Professional Documents

Culture Documents

KM-T20 Catalog

Uploaded by

Jackson SilvaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KM-T20 Catalog

Uploaded by

Jackson SilvaCopyright:

Available Formats

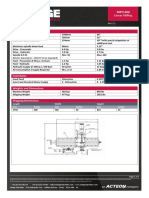

KM-T20 Swiss Type CNC Lathe CONFIGURATION

1.LNC5850 control system(two-channel) Two-channel KM-T20

2.Pneumatic unit

3.Automatic centerlized lubrication unit Control system LNC5850

Machining dia.1-20mm,length 170mm workpiece. 4. Spindle coolant Max. machining dia. 20mm

5.Parts ejection detector

The machine use two-channel system for controlling multi-spindle. Capacity

6. 4-station turning tool Max. machining length 170mm

(one choice milling head)

7. 6-station cross drilling unit Spindle speed 50-8000r/min

(including one power head tapping )

Spindle power 2kw

8.chip car

X1 axis travel 120mm

Optional

X2, X3 travel 50mm

Automatic bar feeder

System 1 Z axis travel 220mm

SYNTEC 22TB control system

X axis feedrate 16000mm/min

Travel Z axis feedrate 18000mm/min

SAMPLE MACHINING X axis travel 120mm

System 2 Z travel 230mm

X axis feedrate 16000mm/min

CH1: 4pcs turning tool with milling Z axis feedrate 18000mm/min

CH2: 6pcs gang tool (one tapping) Tapping axis Tapping speed 50-5500r/min

Tapping motor 750W

System 1 independent type 4 pcs

System 1 tool size 8×8mm

Tool System 2 gang tool 6 pcs

System 2 gang tool Φ16

Tapping collet type ER11

Power Power voltage 380V/50Hz/3PH

Coolant system Motor Power 0.12KW

Water volume 120L

Pneumatic system Air pressure 0.4-0.6Mpa

Other Machine size L*W*H 1500×900×1630mm

The inner and outer diameters of workpiece The spindle box is fixed Machine weight 1300 kg

can be processed simultaneously. and tool saddle can move 220mm on Z axis

You might also like

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- Qmb206G Automatic Woodworker Double Surfaced Planer Operation Manual P-1Document2 pagesQmb206G Automatic Woodworker Double Surfaced Planer Operation Manual P-1Sebastian SaltosNo ratings yet

- PCI Meteor3000 ENDocument2 pagesPCI Meteor3000 ENHX WEINo ratings yet

- H E V M C: High Efficiency Vertical Machining CenterDocument8 pagesH E V M C: High Efficiency Vertical Machining CenterAbhishek VelagaNo ratings yet

- M20200812-2 (ME-1055 With Siemens 828D PPU260)Document2 pagesM20200812-2 (ME-1055 With Siemens 828D PPU260)donny rebornNo ratings yet

- Esls ErieDocument16 pagesEsls ErieHavanhuy HaNo ratings yet

- 1100m Spec Sheet - 0121Document1 page1100m Spec Sheet - 0121Ben LernerNo ratings yet

- 福裕qp2033 40linearDocument10 pages福裕qp2033 40linearmislab520No ratings yet

- LU-2810-6 LU-2860-6: Is Added To The Machine Lineup Following The Direct-Drive TypeDocument2 pagesLU-2810-6 LU-2860-6: Is Added To The Machine Lineup Following The Direct-Drive TypeRaitziel KlossNo ratings yet

- VF-Mill: SeriesDocument31 pagesVF-Mill: SeriesWillem PrinseNo ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Comet GB PDFDocument16 pagesComet GB PDFPelitamaju MsNo ratings yet

- MX2600 3100 Leaflet EU0805SPDocument2 pagesMX2600 3100 Leaflet EU0805SPGilberto XavierNo ratings yet

- 612sg Spec Sheet 0920Document1 page612sg Spec Sheet 0920Ben LernerNo ratings yet

- MR. AbdulDocument1 pageMR. Abdulabdul quadirNo ratings yet

- MM - Buyers - Guide - Linear - Milling 23Document1 pageMM - Buyers - Guide - Linear - Milling 23Rajesh PotluriNo ratings yet

- Catalogue HACINT MEGAINDUS 2023 Fully Automatic MachineDocument31 pagesCatalogue HACINT MEGAINDUS 2023 Fully Automatic MachineNabil daiouneNo ratings yet

- File 1688538953 CNC Sliting LatheDocument19 pagesFile 1688538953 CNC Sliting Lathealshahrysnan527No ratings yet

- NMV106A 40x100cmDocument1 pageNMV106A 40x100cmAbhishek VelagaNo ratings yet

- Environmental Information: Machine SpecificationDocument4 pagesEnvironmental Information: Machine SpecificationbadrezzineNo ratings yet

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationJosé PeNo ratings yet

- MM - Buyers - Guide - Linear - Milling 26Document1 pageMM - Buyers - Guide - Linear - Milling 26Rajesh PotluriNo ratings yet

- Citizen A16VI Machine SpecificationsDocument2 pagesCitizen A16VI Machine SpecificationscmganklNo ratings yet

- XL 150 SeriesDocument2 pagesXL 150 SeriescoronaqcNo ratings yet

- Backhoe Loader Quotation SheetDocument1 pageBackhoe Loader Quotation SheetDiego Sanmiguel VillacresesNo ratings yet

- Mazak Make Turning Center: MODEL: - Quick Turn 6T, YOM: - 2006Document1 pageMazak Make Turning Center: MODEL: - Quick Turn 6T, YOM: - 2006voho nhattanNo ratings yet

- I-110 - 2010 - Spec Sheet 1 PDFDocument4 pagesI-110 - 2010 - Spec Sheet 1 PDFeaglego00No ratings yet

- E2. MC-043 Flat Bed CNC Lathe Machine (Siemens Controller)Document2 pagesE2. MC-043 Flat Bed CNC Lathe Machine (Siemens Controller)manual imbNo ratings yet

- MR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineDocument43 pagesMR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineSamaksh JhalaniNo ratings yet

- Cat-14 UWIFDocument8 pagesCat-14 UWIFudaysahgalNo ratings yet

- PCI MeteorTS900V ENDocument2 pagesPCI MeteorTS900V ENHX WEINo ratings yet

- Terex Finlay I-110 Impact Crusher PDFDocument4 pagesTerex Finlay I-110 Impact Crusher PDFeaglego00No ratings yet

- AS200 200L SeriesDocument24 pagesAS200 200L Seriescoronaqc100% (1)

- Enshu Vertical Machining Center GE15Ve PDFDocument2 pagesEnshu Vertical Machining Center GE15Ve PDFManish GaurNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our Drillingyo2k_123No ratings yet

- Union e PDFDocument33 pagesUnion e PDFGuillermo RamirezNo ratings yet

- Terex Finlay I-110RS Impact Crusher PDFDocument4 pagesTerex Finlay I-110RS Impact Crusher PDFeaglego00No ratings yet

- CNC Vertical Milling Machines: Key PointsDocument4 pagesCNC Vertical Milling Machines: Key PointsJagadisha PandurangaiahNo ratings yet

- Terex Finlay MP-300Document4 pagesTerex Finlay MP-300eaglego00No ratings yet

- Punzonadora Boschert CU Flex para CobreDocument2 pagesPunzonadora Boschert CU Flex para CobreBoschert MéxicoNo ratings yet

- Series: Ultra High Performance Vertical Machining CenterDocument20 pagesSeries: Ultra High Performance Vertical Machining Centerwataneta valveNo ratings yet

- Tsugami America M08SY IIDocument8 pagesTsugami America M08SY IIchinhtrungvttNo ratings yet

- Terex Finlay J-1160Document4 pagesTerex Finlay J-1160eaglego00No ratings yet

- Asn 690Document2 pagesAsn 690fikriimam1No ratings yet

- Quote of FLASH FL400-Z20Q121207Document2 pagesQuote of FLASH FL400-Z20Q121207Mohammed SakhibNo ratings yet

- JUKI's Industrial Sewing MachinesDocument4 pagesJUKI's Industrial Sewing MachinesfilisavicNo ratings yet

- MM MM MM MM MM - MM MM MM Mm/min MM/M¡N Mm/min Mm/min 4 R/min MM Station MMDocument8 pagesMM MM MM MM MM - MM MM MM Mm/min MM/M¡N Mm/min Mm/min 4 R/min MM Station MMJuan Sebastián ChinomeNo ratings yet

- Band Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryDocument1 pageBand Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryMantención FastpackNo ratings yet

- Mill 55Document4 pagesMill 55Manuel XamanNo ratings yet

- CNC Lathe List: Item CK0640 CK0660 CK0680Document10 pagesCNC Lathe List: Item CK0640 CK0660 CK0680MUHAMMAD NAUMANNo ratings yet

- MM - Buyers - Guide - Linear - Milling 29Document1 pageMM - Buyers - Guide - Linear - Milling 29Rajesh PotluriNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- DHP486 DDF486 BrochureDocument2 pagesDHP486 DDF486 BrochureZxcvNo ratings yet

- Size Matters: New Ultra Compact ToolDocument2 pagesSize Matters: New Ultra Compact ToolIuriiNo ratings yet

- AMS-210E-2210: Computer-Controlled Cycle Machine With Input FunctionDocument2 pagesAMS-210E-2210: Computer-Controlled Cycle Machine With Input FunctionShafikul IslamNo ratings yet

- Volvo Ingersoll Rand DD14S DD16Document4 pagesVolvo Ingersoll Rand DD14S DD16Jozef50% (2)

- General Catalogue: Sample Preparation MachinesDocument16 pagesGeneral Catalogue: Sample Preparation Machinesfatih_hideNo ratings yet

- f573 Okuma Ma 600 HB Space Center Technical DetailsDocument4 pagesf573 Okuma Ma 600 HB Space Center Technical DetailsJordan Martinez LizNo ratings yet

- Product Presentation: LL 20T L5Document12 pagesProduct Presentation: LL 20T L5PRASANNAKUMAR THANGARAJNo ratings yet

- 210902quoattion of V7 CNC Milling Machine-BLIN MACHINERYDocument2 pages210902quoattion of V7 CNC Milling Machine-BLIN MACHINERYJackson SilvaNo ratings yet

- Citizen A16VI Machine SpecificationsDocument2 pagesCitizen A16VI Machine SpecificationscmganklNo ratings yet

- PI of Swiss Type AK164Document5 pagesPI of Swiss Type AK164Jackson SilvaNo ratings yet

- Cyclone-32-CS ManualDocument9 pagesCyclone-32-CS ManualJackson SilvaNo ratings yet

- Used Ganesh Ganesh CNC Lathe - HGR Industrial SurplusDocument1 pageUsed Ganesh Ganesh CNC Lathe - HGR Industrial SurplusJackson SilvaNo ratings yet

- SR 10JDocument2 pagesSR 10JJackson SilvaNo ratings yet

- Business Maths Chapter 5Document9 pagesBusiness Maths Chapter 5鄭仲抗No ratings yet

- Dimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringDocument22 pagesDimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringUCSC Students100% (1)

- Writofsummons ForrevisionpurposesonlyDocument7 pagesWritofsummons ForrevisionpurposesonlyNuur KhaliilahNo ratings yet

- AppendixA LaplaceDocument12 pagesAppendixA LaplaceSunny SunNo ratings yet

- Applications of Remote Sensing and Gis For UrbanDocument47 pagesApplications of Remote Sensing and Gis For UrbanKashan Ali KhanNo ratings yet

- Formula BookletDocument2 pagesFormula BookletOm PatelNo ratings yet

- Amplifier Frequency ResponseDocument28 pagesAmplifier Frequency ResponseBenj MendozaNo ratings yet

- New Python Basics AssignmentDocument5 pagesNew Python Basics AssignmentRAHUL SONI0% (1)

- Chapter-4 Conditional and Iterative Statements in PythonDocument30 pagesChapter-4 Conditional and Iterative Statements in Pythonashishiet100% (1)

- DS WhitePaper Troubleshooting 3DEXPERIENCE ABEND SituationsDocument26 pagesDS WhitePaper Troubleshooting 3DEXPERIENCE ABEND SituationsSam AntonyNo ratings yet

- CHAPTER I KyleDocument13 pagesCHAPTER I KyleCresiel Pontijon100% (1)

- CFA L1 Ethics Questions and AnswersDocument94 pagesCFA L1 Ethics Questions and AnswersMaulik PatelNo ratings yet

- First Certificate Star SB PDFDocument239 pagesFirst Certificate Star SB PDFPatricia Gallego GálvezNo ratings yet

- Aggregate Production PlanningDocument5 pagesAggregate Production PlanningSarbani SahuNo ratings yet

- Miso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsDocument8 pagesMiso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsEllie M.No ratings yet

- Gulf Case Study SolnDocument9 pagesGulf Case Study SolnHarsh SNo ratings yet

- Cuerpos Extraños Origen FDADocument30 pagesCuerpos Extraños Origen FDALuis GallegosNo ratings yet

- Transportation Engineering Unit I Part I CTLPDocument60 pagesTransportation Engineering Unit I Part I CTLPMadhu Ane NenuNo ratings yet

- CPARDocument2 pagesCPARHarryrich MarbellaNo ratings yet

- Travel OrderDocument2 pagesTravel OrderStephen EstalNo ratings yet

- Cs09 404 Programming Paradigm (Module 1 Notes)Document24 pagesCs09 404 Programming Paradigm (Module 1 Notes)Rohith BhaskaranNo ratings yet

- Hormone Replacement Therapy Real Concerns and FalsDocument13 pagesHormone Replacement Therapy Real Concerns and FalsDxng 1No ratings yet

- Grammar and Oral Language Development (GOLD) : Reported By: Melyn A. Bacolcol Kate Batac Julie Ann OcampoDocument17 pagesGrammar and Oral Language Development (GOLD) : Reported By: Melyn A. Bacolcol Kate Batac Julie Ann Ocampoclara dupitasNo ratings yet

- Karamadi - A Waning Practice of Shore Seine Operation Along Kerala, SouthwestDocument6 pagesKaramadi - A Waning Practice of Shore Seine Operation Along Kerala, SouthwestQ8123No ratings yet

- Software Requirements SpecificationDocument9 pagesSoftware Requirements SpecificationSu-kEm Tech LabNo ratings yet

- Python PyDocument19 pagesPython Pyakhilesh kr bhagatNo ratings yet

- Injection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkDocument1 pageInjection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkAlexanderNo ratings yet

- Problem SetsDocument69 pagesProblem SetsAnnagrazia ArgentieriNo ratings yet

- Chiba International, IncDocument15 pagesChiba International, IncMiklós SzerdahelyiNo ratings yet

- Araldite 2020 + XW 396 - XW 397Document6 pagesAraldite 2020 + XW 396 - XW 397Paul Dan OctavianNo ratings yet