Professional Documents

Culture Documents

Axial Pin Connector

Uploaded by

dbaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axial Pin Connector

Uploaded by

dbaCopyright:

Available Formats

INTERNATIONAL DESIGN CONFERENCE - DESIGN 2002

Dubrovnik, May 14 - 17, 2002.

DESIGN OF AXIAL PIN CONNECTIONS FOR

TORQUE TRANSMISSION

H. Birkholz

Keywords: Shaft-Hub-Connection, Axial Pin, Calculation Methods,

Design

1. State of the Art

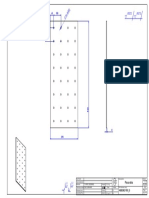

Axial pin connections consist of pins arranged axially around the perimeter as driving pins (Fig. 1).

The pins can be varied with respect to number and arrangement.

dS

da,N

dW

Figure 1. Longitudinal pin connection as driving pin in a shaft-hub-connection

There is no literature concerning the design of longitudinal pin connections with clearance

[Faulwasser 1998]. It appears feasible to use the data for no-clearance connections as reference point.

These design references are however few. The first dimensioning basis for the longitudinal pin

connections with clearance was developed at the Institut für Maschinenwesen within the framework of

a research project sponsored by the DFG.

2. Determination of Stress concentration factors

2.1 Stress concentration factors for Torsion

Due to the lack of knowledge concerning the form and fatigue strength of shafts and hubs weakened

by a semicircular notch in the axial direction [Kollmann 1984], the work here concentrates on the

determination of stress concentration factor diagrams for shafts and hubs with the help of the finite

element method. The highest notch stress determined using the FE calculation is divided by the

analytically calculated stress in the undisturbed cross-section:

maximum stress by FE - Analysis (1)

αK =

nominal stress, analytical

TECHNICAL SYSTEMS 1029

This methodology was carried out for the shaft and hub-sided notch for different types of stress and

variations in geometry:

• shaft: ratio of pin diameter to shaft diameter dS/dW; number of driving pins

• hub: ratio of outer hub diameter to shaft diameter da,N/dW at various dS/dW; number of driving

pins

The stress was determined both analytically and using the FEM for an unattenuated geometry in order

to clarify the mounting and load conditions. The chosen boundary conditions with reference to

[Wesolowski 1994] resulted in a maximum deviation of < 1 % from the analytical calculations, i.e. an

adequately high precision was guaranteed. The position of the pins was arranged so that the seam

radius between the shaft and hub runs through the central point of the pin. The parameter calculations

were then carried out using these boundary conditions. Figure 2 shows the stress concentration factor

diagram of the shaft for torsion.

3.3

1 pin

3.1 2 pins

stress concentration factor αkt

3 pins

2.9

4 pins

2.7 6 pins

8 pins

2.5 12 pins

2.3

2.1

1.9

1.7

1.5

0.1 0.125 0.1875 0.25 0.3125 0.35

ds/dw

Figure 2. Stress concentration factor for the shaft at various dS/dW ratios and n pins

For 8 and 12 pins, no meaningful geometry resulted for dS/dW > 0.25 or 0.1875 so that the stress

concentration factors could not be determined in this range. Equations for the analytical determination

of the stress concentration factors were then derived from the curves.

It should be mentioned that although the notch radius increases with the ratio dS/dW and therefore

reaches good values, an increase in the stress concentration factor results. This is due to the influence

of the reduced load-bearing cross-sectional area which outweighs that of the increased notch radius.

Figure 3 shows the stress concentration factors determined for the hub at a ratio of da,N/dW =2.

1.45

1 pin

stress concentration factor αkt

1.4 2 pins

1.35 3 pins

4 pins

1.3 6 pins

8 pins

1.25 max. stress

12 pins at hub notch

1.2

1.15

1.1 max. stress

outer perimeter

1.05

1

0.1 0.125 0.1875 0.25 0.3125 0.35

ds/dw

Figure 3. Stress concentration factor for the hub, da,N/dW = 2; various dS/dW ratios and n pins

The stress concentration factor diagram was also determined for the ratios da,N/dW = 1.5 and da,N/dW =

2.5. The further away a point in a hollow shaft is from the central axis, the greater the torsion stress at

this point. Therefore, the maximum stress must not necessarily occur in the internal notch. The

1030 TECHNICAL SYSTEMS

transitional range of maximum stress from the interior to the exterior is shown in Figure 3 in addition

to the course of the stress concentration factors. At a ratio of da,N/dW = 1.5, the maximum stress is

independent of the number of pins and the ratio dS/dW is always in the range of the notch. At a ratio of

da,N/dW = 2.5, the maximum stress occurs at the outer diameter.

2.2 Stress concentration factors for Bending

The stress concentration factor diagrams for the bending strain are formulated using a procedure

analogous to that for the determination of the stress concentration factors for torsion. Figure 4 shows

the stress concentration factor diagram for the shaft.

1.6

1 pin

2 pins

1.5 3 pins

stress concentration factor αkb

4 pins

6 pins

1.4

8 pins

12 pins

1.3

1.2

1.1

1

0.1 0.125 0.1875 0.25 0.3125 0.35

ds/dw

Figure 4. Bending stress concentration factor for the shaft for various dS/dW ratios and n pins

The interaction between the notch radius and the weakened cross section can also be observed for this

type of stress.

Figure 5 shows the bending stress concentration factor diagram for the hub with a ratio of

da,N/dW = 1.5.

1.3

1 pin

stress concentration factor αkb

2 pins

1.25

3 pins

4 pins

1.2 6 pins

8 pins

12 pins

1.15

1.1

1.05

1

0.1 0.125 0.1875 0.25 0.3125 0.35

ds/dw

Figure 5. Bending stress concentration factor for the hub, da,N/dW = 1.5; various dS/dW ratios and

n pins

The values for da,N/dW = 2 and da,N/dW = 2.5 lie clearly beneath those shown in Figure 5. Already at the

ratio da,N/dW = 2, the maximum stress concentration factors occurring lie at αkb = 1.07, so that the use

of a stress concentration factor αkb = 1.1 above a ratio of da,N/dW = 2 for a stability test represents a

conservative design.

3. Influence of the connection width on the load-bearing capacity

The few sources available give a ratio of connection length to shaft diameter l/dW of 1...1.5 as

approximate value for the dimensioning of a longitudinal pin connection [Niemann 1981] [Fronius

1987] [Wächter 1987]. However, extensive investigations of cog-shaft connections [Wesolowski

1997] show that at a ratio of l/dB > 0.6 (l: connection width, dB: reference diameter for spline shafts),

the maximum stress resulting from the jump in stiffness at the start of the connection cannot be

TECHNICAL SYSTEMS 1031

reduced. The maximum stress drops steeply in the axial direction (higher stress gradient) and then

flattens out to a low level until the end of the connection.

Since the geometry of a longitudinal pin connection suggests an analogy to a spline-shaft, the range

l/dW = 0.5...0.75 was examined more closely. Figure 6 shows the influence of the connection length

on the pin.

l=16mm

l/dw=0.5

l=20mm

l/dw=0.625

l=24mm

l/dw=0.75

shear stress τ

pin length

Figure 6. Influence of the connection width on stress for dS/dW = 0.125; dW = 32mm, 4 pins

A distinct influence of the connection length on the pin can clearly be seen. The shearing stress could

be reduced up to 16 % by using a longer connection. This supports the conclusion that a wider

connection reduces the stress of the entire connection.

Figure 7 shows the course of the equivalent stress in the notch base of the hub. A reduction of the

stress in the hub analogous and in the same order of magnitude as that in the shaft can be observed.

l/dw=0.5

l=16mm

l=20mm

l/dw=0.625

l=24mm

l/dw=0.75

equivalent stress

connection length

Figure 7. Influence of the connection width on the stress in the hub for dS/dW = 0.125,

dW = 32mm, 4 pins

Figure 8 shows the course of the equivalent stress for a shaft.

connection

border l/dw=0.

l=16mm

5l=20mm

l/dw=0.625

l=24mm

l/dw=0.7

5

equivalent stress

shaft length

Figure 8. Influence of the connection width on stress in the shaft for dS/dW = 0.125,

dW = 32mm, 4 pins

A change in the connection width has a significantly greater effect on the shaft than the pin and the

hub. A corresponding course of equivalent stress can be seen for all ratios l/dW in the undisturbed

section of the shaft, in other words before the beginning of the connection. A section with a distinct

1032 TECHNICAL SYSTEMS

stress increase is present at the beginning of the connection, which exhibits an increased value of 60%

opposed to the undisturbed section for the ratio l/dW =0.5. A widening of the connection leads to a

significant reduction of the overstress to 19%. At ratios above l/dW = 0.625, it must be observed that

no significant reduction in the overstressing occurs. Therefore, it can be recommended that a ratio of

the connection width to shaft diameter of l/dW = 0.6...0.7 should be maintained.

4. Influence of the pin diameter on the connection stress

A reduction of the shearing stress in the pin is to be expected due to the increase of the pin diameter

and the corresponding increase of the shearing area. This is clearly shown in Figure 9. The shearing

stress in the pin is significantly reduced.

ds/dw=0.12

4mm

5

6mm

ds/dw=0.1875

10mm

ds/dw=0.312

5

shear stress

pin length

Figure 9. Influence of the pin diameter on the pin stress. 4 pins, dW = 32; l/DW = 0.625;

da,N/dW = 2

The level of stress in the notch root is shown in Figure 10.

connection

equivalent stress

ds/dW = 0.125

ds/dW = 0.1875

ds/dW = 0.3125

shaft length

Figure 10. Influence of the pin diameter on the shaft stress. 4 pins, dW = 32; l/DW = 0.625;

da,N/dW = 2

Due to the increase in the pin diameter, the stress peak at the beginning of the connection is reduced

on the one hand and on the other, the cross-section of the shaft in simultaneously weakened causing

the stress before the contact to increase significantly. With a pin diameter of dS = 6 mm, which

corresponds to a ratio of dS/dW = 0.1875, the stress before and in the contact zone are almost equal for

a connection with 4 pins.

In contrast to the shaft, the equivalent stress in the hub sinks, whereby the changes are slight for a pin

diameter of 6 mm, Figure 11. An increase in the stress is to be expected for larger pin diameters dS>10

TECHNICAL SYSTEMS 1033

mm because the load-bearing cross-section is reduced.

dS/dW = 0.125

4mm

dS/dW = 0.1875

6mm

10mm

dS/dW = 0.3125

equivalent stress

connection length

Figure 11. Influence of the pin diameter on the hub stress. 4 pins, dW = 32; l/DW = 0.625;

da,N/dW = 2

5. Conclusion

Extensive parameter studies lead to the development of stress concentration factor diagrams for the

shaft and hub for the torsion and bending stress for a shaft-hub connection with axially arranged pins.

The influence of the different geometry variations could clearly be seen when the entire longitudinal

pin connection system is taken into consideration. A protrusion of the pin at the beginning of the

connection reduces the stress in the pin and shaft, the influence on the hub is only slight. The

advantage over other stress-reducing measures, such as increasing the number of pins or the pin

diameter, lies in the fact that neither the shaft nor the hub are weakened through a higher notch effect

or that the manufacturing expenditure increases through additional notches and pins.

References

Faulwasser, M.: Beanspruchungsverhalten drehmomentbelasteter Längsstiftverbindungen. unveröffentlichte

Studienarbeit, IMW, TU Clausthal, 1998

Kollmann, F.G.: Welle-Nabe-Verbindungen. Springer-Verlag, Berlin, Heidelberg u.a., 1984

Niemann, G.: Maschinenelemente. Erster Band: Konstruktion und Berechnung von Verbindungen, Lagern,

Wellen. 2. Auflage Berlin, Heidelberg, New York: Springer 1981

Fronius, St.: Taschenbuch Maschinenbau in acht Bänden. Dritter Band: Maschinenelemente, Getriebe,

Mechanismen, Hydrostatische und pneumatische Antriebe, Elektrische Antriebe. Berlin. Verlag Technik 1987

Wächter, K.: Konstruktionslehre für Maschineningenieure. Grundlagen, Konstruktions- und Antriebselemente.

Berlin: Verlag Technik 1987

Wesolowski, K.: Dreidimensionale Beanspruchungszustände und Festigkeitsnachweis drehmomentbelasteter

Zahnwellen-Verbindungen unter elastischer und teilplastischer Verformung. Düsseldorf: VDI Verlag 1997

Wesolowski, K.: Ausnutzung von Symmetrieebenen zur Berechnung drehmomentbeanspruchter Bauteile.

Mitteilungen aus dem Institut für Maschinenwesen Nr. 19; Clausthal 1994

Dipl.-Ing. Hagen Birkholz

Institut für Maschinenwesen der TU Clausthal

Robert-Kochstr. 32, 38678 Clausthal-Zellerfeld, Germany

Tel.: +49/5323/72-2683

Fax: +49-5323-723501

Email: birkholz@imw.tu-clausthal.de

1034 TECHNICAL SYSTEMS

You might also like

- Strength of Materials: Theory and ExamplesFrom EverandStrength of Materials: Theory and ExamplesRating: 4 out of 5 stars4/5 (14)

- Hopper Design Report 1 Calculation ManualDocument19 pagesHopper Design Report 1 Calculation ManualHaziq SulaimanNo ratings yet

- Watts - Stresses in A Pressure Vessel With A Conical HeadDocument13 pagesWatts - Stresses in A Pressure Vessel With A Conical Headm5416100% (2)

- Drilled Glass BearingDocument11 pagesDrilled Glass BearingRichard GreenNo ratings yet

- Simple Calculations For Cable PullingDocument5 pagesSimple Calculations For Cable PullingMena Balan SerbuNo ratings yet

- PHYS194 Report 3Document4 pagesPHYS194 Report 3AbdulNo ratings yet

- 23.contact Stress Analysis of Shrink-Fitted Joints For Various Fit Forms Via Finite Element MethodDocument9 pages23.contact Stress Analysis of Shrink-Fitted Joints For Various Fit Forms Via Finite Element MethodParag NaikNo ratings yet

- VDI 3400 Surface Finish Grade Definition PDFDocument1 pageVDI 3400 Surface Finish Grade Definition PDFdbaNo ratings yet

- Stress Concentration Factors For Snap-Ring Grooves in TensionDocument7 pagesStress Concentration Factors For Snap-Ring Grooves in TensionadamtuongNo ratings yet

- Jayaram: Hand Book For Piping Stress AnalysisDocument59 pagesJayaram: Hand Book For Piping Stress AnalysisMohan KumarNo ratings yet

- Compression 1 1 PDFDocument57 pagesCompression 1 1 PDFrahimi mohamadNo ratings yet

- Material Model:: Neoprene 40Document9 pagesMaterial Model:: Neoprene 40pradeshkumarsngcNo ratings yet

- ME463 Plate No.6 AntoDocument14 pagesME463 Plate No.6 AntoEman Lampago AntoNo ratings yet

- Particularities of Single Shear Pin Joints Modeling For Msc/NastranDocument12 pagesParticularities of Single Shear Pin Joints Modeling For Msc/NastranThale1905No ratings yet

- WRC368Document33 pagesWRC368fahid masoodNo ratings yet

- Beam TheoryDocument13 pagesBeam TheoryRobby TriNo ratings yet

- Steelwise Strength and EngagementDocument3 pagesSteelwise Strength and EngagementGiri DharanNo ratings yet

- MH Stress ConcentrationsDocument6 pagesMH Stress ConcentrationstripsachinNo ratings yet

- Toe Rock Stability For Rubble Mound Breakwaters: N D H D HDocument13 pagesToe Rock Stability For Rubble Mound Breakwaters: N D H D HvanjadamjanovicNo ratings yet

- FinalDocument14 pagesFinalapi-443631703No ratings yet

- Idealization of T-Stub, Lower Beam Idealization of T-Stub, Upper BeamDocument5 pagesIdealization of T-Stub, Lower Beam Idealization of T-Stub, Upper BeambalaNo ratings yet

- Tensioner Nuts & Bolts We Make Thread Gauges Cold Forgings From ChinaDocument4 pagesTensioner Nuts & Bolts We Make Thread Gauges Cold Forgings From ChinamohanjatinderNo ratings yet

- Helical Spring DesignDocument7 pagesHelical Spring DesignsohamkoliNo ratings yet

- 92 The Principles of Naval Architecture Series: 3.13 Stress ConcentrationDocument19 pages92 The Principles of Naval Architecture Series: 3.13 Stress ConcentrationJuan SilvaNo ratings yet

- I Have Read The University's Guidance On Plagiarism, and Declare That The Submitted Work Is My Own Except Where Otherwise Indicated. NameDocument4 pagesI Have Read The University's Guidance On Plagiarism, and Declare That The Submitted Work Is My Own Except Where Otherwise Indicated. Nameரகுபதி குNo ratings yet

- Fatigue Examination Paper2Document9 pagesFatigue Examination Paper2hatimalhajNo ratings yet

- Swage Diameter ChartDocument3 pagesSwage Diameter ChartShariq KhanNo ratings yet

- Simplification of Least Work Solution To An Empirical Method For Prediction of Shear Lag Stress in Steel BDocument12 pagesSimplification of Least Work Solution To An Empirical Method For Prediction of Shear Lag Stress in Steel BChhay TengNo ratings yet

- Chapter2 Stress ConceptDocument11 pagesChapter2 Stress Conceptk.ghanemNo ratings yet

- CE 321 - Steel Design (Bolted and Riveted Connections)Document51 pagesCE 321 - Steel Design (Bolted and Riveted Connections)John Eduard GallegoNo ratings yet

- 1-3 Stress Strain RelationshipDocument11 pages1-3 Stress Strain RelationshipRonee PangilinanNo ratings yet

- Title: Modeling and Finite Element Analysis (Static Structural) of An Aluminium Alloy Shaft On ANSYS WorkbenchDocument12 pagesTitle: Modeling and Finite Element Analysis (Static Structural) of An Aluminium Alloy Shaft On ANSYS WorkbenchMuneeb AliNo ratings yet

- The Tension TestDocument8 pagesThe Tension TestAditya agrawalNo ratings yet

- 04 FractureDocument25 pages04 FractureMücahit YaylaNo ratings yet

- 2 - Introduction To Fem PDFDocument34 pages2 - Introduction To Fem PDFCarl AriffNo ratings yet

- GeoSS Event Seminar 26 Sep 2012 - SlidesDocument65 pagesGeoSS Event Seminar 26 Sep 2012 - SlidesfreezefreezeNo ratings yet

- Chapter 2 Tension MembersDocument8 pagesChapter 2 Tension MembersGamtesa EjetaNo ratings yet

- HTW-F61KB Series Liquid Flow SwitchDocument4 pagesHTW-F61KB Series Liquid Flow SwitchMohamed SaidNo ratings yet

- 03 Grippon DynaS+PDocument10 pages03 Grippon DynaS+PHammertalNo ratings yet

- Design of Springs: DR Andrei Lozzi Design IIA, MECH3460Document12 pagesDesign of Springs: DR Andrei Lozzi Design IIA, MECH3460KTMONo ratings yet

- STL261S Assignment 2 - 2022Document5 pagesSTL261S Assignment 2 - 2022SimphiweNo ratings yet

- Dos PPT 3Document33 pagesDos PPT 3Keerthana PNo ratings yet

- Wrc-Bull368 91Document38 pagesWrc-Bull368 91ochableNo ratings yet

- Hes B117-03 Flange NutsDocument5 pagesHes B117-03 Flange NutsPreetam KumarNo ratings yet

- Design of Knuckle JointDocument26 pagesDesign of Knuckle Jointvikasporwal2605100% (2)

- Design and Analysis of Knuckle Joint by Using Fea: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-4, ISSUE-6, 2017Document8 pagesDesign and Analysis of Knuckle Joint by Using Fea: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-4, ISSUE-6, 2017salehNo ratings yet

- Structural Bolts CatalogueDocument3 pagesStructural Bolts CatalogueTom CaineNo ratings yet

- Bolt CalculateDocument6 pagesBolt CalculateBahtiar YudhistiraNo ratings yet

- The Importance of Maximum Allowable Stem Torque in Valves: April 2019Document6 pagesThe Importance of Maximum Allowable Stem Torque in Valves: April 2019iJordanScribdNo ratings yet

- The Importance of Maximum Allowable Stem Torque in Valves: April 2019Document6 pagesThe Importance of Maximum Allowable Stem Torque in Valves: April 2019Gangsar DwikaNo ratings yet

- Elab 4 Buckling of StrutsDocument11 pagesElab 4 Buckling of StrutsKhairul NazmanNo ratings yet

- Fastener and Screw Torque DesignDocument6 pagesFastener and Screw Torque DesignjigneshNo ratings yet

- Andre Luison H00356032Document22 pagesAndre Luison H00356032jqwj1292No ratings yet

- Salak 2017Document12 pagesSalak 2017Paloma CortizoNo ratings yet

- Tony Vo September 13, 2018 Homework #2Document19 pagesTony Vo September 13, 2018 Homework #2Tony VoNo ratings yet

- Network Analysis: Minimum Spanning TreeDocument8 pagesNetwork Analysis: Minimum Spanning TreeRafiaNo ratings yet

- Stress & Deflection Analysis of Belleville SpringDocument47 pagesStress & Deflection Analysis of Belleville SpringPrihastyaWishnutamaNo ratings yet

- Question 01: Elastic and Crack Length A 0.2mm: Fig. 1.2: Mises and S22 PlotDocument7 pagesQuestion 01: Elastic and Crack Length A 0.2mm: Fig. 1.2: Mises and S22 PlotzishanNo ratings yet

- Engineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandEngineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4.5 out of 5 stars4.5/5 (3)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Merenje - USB Microscope - ShadowgraphDocument4 pagesMerenje - USB Microscope - ShadowgraphdbaNo ratings yet

- Ra3.2 Ra1.6: Napomena: Ostre Ivice Oboriti 0.5X45° Kolicina: 1 KomDocument1 pageRa3.2 Ra1.6: Napomena: Ostre Ivice Oboriti 0.5X45° Kolicina: 1 KomdbaNo ratings yet

- Oslonac Horizontalni: 1:20 Rev - 0 A3Document1 pageOslonac Horizontalni: 1:20 Rev - 0 A3dbaNo ratings yet

- Leveling ScrewsDocument1 pageLeveling ScrewsdbaNo ratings yet

- A000296 Rev - 0Document1 pageA000296 Rev - 0dbaNo ratings yet

- PlocaDocument1 pagePlocadbaNo ratings yet

- Iso 1207Document1 pageIso 1207dbaNo ratings yet

- Alati I Oruđa - Oštrač Burgija MAR-POL ... 2.2020 - ID 71004985 - KupujemProdajemDocument2 pagesAlati I Oruđa - Oštrač Burgija MAR-POL ... 2.2020 - ID 71004985 - KupujemProdajemdbaNo ratings yet

- CNC Duborez - Civiluk Za KljuceveDocument2 pagesCNC Duborez - Civiluk Za KljucevedbaNo ratings yet

- Elektronika I Komponente - Cekas Kantal.... 2020 - ID 100280604 - KupujemProdajemDocument2 pagesElektronika I Komponente - Cekas Kantal.... 2020 - ID 100280604 - KupujemProdajemdbaNo ratings yet

- AUTO Injection Molding Machine - 3D CAD Model Library - GrabCADDocument2 pagesAUTO Injection Molding Machine - 3D CAD Model Library - GrabCADdbaNo ratings yet

- Vericut 7.4.1 x86 x64 (16.10.2015, MULTILANG + RUS)Document4 pagesVericut 7.4.1 x86 x64 (16.10.2015, MULTILANG + RUS)dbaNo ratings yet

- A000478 REV - 1 - Sheet1Document1 pageA000478 REV - 1 - Sheet1dbaNo ratings yet

- Dvorište I Bašta - Mlin Za Jabuke Elekt... 0.2020 - ID 66174349 - KupujemProdajemDocument2 pagesDvorište I Bašta - Mlin Za Jabuke Elekt... 0.2020 - ID 66174349 - KupujemProdajemdbaNo ratings yet

- ENPEKS - Dimenzije KamionaDocument2 pagesENPEKS - Dimenzije KamionadbaNo ratings yet

- Design and Analysis With Numerical Method of Gantry Crane Main BeamDocument7 pagesDesign and Analysis With Numerical Method of Gantry Crane Main BeamdbaNo ratings yet

- Kolica HFSDocument1 pageKolica HFSdbaNo ratings yet

- Morse Taper Shank SocketsDocument1 pageMorse Taper Shank SocketsdbaNo ratings yet

- Pipe Span ChartDocument1 pagePipe Span ChartazamshafiqNo ratings yet

- Piping - Fitings HandbookDocument240 pagesPiping - Fitings HandbookzohirNo ratings yet

- GFRC Floating Concrete Hearth For Concrete Wood FiDocument11 pagesGFRC Floating Concrete Hearth For Concrete Wood FiJuliano. PQMNo ratings yet

- Poisson, Poisson-Gamma and Zero-Inflated Regression ModelsDocument43 pagesPoisson, Poisson-Gamma and Zero-Inflated Regression ModelszohrehNo ratings yet

- Industrial Training Sample Report of Last YearDocument42 pagesIndustrial Training Sample Report of Last YearKetan NikamNo ratings yet

- J-20 Stealth Fighter Design Balances Speed and Agility - Defense Content From Aviation WeekDocument9 pagesJ-20 Stealth Fighter Design Balances Speed and Agility - Defense Content From Aviation WeekMahesNo ratings yet

- Country Item Name Litre Quart Pint Nip 700 ML IndiaDocument17 pagesCountry Item Name Litre Quart Pint Nip 700 ML Indiajhol421No ratings yet

- ShimadzuDocument66 pagesShimadzueka_setyowati0No ratings yet

- WBMDocument90 pagesWBMMiguel RegisNo ratings yet

- AE240 Notes Early-Airfoil-Development-Handout-1Document5 pagesAE240 Notes Early-Airfoil-Development-Handout-1mohamedNo ratings yet

- Yamaha Tank Removal wr250rDocument2 pagesYamaha Tank Removal wr250rMotoc Mircea-RazvanNo ratings yet

- Le - 2 Sep. 2019: Reçuclt/Cih/IthDocument18 pagesLe - 2 Sep. 2019: Reçuclt/Cih/IthAlero ViteNo ratings yet

- PDS Syncade RADocument6 pagesPDS Syncade RAKeith userNo ratings yet

- 22.anaerobes (Part II)Document91 pages22.anaerobes (Part II)sigrid jaramilloNo ratings yet

- NUTRACEUTICALDocument8 pagesNUTRACEUTICALShubham GuptaNo ratings yet

- Measure Guide Air Cond DiagnosticsDocument70 pagesMeasure Guide Air Cond Diagnosticsayad60No ratings yet

- Modules With Available Quota - 2019!11!12 - 9amDocument7 pagesModules With Available Quota - 2019!11!12 - 9amdhmanoharNo ratings yet

- Tecnical Data TYPE 139 L12R / L16RDocument1 pageTecnical Data TYPE 139 L12R / L16RLada LabusNo ratings yet

- ER2 Manual 125kg 5t - 04Document144 pagesER2 Manual 125kg 5t - 04Muhammed ShamseerNo ratings yet

- Training Matrix Competency 4 Organic ConcoctionsDocument3 pagesTraining Matrix Competency 4 Organic ConcoctionsST. ISIDORE THE FARMERNo ratings yet

- NUMBERS 2 Percentage ChangeDocument2 pagesNUMBERS 2 Percentage ChangeDinangaNo ratings yet

- RfI SB Listening ScriptsDocument18 pagesRfI SB Listening ScriptsKate PolissyaNo ratings yet

- S800 SCL SR - 2CCC413009B0201 PDFDocument16 pagesS800 SCL SR - 2CCC413009B0201 PDFBalan PalaniappanNo ratings yet

- Un EinsteinDocument22 pagesUn Einsteinapi-26005027No ratings yet

- MAIN Electrical Parts List: Design LOC Sec-Code DescriptionDocument12 pagesMAIN Electrical Parts List: Design LOC Sec-Code DescriptionAndroid Schematics and CircuitsNo ratings yet

- Ground Power Unit: GA ModelDocument17 pagesGround Power Unit: GA ModelAngelica Nava0% (1)

- PT Activity 3.4.2: Troubleshooting A VLAN Implementation: Topology DiagramDocument3 pagesPT Activity 3.4.2: Troubleshooting A VLAN Implementation: Topology DiagramMatthew N Michelle BondocNo ratings yet

- DSP Lab RecordDocument97 pagesDSP Lab RecordLikhita UttamNo ratings yet

- Fra Assignment 1Document11 pagesFra Assignment 1Ruchi SambhariaNo ratings yet

- Acer Iconia Tab W500 Pegatron EAB00 SchematicsDocument60 pagesAcer Iconia Tab W500 Pegatron EAB00 SchematicsIIIkwarkaNo ratings yet