Professional Documents

Culture Documents

1-Needle and 2-Needle Lockstitch Machines with Large Hooks

Uploaded by

Raitziel KlossOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-Needle and 2-Needle Lockstitch Machines with Large Hooks

Uploaded by

Raitziel KlossCopyright:

Available Formats

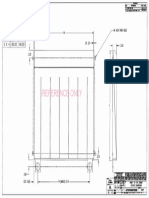

LU-2810-6

1-needle,Unison-feed,Lockstitch Machine

with Vertical-axis Large Hook〈with automatic thread trimmer of V-Belt type〉

LU-2860-6

2-needle,Unison-feed,Lockstitch Machine

with Vertical-axis Large Hook〈with automatic thread trimmer of V-Belt type〉

High and long arm has been adopted. Wide machine bed area contributes to improved workability.

The V-belt type machine head is added to

the machine lineup following the Direct-Drive type.

LU-2810-6 LU-2860-6

Functions for improving seam quality and workability

Double tension provided as : standard New bobbin thread winder

A dual-tension is provided as standard New bobbin thread winder is no neccessity

responding to the sewing with thick thread of rolling thread manually.

under a higher tension.

Multi-functional 6-string switch

(with automatic thread trimmer)

The machine with thread trimmer can Higher lift of the presser bar

change over the needle thread tension A 20mm presser bar lift is achieved by

from single to double and vice versa automatic presser bar lift, which provides

(increase the responsiveness to thicker easy operation for joining leather and thick

materials), change over the alternating sponges often applied to making luxurious

vertical movement amount, the stitch sofas. 20 mm

length, etc. by simply pushing the

The picture is LU-2860-6.

Multi-functional 6-string switch.

Walking-foot/presser-foot alternating

vertical movement mechanism

Wide machine bed area contributes to improved workability.

The adopted feed mechanism makes up

The machine is suited to sew car seats, sofas and bags, provided with

less variance of the balance of the

dramatically improved workability and functions required for sewing

alternating vertical movement amounts.

large products and extra heavy-weight materials.

The maximum presser foot lift is 9mm

which can be adjusted with ease by the

large dial on top of the machine head. 9 mm

Eccentricity of the feed

driving cam is adjustable.

Adjustment of the eccentricity of the feed

driving cam has been enabled. As a

127 mm 103 mm result, the sewing machine is able to

347 mm perform sewing with the feed that is

255 mm

best-suited to the material and thread

used. It is no longer necessary to prepare

other subclass model sewing machines.

ATTACHMENTS SPECIFICATIONS

Suspended ruler H152 Model name LU-2810-6 LU-2860-6

Description Parts No. 1-needle (with automatic 2-needle (with automatic

Type

Suspended ruler (asm.) H152 MAH-152010A0 thread trimmer of V-Belt type) thread trimmer of V-Belt type)

Suspended ruler adapter plate※ 40112214 Max. sewing speed 3,000sti/min 2,700sti/min

Screw※ SM6051402TP ×2 Max. stitch length 9mm

Screw※ SM6061402TP ×2 Stitch length dial 2 pitch dial

※The parts is contained in the accessories of a head. Presser foot Auto: 20mm, By hand: 10mm

Auto lifter Provide as standard

Presser foot with center guide Alternating vertical movement 1~9mm

(for europe gauge) Alternating vertical movement

Large dial

Needle Gauge Parts No. adjusting method

B : 6mm 40038810 DL device Provide as standard

C : 8mm 40038808 Needle thread tension Single/Double-tension

D : 10mm 40038806 Bottom-feed micro-adjustment

Provided as standard

E : 12mm 40038802 mechanism

※For standard gauge, please contact your nearest JUKI distributor. Hook Vertical axis 2 fold-capacity hook

Needle 135×17 Nm160 (Nm125~Nm180)

Slide plate with window Thread #30~#5, B46~B138, Mn=60/3~20/3

Description Parts No. Lubrication Automatic (Tank system)

Slide plate with window One-touch type reverse feed switch Provide as standard

40133312

(right & left) Hand switch Multi-functional 6-string switch

Safety mechanism Provided as standard (reset with the push of a button)

Machine head weight 62kg 67kg

*"sti/min" stands for "Stitches per Minute."

WHEN YOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

Machine head

[ 1-needle (with automatic thread trimmer) ] LU2810 60BBS

Gauge type Code Wiper and one-touch type reverse feed Automatic foot lifter Code Alternating vertical dial Code

Standard gauge S Wiper One-touch type reverse feed Code Provided (pedal-driven) B Provided S

gauge for europe A Not provided Provided 0B

Machine head Gauge type Code Wiper and one-touch type reverse feed

[ 2-needle (with automatic thread trimmer) ] Standard gauge S Wiper One-touch type reverse feed Code

gauge for europe A Not provided Provided 0B

※ In case of “ S ” type ※ In case of “ A ” type

in Gauge type, please in Gauge type, please

choose from below.

Needle Gauge Code

choose from below.

Needle Gauge Code LU2860 60BBS

4.8mm D 6mm B

6.4mm F 8mm C

7.9mm H 10mm D

9.5mm K 12mm E Automatic foot lifter Code Alternating vertical dial Code

Provided (pedal-driven) B Provided S

New-type tank style automatic lubrication mechanism has been adopted.

The oil dropped from the hook and its surrounding sections into the under-cover is filtered to

remove dirt and dust and is then returned to the oil tank. This method saves the effort of oiling and Dry

reduces oil consumption. The remaining oil quantity indicator is provided on the front face of the

Hook Oil

machine head. Lubrication can be carried out without tilting the machine head. Oiling part tank

Oiling

Circulation filter

JUKI ECO PRODUCTS The LU-2800 Series is an eco-friendly product which complies with JUKI ECO PRODUCTS standards for protecting the environment.

The sewing machine complies with the "Juki Group Green Procurement Guidelines" on the use of

hazardous substances, which is stricter than other restrictions, such as those of the RoHS Directive.

For details of JUKI ECO PRODUCTS, refer to: http://www.juki.co.jp/eco_e/index.html

The RoHS Directive is an EU Directive limiting the use of 6 hazardous substances (lead, hexavalent chromium, mercury, cadmium, PBB and PBDE) in electrical and electronic equipment.

The Juki Green Procurement Guideline is the voluntarily established criteria to eliminate not only the aforementioned six substances, but also other ones which also adversely affect the environment.

※Above-mentioned JUKI ECO PRODUCTS is data of LU-2810-6 (with automatic thread timmer).

To order, please contact your nearest JUKI distributor. Juki Corporation operates an environmental management system

to promote and conduct the following as the company engages in

the research, development, design, sales, distribution,and

maintenance of industrial sewing machines, household sewing

machines, industrial robots, etc., and in the provision of sales and

maintenance services for data entry systems:

(1) The development of products and engineering processes

that are safe to the environment

(2) Green procurement and green purchasing

(3) Energy conservation (reduction in carbon-dioxide emissions)

(4) Resource saving (reduction of papers purchased, etc.)

(5) Reduction and recycling of waste

(6) Improvement of logistics efficiency (modal shift and

improvement of packaging, packing, etc.)

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO 206-8551, JAPAN

PHONE : (81) 42-357-2254

FAX : (81) 42-357-2274

SEWING MACHINERY BUSINESS UNIT http://www.juki.com

✽ Specifications and appearance are subject to change without prior notice for improvement.

✽ Read the instruction manual before putting the machine into service to ensure safety.

✽ This catalogue prints with environment-friendly soyink on recycle paper.

NOVEMBER, 2013 Printed in Japan(C)

You might also like

- LU-2800 SeriesDocument12 pagesLU-2800 SeriesNathan Peroni AlvesNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Precise Electronic Eyelet Buttonhole MachineDocument4 pagesPrecise Electronic Eyelet Buttonhole Machinedharmik borisagarNo ratings yet

- High and Long Arm Sewing Machine With Automatic Thread TrimmerDocument2 pagesHigh and Long Arm Sewing Machine With Automatic Thread TrimmerSheikh RizwanNo ratings yet

- SKG 230 BrochuresDocument2 pagesSKG 230 Brochuresdion.dsiNo ratings yet

- PM2000,3000,4000Document8 pagesPM2000,3000,4000rago4uNo ratings yet

- High-Performance Strip Feed UnitDocument7 pagesHigh-Performance Strip Feed UnitSaša LjubišićNo ratings yet

- Product Manual - Juki PLC-2700 (2 Needle Post)Document6 pagesProduct Manual - Juki PLC-2700 (2 Needle Post)WillNo ratings yet

- 570 590 LeafletDocument12 pages570 590 LeafletfgfgfgNo ratings yet

- Juki MF-7700 CatalogDocument8 pagesJuki MF-7700 CatalogDaniel PereaNo ratings yet

- Hydraulic Guillotine Shears: TypesDocument8 pagesHydraulic Guillotine Shears: TypesDominik RaczykNo ratings yet

- Juki DLN-9010Document4 pagesJuki DLN-9010Jose Antonio Rojas BautistaNo ratings yet

- Masina Feston MO6916RDocument6 pagesMasina Feston MO6916RDariaNo ratings yet

- DDL 5600 NDocument2 pagesDDL 5600 NJesús Sánchez CarriónNo ratings yet

- NEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Document12 pagesNEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Marlon GilerNo ratings yet

- Direct-drive, High-speed, 1-needle Lockstitch MachineDocument4 pagesDirect-drive, High-speed, 1-needle Lockstitch MachineAdriana MolinaNo ratings yet

- Forceturn 630.30 DatasheetDocument3 pagesForceturn 630.30 DatasheetLukasz PawellaNo ratings yet

- Juki Dnu 1541Document4 pagesJuki Dnu 1541Jose Antonio Rojas BautistaNo ratings yet

- Fast Sewing Machine Mo6800sDocument4 pagesFast Sewing Machine Mo6800sKabir MahlotraNo ratings yet

- Shoe Machinery Unit II & IIIDocument106 pagesShoe Machinery Unit II & IIIashutosh100% (1)

- Automatic Pocket Welting MachinesDocument6 pagesAutomatic Pocket Welting MachinesRahul Raj100% (1)

- Button Hole MachineDocument4 pagesButton Hole MachineHarun ar RashidNo ratings yet

- PUMA V400 CatalogDocument16 pagesPUMA V400 CatalogPSIX FACTORYNo ratings yet

- Kel Univ ECatDocument8 pagesKel Univ ECatShAi_MyStERiOuSNo ratings yet

- KM-T20 CatalogDocument1 pageKM-T20 CatalogJackson SilvaNo ratings yet

- Mo 881Document2 pagesMo 881Vasile TipcuNo ratings yet

- Manual Rack Presses 2020Document14 pagesManual Rack Presses 2020anthonyMNo ratings yet

- High Performance Vertical Turning CenterDocument16 pagesHigh Performance Vertical Turning CenterMirko GallonNo ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Cutting EquipmentsDocument23 pagesCutting EquipmentsManoj SahuNo ratings yet

- Agma MachineDocument6 pagesAgma MachineNursena SEVİNÇNo ratings yet

- Multi CutDocument2 pagesMulti CutSEC MachinesNo ratings yet

- Hobbing Machines LC 80-180Document8 pagesHobbing Machines LC 80-180Abdisalaam mohamudNo ratings yet

- Wide Cutting On The Solid Body: MLT100 Table SawDocument2 pagesWide Cutting On The Solid Body: MLT100 Table SawIka Novianty MANo ratings yet

- Partsbook Juki Zigzag 2280aDocument8 pagesPartsbook Juki Zigzag 2280aMaskusyaniNo ratings yet

- ASC-TBH200 A4DM 20230130 SDocument2 pagesASC-TBH200 A4DM 20230130 Sdroessaert_stijnNo ratings yet

- Kubota 2016 KV RM Plough IENDocument24 pagesKubota 2016 KV RM Plough IENdejanflojdNo ratings yet

- Ful 56 Introducción A La Maquina ÍnternaDocument4 pagesFul 56 Introducción A La Maquina Ínternafernando rochaNo ratings yet

- E - Product View-PrDocument16 pagesE - Product View-PrJack ReacherNo ratings yet

- Ultra High Performance NSV Series Vertical Machining CentersDocument20 pagesUltra High Performance NSV Series Vertical Machining Centerswataneta valveNo ratings yet

- ht30c eDocument4 pagesht30c eSharma JiteshNo ratings yet

- DNLS 4Document23 pagesDNLS 4Gangadhar MalikNo ratings yet

- lt591 PDFDocument2 pageslt591 PDFJUAN LOZANO - JFUANNo ratings yet

- Partsbook Juki LBH-1790aDocument5 pagesPartsbook Juki LBH-1790aMaskusyani100% (2)

- Catálogo HabasitDocument40 pagesCatálogo Habasitjackson.silvaNo ratings yet

- Chainstitch MachineDocument6 pagesChainstitch MachineNikita JainNo ratings yet

- Louvretec Design Manual Section 7 300mm AirfoilDocument10 pagesLouvretec Design Manual Section 7 300mm AirfoiljoseocsilvaNo ratings yet

- Cat-14 UWIFDocument8 pagesCat-14 UWIFudaysahgalNo ratings yet

- 2018 - UMC-1000 2016 - NewDocument16 pages2018 - UMC-1000 2016 - NewAbhishek VelagaNo ratings yet

- Ze-855a BrochureDocument6 pagesZe-855a BrochureDani Perry (Dinara)No ratings yet

- Technical Specifications of Cutting and Spreading MachinesDocument49 pagesTechnical Specifications of Cutting and Spreading MachinesIndranil Saha50% (4)

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet

- Sampsistemi Pouzavanje PDFDocument8 pagesSampsistemi Pouzavanje PDFOscarBarretoNo ratings yet

- Silentpiler f401-1400Document5 pagesSilentpiler f401-1400Nguyen The PhatNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Woodturning LathesDocument24 pagesWoodturning LatheslucibrandusNo ratings yet

- SeamerweldersDocument4 pagesSeamerweldersstefan.e.bathoryNo ratings yet

- General Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentDocument18 pagesGeneral Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentLoki C GowdaNo ratings yet

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDocument16 pagesCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNo ratings yet

- Pfaff 1245 Instruction ManualDocument36 pagesPfaff 1245 Instruction ManualRaitziel KlossNo ratings yet

- The Tailoring Book 1899Document430 pagesThe Tailoring Book 1899lover.forever100% (4)

- SL 87915 120Document2 pagesSL 87915 120Raitziel KlossNo ratings yet

- Ja 1245 1246 10-15 enDocument44 pagesJa 1245 1246 10-15 enRaitziel KlossNo ratings yet

- Vinyl Cutter: User Manual & Assembly InstructionsDocument17 pagesVinyl Cutter: User Manual & Assembly InstructionsSEORNo ratings yet

- 2020 Summit 3000Document2 pages2020 Summit 3000Raitziel KlossNo ratings yet

- Ramp Drawing s2950fDocument1 pageRamp Drawing s2950fRaitziel KlossNo ratings yet

- 2018 HBBDocument1 page2018 HBBRaitziel KlossNo ratings yet

- Brother Overlock 1034DDocument68 pagesBrother Overlock 1034DsenditalNo ratings yet

- 49 Annals90Document12 pages49 Annals90Raitziel KlossNo ratings yet

- Dect2005-85035 Benchmarking of MBS Simulation SoftDocument11 pagesDect2005-85035 Benchmarking of MBS Simulation SoftRaitziel KlossNo ratings yet

- 2020 Summit 3000Document2 pages2020 Summit 3000Raitziel KlossNo ratings yet

- SL 105278 120plusDocument2 pagesSL 105278 120plusRaitziel KlossNo ratings yet

- 2018 rl50210 Ta 50lb 500lbDocument2 pages2018 rl50210 Ta 50lb 500lbRaitziel KlossNo ratings yet

- lp340 DatasheetDocument1 pagelp340 DatasheetRaitziel KlossNo ratings yet

- 2018 rl50210 Ta 50lb 500lbDocument2 pages2018 rl50210 Ta 50lb 500lbRaitziel KlossNo ratings yet

- Ja 1245 1246 10-15 enDocument44 pagesJa 1245 1246 10-15 enRaitziel KlossNo ratings yet

- Sample PagesDocument13 pagesSample PagesRaitziel KlossNo ratings yet

- Brochure D300 en NHKDocument13 pagesBrochure D300 en NHKRaitziel KlossNo ratings yet

- lp340 DatasheetDocument1 pagelp340 DatasheetRaitziel KlossNo ratings yet

- Nikon D300 Vs D300sDocument1 pageNikon D300 Vs D300sRaitziel KlossNo ratings yet

- D300 Setup Guide v1 1Document2 pagesD300 Setup Guide v1 1Johny WhestNo ratings yet

- Launchpad Mk2 With Ableton GuideDocument6 pagesLaunchpad Mk2 With Ableton GuideDavide ZanattaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Launchpad mk2 Advanced Features Guide PDFDocument5 pagesLaunchpad mk2 Advanced Features Guide PDFRaitziel KlossNo ratings yet

- Industrial: Instruction ManualDocument46 pagesIndustrial: Instruction ManualRaitziel KlossNo ratings yet

- Nalcom FTL800Document32 pagesNalcom FTL800Raitziel KlossNo ratings yet

- 2005 Equinox Premium SoundDocument1 page2005 Equinox Premium SoundRaitziel KlossNo ratings yet

- A Seminar Report On Floating Wind TurbineDocument26 pagesA Seminar Report On Floating Wind Turbinevaishakh123450% (6)

- Lay Up ProcedureDocument21 pagesLay Up ProcedureAmir100% (1)

- KUL CGK: Mohd Hafiz / Bin Suhaimi MRDocument1 pageKUL CGK: Mohd Hafiz / Bin Suhaimi MRDely DeeNo ratings yet

- Colonial Comparison Powerpoint TemplateDocument10 pagesColonial Comparison Powerpoint TemplateGraham NicholsNo ratings yet

- Power Converters Simulation Lab Manual - (2015-2016)Document41 pagesPower Converters Simulation Lab Manual - (2015-2016)Leela KrishnaNo ratings yet

- Activity#tachometer - MEC 0326.1-2Document4 pagesActivity#tachometer - MEC 0326.1-2MarkJude MorlaNo ratings yet

- Ryanair Strategic AnalysisDocument36 pagesRyanair Strategic AnalysisAlmas Uddin100% (1)

- Easergy PS100 48VDC Power SupplyDocument2 pagesEasergy PS100 48VDC Power SupplyRichard SyNo ratings yet

- File 5119 PDFDocument5 pagesFile 5119 PDFIsabele LavadoNo ratings yet

- Thk2e BrE L3 Vocabulary Standard Unit 3Document2 pagesThk2e BrE L3 Vocabulary Standard Unit 3Suki ChuahNo ratings yet

- Project Report ON: "Brand Preference of Onida Colour TV in Coastal OrissaDocument66 pagesProject Report ON: "Brand Preference of Onida Colour TV in Coastal OrissaApurba KhanduriNo ratings yet

- Solutions Manual For Introduction To Management Accounting 16Th Edition Horngren Sundem Schatzberg Burgstahler 0133058786 9780133058789 Full Chapter PDFDocument36 pagesSolutions Manual For Introduction To Management Accounting 16Th Edition Horngren Sundem Schatzberg Burgstahler 0133058786 9780133058789 Full Chapter PDFdavid.rex111100% (10)

- Home Work Chapter 1 To 12Document50 pagesHome Work Chapter 1 To 12Haha JohnNgNo ratings yet

- Extracting Data From GpsDocument7 pagesExtracting Data From GpsRidhima KhajuriaNo ratings yet

- Men S Health South Africa - March 2017 PDFDocument132 pagesMen S Health South Africa - March 2017 PDFAbimaelGomesNo ratings yet

- UI UX Research DesignDocument7 pagesUI UX Research DesignSomya ShrivastavaNo ratings yet

- SEBI Claim Form Details for Shukul Wealth AdvisoryDocument3 pagesSEBI Claim Form Details for Shukul Wealth Advisoryandrew punekarNo ratings yet

- Razwan Iqbalcv1Document3 pagesRazwan Iqbalcv1razwaniqbalNo ratings yet

- Viewing Partition of India as an Imperfect SolutionDocument36 pagesViewing Partition of India as an Imperfect Solutionsingh1910511753No ratings yet

- English For Academic and Professional Purposes: Quarter 1 - Module 3Document9 pagesEnglish For Academic and Professional Purposes: Quarter 1 - Module 3John Vincent Salmasan100% (5)

- Loading Arms and Their Control Panels BrochureDocument5 pagesLoading Arms and Their Control Panels Brochureminah22No ratings yet

- PDF Vertical Axis Wind Turbines DDDocument38 pagesPDF Vertical Axis Wind Turbines DDKunal AhiwaleNo ratings yet

- Newspaper Layout DummyDocument1 pageNewspaper Layout Dummy1w2e3r4t5y100% (9)

- Databases 2 Exercise Sheet 4Document2 pagesDatabases 2 Exercise Sheet 4Shivam ShuklaNo ratings yet

- RTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealDocument5 pagesRTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealAmmie AsturiasNo ratings yet

- PR100 Locks With Aperio Wireless Technology: Key FeaturesDocument2 pagesPR100 Locks With Aperio Wireless Technology: Key FeaturesMay SamboNo ratings yet

- Elevator PitchDocument2 pagesElevator PitchChandni SeelochanNo ratings yet

- Digital Transducers: Group 3Document76 pagesDigital Transducers: Group 3Jasmine RaiNo ratings yet

- HyungJae Yang Sound Water EnvironmentDocument25 pagesHyungJae Yang Sound Water EnvironmentPepeNo ratings yet

- Network Fundamentals - Chapter 4 Exam AnswersDocument4 pagesNetwork Fundamentals - Chapter 4 Exam AnswersBart AbraasNo ratings yet