Professional Documents

Culture Documents

PTO - Cutting and Grinding Rev 2

Uploaded by

grantCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTO - Cutting and Grinding Rev 2

Uploaded by

grantCopyright:

Available Formats

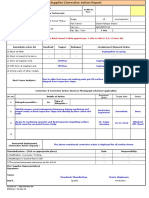

Document: PTO –

Cutting and Grinding

PLANED TASK OBSERVATION Rev 2

Next Revision date:

CUTTING AND GRINDING 18/8/16

Date Issued 18/8/15

Date Department

Work Area Section

Employee Being Observed

How often is Task performed Company Name

Machine/Equipment No being used Observers Name

Task being observed ID Number/ Coy No

Reason for observation Change Management Legal Compliance

New Worker Unplanned Task

New Task Ergonomic Factor

Known Risk Taker Incident Repeater

Poor Performer Good Performer

New/Unfamiliar Equipment Complicated Task

1. Task Steps being observed

Was a continues risk assessment/DSTI conducted by all team members and signed by them?

Is the mini risk assessment/DSTI relevant to the current activities performed?

Pre use check carried out by whom? Name and signed off by relevant Supervisor

Is the operator competent to operate a grinder

Does the operator have an assistant to assist whilst performing task?

Is there good communication between the operator and his team members?

By means of what is the material that must be cut or grind secured?

Is there a signed off and valid hot work permit available for the activities in the section?

What pre-causing measures are in place to prevent a fire and in case of a fire?

Is the dead man switch removed from the Angle Grinder?

Is the electrical extension completely un routed and out of the walk ways?

Is the correct disk used for the task performed and still valid and safe?

Page 1 of 3 Printed: 22 October 2022

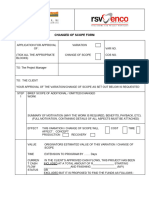

Document: PTO –

Cutting and Grinding

PLANED TASK OBSERVATION Rev 2

Next Revision date:

CUTTING AND GRINDING 18/8/16

Date Issued 18/8/15

If cutting with a 9” Grinder, is a back flange fitted?

Can the operator slip, trip or fall over anything whilst performing the task?

How is the operator standing position?

What PPE is the operator wearing whilst performing the task and is it to standard?

Does the operator ensure that his assistants (s) are complying with the PPE Requirements?

Does the operator allow the machine to come to a complete stop before putting it down?

When leaving the machine un attendant what does the operator do?

After completion of the task, are all steel shavings and cut offs removed from the area?

5. Suggested Improvements (TO BE COMPLETED BY THE SUPERVISOR )

Revise SOP? Yes Use different PPE? Yes Engineering change Yes Re-Train Yes Placement of Yes

required? employee? employee?

No No No No No

Employee Task Observation

Employee Name: ______________________________________ I.D. No.: ______________

Job Title: _________

Date Assigned to Job: __

Operating Procedures Checked

Number Title Date Reviewed

SOP

RA

Page 2 of 3 Printed: 22 October 2022

Document: PTO –

Cutting and Grinding

PLANED TASK OBSERVATION Rev 2

Next Revision date:

CUTTING AND GRINDING 18/8/16

Date Issued 18/8/15

6. Feedback by observer to employee

1. TASK STEPS

DEVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

2. PPE

DEVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

3. EQUIPMENT CONDITION

DIVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

7. Acknowledgement and agreement on feedback received

Observation conducted by: Signature Date

Reviewed with Employee: Signature Date

Reviewed by Site Manager: Signature Date

Page 3 of 3 Printed: 22 October 2022

You might also like

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

- Pto - Threading Machine Rev 2Document3 pagesPto - Threading Machine Rev 2grantNo ratings yet

- Plastering Rev 2Document2 pagesPlastering Rev 2grantNo ratings yet

- SheetingDocument2 pagesSheetinggrantNo ratings yet

- PTO TilingDocument2 pagesPTO TilinggrantNo ratings yet

- Gas Cutting Rev 2Document3 pagesGas Cutting Rev 2grantNo ratings yet

- PTO - Plumbing Rev 2Document2 pagesPTO - Plumbing Rev 2grantNo ratings yet

- PTO Manual Handling Rev 2Document2 pagesPTO Manual Handling Rev 2grantNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- PTO - SteelfixingDocument2 pagesPTO - SteelfixinggrantNo ratings yet

- Operating Skill SawDocument2 pagesOperating Skill SawgrantNo ratings yet

- PTO - BrickworkDocument2 pagesPTO - BrickworkgrantNo ratings yet

- Operate A Hand Drill Rev 2Document3 pagesOperate A Hand Drill Rev 2grantNo ratings yet

- SupervisorDocument2 pagesSupervisorgrantNo ratings yet

- Operate A Pencil Grinder Rev 2Document3 pagesOperate A Pencil Grinder Rev 2grantNo ratings yet

- PTO - Pouring of Concrete Rev 2Document2 pagesPTO - Pouring of Concrete Rev 2grantNo ratings yet

- PTO - Pre Mix Concrete TruckDocument2 pagesPTO - Pre Mix Concrete TruckgrantNo ratings yet

- Operate A Magnetic Base Drill Rev 2Document3 pagesOperate A Magnetic Base Drill Rev 2grantNo ratings yet

- PTO - Use of Hand ToolsDocument2 pagesPTO - Use of Hand ToolsgrantNo ratings yet

- Operate An Impact Wrench Rev 2Document3 pagesOperate An Impact Wrench Rev 2grantNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- Cm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)Document1 pageCm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)ali morisyNo ratings yet

- PTO PaintingDocument2 pagesPTO Paintinggrant100% (1)

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- Cm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)Document1 pageCm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)ali morisyNo ratings yet

- Cm-Elec - (51 To 51) - Send To MGPS at (12-08-2020)Document1 pageCm-Elec - (51 To 51) - Send To MGPS at (12-08-2020)ali morisyNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Cm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)Document1 pageCm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)ali morisyNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Permit Lifting Kota MinyakDocument3 pagesPermit Lifting Kota MinyakYogi OktabertoNo ratings yet

- Binded Hook Up & InstallationDocument44 pagesBinded Hook Up & InstallationrajNo ratings yet

- Indra: Vendor's Name Company's NameDocument14 pagesIndra: Vendor's Name Company's NameHuy Thieu BuiNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- Form Izin Kerja - LiftingDocument3 pagesForm Izin Kerja - Liftingsafetyofficer752No ratings yet

- Cm-Elec - (01 To 01) - Send To MGPS at (01-01-2021)Document1 pageCm-Elec - (01 To 01) - Send To MGPS at (01-01-2021)Ali AlmorisyNo ratings yet

- Cm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)Document2 pagesCm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)ali morisyNo ratings yet

- ENG-DUQM-101 - Painting Procedure - Rev 3.Document269 pagesENG-DUQM-101 - Painting Procedure - Rev 3.Shiva RajNo ratings yet

- Cm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)Document2 pagesCm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)ali morisyNo ratings yet

- CM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) ReprintDocument2 pagesCM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) Reprintali morisyNo ratings yet

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- Commissioning TestDocument30 pagesCommissioning TestErlen PolancoNo ratings yet

- Cm-Inst - (23 To 24) - Send To MGPS at ( 27-07-2020)Document2 pagesCm-Inst - (23 To 24) - Send To MGPS at ( 27-07-2020)ali morisyNo ratings yet

- Contract Review FormDocument2 pagesContract Review Formsunday babalolaNo ratings yet

- Cm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)Document3 pagesCm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)ali morisyNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- SA048-WSP-GEN-MTS-MNCR-2 Non-Conformance Report - Tested Stockpile BarricationDocument2 pagesSA048-WSP-GEN-MTS-MNCR-2 Non-Conformance Report - Tested Stockpile BarricationmustafaansmeNo ratings yet

- 16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.02Document1 page16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.02Mohammad MohammadNo ratings yet

- 2018-04-24 RRAA Structural Steel QCS (Baras) - Rev ADocument1 page2018-04-24 RRAA Structural Steel QCS (Baras) - Rev AgregNo ratings yet

- Method Statement of Quality C Concrete Rev 02Document19 pagesMethod Statement of Quality C Concrete Rev 02mayu mayutharanNo ratings yet

- Cradle Operation Permit: (Name of Company)Document2 pagesCradle Operation Permit: (Name of Company)MUhammad RanaNo ratings yet

- JTO-2572-0004 Sander and Plow Truck Job Task Observation ReportDocument2 pagesJTO-2572-0004 Sander and Plow Truck Job Task Observation ReportdrakoniiNo ratings yet

- Functional Design Specifications - Esd/Bms/F&G Software: J-DmsDocument415 pagesFunctional Design Specifications - Esd/Bms/F&G Software: J-Dmsالدر المكنون الدر المكنونNo ratings yet

- Tugas Pembuatan HSE Performance Statistik KecelakaanDocument5 pagesTugas Pembuatan HSE Performance Statistik KecelakaanElmia WijayaNo ratings yet

- RN 005 Airman Generator Id. 1723A62663Document4 pagesRN 005 Airman Generator Id. 1723A62663Wahyu RahmadNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- Maintenance / Fabrication Process Traceability Card: Part No (Fab. process) (عينصت ةيلمع) ءزجلا مقرDocument1 pageMaintenance / Fabrication Process Traceability Card: Part No (Fab. process) (عينصت ةيلمع) ءزجلا مقرMohamed MossadNo ratings yet

- NCR FormatDocument5 pagesNCR FormatSakib KhanNo ratings yet

- NCR Reported by NCR Issued To: Non-Conformance ReportDocument2 pagesNCR Reported by NCR Issued To: Non-Conformance ReportRahul SundarNo ratings yet

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- ISO Training List - ConstructionDocument2 pagesISO Training List - ConstructiongrantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- PM Site 15b - Site Materials Control - REVISED JHLDocument2 pagesPM Site 15b - Site Materials Control - REVISED JHLgrantNo ratings yet

- PM Site 02b - Revised JHL #Document1 pagePM Site 02b - Revised JHL #grantNo ratings yet

- 6 PM PROJ 06 - Change of Scope FormDocument2 pages6 PM PROJ 06 - Change of Scope FormgrantNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- Xconstruction Method StatementDocument10 pagesXconstruction Method StatementgrantNo ratings yet

- Working at HeightsDocument1 pageWorking at HeightsgrantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- Amc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpDocument8 pagesAmc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpgrantNo ratings yet

- Amc She Env Pro 0011 Used Oil HandlingDocument7 pagesAmc She Env Pro 0011 Used Oil HandlinggrantNo ratings yet

- Amc She Env Pro 0007 Hazardous Materials ManagementDocument29 pagesAmc She Env Pro 0007 Hazardous Materials ManagementgrantNo ratings yet

- Working at Heights Rescue PlanDocument2 pagesWorking at Heights Rescue PlangrantNo ratings yet

- X Pgndp0464 03 Eci SPC 019 Ups Specification RevaDocument9 pagesX Pgndp0464 03 Eci SPC 019 Ups Specification RevagrantNo ratings yet

- X PGNDP0464 03 ECI SPC 020 Control Valve Specification RevADocument7 pagesX PGNDP0464 03 ECI SPC 020 Control Valve Specification RevAgrantNo ratings yet

- Written WarningDocument1 pageWritten WarninggrantNo ratings yet

- X PGNDP0464 03 ECI SPC 009 Generator Specification RevADocument34 pagesX PGNDP0464 03 ECI SPC 009 Generator Specification RevAgrantNo ratings yet

- X PGNDP0464 03 ECI SPC 017 Magnetic Flow Transmitter Specification RevADocument8 pagesX PGNDP0464 03 ECI SPC 017 Magnetic Flow Transmitter Specification RevAgrantNo ratings yet

- X - PGNDP0464-03-ECI-SPC-015 Belt Scale and Speed Transmitters Specification RevADocument9 pagesX - PGNDP0464-03-ECI-SPC-015 Belt Scale and Speed Transmitters Specification RevAgrantNo ratings yet

- X PGNDP0464 03 ECI SPC 016 Security System SpecificationDocument17 pagesX PGNDP0464 03 ECI SPC 016 Security System SpecificationgrantNo ratings yet

- X PGNDP0464 03 ECI SPC 006 High Mast Lighting Specification RevADocument19 pagesX PGNDP0464 03 ECI SPC 006 High Mast Lighting Specification RevAgrantNo ratings yet

- X PGNDP0464 03 ECI SPC 013 Battery Tripping Unit Specification RevADocument20 pagesX PGNDP0464 03 ECI SPC 013 Battery Tripping Unit Specification RevAgrantNo ratings yet

- X PGNDP0464 03 ECI SPC 016 Density Transmitter Specification RevADocument9 pagesX PGNDP0464 03 ECI SPC 016 Density Transmitter Specification RevAgrantNo ratings yet

- Tort Outline .. Internet SourceDocument43 pagesTort Outline .. Internet SourceColeman HengesbachNo ratings yet

- Auditing Gray 2015 CH 15 Assurance Engagements Internal AuditDocument46 pagesAuditing Gray 2015 CH 15 Assurance Engagements Internal AuditAdzhana AprillaNo ratings yet

- Uy Tong V CADocument3 pagesUy Tong V CAcmv mendozaNo ratings yet

- Pressure Vessel CertificationDocument3 pagesPressure Vessel CertificationYetkin ErdoğanNo ratings yet

- Gmail - Bus Ticket - Sagar To Bhopal On Wed, 18 Dec 2019 and Rate Your ExperienceDocument3 pagesGmail - Bus Ticket - Sagar To Bhopal On Wed, 18 Dec 2019 and Rate Your ExperienceShivamSrivastavaNo ratings yet

- Please Return This Form To:: Brill - Nl/rightsDocument1 pagePlease Return This Form To:: Brill - Nl/rightslimetta09No ratings yet

- TYBBI AuditDocument3 pagesTYBBI AuditNandhiniNo ratings yet

- And Prescribed by The National Office." (Italics and Emphasis Supplied)Document2 pagesAnd Prescribed by The National Office." (Italics and Emphasis Supplied)Ckey ArNo ratings yet

- Apostolic Succession and The AnteDocument10 pagesApostolic Succession and The AnteLITTLEWOLFE100% (2)

- Sample Affidavit of Loss of A DiplomaDocument1 pageSample Affidavit of Loss of A DiplomaDina Pasion92% (13)

- Community Affairs PlanDocument4 pagesCommunity Affairs PlanFranklin Onuorah67% (3)

- EHDF Module 4 & 5Document5 pagesEHDF Module 4 & 5Faizal KhanNo ratings yet

- Form - 28Document2 pagesForm - 28Manoj GuruNo ratings yet

- Federal Lawsuit Against Critchlow For Topix DefamationDocument55 pagesFederal Lawsuit Against Critchlow For Topix DefamationJC PenknifeNo ratings yet

- Marijuana Prohibition FactsDocument5 pagesMarijuana Prohibition FactsMPPNo ratings yet

- GR 220835 CIR vs. Systems TechnologyDocument2 pagesGR 220835 CIR vs. Systems TechnologyJoshua Erik Madria100% (1)

- Sydeco Vs PeopleDocument2 pagesSydeco Vs PeopleJenu OrosNo ratings yet

- About Dhanalaxmi Bank KarthikDocument4 pagesAbout Dhanalaxmi Bank KarthikYkartheek GupthaNo ratings yet

- DRAC Combined 07.04.2023Document39 pagesDRAC Combined 07.04.2023Ankit DalalNo ratings yet

- Retro 80s Kidcore Arcade Company Profile Infographics by SlidesgoDocument35 pagesRetro 80s Kidcore Arcade Company Profile Infographics by SlidesgoANAIS GUADALUPE SOLIZ MUNGUIANo ratings yet

- 2015-08-24 065059 4.blood RelationsDocument20 pages2015-08-24 065059 4.blood Relationsჯონ ფრაატეეკNo ratings yet

- Licensing Notes For Oracle'S Peopletools 8.52Document19 pagesLicensing Notes For Oracle'S Peopletools 8.52Juan Pablo GasparriniNo ratings yet

- Complaint On Tamil GenocideDocument67 pagesComplaint On Tamil GenocideNandhi VarmanNo ratings yet

- Baltik Remedial Law ReviewerDocument115 pagesBaltik Remedial Law ReviewerrandellgabrielNo ratings yet

- Public Prosecutor: Section 24 Provides As UnderDocument12 pagesPublic Prosecutor: Section 24 Provides As UnderAkasa SethNo ratings yet

- GA Tax GuideDocument46 pagesGA Tax Guidedamilano1No ratings yet

- (Azizi Ali) Lesson Learnt From Tun Daim E-BookDocument26 pages(Azizi Ali) Lesson Learnt From Tun Daim E-BookgabanheroNo ratings yet

- Arens14e ch19 PPTDocument41 pagesArens14e ch19 PPTFathinus SyafrizalNo ratings yet

- Cash and Cash EquivalentDocument2 pagesCash and Cash EquivalentJovani Laña100% (1)

- IHP: Human Rights: Foundations, Challenges, and AdvocacyDocument25 pagesIHP: Human Rights: Foundations, Challenges, and AdvocacyPaul Omar PastranoNo ratings yet