Professional Documents

Culture Documents

40-20-56 Rev B - Output Shaft Seal Kit For Sundyne Gearboxes

Uploaded by

jamil ahmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40-20-56 Rev B - Output Shaft Seal Kit For Sundyne Gearboxes

Uploaded by

jamil ahmedCopyright:

Available Formats

Field Engineering Bulletin

Bulletin No. 40.20.56

Output Shaft Seal Kit for Sundyne Gearboxes

EFFECTIVE DATE: OCTOBER 2014 REV: B

AFFECTED MODELS: LMX/BMX-31X, LMV-32X, LMX/BMX-33X&33XN PAGE 1 OF 3

LMC/BMC-341P&F, LMG-330L

In effort to reduce leakage and prolong seal life over existing market options, two new

gearbox output seals have been made available. The mechanical design and material

selection has been specifically engineered for the Sundyne gearbox and is optimized

based on output speed. Each seal is packaged into a kit containing one SE04AA9XX

stationary seal and one RJ09AXXXSN1HN00 mating ring. Packaged kits cover all

applicable pump, compressor, and unique configured gearboxes.

KT01SE98X0 Low-RPM Seal Kit

Output speed ≤ 20,000-RPM

275-PSI (19-bar) reverse pressure capability

Contains SE04AA98X and RJ09AA41SN1HN00

KT01SE98X1 Low-RPM Seal Kit (high-flow pump models only)

Output speed ≤ 20,000-RPM

275-PSI (19-bar) reverse pressure capability

Contains SE04AA98X and RJ09AK16SN1HN00

KT01SE99X High-RPM Seal Kit

Output speed ˃ 20,000-RPM

150-PSI (10.3-bar) reverse pressure capability

Contains SE04AA99X and RJ09AA41SN1HN00

The ‘X’ suffix character corresponds to o-ring material type:

SUFFIX CHARACTER O-RING MATERIAL

A Fluorocarbon

B Nitrile

C Perfluoroelastomer

D Fluorocarbon, Low Temp

The four o-ring material options made available accommodate most Process

compositions. Sundyne does not make o-ring material recommendations. Material

selection is based on knowledge of the Process fluid/gas chemical composition and is

the responsibility of the end-user.

Nitrile and Perfluoroelastomer option selections should also consider utilization of a

chemical barrier gasket between the seal housing and lower gearbox housing. Contact

the factory for more information and hardware sourcing.

www.sundyne.com Questions? Call 303-425-0800 or email service@sundyne.com ISO 3004 Rev I

Title: Output Shaft Seal Kit for Sundyne Gearboxes Rev: B

Bulletin No. 40.20.56 Page 2 of 3

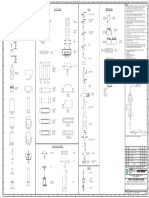

APPLICATION OUTPUT SPEED OUTPUT SPEED

MODEL

TYPE ≤ 20,000 RPM ˃ 20,000 RPM

311 / 312 / 316 KT01SE98X0 KT01SE99X

321 / 322 KT01SE98X0 N/A

High Flow:

KT01SE98X1 N/A

PUMP 313 / 333

331 / 336

KT01SE98X0 KT01SE99X

331N / 336N

High Flow:

KT01SE98X1 N/A

338

COMPRESSOR 31X / 33X / 34X KT01SE98X0 KT01SE99X

UNIQUE

LMG-330L KT01SE98X0 N/A

CONFIGURATION

The KT01SE9XX seal kit offers an average 2:1 reduction in leakage over existing

SE04AA53X and similar type aftermarket seals while also providing reverse

pressure capability to protect the gearbox from process upset conditions.

The allowable leakage rate for each seal kit is ½ pint (8-oz) per week.

The seal kits are 100% retrofitable with existing hardware and components.

No substitute mating ring should be used with the SE04AA9XX stationary seal;

the RJ09AXXXSN1HN00 mating ring must be utilized.

Mating ring flatness is factory certified.

Repair kits are available for field maintenance. Used mating rings cannot be lapped

and require replacement. Each repair kit includes one mating ring assembly and all

parts necessary to rebuild the stationary seal.

RK01SE98X0 Low-RPM Seal Repair Kit

RK01SE98X1 Low-RPM Seal Repair Kit (high-flow pump models only)

RK01SE99X High-RPM Seal Repair Kit

www.sundyne.com Questions? Call 303-425-0800 or email service@sundyne.com ISO 3004 Rev I

Title: Output Shaft Seal Kit for Sundyne Gearboxes Rev: B

Bulletin No. 40.20.56 Page 3 of 3

Installation Notes

1) After shipping and handling, and prior to assembly, always verify that the

stationary seal is seated within the retainer properly.

INCORRECT CORRECT

2) If the stationary seal face

washer needs adjustment, apply

light hand pressure to the outer

area of the washer: cycle up and

down (limited to about .125-inch

or 3.175-mm) to reposition

correctly.

3) The mating ring side with the large inside diameter chamfer should be placed

against the output shaft shoulder.

CHAMFER

TOWARDS TOWARDS

SHAFT STATIONARY

SHOULDER SEAL FACE

4) The stationary seal face and mating ring face should be cleaned with Isopropyl

Alcohol to remove any debris, film, or fingerprints that may be present.

5) Assemble the seal faces dry; no lubricant should be applied during installation.

www.sundyne.com Questions? Call 303-425-0800 or email service@sundyne.com ISO 3004 Rev I

You might also like

- HKS Manual GT86 BRZ SuperchargerDocument41 pagesHKS Manual GT86 BRZ SuperchargerAntonino AlduinaNo ratings yet

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- HKS V3 ManualDocument44 pagesHKS V3 ManualДмитрий СерочкинNo ratings yet

- SM-24 SM 175Document32 pagesSM-24 SM 175Raimundo GuevaraNo ratings yet

- 7.0 Reference: 7.1 Engine Room LayoutDocument3 pages7.0 Reference: 7.1 Engine Room LayoutCarlos MenaNo ratings yet

- Duratec 16v tTI-VCTDocument40 pagesDuratec 16v tTI-VCTStarsky UrblejoNo ratings yet

- 32 BrakeDocument63 pages32 BrakeTung NguyenNo ratings yet

- FS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service ManualDocument63 pagesFS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service Manualnik_nicholson_189% (18)

- Valves, Valve Springs, Valve Rotocoils, and LocksDocument55 pagesValves, Valve Springs, Valve Rotocoils, and Locksbetoven8437No ratings yet

- G300 Brake BleederDocument7 pagesG300 Brake BleederluisNo ratings yet

- SEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series EnginesDocument19 pagesSEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series Enginesyahmanmahira4No ratings yet

- Lexus - GS300 - GS430 - Service - Manual 15Document38 pagesLexus - GS300 - GS430 - Service - Manual 15seregap84100% (2)

- Maytag Triple Lip and Bearing Kit Installation InstructionsDocument8 pagesMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManNo ratings yet

- Milton Roy Metering Pumps PL1999Document4 pagesMilton Roy Metering Pumps PL1999Alfredo Anzures EearnNo ratings yet

- Air Hydrilic PumpDocument6 pagesAir Hydrilic Pumpcampa150No ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- CO2 AnsulDocument17 pagesCO2 AnsulJorge RVNo ratings yet

- Stanadyne 05001Document4 pagesStanadyne 05001José O TelloNo ratings yet

- Tra 026Document7 pagesTra 026Trọng Nghĩa VõNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- LOCOPUMP S2 User ManualDocument9 pagesLOCOPUMP S2 User ManualAngelica DragulescuNo ratings yet

- Gas Pressure Regulator RMG 512: Operation and Maintenance, Spare PartsDocument20 pagesGas Pressure Regulator RMG 512: Operation and Maintenance, Spare PartsPop IonutNo ratings yet

- Corolla LE Sedan RepairDocument17 pagesCorolla LE Sedan RepairmaximlevNo ratings yet

- Service Manual for Caterpillar 3304 and 3306 Industrial & Marine EnginesDocument827 pagesService Manual for Caterpillar 3304 and 3306 Industrial & Marine Enginesruss mathis100% (35)

- 1200stxr FP ManualDocument12 pages1200stxr FP ManualJonathan RauloNo ratings yet

- Perrin High Pressure Valves For Hydrogen ServiceDocument12 pagesPerrin High Pressure Valves For Hydrogen ServiceKunming Wang100% (1)

- Assembly: Engine (Engine - 2.0L Ecoboost (177Kw/240Ps) - Mi4)Document20 pagesAssembly: Engine (Engine - 2.0L Ecoboost (177Kw/240Ps) - Mi4)Bartłomiej StępieńNo ratings yet

- Pneumatic Drill: Cs UnitecDocument8 pagesPneumatic Drill: Cs UnitecMarniel EspinozaNo ratings yet

- Lc320dxj Sfe1 LGDocument8 pagesLc320dxj Sfe1 LGdreamyson1983No ratings yet

- Dokumen - Tips Dv200 Manual Master1Document45 pagesDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezNo ratings yet

- 0 17 018 PDFDocument42 pages0 17 018 PDFjoekid12No ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- CK313 CVT P2757 Valve Body Replacement: T-SB-0150-16 Rev1 October 20, 2016Document12 pagesCK313 CVT P2757 Valve Body Replacement: T-SB-0150-16 Rev1 October 20, 2016Gearauto Power50% (2)

- Actuator DX PDFDocument6 pagesActuator DX PDFFelix Enrique MoratayaNo ratings yet

- Service Bulletin: Safety Recall: 2015-16 CR-V Replacement Engine Short Block Out of SpecificationDocument4 pagesService Bulletin: Safety Recall: 2015-16 CR-V Replacement Engine Short Block Out of SpecificationOscar GonzálezNo ratings yet

- ZZ - 1209039169 - CPC MkII Rev 0Document12 pagesZZ - 1209039169 - CPC MkII Rev 0hopkhtnNo ratings yet

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVONo ratings yet

- Precise Spindle ManualDocument17 pagesPrecise Spindle Manualmarkp8767No ratings yet

- Yamaha XTZ750 Super Tenere Service ManualDocument425 pagesYamaha XTZ750 Super Tenere Service ManualDhery Prieto Barrientos100% (2)

- Service Bulletin: Air-Operated Clutch Assist System - Adjustment, Troubleshooting and Retrofit InstructionsDocument21 pagesService Bulletin: Air-Operated Clutch Assist System - Adjustment, Troubleshooting and Retrofit Instructionshamilton miranda100% (2)

- 05000Document4 pages05000José O TelloNo ratings yet

- Timing Chain - 2003 Toyota Camry Sedan l4-2Document10 pagesTiming Chain - 2003 Toyota Camry Sedan l4-2ftafedeNo ratings yet

- Sure Cure Kit: Chrysler 41TE (A604), 42LE (A606)Document10 pagesSure Cure Kit: Chrysler 41TE (A604), 42LE (A606)carloaex23No ratings yet

- John Deere CT322 Compact Track Loader Service Repair Manual (TM2152)Document17 pagesJohn Deere CT322 Compact Track Loader Service Repair Manual (TM2152)laopaodunNo ratings yet

- Chapter 18 BrakeSystemsDocument7 pagesChapter 18 BrakeSystemsMark Evan SalutinNo ratings yet

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 pagesOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonNo ratings yet

- Scotch-Yoke Pneumatic Actuator Instruction ManualDocument24 pagesScotch-Yoke Pneumatic Actuator Instruction ManualJunior CostaNo ratings yet

- 2006 Dirt Jam Pro SLDocument24 pages2006 Dirt Jam Pro SLBence BadarNo ratings yet

- Camisa de CilindroDocument16 pagesCamisa de CilindroFelipe CarranzaNo ratings yet

- SC 41te inDocument10 pagesSC 41te inBrad FrancNo ratings yet

- LO 9 2320 272 12 Lube Order 1990Document35 pagesLO 9 2320 272 12 Lube Order 1990DCMAT DjiboutiNo ratings yet

- Nissan Sentra Timing Chain ServiceDocument14 pagesNissan Sentra Timing Chain ServiceShahebaz WandrickNo ratings yet

- SYSTEM #17133: Installation Instructions ForDocument3 pagesSYSTEM #17133: Installation Instructions ForAlfonso JaureguiNo ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- SB 7-1-108Document6 pagesSB 7-1-108jussmeeeNo ratings yet

- Rs125 Race: De-Restrict An Aprilia Rs 125 2006 Euro 3Document9 pagesRs125 Race: De-Restrict An Aprilia Rs 125 2006 Euro 3Administrator100% (9)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Pump hmp3000 Gearbox Seal Improvement 40-20-02 Field Engineering BulletinDocument3 pagesPump hmp3000 Gearbox Seal Improvement 40-20-02 Field Engineering Bulletinjamil ahmedNo ratings yet

- Filter Select, SizingDocument5 pagesFilter Select, Sizingdj.amin07No ratings yet

- Sundyne Gearbox Reliability Upgrade KitDocument2 pagesSundyne Gearbox Reliability Upgrade Kitjamil ahmedNo ratings yet

- High Speed Integrally Geared Pumps API 610 Type OH6 Pumps Presented by Sandy Sutherland Sundyne PumpsDocument37 pagesHigh Speed Integrally Geared Pumps API 610 Type OH6 Pumps Presented by Sandy Sutherland Sundyne Pumpsjamil ahmedNo ratings yet

- Gearbox Casestudy-US 111015Document1 pageGearbox Casestudy-US 111015jamil ahmedNo ratings yet

- Pump 200 HP Gearbox Module Change 40-2-15 Sundyne Field Engineering BulletinDocument1 pagePump 200 HP Gearbox Module Change 40-2-15 Sundyne Field Engineering Bulletinjamil ahmedNo ratings yet

- Jog Starting Sundyne Pumps and CompressorsDocument2 pagesJog Starting Sundyne Pumps and Compressorsjamil ahmedNo ratings yet

- Pump Upgraded LMX BMX 33x Gearbox 40-20-25 Field Engineering BulletinDocument4 pagesPump Upgraded LMX BMX 33x Gearbox 40-20-25 Field Engineering Bulletinjamil ahmedNo ratings yet

- Improved Tapered Land Thrust Bearing 40-20-38 Field Engineering BulletinDocument2 pagesImproved Tapered Land Thrust Bearing 40-20-38 Field Engineering Bulletinjamil ahmedNo ratings yet

- Sundyne Gearbox Lubricant UpdateDocument2 pagesSundyne Gearbox Lubricant Updatejamil ahmedNo ratings yet

- Gearbox Phoenix 2 Upgrade Sundyne 40-20-26 Field Engineering BulletinDocument4 pagesGearbox Phoenix 2 Upgrade Sundyne 40-20-26 Field Engineering Bulletinjamil ahmedNo ratings yet

- Field Engineering Bulletin: Long-Term Storage and Protection of Sundyne Pumps and CompressorsDocument8 pagesField Engineering Bulletin: Long-Term Storage and Protection of Sundyne Pumps and CompressorsJoshua McAlisterNo ratings yet

- Gearbox Low Foam Sight Glass Sundyne 40-20-35 Field Engineering BulletinDocument1 pageGearbox Low Foam Sight Glass Sundyne 40-20-35 Field Engineering Bulletinjamil ahmedNo ratings yet

- Gearbox Alignment Bolt Change 40-20-42 Sundyne Field Engineering BulletinDocument2 pagesGearbox Alignment Bolt Change 40-20-42 Sundyne Field Engineering Bulletinjamil ahmedNo ratings yet

- 40-20-64 Rev Orig New 34X Upgrade GearboxDocument2 pages40-20-64 Rev Orig New 34X Upgrade Gearboxjamil ahmedNo ratings yet

- PE PPBrochure - v1 - A4 - 110717Document8 pagesPE PPBrochure - v1 - A4 - 110717jamil ahmedNo ratings yet

- Offshore Brochure A4 052316 v2Document16 pagesOffshore Brochure A4 052316 v2jamil ahmedNo ratings yet

- Desicant Breather - Flyer - USDocument2 pagesDesicant Breather - Flyer - USjamil ahmedNo ratings yet

- Aftermarket Service Repair A4Document8 pagesAftermarket Service Repair A4jamil ahmedNo ratings yet

- LMV 803Lr Data Sheet US FinalDocument2 pagesLMV 803Lr Data Sheet US Finaljamil ahmedNo ratings yet

- 34X 550HP Gearbox US 052416Document4 pages34X 550HP Gearbox US 052416jamil ahmedNo ratings yet

- LMVBMP US v3 042616Document8 pagesLMVBMP US v3 042616jamil ahmedNo ratings yet

- Sundyne Gearbox Reliability Upgrade KitDocument2 pagesSundyne Gearbox Reliability Upgrade Kitjamil ahmedNo ratings yet

- Unit 1 Vehicle Components - BackDocument20 pagesUnit 1 Vehicle Components - BackCarlos CabreraNo ratings yet

- 68RFE Transmission Relearn ProcedureDocument17 pages68RFE Transmission Relearn ProcedureStewart Firearms100% (1)

- Brochure - 2017.07 Sacindo Master BrochureDocument2 pagesBrochure - 2017.07 Sacindo Master BrochureRizkiRamadhanNo ratings yet

- ClistDocument4 pagesClist23174 ThenabaduNo ratings yet

- 4650 and 4850 Section 55Document100 pages4650 and 4850 Section 55josephmw0308No ratings yet

- Durant Catalog 2011Document56 pagesDurant Catalog 2011impwrcNo ratings yet

- Multi-purpose diesel additiveDocument2 pagesMulti-purpose diesel additivekrupa krupaNo ratings yet

- Ingersol Rand IOMDocument147 pagesIngersol Rand IOMCarlos PinnaNo ratings yet

- Caterpillar generator tappet clearance sequenceDocument1 pageCaterpillar generator tappet clearance sequenceMd Nazrul75% (4)

- Grundfos Fire Pump Solutions ExpertiseDocument16 pagesGrundfos Fire Pump Solutions ExpertiseRAFID SUHAILNo ratings yet

- Engine and Transaxle Configuration DiagramsDocument24 pagesEngine and Transaxle Configuration DiagramsSaHdo AbdelHamid100% (1)

- Ep 1083PMDocument40 pagesEp 1083PMMauricio Yamamoto PNo ratings yet

- PADO Overview NewDocument17 pagesPADO Overview NewNILESHNo ratings yet

- Off RoadDocument74 pagesOff Roadtom souzaNo ratings yet

- Air Conditioning System (Presentation 1)Document26 pagesAir Conditioning System (Presentation 1)dreamst4rNo ratings yet

- Turbine governor model data sheetsDocument13 pagesTurbine governor model data sheetskomiks0609No ratings yet

- RB PDFDocument13 pagesRB PDFBanksyNo ratings yet

- Legend Sheet P&ID For As-Built - Drafting On 20210722-1Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-1Ludi D. LunarNo ratings yet

- 16H Motor Grader ATS00001-UP (MACHINE) POWERED BY 3196 Engine (SEBP3329 - 89) - Círculo - InstalarDocument12 pages16H Motor Grader ATS00001-UP (MACHINE) POWERED BY 3196 Engine (SEBP3329 - 89) - Círculo - InstalarDouglas GomesNo ratings yet

- Hyster Spreader Parte Electrica PDFDocument47 pagesHyster Spreader Parte Electrica PDFFredy VelazquezNo ratings yet

- FIAT KOBELCO Ex255t Service Manual PDFDocument971 pagesFIAT KOBELCO Ex255t Service Manual PDFjony89% (18)

- Unit 2 IC Engine CyclesDocument12 pagesUnit 2 IC Engine CyclesFrezer BelayNo ratings yet

- Six Weeks Training Report DLWDocument20 pagesSix Weeks Training Report DLWvinaykumaryadav75% (4)

- Mechanical Advantage and EfficiencyDocument18 pagesMechanical Advantage and EfficiencyVinceeNo ratings yet

- VW Passat B6 parking brake components overview under 40 charsDocument7 pagesVW Passat B6 parking brake components overview under 40 charsPopa MihaiNo ratings yet

- Ar ManualDocument43 pagesAr ManualParamasivan. SNo ratings yet

- TR-100ML and TR-100M Rough Terrain Crane SpecificationsDocument12 pagesTR-100ML and TR-100M Rough Terrain Crane SpecificationsKirupa KaranNo ratings yet

- Repuestos TK30Document108 pagesRepuestos TK30Juan Esteban GiraldoNo ratings yet

- National Crane Series 1400H: Product GuideDocument12 pagesNational Crane Series 1400H: Product GuideTomas HernandezNo ratings yet

- Boiler & AuxiliaryDocument8 pagesBoiler & AuxiliaryOM PRAKASHNo ratings yet