Professional Documents

Culture Documents

11a Vs300 Quick Guide en v2.10 Eag

Uploaded by

moh taCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11a Vs300 Quick Guide en v2.10 Eag

Uploaded by

moh taCopyright:

Available Formats

Quick Guide for VS 300 - Version V2.

10 Control keys Function in basic display mode

Function in parameter set

mode

- Reset messages - Cancel entry

- Delete message indication - Previous operating level

- Change to other control loop - Select parameters/parameter

8 CL1 active: (4) - Flashing lists

CL2 active: (5) - Flashing - Increase/decrease values

- Start parameter setting - Entering of parameters

(open parameter list selection) - Next operating level

9 On-off switch for external devices

1 Menu structure

1.1 Basic display mode

This Quick Guide does not replace the full User Guide for the VS 300. Legend: CL = Control loop

Make sure to read and observe the safety notes contained in the User Guide Controller switches to basic display mode (CL1 temperature displayed, left trend LED(s) flashing) on

before starting and working with this product!

power-up or if no entry is made for 5 minutes or when (repeatedly) pressing the key:

Display and LEDs Function

Reading of temperature [°C] / pressure [bar]:

Display: Shows actual values/setpoints, parameters,

1

compressor/condenser numbers or messages. Temperature: Reading to one decimal place e.g.: -20.5

Pressure: Reading to two decimal places e.g.: I I.50

2 Alarm/message LED (red): Flashes to alert to a message or fault Change to other In sensor break or short circuit, display shows - - -

control loop

Operating and status indicators for relay stages (green) When a message is generated, the message code (E00 I .. E246 ) is shown in the display

3 (4, 8 or 12 relay stages to show status of compressors/condensers (see Parameter list F )

assigned to control loops CL1 and CL2)

Press key to delete message indication.

Trend LEDs: Flashes to indicate control loop active in display:

Fault report is repeated after about 10 seconds if fault/message is still in effect.

⇒

Upper LED: Temperature/pressure above neutral zone Load

4/5 1.2 Selection of parameter lists

Both LEDs: Temperature/pressure within neutral zone

CL1 CL2 ⇒

⇒ 1. Press key in basic display mode:

Lower LED: Temperature/pressure below neutral zone

Unload ⇒

2. Scroll with keys to select the parameter list wanted

Status indicated when simultaneously pressing keys : A Actual Values ONLY display of actual values / change of access level

S1 Setpoints 1 Basic controller parameters

1. LED segment below/above symbol: 2. Relay stage indicators:

S2 Setpoints 2 Auxiliary controller parameters

Load shedding S3 Setpoints 3 System configuration

S4 Setpoints 4 Alarm priorities

2nd setpoint active

6/7 (Example) S5 Setpoints 5 Suction pressure shift / Additional Parameters

Heat recovery mode Timer setpoints Timers

Continuously lighted LEDs:

Fast unload Relay stages assigned to CL1 C Check mode Service mode: Manual actuation of outputs

CL1 CL2 Flashing LEDs: F Fault messages Process and system fault reports

Relay stages assigned to CL2

3. Press key to select the parameter list wanted.

4. Press key (repeatedly) to return to basic display mode.

© Eckelmann AG • Berliner Straße 161 • 65205 Wiesbaden www.eckelmann.de • elds-support@eckelmann.de

Technical modifications and errors reserved - version September 2017 - VS 300 - Parameter V2.10 Page 1 / 4

2 Startup – Main settings and parameters 4 First startup – Loading default settings

To load the default settings, simultaneously press and hold the , and keys during power-up.

1. Set CAN bus address on decade switch at rear (only on VS 300 with CAN bus module)

NOTE: A unique address MUST be assigned to each CAN bus station: 101..109 At first startup, the default settings for all parameters are loaded and all archives, messages

2. Set date and time and operating data (e.g. run times, starts, activity) are deleted!

(only on VS 300 without CAN bus module) See Parameter S280 .. S285

3. Configure controller See Parameter S390 5 Displaying fault messages

4. Set individual parameters

1. Basic display mode: Latest current message with message code (E00 I .. E246 ) / Alarm/message LED

- (Set control type for each CL) See Parameter S300 / S330 (CL1 / CL2) flashes:

- System configuration/relay stage assignment See Parameter S30 I / S33 I (CL1 / CL2)

⇒

- Set for LP/HP sensor characteristics See Parameter S308 - S309 / S338 - S339 (CL1 / CL2) Example: + Cancel display / Return to basic display mode.

- Configure 4 digital inputs See Parameter S360 .. S375 If no message is current at the time or if no fault is then in effect, pressing the key cancels the message

- Adjust setpoints See Parameter S I00 - S I02 / S II0 - S I I2 (CL1 / CL2) and deletes it from the fault memory.

5. Back up parameters See Parameter S392

2. Parameter List F (Message index/number in message memory):

3 Enabling setpoint adjustment - Parameter A060 ⇒ ⇒ ⇒ ⇒ ⇒

ONLY when message is current/not cancelled,

⇒

1. Press key in basic display mode: otherwise when no message present. By contrast with messages no longer

effective, display flashes for messages

⇒

2. Press key: that are still in effect!

⇒

3. Scroll with keys to select Parameter A060 : Change to previous messages (F002 .. max. F I00)

⇒ ⇒ ⇒

4. Press key to change to entry mode: Display flashes! Example: Message code (E00 I .. E246 - see Parameter List 7.1 - Message Code)

⇒ ⇒

5. Press key to select Parameter " I ": Display flashes! Example: View additional message details:

Message details are indicated by the Status LEDs of the relay stages (LED 1..12) for support.

0 = Display only (setpoint adjustment not enabled)

Example: Display shows day date (15) of time stamp in:

I = Setpoint adjustment enabled

I0 = Superuser mode (access additional parameters)

⇒

6. Press key to confirm entry

⇒

7. Press key:

⇒

8. Press key: Basic display mode

3.1 Actual value display and parameter setting - Parameter Lists A, S I - S5, and c

Setpoints are adjusted by the same pattern at every operating level. Example:

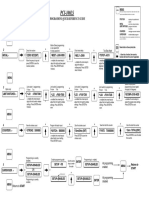

6 Example of system configuration with VS 300

⇒ ⇒ ⇒ e.g. ⇒

⇒ ⇒ ⇒ e.g. ⇒

⇒ ⇒ ⇒ ⇒

(e.g. current setpoint) Change value e.g.

⇒ ⇒

Apply new value Return to basic display mode

3.2 Parameter groups – Parameter index

Certain parameters contain a group of setpoints (e.g. separate enabling for each relay stage).

These parameters can be accessed under a parameter number. Example:

⇒ ⇒ ⇒ e.g. ⇒

⇒ ⇒ ⇒ e.g. ⇒ ⇒ ⇒

⇒ ⇒

Select relay number (0 I .. I2 ) 0 (Not enabled) I (Enabled)

⇒ ⇒

Apply new value Return to basic display mode

© Eckelmann AG • Berliner Straße 161 • 65205 Wiesbaden www.eckelmann.de • elds-support@eckelmann.de

Technical modifications and errors reserved - version September 2017 - VS 300 - Parameter V2.10 Page 1 / 4

7 VS 300 Parameter Lists (extract) - Version V2.10

7.1 Message code E 00 I .. E 246 - System and process fault alarms (see also - 6 Display of fault alarms)

CL1 / CL2 Description CL1 / CL2 Description

E004 .. E010 Intern fault alarms – Please contact service organization! E209 Low pressure in CL1 (LT1, NT1 or HP1)

… E210 Low pressure in CL2 (LT2, NT2 or HP2)

E050 First start with default parameters E211 Pressure sensor measuring loop fault in CL1

E051 Restart following power failure E212 Pressure sensor measuring loop fault in CL2

E180 Service mode active E222 No Load Level CL1

E181 Fast unload active in CL1/CL2 E223 No Load Level CL2

E182 Load shedding active in CL1/CL2 E224 No UA 300 found with refrigeration point control

E203 Parameters changed for pressure sensors E240 Setpoint adjusted

E207 High pressure in CL1 (LT1, NT1 or HP1) E241 Controller configuration changed

E208 High pressure in CL2 (LT2, NT2 or HP2) E243 .. E246 Digital alarm input 1..4 active

7.2 Parameter List A System data actual values

CL1 CL2 Description Limits Dim. Visible / Condition

A000 A010 Actual value Pressure bar All times

A001 A011 Setpoint Pressure Limits vary with controller bar

configuration and operating Parameter set for 1 stage in CL1: S301 >0

A002 A012 Actual value Temperature mode °C or

A003 A013 Parameter set for 1 stage in CL2: S331 >0

Setpoint Temperature °C

… …

7.3 Parameter List A System data common actual values

CL1 / CL2 Description Limits Dim. Visible / Condition

…

A030 .. A033 Status digital input E1..E4

0: Not activated

-

A034 .. A035 Status alarm output A1 and A2 1: Activated

…

All times

0: No setpoint adjustment

A060 Password entry, change of access level 1: Setpoint adjustment enabled -

10: Superuser mode

7.4 Parameter List S I Main setpoints

Day operation Night operation

CL1 CL2 Description CL1 CL2 Description Limits Dim. Visible / Condition

Parameter set for 1 stage in CL1: S301 >0

S100 S110 1st setpoint t S102 S112 2nd setpoint t -50..45 °C or

Parameter set for 1 stage in CL2: S331 >0

… … … …

7.5 Parameter List S2 Basic parameter setpoints

Day operation Night operation

CL1 CL2 Description CL1 CL2 Description Limits Dim. Visible / Condition

… … … …

S204 S244 Neutral zone 1st setpoint S214 S254 Neutral zone 2nd setpoint Parameter set for 1 stage in CL1: S301 >0

1..10 K or

S205 S245 Control constant 1st setpoint S215 S255 Control constant 2nd setpoint Parameter set for 1 stage in CL2: S331 >0

… … … …

7.6 Parameter List S2 Basic parameter setpoints – Day and night operation

RK1 RK2 Description Limits Dim. Visible / Condition

S220 S260 Basic load time

S221 S261 Variable load time

3..250 Sek.

S222 S262 Basic unload time

S223 S263 Variable unload time

S224 S264 High starts limiting 4..60 1/h

S225 Temperature t_max in CL1 for alarm "High pressure in CL1 (E207)" -30..55 °C

Temperature t_max in CL2 for alarm "High pressure in CL2 (E208)". Parameter set for 1 stage in CL1: S301 >0

S265 When high temperature disabling is enabled (S343=1), stages are disabled in CL1 -20..55 °C or

when temperature rises above this value. Parameter set for 1 stage in CL2: S331 >0

S226 Temperature in CL1 for resetting alarm "High pressure in CL1 (E207)"

Temperature in CL2 for resetting alarm "High pressure in CL2 (E208)". -35..48 °C

S266 When high temperature disabling is enabled (S343=1), stages in CL1 are re-enabled

when temperature drops below this value.

Temperature in CL1/CL2 below which alarm "Low pressure in CL1/CL2 (E209/E210)"

S227 S267 is generated. -50..20 °C

When low temperature disabling is enabled (S314=1 / S344=1), stages of CL1/CL2

are shed when temperature drops below this level (LP control only).

… …

S230 S270 Delay for alarm "Low pressure CL1/CL2"

0..60 Min.

S231 S271 Delay for alarm "High pressure CL1/CL2" Parameter set for 1 stage in CL1: S301 >0

S232 S272 5..720 oder --- Min. or

Cycle time for base load rotation

Parameter set for 1 stage in CL2: S331 >0

0: Fixed switching sequence

S233 S273 Switching mode 1: According to run times

… …

7.7 Parameter List S2 Common setpoints

CL1 / CL2 Description Limits Dim. Visible / Condition

S280 Current time Hour 0..23 Hour

S281 Current time Minute NOTE: Date and time can, and only need 0..59 Min.

S282 Current date Day to, be set in stand-alone operation! Date 1..31 Day

and time are taken over from time master

S283 Current date Month 1..12 Month All times

(CI 3000 / AL 300 ) when connected to

S284 Current date Year VS 300 via CAN bus module, in which 1900..2155 Year

case they cannot be changed.

0: No adjustment -

S285 Daylight saving time change adjustment

1: Adjustment enabled

…

© Eckelmann AG • Berliner Straße 161 • 65205 Wiesbaden www.eckelmann.de • elds-support@eckelmann.de

Technical modifications and errors reserved - version September 2017 - VS 300 - Parameter V2.10

page 3 / 4

7.8 Parameter List S3 System configuration setpoints

CL1 CL2 Description Limits Dim. Visible / Condition

0: Step control Parameter set for 1 stage in CL1: S301 >0

S300 S330 Control type 1: Speed control - or

2: Combined control Parameter set for 1 stage in CL2: S331 >0

S300/S330=0: 0 .. max -

S301 S331 No. of base load stages S300/S330=1: 1 or 2 All times

S300/S330=2: min. 2 .. max

S300/S330=0: 1..3 -

S302 S332 No. of capacity stages per base load stage S300/S330=1: = 1

S300/S330=2: = 1

S300/S330=0: 0..[S301 / S331] -

S303 S333 No of capacity-controlled base load stages S300/S330=1: = 0

S300/S330=2: = 0

S304.1.. S334.1.. Enable/disable relay stages 1 to max. 4/8/12 (depending on 0: Disabled 2: With 1 load stage

- Parameter set for 1 stage in CL1: S301 >0

S304.12 S334.12 configuration) 1: Enabled 3: With 2 load stages

or

S305 S335 No. of disabled relays on load shedding 0..3 - Parameter set for 1 stage in CL2: S331 >0

0=R22, 1=R502, 2=R134a, 3=R404A, 4=R402A, 5=R717, 6=R1270, 7=R507, 8=R407C,

Refrigerant 9=R410A, 10=R290, 11=R744, 12=R407F, 13=R422A, 14=R422D, 15=R408A, 16=R407D, -

S306 S336

type 17=R407A, 18=R427A, 19=R438A, 20=R152a, 21=R170, 22=R600, 23=R600a, 24=R449A,

25=R450A, 26=R448A, 27=R455A, 28=R447B, 29=R1234ze, 30=R1233zd, 31=R1234yf

S308 S338 Sensor parameter setting: Pressure at 4 mA 0,0..2,0 bar

S309 S339 Sensor parameter setting: Pressure at 20 mA 8,0..60,0 bar

… …

0: Disabled Parameter set for 1 stage in CL2: S331

S343 Enable high temperature disabling CL2 -

1: Enabled >0 and CL2 must be HP controller

Parameter set for 1 stage in CL1: S301

>0 and CL1 must not be HP controller

0: Disabled

S314 S344 Enable low temperature disabling CL1 / CL2 - or

1: Enabled

Parameter set for 1 stage in CL2: S331

>0 and CL2 must not be HP controller

… …

7.9 Parameter List S3 System configuration common setpoints

CL1 / CL2

E1 E2 E3 E4 Description Limits Dim. Visible / Condition

0: Off 4: Register alarm

1: Fast unload 5: Heat rec. mode

S360 S364 S368 S372 Function of digital input E1..E4 - All times

2: Load shedding 6: Safety loop

3: Setpoint toggle

0: To CL1 Parameter set for 1 stage in one of the

S361 S365 S369 S373 Assignment of digital input E1..E4 1: To CL2 - two control loops:

2: To both control loops S301 >0 or S331 >0

S362 S366 S370 S374 Polarity of digital input E1..E4 0: Low active 1: High active -

S363 S367 S371 S375 Alarm delay for digital input E1..E4 0..60 Sek. All times

S376 Number of internal alarm relay 0..2 -

…

7.10 Parameter List S3 System configuration common setpoints

CL1 / CL2 Description Limits Visible / Condition

Selection of controller configuration: 0: CL1=LT / CL2=LT 4: CL1=NT / CL2=HP

NT = Normal-temp. refrig. (Compressor control) 1: CL1=LT / CL2=NT 5: CL1=HP / CL2=HP

S390 Requires "Superuser Mode"

LT = Low-temp. refrig. (Compressor control) 2: CL1=LT / CL2=HP 6: CL1=NT / CL2=LT access rights

HP = High pressure (Fan control) 3: CL1=NT / CL2=NT

(Parameter A060 = 10)

…

S392 Parameter backup 0: No 1: Back up parameters

…

7.11 Parameter List S4 Alarm priority setpoints

CL1 / CL2 Description Limits Visible / Condition

S400 Alarm priority: High pressure CL1

S401 Alarm priority: High pressure CL2

S402 Alarm priority: Low pressure CL1

S403 Alarm priority: Low pressure CL2

S404 Alarm priority: Pressure measuring loop CL1

S405 Alarm priority: Pressure measuring loop CL2 -- : Alarm not registered

S409 Alarm priority: Service mode active 0: Only entered in message list

All times

S410 1: Alarm priority 1

Alarm priority: Load shedding

2: Alarm priority 2

S411 Alarm priority: Fast unload

…

S418 .. S421 Alarm priority. Digital input E1..E4

S422 Alarm priority: Sensor type change

…

S433 Internal error

7.12 Parameterliste S5 Suction pressure shift / Additional Parameters

CL1 CL2 Description Limits Visible / Condition

0: No shift -

S500 S550 Suction pressure shift mode CL1/CL2 1: Shift by refrigeration point Minimum of one stage must be

70..10 % defined in CL:

S501 S551 Maximum load level for to shift CL1/CL2

CL1: S301 > 0

S502 S552 Minimum load level for to shift CL1/CL2 10..60 % CL2: S331 > 0

Control loop must be low−pressure

S503 S553 Increment CL1/CL2 0,0..10,0 K

loop (LT or NT)

S504 S554 Time interval to shift CL1/CL2 1..20 Min.

Legend: CL = Control

© Eckelmann AG • Berliner Straße 161 • 65205 Wiesbaden www.eckelmann.de • elds-support@eckelmann.de

Technical modifications and errors reserved - version September 2017 - VS 300 - Parameter V2.10

page 4 / 4

You might also like

- Fuse Box Diagram JeepDocument7 pagesFuse Box Diagram JeepSumedin Nisic100% (1)

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- Service ManualDocument44 pagesService ManualMahmod Mahmod100% (2)

- VPC & VSD SetupDocument15 pagesVPC & VSD Setuppanca nanginNo ratings yet

- SZ 7510 T - 69T - Catalog REV.02 1Document2 pagesSZ 7510 T - 69T - Catalog REV.02 1Gaurav50% (4)

- 1 Starting Time Calculation 2Document15 pages1 Starting Time Calculation 2Sankalp MittalNo ratings yet

- Miconic TX-GC 10-GC Operation SMLCD K604005 - 02Document40 pagesMiconic TX-GC 10-GC Operation SMLCD K604005 - 02Luis Alejandro Sanchez100% (2)

- 7 - GEH-6370 MK V Time SynchronizationDocument44 pages7 - GEH-6370 MK V Time SynchronizationBouazzaNo ratings yet

- Seipl Profile and CapabilitiesDocument32 pagesSeipl Profile and CapabilitiesAbhishek GuptaNo ratings yet

- Spray Nozzle Flow Rate CalculatorDocument10 pagesSpray Nozzle Flow Rate CalculatorRavindra VasudevaNo ratings yet

- VS 3000 Pack Controller Firmware V3.00: Eckelmann - deDocument126 pagesVS 3000 Pack Controller Firmware V3.00: Eckelmann - demoh taNo ratings yet

- 9100 User ManualDocument48 pages9100 User Manualหน่อง นพดล83% (35)

- 9IS54271.08 - EWCM - EO - InstructionSheet - EN - 0921 Eliwell Do Clint MEA/KDocument20 pages9IS54271.08 - EWCM - EO - InstructionSheet - EN - 0921 Eliwell Do Clint MEA/KzydradeeNo ratings yet

- CIECO PCI-100LS Quick Programming ReferenceDocument1 pageCIECO PCI-100LS Quick Programming ReferenceTomNo ratings yet

- 2.2 Pictographs: Abbre-Desig - Function Viation Nation Prog Rset RTRN Unld XtraDocument2 pages2.2 Pictographs: Abbre-Desig - Function Viation Nation Prog Rset RTRN Unld XtraRE musicNo ratings yet

- Connections, Displays and Operating Elements: G F MN HDocument10 pagesConnections, Displays and Operating Elements: G F MN HdogasanchesNo ratings yet

- Quick Guide: Dash 2500 Patient MonitorDocument6 pagesQuick Guide: Dash 2500 Patient MonitornadtrianaNo ratings yet

- Altistart 48 - Руководство по программированию - ENGDocument41 pagesAltistart 48 - Руководство по программированию - ENGZhiger Fox SaurambayevNo ratings yet

- 01180-Neuro 105 - 2Document68 pages01180-Neuro 105 - 2bmendoleNo ratings yet

- Schneider XBTZG9775 PLC Control Cable To Mitsubishi FX Series MINI DIN 8-PIN RS232 MALE To RS232 DB9 FEMALE Black Length 1.8MDocument15 pagesSchneider XBTZG9775 PLC Control Cable To Mitsubishi FX Series MINI DIN 8-PIN RS232 MALE To RS232 DB9 FEMALE Black Length 1.8MSyed Hassan TariqNo ratings yet

- Users Manual: Eimova 880, 572 01 Polička Czech Republic Tel.: +420 461 619 515 Fax: +420 461 619 513Document73 pagesUsers Manual: Eimova 880, 572 01 Polička Czech Republic Tel.: +420 461 619 515 Fax: +420 461 619 513freddyapazaNo ratings yet

- Gamme Sepam Utilisation Mise en ServiceDocument28 pagesGamme Sepam Utilisation Mise en ServicemedNo ratings yet

- MEGA G2 UM E cp03Document49 pagesMEGA G2 UM E cp03Evidence Ndaramo JusticeNo ratings yet

- VP 09086 El 004 008 02Document20 pagesVP 09086 El 004 008 02ussaNo ratings yet

- Synesthesia - User Manual (En) - v1.0.2Document18 pagesSynesthesia - User Manual (En) - v1.0.2GFI SystemNo ratings yet

- Vc34 Kompend Kap05 eDocument44 pagesVc34 Kompend Kap05 eSafetyjoe2No ratings yet

- Termostato Digital - SMP55Document88 pagesTermostato Digital - SMP55Julio Cesar T ProcopioNo ratings yet

- Series: Intuitively Innovative!Document48 pagesSeries: Intuitively Innovative!Hector Velez PizaNo ratings yet

- Gipam 2000Document6 pagesGipam 2000hoangepuNo ratings yet

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDocument2 pagesAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinNo ratings yet

- TICO732Document3 pagesTICO732edueu21No ratings yet

- Installation V 1: Les Étapes de La Mise en ŒuvreDocument30 pagesInstallation V 1: Les Étapes de La Mise en ŒuvreAbdelazizNo ratings yet

- Manuale OEM IngleseDocument19 pagesManuale OEM IngleseAnne S. SokolovskaNo ratings yet

- Xbta71101 Klawiatura Zamiennik Do Panela Telemecanique ManualDocument21 pagesXbta71101 Klawiatura Zamiennik Do Panela Telemecanique ManualRizqi FirmansyahNo ratings yet

- Toubleshoot FR-E700Document5 pagesToubleshoot FR-E700SilentXNo ratings yet

- SM 2035 ADocument5 pagesSM 2035 Aajc2_1984No ratings yet

- XT210C - XT211C: Single Stage Digital Controller With Multi Probe InputDocument3 pagesXT210C - XT211C: Single Stage Digital Controller With Multi Probe InputJennifer Eszter Sárközy100% (1)

- Operating Emergency Power Units With The Easygen-1500 Brief InformationDocument1 pageOperating Emergency Power Units With The Easygen-1500 Brief InformationAnderson DuarteNo ratings yet

- Chapter 3: Keys and Displays: 1/32 DIN (PM3)Document2 pagesChapter 3: Keys and Displays: 1/32 DIN (PM3)Henry WildNo ratings yet

- LG 21FD5 +CP79BDocument20 pagesLG 21FD5 +CP79BSonu Kumar100% (5)

- Music ChartDocument14 pagesMusic ChartMauro BianchiniNo ratings yet

- Synesthesia - User Manual en - V2.0.xDocument19 pagesSynesthesia - User Manual en - V2.0.xPedro NNo ratings yet

- GW621/GW626/GW631/GW636 Multifunctional Pulse Meter Instruction ManualDocument18 pagesGW621/GW626/GW631/GW636 Multifunctional Pulse Meter Instruction ManualSlobodan NocajNo ratings yet

- Id 985/s/e/ck - Id985/e LXDocument14 pagesId 985/s/e/ck - Id985/e LXFabricio RegesNo ratings yet

- 23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enDocument16 pages23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enjosepadilla1987No ratings yet

- Manual Display Bomba NM076BYDocument1 pageManual Display Bomba NM076BYzuriqueNo ratings yet

- Microprocessor-Based Digital Electronic Controller: Operating Instructions Tecnologic S.P.ADocument21 pagesMicroprocessor-Based Digital Electronic Controller: Operating Instructions Tecnologic S.P.AneilNo ratings yet

- Belimo VRP-M STP Technische BrochureDocument36 pagesBelimo VRP-M STP Technische BrochureAdrianSebastianDarmansyahNo ratings yet

- SZ-7520T / SZ-7529T: Operating InstructionsDocument2 pagesSZ-7520T / SZ-7529T: Operating InstructionsMathalinNo ratings yet

- ZKD Series: EN DE ES FR ITDocument52 pagesZKD Series: EN DE ES FR ITwissam zaatuorNo ratings yet

- COMAP IL-MRS11-16 Thong So Ky Thuat PDFDocument2 pagesCOMAP IL-MRS11-16 Thong So Ky Thuat PDFthanhhai31No ratings yet

- 2.5 DisplayDocument34 pages2.5 DisplayJhonPaul TarazonaNo ratings yet

- ACF624 680and625manualsDocument2 pagesACF624 680and625manualsGreg OneofakindNo ratings yet

- Teknaevo TPG: Instructions ManualDocument78 pagesTeknaevo TPG: Instructions ManualClaudio carrerasNo ratings yet

- +reg DA Relay PDFDocument16 pages+reg DA Relay PDFillemariusNo ratings yet

- General Specifications: GS 05P03D21-01ENDocument9 pagesGeneral Specifications: GS 05P03D21-01ENHoang Vu HungNo ratings yet

- T2000 ManualDocument61 pagesT2000 Manualjesus garciaNo ratings yet

- 409 M Quick User GuideDocument2 pages409 M Quick User GuidePuneet BachalNo ratings yet

- Belimo VRP-M Vav 4 1 enDocument36 pagesBelimo VRP-M Vav 4 1 enNenad MutavdzicNo ratings yet

- Operation Guide EL-531V R S PDFDocument30 pagesOperation Guide EL-531V R S PDFlotannaNo ratings yet

- The 2points Temperaturecontrollers Manual Rev B EngDocument1 pageThe 2points Temperaturecontrollers Manual Rev B EngyulfreNo ratings yet

- IC915 (LX) Set Point Differenziale Eng 12-04Document10 pagesIC915 (LX) Set Point Differenziale Eng 12-04Julien GoubaultNo ratings yet

- FRENIC Ace Instruction Manual INR SI47 1733f EDocument5 pagesFRENIC Ace Instruction Manual INR SI47 1733f EQuốc ĐạtNo ratings yet

- Warning: Unintentional Equipment OperationDocument190 pagesWarning: Unintentional Equipment OperationSaasiNo ratings yet

- User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical SystemsDocument2 pagesUser Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical SystemsAnggara KusumaNo ratings yet

- Teknaevo TPG: Installation ManualDocument95 pagesTeknaevo TPG: Installation ManualDragisa DjukicNo ratings yet

- NS1000 50Document28 pagesNS1000 50moh taNo ratings yet

- 18 VS3010CT en 1.7 V5.44 EagDocument189 pages18 VS3010CT en 1.7 V5.44 Eagmoh taNo ratings yet

- 11 VS300 en 2.05 V2.10 EagDocument172 pages11 VS300 en 2.05 V2.10 Eagmoh taNo ratings yet

- Operating Instruction VS 3010Document224 pagesOperating Instruction VS 3010moh taNo ratings yet

- Walls2017 DemolitionforsustainableconstructionRGDocument6 pagesWalls2017 DemolitionforsustainableconstructionRGStefan GhidiuNo ratings yet

- Crane GBLDocument2 pagesCrane GBLbudi setiawanNo ratings yet

- New Horizons and Opportunities of Modular Constructions and Their TechnologyDocument9 pagesNew Horizons and Opportunities of Modular Constructions and Their TechnologyPhD. Arch. Klodjan XhexhiNo ratings yet

- 2 BoilersDocument83 pages2 BoilersSurasan ThepsiriNo ratings yet

- Referencing Using The Documentary-Note (Oxford) System, Deakin UniversityDocument9 pagesReferencing Using The Documentary-Note (Oxford) System, Deakin UniversityjengadjNo ratings yet

- Environmental Life Cycle AssessmentDocument1 pageEnvironmental Life Cycle Assessmentkayyappan1957No ratings yet

- IELTS Writing - Bar ChartDocument2 pagesIELTS Writing - Bar ChartTrí Võ PhạmNo ratings yet

- DPC6HG Aa00 G0000 ZS001 - 001 - 01Document6 pagesDPC6HG Aa00 G0000 ZS001 - 001 - 01rajitkumar.3005No ratings yet

- Free Space For Shanghair CompressorDocument1 pageFree Space For Shanghair CompressorAndri YansyahNo ratings yet

- SolarDocument4 pagesSolarShweta RawatNo ratings yet

- Manual - Submersible PumpDocument4 pagesManual - Submersible PumpcodersriramNo ratings yet

- Adly 50 RS Parts ListDocument50 pagesAdly 50 RS Parts ListZsibrita GyörgyNo ratings yet

- Multibio BrochureDocument1 pageMultibio Brochuree-ComfortUSANo ratings yet

- 6 Data Storage and QueryingDocument58 pages6 Data Storage and Queryingfdghj100% (1)

- Lesson Plan MathsDocument3 pagesLesson Plan MathsRuthira Nair AB KrishenanNo ratings yet

- K13 High-Flex Waterproofing SlurryDocument3 pagesK13 High-Flex Waterproofing SlurryAmila SampathNo ratings yet

- AT&T Syntax MMXDocument17 pagesAT&T Syntax MMXakirank1No ratings yet

- Modes in Optical FibersDocument10 pagesModes in Optical FibersAdamStone100% (1)

- Android OpenGL 2.0 PDFDocument14 pagesAndroid OpenGL 2.0 PDFdalaran34100% (1)

- Muhammad ALI Azmi: Contact +62 812 1944 5086 Komplek Poin Mas Blok F-2 No. 20B, Depok, Jawa BaratDocument1 pageMuhammad ALI Azmi: Contact +62 812 1944 5086 Komplek Poin Mas Blok F-2 No. 20B, Depok, Jawa BaratanggaraNo ratings yet

- Mica PDFDocument2 pagesMica PDFomarNo ratings yet

- Non Destructive Testing Tech EnglishDocument1 pageNon Destructive Testing Tech Englishvictor hugoNo ratings yet

- Hazardous Area Heater Crex 020 Old Version 2721512-544292Document2 pagesHazardous Area Heater Crex 020 Old Version 2721512-544292Achintya KarmakarNo ratings yet

- GSECL - Daily Progress Report 11.9.21Document2 pagesGSECL - Daily Progress Report 11.9.21krishna mohanNo ratings yet

- EEPW3142 QP Version-ADocument8 pagesEEPW3142 QP Version-A3nathNo ratings yet