Professional Documents

Culture Documents

Maham

Uploaded by

Samman Khan0 ratings0% found this document useful (0 votes)

9 views5 pagescalibration

Original Title

maham

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcalibration

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views5 pagesMaham

Uploaded by

Samman Khancalibration

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

LAB REPORT # 2

BURDON TUBE APPARATUS

OBJECTIVE:

To measure high and low pressure and to calibrate them

For accurate readings.

APPARATUS:

1. Bourdon pressure guage

2. Weights

3. Bourdon guage

4. Weight support

5. Base plate

6. Plunger piston

7. Water

THEORY:

Pressure is define as the force act on a unit area.The

bourdon tube works on a simple principle that a bent tube will

change its shape when exposed to variations of internal and

external pressure. As pressure is applied internally ,the tube

straightens and return to its original form when the pressure is

released. A bourdon tube is used to measure pressure in a

system giving the user visual indication of the pressure level,

ensuring the amount of pressure does not exceed the maximum

level or stop too low. The weights that act and applies on a

water is equal to mass multiply the acceleration due to gravity.

W=mg

As pressure is force divided by area so in term of guage the

pressure will be shown as

P=mg/A

PROCEDURE:

1. Measure the weight of the calibration masses.

2. Note down the weight of the piston and it’s cross

sectional area.

3. Remove the piston and pour the water into the cylinder

until it is full to overflow level. Any air trapped in the

tube may be cleared by tilting and gently tapping the

apparatus.

4. Insert the piston carefully and spin it to minimize any

friction effects.

5. Note the pressure reading from the gauge.

6. Add the weights in convenient increments, and at each

increment, observe the pressure gauge reading.

7. Take the similar sets of readings with decreasing

weights.

8. Now determine the average pressure of increase

and decrease readings.

9. Now subtract the average pressure from applied At

pressure to get average error.

10. last multiply the average error with 100 and

divide the value with 200 to attain the error.

CALCULATION:

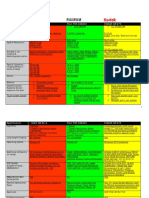

s. Mass Forc Applied Guage Average Error=

no e pressur Reading Error (Error*100)/

100

=mg e Average

Inc Dec Av

g

1 1kg 9.8 0.0311 30 30 30 29.9 14.95

2 2kg 19.6 0.0622 60 60 60 59.93 29.96

3 3kg 29.4 0.0933 90 95 92. 92.40 46.2

5

4 4kg 39.2 0.1244 120 100 110 110.37 55.25

.5

5 5kg 49 0.1555 155 125 140 139.84 69.93

.5

APPLICATIONS:

1. The bourdon tube is used in analog pressure meter.

2. It is used in many hydraulic systems.

3. It is used in foot pump to indicate pressure developed.

4. They are used to measure medium to very high pressure.

5. Measure high pressure in steam boilers,compressor etc.

6. Measuring pressure in vehicals tube tire.

PRECAUTIONS:

1. The distance between the pressure guage installation

and the measuring points should be as short as

possible to avoid slow indication.

2. The pressure guage should be installed perpendicular

to the horizontal.

3. Ensure the tightness,and there should be no leakage

especially for flammable and explosive gas media and

toxic and harmful media.

4. In order to ensure that the stainless steel pressure

guage is not affected by the corrosion of the measured

medium and crystallization.

5. At each step , gently rotate the piston to help prevent

the piston sticking and record the guage reading in the

increasing order

6. Reverse the procedure to reduce the weights and

record the pressure in decreases order.

You might also like

- Saet Work AnsDocument5 pagesSaet Work AnsSeanLejeeBajan89% (27)

- Report 7Document9 pagesReport 7Muizzuddin Saleh100% (4)

- Me Lab. Report 2Document12 pagesMe Lab. Report 2Henry Datangel100% (1)

- Calibration of Pressure GaugeDocument4 pagesCalibration of Pressure Gaugepammy313100% (1)

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNo ratings yet

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambweNo ratings yet

- Lea 4Document36 pagesLea 4Divina DugaoNo ratings yet

- LAB No. 08Document3 pagesLAB No. 08M. TahmanNo ratings yet

- Calibration of Bourdon GaugeDocument5 pagesCalibration of Bourdon GaugeShenal Perera0% (1)

- Pressure Gauge Calliberation ExperimentDocument17 pagesPressure Gauge Calliberation ExperimentTemitayo SolankeNo ratings yet

- Lab 1 HydraulicDocument12 pagesLab 1 HydraulicRuHuiNo ratings yet

- Calibration of Pressure GaugeDocument4 pagesCalibration of Pressure GaugeKrish Manglani40% (5)

- KKK 5 ExpDocument11 pagesKKK 5 ExpKhairil IkramNo ratings yet

- Experiment 1 Calibration of Bourdon GaugeDocument7 pagesExperiment 1 Calibration of Bourdon Gaugeنزار الدهاميNo ratings yet

- Calibration of Bourdon Gauge: Report TitleDocument10 pagesCalibration of Bourdon Gauge: Report Titlewlyan harkiNo ratings yet

- BioFluid Report 1Document6 pagesBioFluid Report 1Ahmed HusseinNo ratings yet

- Callibration of Pressure Gauge Lap ReportDocument11 pagesCallibration of Pressure Gauge Lap ReportEDISON OCHIENGNo ratings yet

- Dead Weight Calibrator I&C Exp 2Document7 pagesDead Weight Calibrator I&C Exp 2tabish miraj0% (1)

- 220s15 ExpB LabManualDocument5 pages220s15 ExpB LabManualMetu Ncc HaberlerNo ratings yet

- Calibration of A Bourdon Pressure GaugeDocument4 pagesCalibration of A Bourdon Pressure GaugesubyNo ratings yet

- Ex. - 2 Final ReportDocument13 pagesEx. - 2 Final ReportSaid Ahmed AliNo ratings yet

- Experiment 5 (Calibration of Pressure Measuring Devices - A4)Document17 pagesExperiment 5 (Calibration of Pressure Measuring Devices - A4)Jamiel Catapang100% (1)

- Calibration of A Pressure Gauge (GRP 7)Document7 pagesCalibration of A Pressure Gauge (GRP 7)Nene Kojo AddicoNo ratings yet

- Arcilla, Zoren - Me Lab1 - Exp4 - M4act5Document12 pagesArcilla, Zoren - Me Lab1 - Exp4 - M4act5dracarysNo ratings yet

- Technological University of The Philippines College of Engineering Department of Mechanical EngineeringDocument9 pagesTechnological University of The Philippines College of Engineering Department of Mechanical EngineeringJC VelarNo ratings yet

- PendulumlabDocument4 pagesPendulumlabapi-198081658No ratings yet

- Calibration of Pressure 1Document5 pagesCalibration of Pressure 1Amer Abo OmarNo ratings yet

- 5 - Pressure Measurment and CalibrationDocument10 pages5 - Pressure Measurment and CalibrationromasokyNo ratings yet

- LBYME2C Experiment1 OlegarioDocument10 pagesLBYME2C Experiment1 OlegarioBowie S. PascualNo ratings yet

- A Technical Report ON Centre of Pressure ONA Plane Surface ExperimentDocument13 pagesA Technical Report ON Centre of Pressure ONA Plane Surface ExperimentVictor OwolekeNo ratings yet

- تجربه السيطرهDocument12 pagesتجربه السيطرهMOHAMMED HADINo ratings yet

- Entc 303-Lab 2-Pressure Measurement and Gage Calibration-1Document10 pagesEntc 303-Lab 2-Pressure Measurement and Gage Calibration-1kabbirhossainNo ratings yet

- Pressure Measurement Part 1 of 3 PDFDocument13 pagesPressure Measurement Part 1 of 3 PDFSimanjuntak JulpianNo ratings yet

- Chapter - 5 - Pressure Measurements RCOEM PDFDocument76 pagesChapter - 5 - Pressure Measurements RCOEM PDFHarshvardhan RaiNo ratings yet

- Calibration of Pressure GaugeDocument3 pagesCalibration of Pressure Gauge047-Nidhi HingankarNo ratings yet

- Ex 1Document7 pagesEx 1yad AGNo ratings yet

- Calibration of Pressure GaugeDocument5 pagesCalibration of Pressure GaugeVarun SinghNo ratings yet

- Lab 3bcentre of Pressure Resultant Force On A Plane SurfaceDocument5 pagesLab 3bcentre of Pressure Resultant Force On A Plane SurfaceShehan FernandoNo ratings yet

- Experiment No 3 - Manometer Group 1Document4 pagesExperiment No 3 - Manometer Group 1Cayle MalitNo ratings yet

- Pressure GaugesDocument4 pagesPressure GaugesmuratsrkNo ratings yet

- Expt - No: Date: Dead Weight Pressure GaugeDocument2 pagesExpt - No: Date: Dead Weight Pressure GaugeMadhumathiNo ratings yet

- ME Lab 1 Exp 2 Calibration of Pressure Measuring Instrument PDFDocument6 pagesME Lab 1 Exp 2 Calibration of Pressure Measuring Instrument PDFJAMAL HALIBAYNo ratings yet

- Ce-271 Fluid Mechanics: Experiment No 05-Calibration of Bourdon GaugeDocument8 pagesCe-271 Fluid Mechanics: Experiment No 05-Calibration of Bourdon Gaugeuthman98No ratings yet

- Experiment No. 3Document12 pagesExperiment No. 3Lemuel Larin0% (1)

- Meng203 Exp 1Document5 pagesMeng203 Exp 1rainraingoNo ratings yet

- Experiment No 1: Objectives: ApparatusDocument7 pagesExperiment No 1: Objectives: ApparatusXodab21683No ratings yet

- Bermas EXP4 MELAB1Document18 pagesBermas EXP4 MELAB1Jed BermasNo ratings yet

- Hydraulics Micro-Project: Topic: Study of Pressure Measuring DevicesDocument18 pagesHydraulics Micro-Project: Topic: Study of Pressure Measuring DevicesGvanNo ratings yet

- Online Lab - Me Lab1 Expt 1 Bourdon Pressure GageDocument6 pagesOnline Lab - Me Lab1 Expt 1 Bourdon Pressure GageDessa GuditoNo ratings yet

- Experiment No: 1 Measurements of Pressure and Pressure Head by Piezometer, U-Tube ManometerDocument47 pagesExperiment No: 1 Measurements of Pressure and Pressure Head by Piezometer, U-Tube Manometerزياد الحربيNo ratings yet

- Dead Weight Tester KY SeiresDocument7 pagesDead Weight Tester KY SeiresIbnu HamdunNo ratings yet

- Calibration of A Bourdon Pressure GaugeDocument5 pagesCalibration of A Bourdon Pressure GaugeFaizaan EE14No ratings yet

- (Dead Weight Pressure Tester) : Group MembersDocument15 pages(Dead Weight Pressure Tester) : Group MembersDuniaku ComelNo ratings yet

- Pressure Measurement and CalibrationDocument7 pagesPressure Measurement and Calibrationjustdanish100% (1)

- Fundamentals of Pressure MeasurementDocument13 pagesFundamentals of Pressure Measurementmohammad. 21No ratings yet

- Pressure Gauge LabDocument10 pagesPressure Gauge LabSidharth TherrothNo ratings yet

- Calibration of Pressure GaugeDocument4 pagesCalibration of Pressure Gaugeyash ajay kashidNo ratings yet

- Experiment 2 Calibration of Bourdon Gauge: Asst - Lectuer: Mohammed Abid JameelDocument5 pagesExperiment 2 Calibration of Bourdon Gauge: Asst - Lectuer: Mohammed Abid JameelMohemen KhaledNo ratings yet

- Calibration of A Bourdon ManometerDocument5 pagesCalibration of A Bourdon ManometerMyat Thu HtetNo ratings yet

- MENG370L - Worksheets - Student Version - 2016-2017 - Protected PDFDocument42 pagesMENG370L - Worksheets - Student Version - 2016-2017 - Protected PDFMahdi GharibNo ratings yet

- Lecture 3 Pressure Measuring InstrumentsDocument47 pagesLecture 3 Pressure Measuring InstrumentsChristian Patrice100% (1)

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- CNC USB English ManualDocument31 pagesCNC USB English ManualHarold Hernan MuñozNo ratings yet

- CS321 Computer ArchitectureDocument160 pagesCS321 Computer ArchitectureAnurag kumarNo ratings yet

- ICSI-Admit-Card (1) - 230531 - 163936Document17 pagesICSI-Admit-Card (1) - 230531 - 163936SanjayNo ratings yet

- Multispan LC 2046 Length Counter PDFDocument2 pagesMultispan LC 2046 Length Counter PDFvinod kumarNo ratings yet

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamNo ratings yet

- Gender Ratio of TeachersDocument80 pagesGender Ratio of TeachersT SiddharthNo ratings yet

- Water Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Document160 pagesWater Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Aldrian PradanaNo ratings yet

- 4109 CPC For ExamDocument380 pages4109 CPC For ExamMMM-2012No ratings yet

- Ishares Core S&P/TSX Capped Composite Index Etf: Key FactsDocument2 pagesIshares Core S&P/TSX Capped Composite Index Etf: Key FactsChrisNo ratings yet

- Reflections On Free MarketDocument394 pagesReflections On Free MarketGRK MurtyNo ratings yet

- CI Principles of EconomicsDocument833 pagesCI Principles of EconomicsJamieNo ratings yet

- Functions of Commercial Banks: Primary and Secondary FunctionsDocument3 pagesFunctions of Commercial Banks: Primary and Secondary FunctionsPavan Kumar SuralaNo ratings yet

- G.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARDocument2 pagesG.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARTheodore DolarNo ratings yet

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNo ratings yet

- QA/QC Checklist - Installation of MDB Panel BoardsDocument6 pagesQA/QC Checklist - Installation of MDB Panel Boardsehtesham100% (1)

- Efs151 Parts ManualDocument78 pagesEfs151 Parts ManualRafael VanegasNo ratings yet

- 1934 PARIS AIRSHOW REPORT - Part1 PDFDocument11 pages1934 PARIS AIRSHOW REPORT - Part1 PDFstarsalingsoul8000No ratings yet

- Phase 1: API Lifecycle (2 Days)Document3 pagesPhase 1: API Lifecycle (2 Days)DevendraNo ratings yet

- Form16 2018 2019Document10 pagesForm16 2018 2019LogeshwaranNo ratings yet

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument25 pagesCondition Monitoring of Steam Turbines by Performance Analysisabuhurairaqazi100% (1)

- Profile On Sheep and Goat FarmDocument14 pagesProfile On Sheep and Goat FarmFikirie MogesNo ratings yet

- Basics: Define The Task of Having Braking System in A VehicleDocument27 pagesBasics: Define The Task of Having Braking System in A VehiclearupNo ratings yet

- COOKERY10 Q2W4 10p LATOJA SPTVEDocument10 pagesCOOKERY10 Q2W4 10p LATOJA SPTVECritt GogolinNo ratings yet

- Lactobacillus Acidophilus - Wikipedia, The Free EncyclopediaDocument5 pagesLactobacillus Acidophilus - Wikipedia, The Free Encyclopediahlkjhlkjhlhkj100% (1)

- Interruptions - 02.03.2023Document2 pagesInterruptions - 02.03.2023Jeff JeffNo ratings yet

- Experiment On Heat Transfer Through Fins Having Different NotchesDocument4 pagesExperiment On Heat Transfer Through Fins Having Different NotcheskrantiNo ratings yet