument4 pagesTanques Hidroneumaticos ProsourceHéctorNo ratings yet

- Coagulation and FlocculationDocument70 pagesCoagulation and Flocculationahmed samy100% (5)

- Pressure Responses and Phase Transitions During The Release of High Pressure CO From A Large-Scale PipelineDocument35 pagesPressure Responses and Phase Transitions During The Release of High Pressure CO From A Large-Scale PipelinealiNo ratings yet

- Jr.C-120 - Jee-Adv - WTA-06 - Question PaperDocument15 pagesJr.C-120 - Jee-Adv - WTA-06 - Question PaperMurari MarupuNo ratings yet

- 01192015114316IMYB - 2013 - Vol III - BauxiteDocument14 pages01192015114316IMYB - 2013 - Vol III - BauxitevishalNo ratings yet

- MGC 110 L3 2024 Man. IntroDocument29 pagesMGC 110 L3 2024 Man. Introkeletsosekome2No ratings yet

- TCVN 5760-1993 Fire Extingishing SystemDocument6 pagesTCVN 5760-1993 Fire Extingishing Systemochocomike100% (1)

- Colder Products Common Chemical Compatibility GuideDocument7 pagesColder Products Common Chemical Compatibility Guidespamalstublieft1832No ratings yet

- ShamimfinalDocument6 pagesShamimfinalvimalNo ratings yet

- Bomb CalorimeterDocument4 pagesBomb Calorimeteruserh1911100% (1)

- Determining The Bottom Hole PressureDocument8 pagesDetermining The Bottom Hole PressureAhmed AmirNo ratings yet

- Data Sheet For Ss 304 GradeDocument2 pagesData Sheet For Ss 304 Grades swamiNo ratings yet

- Thermodynamic Processes: Analysis of Thermodynamic Processes by Applying 1 & 2 Law of ThermodynamicsDocument10 pagesThermodynamic Processes: Analysis of Thermodynamic Processes by Applying 1 & 2 Law of Thermodynamicsmohdmehrajanwar1860No ratings yet