Professional Documents

Culture Documents

Masonry 20chair 20report 20no. 20104 2011 34

Uploaded by

el000011Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masonry 20chair 20report 20no. 20104 2011 34

Uploaded by

el000011Copyright:

Available Formats

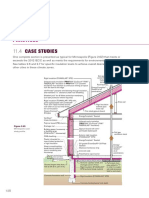

The visual results of Figures 15 to 21 illustrate that heat flows preferentially through

materials with lower thermal resistance, and that a continuous layer of insulation is much

more effective than a discontinuous one. It is readily observed that nearly all of the

temperature change occurs in the continuous insulation layer (i.e. there is a high

temperature gradient in the insulation layer). Without a continuous layer of insulation

there is a more gradual temperature change across the entire thickness of the wall.

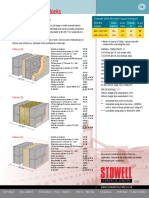

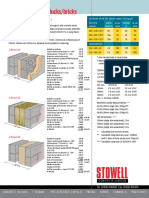

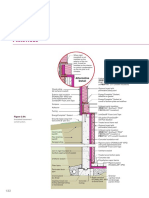

Table 10 presents recommended minimum thicknesses of application to make

single-wythe 190mm concrete masonry walls in Edmonton compliant with the NECB. A

plan view of a typical assembly is provided in Figure 22.

Figure 22 – Foam-insulated single-wythe concrete masonry

Table 10 – Insulation Configurations using POLY-MOR Polyurethane Foam to meet the

Requirements of the NECB 2011 for Single-Wythe Masonry Walls in Edmonton

Recommended

Overall Thermal

Insulating Minimum

Substrate Resistance

Procedure Thickness

(mm) (in) m2∙K/W hr∙ft2∙oF/BTU

Low-density foam

114 4½ 4.87 27.7

filled formwork

High-density foam

Above-ground wall 133 5¼ 4.78 27.1

filled formwork

Low-density spray

152 6 5.09 28.9

applied foam

Low-density foam

83 3¼ 3.58 20.3

filled formwork

High-density foam

Below-ground wall 102 4 3.69 20.9

filled formwork

Low-density spray

127 5 4.27 24.2

applied foam

30

You might also like

- PRICED (R) - FBC Finishing PackageDocument1 pagePRICED (R) - FBC Finishing PackagejatinNo ratings yet

- Aaaa 3Document1 pageAaaa 3ravi rajNo ratings yet

- SIRCONTEC Acoustic Floors: The Power of InnovationDocument24 pagesSIRCONTEC Acoustic Floors: The Power of Innovationالعربية للصناعةNo ratings yet

- Cost Study - ID Area Budget (Arch Finishing)Document7 pagesCost Study - ID Area Budget (Arch Finishing)najmi.maltonNo ratings yet

- BQ Estimate AssignmentDocument9 pagesBQ Estimate AssignmentKar chuen ChewNo ratings yet

- Residential Guide 部分140Document1 pageResidential Guide 部分140xinghaijunNo ratings yet

- Bill of QuantitiesDocument16 pagesBill of QuantitiesKay50% (2)

- Bitu-Impervi LMDocument2 pagesBitu-Impervi LMJoeNo ratings yet

- BoQ Local Clinic Additional BuidlingsDocument26 pagesBoQ Local Clinic Additional BuidlingsswazsurvNo ratings yet

- Esdros OfferDocument29 pagesEsdros Offerelias workuNo ratings yet

- PDF - Group 1 - SubstructureDocument4 pagesPDF - Group 1 - SubstructureSiti Aisyah IleyesNo ratings yet

- Knauf Fire & Moisture Resistant Gypsum Boards (FM)Document2 pagesKnauf Fire & Moisture Resistant Gypsum Boards (FM)Joe PsNo ratings yet

- Btrs System Technical Summary PDFDocument2 pagesBtrs System Technical Summary PDFpaulina7shiNo ratings yet

- Knauf Silentboard BrochureDocument8 pagesKnauf Silentboard Brochurefikadu mengistuNo ratings yet

- Recommended Vented Crawlspace Construction.: Rigid Insulation (FOAMULAR XPS)Document1 pageRecommended Vented Crawlspace Construction.: Rigid Insulation (FOAMULAR XPS)xinghaijunNo ratings yet

- Taking Off Internal Floor Finishes-Example (Updated200421)Document6 pagesTaking Off Internal Floor Finishes-Example (Updated200421)faizsyam01No ratings yet

- Rooftiles Western Slate Datasheet 201106Document2 pagesRooftiles Western Slate Datasheet 201106Radu BriaNo ratings yet

- DMC Floor Screed FS80Document2 pagesDMC Floor Screed FS80Engineer Gul ZamanNo ratings yet

- Proposed Hostel Bill of Quantities: Plain Concrete in Situ Concrete (Concrete Grade 10N/mm2) As Described inDocument20 pagesProposed Hostel Bill of Quantities: Plain Concrete in Situ Concrete (Concrete Grade 10N/mm2) As Described incobbymarkNo ratings yet

- BOQ Abiyot Phase 1 B+G+4 4BIDDERDocument5 pagesBOQ Abiyot Phase 1 B+G+4 4BIDDERKeire HussenNo ratings yet

- 18.10 Plywood Sheets Overview On The German MarketDocument8 pages18.10 Plywood Sheets Overview On The German MarketSameh AbboudNo ratings yet

- 8 FBS Foam Barrier SystemDocument2 pages8 FBS Foam Barrier SystemEduardo Antonio Duran SepulvedaNo ratings yet

- R ValuesDocument1 pageR Valuesnakie08No ratings yet

- Knauf Sheetrock Wetstop 9.5mm-12.5mm - Technical Datasheet - PB09 - LE - FL - 1022 - V1Document2 pagesKnauf Sheetrock Wetstop 9.5mm-12.5mm - Technical Datasheet - PB09 - LE - FL - 1022 - V1Matt WilliamsNo ratings yet

- A - Sub Structure: 1. Excavation & Earth WorkDocument8 pagesA - Sub Structure: 1. Excavation & Earth Workኢትዮጵያ የ 3ሺ አመት እመቤትNo ratings yet

- Name of Work: Rennovation of Roof in ICHR Building, Bangalore. SH:Provision For Replacing Mangalore Tiles and Wooden Planks and WaterproofingDocument21 pagesName of Work: Rennovation of Roof in ICHR Building, Bangalore. SH:Provision For Replacing Mangalore Tiles and Wooden Planks and WaterproofingManasNo ratings yet

- Arkitek PDFDocument1 pageArkitek PDFKamal LatifNo ratings yet

- Regular-Density Panel For Cost-Efficiency and Reliability: Commercial Roof FiberboardDocument2 pagesRegular-Density Panel For Cost-Efficiency and Reliability: Commercial Roof FiberboardNikola BoskovicNo ratings yet

- Typical Physical Properties of Vermiculite ConcreteDocument6 pagesTypical Physical Properties of Vermiculite ConcreteUmeshchandra PatilNo ratings yet

- Factory Produced Mortar For Internal PlasteringDocument4 pagesFactory Produced Mortar For Internal PlasteringJonathan Wang HSNo ratings yet

- Built-Up Roofing: Welding The PliesDocument53 pagesBuilt-Up Roofing: Welding The PliesPhoukham PHILAVONGNo ratings yet

- Rate ComparisonDocument3 pagesRate ComparisonUpendra SahuNo ratings yet

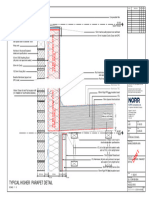

- Bbasn NRR A1 ZZ DR A 00309 Typical Higher Parapet DetailDocument1 pageBbasn NRR A1 ZZ DR A 00309 Typical Higher Parapet DetailNiemNo ratings yet

- The Advantages of "YTONG" AAC Block Over Traditional Concrete Block AreDocument2 pagesThe Advantages of "YTONG" AAC Block Over Traditional Concrete Block AretrickyggNo ratings yet

- Residential Guide 部分134Document1 pageResidential Guide 部分134xinghaijunNo ratings yet

- Cofraj Pierdut Din Material Plastic Minimodulo Catalog Eng 47072Document2 pagesCofraj Pierdut Din Material Plastic Minimodulo Catalog Eng 47072Anonymous eD1l6o9ZsWNo ratings yet

- 00 Flowcrete Uk Technical DataDocument2 pages00 Flowcrete Uk Technical DataCAITLIN AndrewNo ratings yet

- Standard: Robust, Durable, Dense Aggregate BlocksDocument3 pagesStandard: Robust, Durable, Dense Aggregate BlocksMohan BhalmeNo ratings yet

- 1c Dense Concrete Blocks 175nmm2Document1 page1c Dense Concrete Blocks 175nmm2AjdinNo ratings yet

- Pages From Painting Spec TenderDocument2 pagesPages From Painting Spec TenderkareemNo ratings yet

- Deviheat Floor ContructionsDocument7 pagesDeviheat Floor ContructionsMohammad MeekailNo ratings yet

- Fonostrip: Problem 1Document2 pagesFonostrip: Problem 1derdushaNo ratings yet

- Kaleab QuantityDocument32 pagesKaleab Quantitybiniyymail.comNo ratings yet

- Vermiculite Gypsum-PlastersDocument8 pagesVermiculite Gypsum-PlastersSiddhesh Kamat MhamaiNo ratings yet

- Floor Construction ProcessDocument7 pagesFloor Construction ProcessSonile JereNo ratings yet

- RBS EIFS e - BrochureDocument2 pagesRBS EIFS e - BrochureSudiptaNo ratings yet

- Site/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Store Construction A-Sub StructureDocument2 pagesSite/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Store Construction A-Sub Structurebiniyymail.com100% (1)

- Residential Guide 部分119Document1 pageResidential Guide 部分119xinghaijunNo ratings yet

- Sheetrock Firestop PB02 LE FL 0224 V4Document2 pagesSheetrock Firestop PB02 LE FL 0224 V4aisyaNo ratings yet

- Acoustic BasicsDocument14 pagesAcoustic BasicsgirishtiwaskarNo ratings yet

- Injection Molding: Design GuidelinesDocument4 pagesInjection Molding: Design GuidelinesAaselNo ratings yet

- iNJECTION mOLDING5-5Document5 pagesiNJECTION mOLDING5-5AaselNo ratings yet

- Conference HallDocument13 pagesConference HallPrerana ManjunathNo ratings yet

- Brushbond TI FlexicoatDocument2 pagesBrushbond TI Flexicoataneesh kapaNo ratings yet

- Concrete Midi BlocksDocument1 pageConcrete Midi BlocksAjdinNo ratings yet

- Residential Guide 部分138Document1 pageResidential Guide 部分138xinghaijunNo ratings yet

- Lightweight Concrete 16 PagesDocument16 pagesLightweight Concrete 16 Pageschris lee50% (2)

- Invoice Iphone XRDocument6 pagesInvoice Iphone XRANNA LEENo ratings yet

- Boq-Rehabilition of Football Stadium and New ConstructionDocument12 pagesBoq-Rehabilition of Football Stadium and New ConstructionAcharya Madridista SunilNo ratings yet

- Internship RHDHV Toprint-8Document5 pagesInternship RHDHV Toprint-8el000011No ratings yet

- Masonry 20chair 20report 20no. 20104 2011 40Document1 pageMasonry 20chair 20report 20no. 20104 2011 40el000011No ratings yet

- Designing An Anaerobic DigesterDocument2 pagesDesigning An Anaerobic Digesterel000011No ratings yet

- Internship RHDHV Toprint-6Document9 pagesInternship RHDHV Toprint-6el000011No ratings yet

- Internship RHDHV Toprint-5Document9 pagesInternship RHDHV Toprint-5el000011No ratings yet

- Masonry 20chair 20report 20no. 20104 2011 36Document1 pageMasonry 20chair 20report 20no. 20104 2011 36el000011No ratings yet

- Pushover Analysis of Jacket Structure in Offshore Platform Subjected To Earthquake With 800 Years Return PeriodDocument10 pagesPushover Analysis of Jacket Structure in Offshore Platform Subjected To Earthquake With 800 Years Return Periodel000011No ratings yet

- Vibration Serviceability of Long-Span Concrete BuiDocument74 pagesVibration Serviceability of Long-Span Concrete Buiel000011No ratings yet

- Thesis JanJermanDocument106 pagesThesis JanJermanel000011No ratings yet

- Merchant-Rankine Approach For The Design of SteelDocument24 pagesMerchant-Rankine Approach For The Design of Steelel000011No ratings yet

- Lateral Stability of Prestressed Precast Concrete Girders During Lifting: Study CaseDocument9 pagesLateral Stability of Prestressed Precast Concrete Girders During Lifting: Study Caseel000011No ratings yet

- Some Research Perspectives in Galloping Phenomena: Critical Conditions and Post-Critical BehaviorDocument28 pagesSome Research Perspectives in Galloping Phenomena: Critical Conditions and Post-Critical Behaviorel000011No ratings yet

- 1992 Concrete Structures, Instructions, 2016Document35 pages1992 Concrete Structures, Instructions, 2016Patrik AlfredssonNo ratings yet

- 2018 Combinedviscousanddryfrictiondampingof Oscillatorymotion RGDocument20 pages2018 Combinedviscousanddryfrictiondampingof Oscillatorymotion RGel000011No ratings yet

- Misconceptions and Generalizations of The Den Hartog Galloping CriterionDocument23 pagesMisconceptions and Generalizations of The Den Hartog Galloping Criterionel000011No ratings yet

- Numerical Study of The in Uence of Fishnet Mesh Size On A Floating PlatformDocument2 pagesNumerical Study of The in Uence of Fishnet Mesh Size On A Floating Platformel000011No ratings yet

- Jmse 08 00343 10Document2 pagesJmse 08 00343 10el000011No ratings yet

- Jmse 08 00343 9Document2 pagesJmse 08 00343 9el000011No ratings yet

- Flutter, Galloping, and Vortex-Induced Vibrations of H-Section HangersDocument10 pagesFlutter, Galloping, and Vortex-Induced Vibrations of H-Section Hangersel000011No ratings yet

- Jmse 08 00343 6Document2 pagesJmse 08 00343 6el000011No ratings yet

- 4.2. Time-Domain ResultsDocument2 pages4.2. Time-Domain Resultsel000011No ratings yet

- A X Z L L X X: 2. Description of The Numerical ModelDocument2 pagesA X Z L L X X: 2. Description of The Numerical Modelel000011No ratings yet

- Hand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF FreeDocument24 pagesHand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF Freeel000011No ratings yet

- Jmse 08 00343 5Document2 pagesJmse 08 00343 5el000011No ratings yet

- Jmse 08 00343 3Document2 pagesJmse 08 00343 3el000011No ratings yet

- 2.8. Wave Forces On The Body: J. Mar. Sci. Eng. 2020, 8, 343Document2 pages2.8. Wave Forces On The Body: J. Mar. Sci. Eng. 2020, 8, 343el000011No ratings yet

- Walrand1980 PDFDocument20 pagesWalrand1980 PDFel000011No ratings yet

- Jones1908 PDFDocument9 pagesJones1908 PDFel000011No ratings yet

- Walrand1980 PDFDocument20 pagesWalrand1980 PDFel000011No ratings yet

- June 2019Document64 pagesJune 2019Eric SantiagoNo ratings yet

- 2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetDocument2 pages2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetswainanjanNo ratings yet

- Invertec 200 260 400tDocument16 pagesInvertec 200 260 400tJxyz QwNo ratings yet

- What Is An Engineering Change OrderDocument3 pagesWhat Is An Engineering Change OrderKundan Kumar MishraNo ratings yet

- C50SCR PLC Complete ManualDocument286 pagesC50SCR PLC Complete ManualthuanNo ratings yet

- Drug Abuse - A Threat To Society, Essay SampleDocument3 pagesDrug Abuse - A Threat To Society, Essay SampleAnonymous o9FXBtQ6H50% (2)

- Toolbox Talks - Near Miss ReportingDocument1 pageToolbox Talks - Near Miss ReportinganaNo ratings yet

- Mental Health & TravelDocument18 pagesMental Health & TravelReyza HasnyNo ratings yet

- Executive SummaryDocument2 pagesExecutive Summarykulsoomalam100% (1)

- Technician's Instructions Estetica E30Document142 pagesTechnician's Instructions Estetica E30виктор100% (1)

- Reaction Paper On Water PollutionDocument1 pageReaction Paper On Water PollutionAztah KivycNo ratings yet

- MLT IMLT Content Guideline 6-14Document4 pagesMLT IMLT Content Guideline 6-14Arif ShaikhNo ratings yet

- Section-A: Terrace Ramp To Basement BalconiesDocument4 pagesSection-A: Terrace Ramp To Basement BalconiesRitikaNo ratings yet

- Pinch & Piston ValvesDocument8 pagesPinch & Piston ValvesJaldhij Patel100% (1)

- Senior Cohousing - Sherry Cummings, Nancy P. KropfDocument86 pagesSenior Cohousing - Sherry Cummings, Nancy P. KropfAnastasia JoannaNo ratings yet

- Economics Half Yearly Question PaperDocument6 pagesEconomics Half Yearly Question PaperBhumika MiglaniNo ratings yet

- Shawarma Refers To The Middle Eastern Method Cooking Where Thin Slices of MeatDocument3 pagesShawarma Refers To The Middle Eastern Method Cooking Where Thin Slices of MeatColai's BcdNo ratings yet

- Epilepsy 2 AAN 2018Document12 pagesEpilepsy 2 AAN 2018Eashaa KumarNo ratings yet

- VedasUktimAlA Sanskrit Hindi EnglishDocument47 pagesVedasUktimAlA Sanskrit Hindi EnglishAnantha Krishna K SNo ratings yet

- Review Dynamic Earth CoreScienceDocument3 pagesReview Dynamic Earth CoreScienceVikram BologaneshNo ratings yet

- 3M Window Film PR SeriesDocument3 pages3M Window Film PR SeriesPhan CrisNo ratings yet

- Biology Lab ReportDocument5 pagesBiology Lab Reportapi-2576094460% (1)

- Process of Reinstatement Value Fire PoliciesDocument1 pageProcess of Reinstatement Value Fire PoliciesvinaysekharNo ratings yet

- Week 4 (Theories)Document15 pagesWeek 4 (Theories)Erica Velasco100% (1)

- Mediclinic Weekly Progress Report No 29Document27 pagesMediclinic Weekly Progress Report No 29Julius Ceasar SanorjoNo ratings yet

- Amino AcidsDocument17 pagesAmino AcidsSiddharth Rohilla100% (2)

- DoveDocument11 pagesDovekattyperrysherryNo ratings yet

- SOP of Conveyor ReplacementDocument11 pagesSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- Canfield FairDocument3 pagesCanfield Fairapi-546463844No ratings yet

- Julie Trimarco: A Licensed Speech-Language PathologistDocument5 pagesJulie Trimarco: A Licensed Speech-Language PathologistJulie TrimarcoNo ratings yet