Professional Documents

Culture Documents

Solar Powered Electroculture Technique For Backyard Farming

Uploaded by

marcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solar Powered Electroculture Technique For Backyard Farming

Uploaded by

marcCopyright:

Available Formats

International Journal of Advanced Research and Publications

ISSN: 2456-9992

Solar-Powered Electroculture Technique For

Backyard Farming

Elenor M. Reyes, GlennJordan M. Achico

Batangas State University, College of Engineering, Architecture and Fine Arts,

Pablo Borbon Main II, Alangilan, Batangas City, Philippines

Len39reyes@gmail.com

Batangas State University, College of Engineering, Architecture and Fine Arts,

Pablo Borbon Main II, Alangilan, Batangas City, Philippines

Glenn_jordan20@yahoo.com

Abstract: To make crops grow larger and faster has been the primary concern of agriculture for ages. All methods of cultivation techniques

and technologies have been developed to fulfill this aim; from simple crop rotation to complex synthetic fertilizers. Another cultivation

technology discovered in agriculture is the application of electricity and magnetism that can accelerate growth rates, increase yields, and

improve crop quality. This technology is called electroculture. Electroculture can protect plants from diseases and insect and likewise

reduce the requirements for fertilizer or pesticides. Farmers can grow bigger and better crops in less time, with less effort, and at a lower

cost. Rationalizing the concept of electricity’s role in plant growth stimulation and application of solar technology, the researcher designed

and developed a project that would help increase the growth of plants without losing their quality and nutrition. Electroculture with proper

watering system will help the plants grow faster. Moreover, the portable solar power supply may be used to power up the project for a more

cost effective operation. With this project, there will be an increase in the production of crops and may help resolve the shortage of food in

the years ahead.

Keywords: solar energy electroculture farming

1. Introduction their quality and nutrition. Electroculture with proper

One major factor contributing in the increase in food demand watering system will help the plants grow faster.[3]

is world population growth. Demographic projections have a Moreover, a portable solar power supply may be used to

high degree of certainty, so projections of future world food power up the project for a more cost effective operation.

needs based on population growth are quite reliable. Demand With this project, there will be an increase in the production

for food in the Philippines is expected to rise because of the of crops and may help resolve the shortage of food in the

expected growth in the economy. The country's growing years ahead.

population shall require greater food supplies. With the fast

increasing population, the need for food will become 2. Material and Methods

increasingly urgent as several factors such as pests, climate The project study used engineering and planning type of

change and the like, force the change of the approach to research which involved the use of plans, procedures and

agriculture, creating or developing new agricultural strategies to come up with the working prototype.

techniques or strategies to ensure enough food supply for the Conceptual literature and related studies were considered in

people. Experts say that farmers now lack the ability to yield the construction of the proposed project. The evaluation of

good quality edible plants. Electroculture is one of the the existing electroculture included the analysis of the

potential solutions to help solve this crisis. Electroculture design, construction and operation of the previous models.

includes the study of the effects of electricity and electric Some modifications for improvement on the previous models

fields on the rate of seed germination and plant growth. For were also included. The study also took into consideration

centuries, farmers had sworn that thunderstorms make crops the requirement and standards of the electrical engineering

grow quicker. Observations have been made that certain and agriculture and the knowledge of the existing technology

types of grass appear healthier after a thunderstorm and grass to be modified to come up with the design of the

that grows below an electric power cable generally looks electroculture on plants. After gathering different

greener. The reason is that after a thunderstorm, the plants information from different references, the design layout and

make use of the electric current produced by the lightning, specifications has been conceptualized and carry out.

then the plants widely open their roots containing the guard Computation and technical analysis are important to have

cells which allow the passage of electric current to increase accurate results and to minimize actual problems that may

the speed of production of their food. The application of arise throughout the operation of the project. Bit-by-bit

electricity, magnetism, monochrome light, and sound can process and the proper machines and tools to be used in the

stimulate the growth of plants to a great extent[1]. This little- project are given attention in the methods of fabrication and

known technology, called electroculture, can accelerate assembly. The fabrication of the project has been assessed

growth rates, increase yields, and improve crop quality. accurately and the safety of the individual was prioritized.

Electroculture can protect plants from diseases, insects and Some tests were performed to determine acceptability of the

frost. These methods also can reduce the requirements for operation of the project and its efficiency. Furthermore,

fertilizer or pesticides. Farmers can grow bigger and better charging and discharging tests were done to measure the

crops in less time, with less effort, and at a lower cost .[2] It current drain capabilities of the solar panel and its

is the researchers’ aspiration to design and develop a project auxiliaries.

that will quickly increase the growth of plants without losing

Volume 3 Issue 3, March 2019 116

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

3. Results and Discussion 3.1.4 Areas for Improvement. The past study

concerned only on using electroculture as a technique

3.1 Evaluation of the existing electroculture technique for plant growing whereas the present study added other

features such as solar power energy as the supply and an

3.1.1 Design. In the study of electroculture technique, automated watering system. Using solar power energy

the proponent planted a vegetable garden in their front as the supply is a means to conserve energy. A 12V DC,

yard. Tomatoes, eggplant, broccoli, peppers, and chard 40 AH deep cycle battery was used to store the energy

were planted. The plants were electrified by Samsung that is generated by the solar panel. The copper rods

phone charger with a 5v, 550 mA output. The charger used in the project and the trigger for the automatic

was connected to two three-inch nails by a 1.75 mm watering system got their supply from the solar power

diameter conductor, one connected to each wire of the connected to it. Having an automated watering system

charger. The nails were buried in the east and west sides. is one way to control or conserve water.

The Samsung charger was plugged in an outside

convenience outlet. The garden was manually watered 3.2 Design Consideration and Requirement

8:00 in the morning and at 4:00 in the afternoon.

3.2.1 Philippine Electrical Code (PEC). In order to

3.1.2 Construction. The garden wherein electroculture ensure the quality of the products, some provisions of

technique was applied is about 25 feet by 14 feet. The the Philippine Electrical Code were cited and considered

long axis was east to west. The nails which are as guides for the development and operation of a solar-

connected to the supply were positioned on the east and powered electroculture technique for backyard farming.

west sides. The positive electrode was about 8 feet away Researchers provided a functional prototype as to

to the right. Figure 1 shows the garden where simulate final design, considering aesthetics, materials,

electroculture technique was applied. quality and functionality. They reduced its size in order

to reduce its cost. The provisions cited were on storage

batteries, wiring and equipment supplied from batteries.

3.2.1.1 Storage batteries. Art. 4.80.18 provides that

racks and trays shall comply with (a) Racks, as required

in this article, are rigid frames designed to support cells

or trays. They shall be substantial and be made of one of

the following: (1) Metal, treated so as to deteriorating

action by the electrolyte and provided with no

conducting members directly supporting the cells or

with continuous insulating material other than paint on

conducting members; or (2) Other construction such as

fiberglass or other suitable nonconductive materials. (b)

Trays are frames, such as crates or shallow boxes

usually of wood or other nonconductive material,

Figure 1. Plot where electroculture technique is applied constructed or treated so as to be resistant to

deteriorating action by the electrolyte.

3.1.3 Operation. The plants were electrified 24/7. The

garden is manually watered 8:00 in the morning and at 3.2.1.2 Wiring and equipment supplied from

4:00 in the afternoon. Three weeks later after the batteries. According to Art. 4.80.1.3, wiring and

electroculture technique was applied, the plants grew equipment supplied from storage batteries shall be

faster. Figure 2 shows the effect of electricity to the subject to the requirements of this code applying to

plants. The row of plants closest to the path is taller than wiring and equipment operating at the same voltage,

the rows further away. This was because the electric unless otherwise permitted by 4.80.1.4.

field was originating next to the path. As the field

diminishes over distance, so does the growth 3.2.1.3 Wiring. Wires shall be identified by sleeve-wire

amplification effect. markers or equivalent at each end. Wiring shall be

thermoplastic and heat-resistant.

3.2.2 Institute of Electrical and Electronics

Engineers (IEEE)

3.2.2.1 IEEE SA - 1562-2007 - IEEE Guide for Array

and Battery Sizing in Stand-Alone Photovoltaic (PV)

Systems. According to this IEEE Standard, a method for

properly sizing the PV array and battery for stand-alone

PV systems where PV is the only charging source is

recommended (in conjunction with IEEE Std 1013TM).

Load calculations and determination of solar radiation in

the sizing of the system need special attention.

Figure 2. Plot after electricity was applied

Volume 3 Issue 3, March 2019 117

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

Additionally, the critical nature of the load in deciding

an acceptable annual availability needs to be considered.

3.2.2.2 Department of Agriculture (DA). Under a

Memorandum of Agreement (MOA) signed by former

Secretary of Department of Agriculture Yap and AFI

president Regina Lopez, the Department will set up

home gardens at the resettlement site; train the

beneficiaries on vegetable farming and teach them

environment-friendly technologies to increase their

production; and provide them with farm inputs in the

form of assorted vegetable seeds, fish tank /fingerlings,

shredder and vermicomposting units.

Figure 3. Solar Powered Electroculture Technique for

3.2.2.3 Pechay Production. Pechay can either be sown Backyard Farming

directly on the soil or transplanted. Direct seeding is

carried out by broadcasting or by sowing in rows. Cover 3.3.2 Design and computation analysis. For a better

the seeds to a depth of about 1 cm by raking or understanding of the prototype, the proponents provided

spreading additional top soil. Water immediately after computations of the components of the design.

sowing. Plant spacing should be 10 cm between plants Sizing of the Solar Panel. In order to determine the size

and 20 cm between rows. Afterwards, harvest in 45 days of the solar module, the total load demand must be

after sowing. Harvest methods are preferably done on computed first.

the leaves and then remove roots. Pechay is about 15-30 Solenoid Valve = 4.8 W

cm tall in vegetative state. [4] Copper Rods = 12V x 2.5A = 30 W

3.3 Design Plans and Specifications The total demand load will be the sum of the individual

load.

3.3.1 General Description of the Project. The solar-

powered electroculture technique for backyard farming Total load = 4.8 W + 30 W = 34.8 W x 1.25 = 43.5

is a project which aims to make crops grow larger and Watts (since 125% is the reciprocal of 80 percent and 80

faster. It is powered by a 50 Watts solar panel connected percent of the rating of the solar panel shall be its

to a 12 Volt DC deep cycle battery. The 12 Volt deep maximum allowable load.

cycle battery supplies the copper rods planted in the soil

through a charge controller. The project has three The researchers used a 50 W solar panel for further

different plots planted with 24 pechay plants per plot. improvement of the prototype. Pmax = 50W and

Plot A was intended for traditional plant growing nominal voltage was 12V.

without fertilizers. In plot B, two copper rods were

planted in the soil of each pechay plant soil. The copper Sizing of the Charge Controller. The researchers came

rods were placed at opposite sides of the plot and did not up with the size of the charge controller using the

touch each other. Using a solar charge controller, the parameter computed in sizing the solar panel.

solar panel charges the battery while the battery supplies Solar Panel = 50 W

the microcontroller. It is programmed that every 8 am Battery = 12VDC

and 4 pm the microcontroller will allow the passage of Ampere Rating:

electricity from the battery to the solenoid valve for the = (50W / 12VDC) x 1.25 = 5.2083 A

watering system and the copper rod for the

electroculture technique for two minutes. Lastly, in plot Twenty five percent (25%) of the ampere rating should

C, liberal amount of organic fertilizer (compost) was be added to take account the special conditions that

applied at the base of the plants and covered lightly with could occur, causing the solar panel to produce more

soil and watered immediately to give the plants enough power than normally rated (e.g. due to sunlight’s

nutrients. In plot A, there was no fertilizer used. The reflection off of water, extraordinary bright conditions,

plots were watered through an automated watering etc.).

system. This system was done by a program using an

Arduino supplied by the 12 Volt DC battery supply. Sizing of the Battery. The researchers provided

This Arduino is connected to a solenoid valve which batteries based on parameters computed in a worst case

triggers every 8am and 4pm. The solenoid valve is scenario that the solar panel will not be available due to

connected to a hose that connects the water supply and insufficient sunlight. The battery at full charge

the pulsating sprinkler in the end. The pulsating condition is assumed to be used 360 minutes (non

sprinkler automatically waters the plant whenever the continuous).

solenoid valve triggers. The growth of the pechay plants

is monitored by using a bullet type CCTV camera. The Therefore:

actual prototype of the project is shown in Figure 3. Ampere-Hour

= (5.20A)(360 minutes x 1 hour/60 minutes)

Ampere-Hour = 31.2 AH

Volume 3 Issue 3, March 2019 118

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

The researchers used 40 AH deep cycle battery because

it is designed for solar applications and the rating is

more than the computed rating.

3.3.3 Design layouts. The construction assembly of

solar powered electroculture technique for backyard

farming is shown in Figure 4. It consists of a solar panel,

a storage battery, sprinkler, a greenhouse, a charge

controller, and a microcontroller of irrigation. The

greenhouse consists of three plots. It has also a CCTV

for monitoring purposes only. Along with it are the

dimensions of the prototype.

Figure 6. Flowchart

The battery supplies the circuit and initializes the device and

is represented by a parallelogram. The RTC is a real time

clock which tracks the current time even if the

microcontroller does not have a power supply because it has

a separate battery. The microcontroller operates based on

real-time manner. The researchers set the time of watering

the plants, 8:00am and 4:00pm only, and the duration of the

process is set for two (2) minutes for each time set. The

Figure 4. Isometric View diamond indicates decision making process where the

Arduino decides if the set time is equal to the current time in

Figure 4 shows the isometric view of the project. The the RTC. If the Arduino decides that the set time is not equal

greenhouse is 2.4m x 1.3m x 1m with the three (3) to the current time, the Arduino repeats the process from the

partitions; Plot A, Plot B, Plot C. Electroculture plot has start until the Arduino reaches the set time equal to the

the copper rods installed 12cm from the base of the current time in the RTC. When the real time clock (RTC) is

plant. The project study has additional features: sprinkle equal to the time set, the Arduino sends electrical signal to

and CCTV camera. Sprinkler post of 1.25m and the the sprinkler’s relay (the solenoid valve is directly connected

solenoid valve post of 1m in height was installed 1.5m to the sprinkler’s relay), the sprinkler’s relay will allow the

from the greenhouse while the CCTV camera post of electric signal to flow to the solenoid valve. The solenoid

1.3m in height was installed from the distance of 2m will open up and allow the water to pass through for duration

from the greenhouse. of two minutes; the sprinkler is directly coupled to the

solenoid valve, which will water the plants. The

3.3.4 Circuit Diagram. The circuit diagram of the microcontroller is again returned to the start until it reaches

project and the connection of all components of project the condition set by the proponents.

is shown in figure 4.5. It composes of a solar panel,

charge controller, microcontroller, solenoid valve and 3.4 Testing Methodologies

the copper rods. Tests were conducted to determine whether the mechanism

and output of the system reached the desired output. A

growth test was conducted in order to establish the

effectiveness and efficiency of the prototype. To confirm that

the necessary output of the project was achieved, a CCTV

camera was used to monitor the growth of the plants.

Researchers will use a ruler to record the height of the plants

in each plot. In the first test, the researchers provided

seedlings of pechay and planted them in the three plots (plot

A, plot B and plot C). All the plots were provided with same

amount of water through an automated watering system. The

plants in plot B were electrocuted 24 hours a day while plot

A and plot C grew the plants in a conventional manner with

and without fertilizer, respectively. The testing lasted only

Figure 5. Schematic Circuit Diagram for two weeks. After such observations made for weeks, the

following results for different parameters set by the

3.3.5 Program and its Implementation. Figure 6 proponents are drawn.

shows the flowchart of the operation of the

microcontroller.

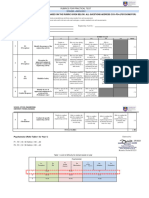

PLANT CONFIGURATION

Volume 3 Issue 3, March 2019 119

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

sense plant growth are being stimulated by electricity

because wet soil improves current flow.

PLANT CONFIGURATION

* P1 – Plant 1 P2 – Plant 2 P3 – Plant 3

P4 – Plant 4 P5 – Plant 5 P6 – Plant 6

P7 – Plant 7 P8 – Plant 8

PLOT A – without fertilizer ; PLOT B – * P1 – Plant 1 P2 – Plant 2 P3 – Plant 3

electroculture; PLOT C – with fertilizer P4 – Plant 4 P5 – Plant 5 P6 – Plant 6

D P7 – Plant 7 P8 – Plant 8

Table 1: Growth Test (Test I) PLOT A – without fertilizer ; PLOT B –

electroculture; PLOT C – with fertilizer

P HEIGHT OF PECHAY PLANT (mm)

L PLANT Table 2: Growth Test (Test II)

O NO. WEEK NO.

T 1 2 3 4 5 6 P HEIGHT OF PECHAY PLANT (mm)

P1 30 72 L PLANT

P2 44 86 O NO. WEEK NO.

P3 35 93 T 1 2 3 4 5 6

P4 45 78

A P1 20 38 70 70 95

P5 35 62

P2 17 35 70 110 115

P6 43 105

P3 20 33 70 70 80

P7 20 80

P4 28 51 88 10 120

P8 30 81 A

P5 19 42 70 100 120

Average 35.25 81.12

P6 30 50 90 130 135

P1 42

P7 20 40 68 80 96

P2 54 85

P8 15 30 60

P3 60 120

Average 21.1 39.9 73.3 95.7 108.7

P4 40 68

B P1 37 70 125 150 160

P5 60 90

P2 34 90 120 135 150

P6 60 103

P3 33 80 110 125 160

P7 60 112

P4 45 85 120 150 155

P8 40 B

P5 34 60 90 100 150

Average 52 96.33

P6 35 80 110 130 142

P1 50 75

P7 30 55 100 130 165

P2 55 150

P8 40 70 130 165 170

P3 50 95

Average 52 32.3 73.8 113 136

P4 45 117

C P1 25 50 90 140 160

P5 40 105

P2 15 30 70 120 125

P6 60 108

P3 20 50 80 115 125

P7 52 85

P4 12 20 60 65 70

P8 70 85 C

P5 28 40 80 113 120

Average 52 102.5

P6 20 40 80 110 130

P7 32 45 90 120 125

Table 1 shows the results of Test 1 of the growth test done in P8 40 60 128 155 160

the three different plots. In the first week, the plants in Plot A Average 52 24 41.9 84.8 117

have the lowest average growth while the plants in Plot C

have the highest average growth. In the second week, all the Table 2 shows the results gathered in the second testing of

plants in the three plots grew but plant 1 and plant 8 in Plot B the project. In first week, plot B had the highest average of

died. Plot C still had the highest growth average. After the growth test. The second was plot C and plot A had the lowest

second week of testing in Test 1, the researchers looked for among the three. Based on the plant monitoring system the

other references on how to improve the design of the project. pechay plants planted on plot B grew faster than the two

Plot B was divided into 8 different sections by a plywood. other plants. The ranking of the average growth of the plants

The copper rods were placed 12 cm from the base of the was the same from first week to fifth week. According to

pechay plants. Instead of supplying the copper rods by DC department of agriculture, pechay plants may be assumed

voltage source for 24 hours, it was minimized for only about fully grown after 45 days or six weeks. As gleaned on the

four minutes a day using the microcontroller. For Test II of results above, plants in plot B grew faster compared with the

growth test, the researchers set the automated plant watering other two plots and reached its full grown state for around

device using a sprinkler for four (4) minutes a day. In this five (5) weeks only. Moreover, it was observed that watering

for four (4) minutes a day and application of electricity

Volume 3 Issue 3, March 2019 120

www.ijarp.org

International Journal of Advanced Research and Publications

ISSN: 2456-9992

stimulates plant growth faster because wet soil improves

electric current flow. Electro-cultured plants require about 10

percent more water than control plants because the charged

water is perspired more rapidly than under normal conditions

[6] Furthermore, the passage of currents through the soil was

beneficial to plant growth. As observed, plants subjected to

electric current for 4 minutes daily results to about four times

the healthier than plants grow the conventional way.

Conclusion

A well designed electroculture technique has great impact on

household income. As observed in the study, the normal

harvesting time of pechay plants is reduced by a week. This

means reduction in the consumption of water, fertilizers and

pests controls. Moreover, electroculture technique illustrates

low maintenance and operating cost that best fits for every

farmers growing vegetables plants. It will give farmers a

chance to grow high quality crops faster, reduce

environmental problems caused by using organic fertilizers

and increase their income.

References

[1]. Diprose, M. F., Benson, F. A. And Willis, A. J., The

Effect of Externally Applied Electrostatic Fields,

Microwave Radiation and Electric Currents on

Plants and Other Organisms, with Special

Reference to Weed Control, 1984

[2]. Nelson, Robert A., The Next Bigly Thing:

ElectroCulture, 1982

[3]. https://www/electrocultureandmagnetoculture.com

/science .hmtl

[4]. http://agris.fao.org/agris-search

[5]. Butchbaker , Allen F., Electricity and Electronics

for Agriculture, (1976)

[6]. Lakhovsky, George,, The Secret Of Life, 2010

[7]. Villaluna, Menchie C.,, Growth of Corn planted in

lahar applied with organic and inorganic fertilizers,

2009

[8]. Electroculture, good vibes for agriculture: retrieved

from

http://www.electrocultureandmagnetoculture.com/

[9]. Electropism: retrieved from http://en.academic.ru/

Volume 3 Issue 3, March 2019 121

www.ijarp.org

You might also like

- Growing Crops by Electricity 1916 Dudgeon PDFDocument48 pagesGrowing Crops by Electricity 1916 Dudgeon PDFMarkAban100% (5)

- Six Ways - Approaches & Entries For Practical Magic-Red Temple Press (2018)Document170 pagesSix Ways - Approaches & Entries For Practical Magic-Red Temple Press (2018)Lavinia Cristina87% (23)

- Electricity in Agriculture AllenDocument148 pagesElectricity in Agriculture Allennbarbarino50% (2)

- Electroculture - Basics - Bargain Orgonite - Buy Cheap, Simple and Efficient Orgonites (And For Gifting)Document6 pagesElectroculture - Basics - Bargain Orgonite - Buy Cheap, Simple and Efficient Orgonites (And For Gifting)bob13542100% (1)

- Detecting Biodynamic Signals Part-1Document11 pagesDetecting Biodynamic Signals Part-1iosua100% (2)

- Earthships: Off-Grid Homes That Harvest RainwaterDocument76 pagesEarthships: Off-Grid Homes That Harvest RainwaterZollner Castellano100% (2)

- Electro-Culture of PlantsDocument11 pagesElectro-Culture of PlantsAC5CHNo ratings yet

- Water StructurizersDocument130 pagesWater StructurizersJason Verbelli96% (26)

- MagnacultureDocument25 pagesMagnacultureJukka Juntunen67% (3)

- Electro HorticultureDocument64 pagesElectro Horticulturepetri_jv67% (6)

- Plant Electrical StimulationDocument21 pagesPlant Electrical StimulationCiro Giordano100% (2)

- Electric Effects On Plant GrouthDocument14 pagesElectric Effects On Plant GrouthCurt Tavi100% (1)

- Quantum agriculture: Bridging physics and nature's knowledgeDocument10 pagesQuantum agriculture: Bridging physics and nature's knowledgeBalazsovics67% (3)

- DIY Methane Generator GuideDocument7 pagesDIY Methane Generator GuidesumfakNo ratings yet

- The Secret of The Wishing Machines by Hilario Garcia FerreroDocument111 pagesThe Secret of The Wishing Machines by Hilario Garcia FerreromarcNo ratings yet

- Electroculture 2Document46 pagesElectroculture 2poimandres100% (1)

- Ohp Water Structurizer Construction Plans EnglishDocument9 pagesOhp Water Structurizer Construction Plans Englishm4dscience100% (1)

- Worms Can Recycle Your Garbage-1 1996Document6 pagesWorms Can Recycle Your Garbage-1 1996soulshineta2No ratings yet

- Electro CultureDocument14 pagesElectro Culturepoimandres80% (5)

- Electric Food Dehydrator PlansDocument5 pagesElectric Food Dehydrator Plansstaticfactory9281No ratings yet

- Electricity in Agriculture LemströmDocument111 pagesElectricity in Agriculture LemströmScopulus100% (1)

- Top TenDocument12 pagesTop TentelkonNo ratings yet

- Electroculture Basics for Giant VegetablesDocument47 pagesElectroculture Basics for Giant Vegetablessicedaca212100% (2)

- Andersen-Bioenergetics Tuning The Soil To Be Healthy and ProductiveDocument7 pagesAndersen-Bioenergetics Tuning The Soil To Be Healthy and ProductiveKaiNo ratings yet

- Make Compost QuicklyDocument69 pagesMake Compost QuicklyAlana BaileyNo ratings yet

- Zinc and Copper Balance in Mental HealthDocument5 pagesZinc and Copper Balance in Mental Healthdr.enzofaversaniNo ratings yet

- A Practical Guide to Building a Small Self-Powered GeneratorDocument38 pagesA Practical Guide to Building a Small Self-Powered GeneratorkwagNo ratings yet

- Root Cellar - 50 Fruits and VegDocument6 pagesRoot Cellar - 50 Fruits and Vegudivljini100% (1)

- The Secrets of Soil BuildingDocument2 pagesThe Secrets of Soil BuildingJoanne PoyourowNo ratings yet

- Electromagnetism - Robert A. Nelson - Electro-Culture - Stimulation of Plant Growth With Electricity, Magnetism, Sound, Etc - PaperDocument9 pagesElectromagnetism - Robert A. Nelson - Electro-Culture - Stimulation of Plant Growth With Electricity, Magnetism, Sound, Etc - PaperShmuelGraziani100% (1)

- Complex Earthbag DomesDocument3 pagesComplex Earthbag Domesdanut_docNo ratings yet

- ElectrocultureDocument7 pagesElectrocultureefraim75100% (3)

- Active Recovery Hydroponic SystemsDocument5 pagesActive Recovery Hydroponic SystemsT0NYSALINASNo ratings yet

- Cosmo Electro Culture 4 PDFDocument45 pagesCosmo Electro Culture 4 PDFJonathan SinclairNo ratings yet

- Marco o Ring Size Chart Japanese PDFDocument12 pagesMarco o Ring Size Chart Japanese PDFraymond ngoNo ratings yet

- Geomantic Talismans - UnknownDocument4 pagesGeomantic Talismans - UnknownmarcNo ratings yet

- Yannick Van Doorne Electromagnetisme 130218Document8 pagesYannick Van Doorne Electromagnetisme 130218Vikky GuptaNo ratings yet

- Electro Culture Boosts Plant Growth with ElectricityDocument4 pagesElectro Culture Boosts Plant Growth with Electricityhansley cook0% (1)

- Earth EnergiesDocument26 pagesEarth EnergiesShubhi Sonal100% (2)

- Earthbag Building Step-by-Step GuideDocument15 pagesEarthbag Building Step-by-Step GuideVander De Almeida Candido0% (1)

- AgriculturalResearchBulletin v019 b210Document37 pagesAgriculturalResearchBulletin v019 b210Adrien PEAUDNo ratings yet

- The Pyramid Les Brown Notes by CraigDocument27 pagesThe Pyramid Les Brown Notes by CraigTristan PanNo ratings yet

- The Only Electroculture Practical Guide for Beginners: Secrets to Faster Plant Growth, Superior Crops and Bigger Yields Using Coil Coppers, Pyramids, Magnetic Antennas and MoreFrom EverandThe Only Electroculture Practical Guide for Beginners: Secrets to Faster Plant Growth, Superior Crops and Bigger Yields Using Coil Coppers, Pyramids, Magnetic Antennas and MoreNo ratings yet

- Organic Agriculture Business InventionDocument32 pagesOrganic Agriculture Business InventionKetan VadorNo ratings yet

- ElectroCulture: Boost Crop Yields Up to 150% With ElectricityDocument14 pagesElectroCulture: Boost Crop Yields Up to 150% With ElectricityJaffar Hussain100% (2)

- Boost plant growth with electroculture, magneticulture and lasercultureDocument5 pagesBoost plant growth with electroculture, magneticulture and lasercultureGuillaume BarrierNo ratings yet

- Electroculture LinksDocument2 pagesElectroculture LinksdeeplahNo ratings yet

- The Effect of Electricity on Fast Plant GerminationDocument14 pagesThe Effect of Electricity on Fast Plant GerminationRoulaNo ratings yet

- The Psionic Generator Pattern Book by John P. BoyleDocument87 pagesThe Psionic Generator Pattern Book by John P. BoylemarcNo ratings yet

- The Effects of Electroculture On Shoot Proliferation of Garlic 2019Document5 pagesThe Effects of Electroculture On Shoot Proliferation of Garlic 2019Jonathan SinclairNo ratings yet

- Effects of Electrostatic Fields, Microwaves and Electric Currents on PlantsDocument54 pagesEffects of Electrostatic Fields, Microwaves and Electric Currents on Plantsluigiram1No ratings yet

- Biodynamic AgricultureDocument3 pagesBiodynamic AgricultureEliane MasonNo ratings yet

- Electricity For Plants Growth TechniquesDocument6 pagesElectricity For Plants Growth TechniquesJesus LopezNo ratings yet

- PartnershipDocument8 pagesPartnershipAnonymous 03JIPKRkNo ratings yet

- Chinese Researchers Claim Electroculture Works As TheorizedDocument2 pagesChinese Researchers Claim Electroculture Works As TheorizedJesus LopezNo ratings yet

- Course 1 Exercise Templates - Elimar SilveiraDocument5 pagesCourse 1 Exercise Templates - Elimar SilveiraElimar José Silveira VegasNo ratings yet

- Electroculture For Crop Enhancement by Air AnionsDocument13 pagesElectroculture For Crop Enhancement by Air Anionspino100% (1)

- Thesis DocumentDocument17 pagesThesis DocumentHarold Asuncion100% (1)

- Seed Sprouting InstructionsDocument1 pageSeed Sprouting InstructionslindahmNo ratings yet

- IFOAM 17 - Vol 1 - Biovedic AgricultureDocument685 pagesIFOAM 17 - Vol 1 - Biovedic AgricultureSteve Diver100% (1)

- (Energy) Solar - Heating - A House Heating by Solar Greenhouse Principle - (Ebook Diy How To PDF) (Tec@Nz) (Backwoods Home Magazine) PDFDocument3 pages(Energy) Solar - Heating - A House Heating by Solar Greenhouse Principle - (Ebook Diy How To PDF) (Tec@Nz) (Backwoods Home Magazine) PDFWalter RamirezNo ratings yet

- Goat Under CoconutDocument3 pagesGoat Under Coconutjhoe eliasNo ratings yet

- Mother Earth vs. World's People - A Play by Doug StewartDocument34 pagesMother Earth vs. World's People - A Play by Doug StewartJan DashNo ratings yet

- Maranam Leni MeeruDocument203 pagesMaranam Leni MeeruRam WarNo ratings yet

- Scheduling The Italian Football LeagueDocument24 pagesScheduling The Italian Football LeagueDavid MohNo ratings yet

- Excel solver maximizes profit for jute mill product mixDocument27 pagesExcel solver maximizes profit for jute mill product mixNeelesh KamathNo ratings yet

- Space Station WebDocument1 pageSpace Station WebHouston ChronicleNo ratings yet

- CSC 102 Answers 1Document17 pagesCSC 102 Answers 1Usman Samuel BabalolaNo ratings yet

- Explore Humans in Space On The International Space Station 2021 CalendarDocument32 pagesExplore Humans in Space On The International Space Station 2021 CalendarmortaNo ratings yet

- 0580 w10 QP 41Document16 pages0580 w10 QP 41Kevin DanyNo ratings yet

- ECG253 (Psychomotor) - RUBRIC PT 2 - MAC 23Document2 pagesECG253 (Psychomotor) - RUBRIC PT 2 - MAC 23Doris AsmaniNo ratings yet

- Calcutta 10 Power SequenceDocument56 pagesCalcutta 10 Power SequenceGie Av100% (3)

- Fabrication Strainers Mesh SizingDocument6 pagesFabrication Strainers Mesh SizingArun GuptaNo ratings yet

- NASA Press Kit For STS-134 Endeavour MissionDocument118 pagesNASA Press Kit For STS-134 Endeavour MissionJeff SondermanNo ratings yet

- ISS Basics: International Space Station ComponentsDocument8 pagesISS Basics: International Space Station ComponentsThe CulMinated AadamiNo ratings yet

- Rules and RegulationsDocument14 pagesRules and RegulationsOllcf Nursing MidwiferyNo ratings yet

- Interactive Fuzzy Meta-Goal Programming For Production Planning in IndustryDocument20 pagesInteractive Fuzzy Meta-Goal Programming For Production Planning in Industryjuni adirahmatNo ratings yet

- Manual JboxDocument36 pagesManual JboxAndrés Sánchez CalderónNo ratings yet

- Perhitungan Theorema BayesDocument11 pagesPerhitungan Theorema BayesMukis AdityaNo ratings yet

- Master Tabel No Nama Kepatuhan P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 S1 S2 S3 S4 S5 S6 S7 S8 S9 S10 Total P Total P Total S Total S PendidikanDocument3 pagesMaster Tabel No Nama Kepatuhan P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 S1 S2 S3 S4 S5 S6 S7 S8 S9 S10 Total P Total P Total S Total S PendidikanISHAKMUHNo ratings yet

- iSAMS Timetable Structure Migration Template: Column Name Required? Unique? Type Max LengthDocument7 pagesiSAMS Timetable Structure Migration Template: Column Name Required? Unique? Type Max Lengthclaude afadhaliNo ratings yet

- Marco o Ring Size Chart JapaneseDocument12 pagesMarco o Ring Size Chart JapaneseandreNo ratings yet

- 1/3, 1/4-Duty General-Purpose LCD Display Driver: Cmos IcDocument35 pages1/3, 1/4-Duty General-Purpose LCD Display Driver: Cmos IcOsama YaseenNo ratings yet

- Answer Key Chapter 3 - Review-2Document6 pagesAnswer Key Chapter 3 - Review-2Maria Dos SantosNo ratings yet

- 268 Boiler Control - Nine Stage Boiler & DHW / SetpointDocument12 pages268 Boiler Control - Nine Stage Boiler & DHW / Setpointe-ComfortUSANo ratings yet

- No Deadlock Resource Allocation ProblemsDocument8 pagesNo Deadlock Resource Allocation ProblemsNeha A100% (1)

- Red de Agua FríaDocument7 pagesRed de Agua FríaRuslanNo ratings yet

- Titanium Console User GuideDocument19 pagesTitanium Console User GuideMilos VujasinovicNo ratings yet

- High Speed Modified Booth's Multiplier For Signed and Unsigned NumbersDocument8 pagesHigh Speed Modified Booth's Multiplier For Signed and Unsigned NumbersInternational Journal of Science and Engineering InvestigationsNo ratings yet

- WPF 3D Solid Wireframe TransformDocument16 pagesWPF 3D Solid Wireframe TransformAbhiNo ratings yet

- Edexcel 2005 Mathematics Exam Grade Boundaries and Pass RatesDocument35 pagesEdexcel 2005 Mathematics Exam Grade Boundaries and Pass Ratese1f123100% (1)

- Sensornet Rs 422 Network Design Guide An LT enDocument36 pagesSensornet Rs 422 Network Design Guide An LT enschatten_3No ratings yet