Professional Documents

Culture Documents

Supervisor

Uploaded by

grantCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supervisor

Uploaded by

grantCopyright:

Available Formats

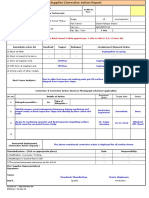

Document: PTO –

Threading machine

PLANED TASK OBSERVATION Rev 2

Next Revision date:

SUPERVISORS / FOREMAN 29/7/16

Date Issued 20/7/15

Date Department

Work Area Section

Employee Being Observed

How often is Task performed Company Name

Machine/Equipment No being used Observers Name

Task being observed ID Number/ Coy No

Reason for observation Change Management Legal Compliance

New Worker Unplanned Task

New Task Ergonomic Factor

Known Risk Taker Incident Repeater

Poor Performer Good Performer

New/Unfamiliar Equipment Complicated Task

1. Task Steps being observed

Does the Supervisor / Foreman have a valid medical and Inductions?

Is the Supervisor / Foreman appointed by the Responsible 2.6.1 appointee?

Is the Supervisor / Foreman competent? Does he/she have the necessary training?

Does the Supervisor give clear instructions to his team and unsure that all employees know what is expected of them?

Is there good communication between the Supervisor / Foreman and his team members?

Was the DSTI conducted with the team and did two-way communication take place?

Does the Supervisor / Foreman have copies of all the applicable Risk assessments / SHE Spec with him?

Does the Supervisor / Foreman make sure that his team members is wearing the correct PPE?

Does the Supervisor / Foreman take part in the Daily Toolbox Talks?

Does the Supervisor / Foreman ensure that Safe walkways and Safe Work platforms is available?

Does Supervisor / Foreman ensure that Housekeeping is maintained?

Does the Supervisor / Foreman take part in Reporting of events?

Does the Supervisor / Foreman help to create safety awareness?

5. Suggested Improvements (TO BE COMPLETED BY THE SUPERVISOR )

Page 1 of 2 Printed: 22 October 2022

Document: PTO –

Threading machine

PLANED TASK OBSERVATION Rev 2

Next Revision date:

SUPERVISORS / FOREMAN 29/7/16

Date Issued 20/7/15

Revise SOP? Yes Use different PPE? Yes Engineering change Yes Re-Train Yes Placement of Yes

required? employee? employee?

No No No No No

Employee Task Observation

Employee Name: ______________________________________ I.D. No.: ______________

Job Title: _________

Date Assigned to Job: __

Operating Procedures Checked

Number Title Date Reviewed

SOP

RA

6. Feedback by observer to employee

1. TASK STEPS

DEVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

2. PPE

DEVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

3. EQUIPMENT CONDITION

DIVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

7. Acknowledgement and agreement on feedback received

Observation conducted by: Signature Date

Reviewed with Employee: Signature Date

Reviewed by Site Manager: Signature Date

Page 2 of 2 Printed: 22 October 2022

You might also like

- SheetingDocument2 pagesSheetinggrantNo ratings yet

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

- PTO - Plumbing Rev 2Document2 pagesPTO - Plumbing Rev 2grantNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- PTO TilingDocument2 pagesPTO TilinggrantNo ratings yet

- Plastering Rev 2Document2 pagesPlastering Rev 2grantNo ratings yet

- PTO Manual Handling Rev 2Document2 pagesPTO Manual Handling Rev 2grantNo ratings yet

- Pto - Threading Machine Rev 2Document3 pagesPto - Threading Machine Rev 2grantNo ratings yet

- PTO - Use of Hand ToolsDocument2 pagesPTO - Use of Hand ToolsgrantNo ratings yet

- PTO - BrickworkDocument2 pagesPTO - BrickworkgrantNo ratings yet

- Operating Skill SawDocument2 pagesOperating Skill SawgrantNo ratings yet

- Operate A Hand Drill Rev 2Document3 pagesOperate A Hand Drill Rev 2grantNo ratings yet

- PTO - Pre Mix Concrete TruckDocument2 pagesPTO - Pre Mix Concrete TruckgrantNo ratings yet

- PTO - Cutting and Grinding Rev 2Document3 pagesPTO - Cutting and Grinding Rev 2grantNo ratings yet

- PTO - SteelfixingDocument2 pagesPTO - SteelfixinggrantNo ratings yet

- PTO - Pouring of Concrete Rev 2Document2 pagesPTO - Pouring of Concrete Rev 2grantNo ratings yet

- PTO PaintingDocument2 pagesPTO Paintinggrant100% (1)

- Operate An Impact Wrench Rev 2Document3 pagesOperate An Impact Wrench Rev 2grantNo ratings yet

- Operate A Pencil Grinder Rev 2Document3 pagesOperate A Pencil Grinder Rev 2grantNo ratings yet

- Gas Cutting Rev 2Document3 pagesGas Cutting Rev 2grantNo ratings yet

- Operate A Magnetic Base Drill Rev 2Document3 pagesOperate A Magnetic Base Drill Rev 2grantNo ratings yet

- 03-Contoh JSA-OKEDocument2 pages03-Contoh JSA-OKEMaster AssassiNNo ratings yet

- JSA SC Area KariangauDocument20 pagesJSA SC Area KariangauSiti AminahNo ratings yet

- Welding JraDocument3 pagesWelding Jraaone mothupiNo ratings yet

- Mehdi hse/EXCAVATION MANUELLEDocument2 pagesMehdi hse/EXCAVATION MANUELLEAbdou BencheikhNo ratings yet

- PTO Control SheetDocument5 pagesPTO Control SheetsalomonbeleckNo ratings yet

- Permit of WorkDocument24 pagesPermit of WorkSantanu SharmaNo ratings yet

- Disciplinary ProcedureDocument11 pagesDisciplinary ProcedureSURESH NAIRNo ratings yet

- PTO Control SheetV1Document6 pagesPTO Control SheetV1salomonbeleckNo ratings yet

- PTO Project - Fire Line Pipe Fabrication at Magazine 10Document3 pagesPTO Project - Fire Line Pipe Fabrication at Magazine 10John NainggolanNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- Efren Ragonjan JRDocument7 pagesEfren Ragonjan JRClarabelle Mae Dela RosaNo ratings yet

- SWMS-09 Pipe Freezing For B1 Level 1 Mechanical Room (27-July-2021) Final (Alstern)Document24 pagesSWMS-09 Pipe Freezing For B1 Level 1 Mechanical Room (27-July-2021) Final (Alstern)Jose Manuel LimNo ratings yet

- Hot Work Lifting Shifting and Unloading WorkDocument4 pagesHot Work Lifting Shifting and Unloading WorkAbhijit ParasharNo ratings yet

- Work Order ProcedureDocument5 pagesWork Order ProcedureJames Reyes100% (1)

- WSWP For Joint SealingDocument7 pagesWSWP For Joint SealingvictorNo ratings yet

- 17.06 Planned Task ObservationsDocument1 page17.06 Planned Task Observationsgrant100% (1)

- Time On This Job Notification Reason For Observation: 1. Suggested RemediesDocument1 pageTime On This Job Notification Reason For Observation: 1. Suggested Remediesgrant50% (4)

- 5 PSI Questions: Ask Isk Dentification ArdDocument2 pages5 PSI Questions: Ask Isk Dentification ArdZaki ChaabnaNo ratings yet

- Permit Lifting Kota MinyakDocument3 pagesPermit Lifting Kota MinyakYogi OktabertoNo ratings yet

- SWMS Scaffolding Erection, Modification and DismantlingDocument2 pagesSWMS Scaffolding Erection, Modification and DismantlingCao Anh HuyenNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- MD-216-4400-QD-IX-ITP-1001-A07 Inspection Test Plan For Earthwork in Tailing Management Facility-4400 PDFDocument7 pagesMD-216-4400-QD-IX-ITP-1001-A07 Inspection Test Plan For Earthwork in Tailing Management Facility-4400 PDFKarthikNo ratings yet

- Cm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)Document1 pageCm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)ali morisyNo ratings yet

- JTO-2572-0004 Sander and Plow Truck Job Task Observation ReportDocument2 pagesJTO-2572-0004 Sander and Plow Truck Job Task Observation ReportdrakoniiNo ratings yet

- JSA Scaffolding (Green) - OSBLDocument20 pagesJSA Scaffolding (Green) - OSBLSiti AminahNo ratings yet

- Cm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)Document1 pageCm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)ali morisyNo ratings yet

- Ehs PR 03.f01 Patos FormDocument2 pagesEhs PR 03.f01 Patos FormClyde Villanueva100% (4)

- EHS-PR-03.F01 PATOS Form PDFDocument2 pagesEHS-PR-03.F01 PATOS Form PDFClyde Villanueva100% (1)

- PMF-012-COM-013 v1 Non Conformance ReportDocument5 pagesPMF-012-COM-013 v1 Non Conformance ReportAbdul RafeequeNo ratings yet

- SWMS For Hoarding GateDocument9 pagesSWMS For Hoarding GateSam LimNo ratings yet

- Fmea CastingDocument8 pagesFmea CastingSuraj RawatNo ratings yet

- Performance Improvement Plan (PIP) TemplateDocument4 pagesPerformance Improvement Plan (PIP) TemplatePia MontielNo ratings yet

- Cm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)Document1 pageCm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)ali morisyNo ratings yet

- Method Statement For Survey WorksDocument13 pagesMethod Statement For Survey WorksSagun Almario100% (1)

- Regular Safety & Mechanical Inspection Marine TransportationDocument6 pagesRegular Safety & Mechanical Inspection Marine TransportationRie ReiNo ratings yet

- Job Hazards Analysis - REVISED TemfacilDocument3 pagesJob Hazards Analysis - REVISED Temfacilarnold arayataNo ratings yet

- JTO-2572-0050 Lawn Mowers Job Task Observation ReportDocument3 pagesJTO-2572-0050 Lawn Mowers Job Task Observation ReportdrakoniiNo ratings yet

- Contoh Isian CPAR Oleh AuditorDocument1 pageContoh Isian CPAR Oleh Auditorsalim agus100% (1)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- Fire Extinguisher TrainingDocument30 pagesFire Extinguisher TrainingenvsandyNo ratings yet

- PM Site 15b - Site Materials Control - REVISED JHLDocument2 pagesPM Site 15b - Site Materials Control - REVISED JHLgrantNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- ElectricalsafetyDocument27 pagesElectricalsafetyNitin K RaviNo ratings yet

- ISO Training List - ConstructionDocument2 pagesISO Training List - ConstructiongrantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

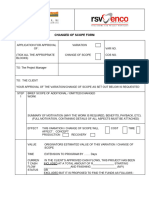

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- PM Site 02b - Revised JHL #Document1 pagePM Site 02b - Revised JHL #grantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- 6 PM PROJ 06 - Change of Scope FormDocument2 pages6 PM PROJ 06 - Change of Scope FormgrantNo ratings yet

- Amc She Env Pro 0007 Hazardous Materials ManagementDocument29 pagesAmc She Env Pro 0007 Hazardous Materials ManagementgrantNo ratings yet

- Working at Heights Rescue PlanDocument2 pagesWorking at Heights Rescue PlangrantNo ratings yet

- Working On HeightsDocument5 pagesWorking On HeightsgrantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- Amc She Env Pro 0011 Used Oil HandlingDocument7 pagesAmc She Env Pro 0011 Used Oil HandlinggrantNo ratings yet

- Amc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpDocument8 pagesAmc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpgrantNo ratings yet

- Working On HeightsDocument5 pagesWorking On HeightsgrantNo ratings yet

- X Pgndp0464 03 Eci SPC 019 Ups Specification RevaDocument9 pagesX Pgndp0464 03 Eci SPC 019 Ups Specification RevagrantNo ratings yet

- Working at HeightsDocument1 pageWorking at HeightsgrantNo ratings yet

- Working On HeightsDocument5 pagesWorking On HeightsgrantNo ratings yet

- Working at Heights Rescue PlanDocument2 pagesWorking at Heights Rescue PlangrantNo ratings yet

- X PGNDP0464 03 ECI SPC 020 Control Valve Specification RevADocument7 pagesX PGNDP0464 03 ECI SPC 020 Control Valve Specification RevAgrantNo ratings yet

- Working at Heights Rescue PlanDocument2 pagesWorking at Heights Rescue PlangrantNo ratings yet