Professional Documents

Culture Documents

BW Gas Detector Manual

Uploaded by

Yume Hendra0 ratings0% found this document useful (0 votes)

77 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

77 views3 pagesBW Gas Detector Manual

Uploaded by

Yume HendraCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

B W Cl i p Re a l Ti m e

2 OR 3 YEAR H2S, CO, O2, SO2 SINGLE-GAS DETECTOR

Part Number 50115903-101 | OM-EN-BWCRT-A5 | BW Clip Real Time Operator Manual

BW Clip Real Time is a portable, single-gas detector manufactured by BW Technologies by

Getting Started

Honeywell (BW). BW Clip Real Time continuously displays the concentration of a speci¿c LED

gas in the ambient environment, and activates an alarm when concentrations exceed alarm visual alarms Infrared port

setpoints. It is your responsibility to respond appropriately to the alarms.

BW Clip Real Time is a member of the GasAlert family of products. It is compatible with

IntelliDoX and MicroDock II automatic test and calibration stations, as well as Fleet Manager

Alligator

II software version 4.2 or higher. For more information, visit the product website at www. clip

LCD

honeywellanalytics.com

Safety Information: Read First Audible Pushbutton

alarm

1. Substitution of components may impair Intrinsic Safety. Sensor and

2. BW recommends performing a bump test prior to each day’s use to con¿rm sensor sensor grill

response and alarm activation by exposing the detector to a concentration of target

gas that exceeds the low alarm set point. BW also recommends performing a bump

test if the detector has been subjected to physical impact, liquid immersion, an Over

Limit alarm event, custody changes, or anytime the detectors performance is in doubt.

Calibrate the detector after a failed bump test. Always bump test and calibrate in a fresh

air environment.

3. Detectors in hibernation mode are not functional. Bubble label Product label

with product name

and gas type

1. Activate the detector before the activation date on the package.

2. This product is a gas detector, not a measurement device.

LCD and Symbols

3. Ensure that the sensor grill is free of dirt, debris, and is not obstructed.

4. Clean the exterior with a soft, damp cloth.

5. For optimal performance, periodically zero the sensor in a normal atmosphere (20.9%

v/v O2) that is free of hazardous gas.

6. Portable safety gas detectors are life safety devices. Accuracy of ambient gas

reading(s) is dependent upon factors such as accuracy of the calibration gas standard

used for calibration and frequency of calibration. BW recommends performing a

calibration at least once every 180 days (6 months). Pushbutton prompt. When this symbol is displayed, press and hold

the pushbutton until the symbol disappears.

Informations de sécurité – À lire au préalable

BW Clip Real Time O2 models only. Oxygen concentration is

AVERTISSEMENT measured as percent by volume.

1. Le remplacement d’un composant de l’appareil peut compromettre la sécurité

intrinsèque du détecteur. BW Clip Real Time H2S, CO and SO2 models only. Toxic gas

2. Avant chaque utilisation quotidienne, BW recommande d’effectuer un test fonctionnel concentration is measured in parts per million.

a¿n de véri¿er la réaction du capteur et l’activation de l’alarme, en exposant le détecteur

Low alarm and high alarm. These symbols are displayed when a

à une concentration de gaz cible supérieure au seuil d’alarme basse. BW recommande

gas concentration that exceeds alarm setpoints is detected.

également d’effectuer un test fonctionnel si le détecteur a été soumis à un impact

physique, à une immersion dans du liquide, à un événement d’alarme Dépassement

de la limite, à des changements d’utilisateur ou chaque fois que les performances

Non-compliance warning. This symbol is displayed when a

du détecteur sont mises en doute. Étalonnez le détecteur après l’échec d’un test

diagnostic or compliance test fails; when the operating life

fonctionnel. Effectuez toujours un test fonctionnel et étalonnez dans un environnement

avec de l’air frais. countdown reaches 24 hours or less; and for up to 30 days after

3. Détecteurs en mode veille prolongée ne sont pas fonctionnels. operating life expiry. It is also displayed when certain noti¿cations

are enabled through Fleet Manager II via an IntelliDoX station.

MISE EN GARDE

1. Activez le détecteur avant la date d’activation sur l’emballage. Real-time clock. This symbol is displayed when real-time clock is

2. Ce produit est un détecteur de gaz, pas un dispositif de mesure. enabled through Fleet Manager II via an IntelliDoX station.

3. Veillez à assurer que la grille du capteur est exempt de saleté, les débris, et ne soit pas

End of operating life warning. This symbol is displayed when the

obstrué.

operating life countdown reaches 24 hours or less.

4. Nettoyez l’extérieur de l’appareil à l’aide d’un chiffon doux et humide.

5. Pour des performances optimales, zéro périodiquement le capteur dans une Peak reading. This symbol is displayed when a maximum gas

atmosphère normale (20,9% v/v O2) qui est exempte de gaz dangereux. exposure event has occurred within the past 24 hours.

6. Les détecteurs portables de gaz de sécurité sont des dispositifs de sécurité des

personnes. La précision des valeurs de gaz ambiant dépend de divers facteurs,

tels que la précision de la norme de gaz d’étalonnage utilisée pour l’étalonnage et la Bump test reminder. If the detector is con¿gured to display a bump

fréquence d’étalonnage. BW recommande d’effectuer un étalonnage au moins une fois test reminder, this symbol is displayed when a bump test is due.

tous les 180 jours (6 mois).

indicates a failed bump test.

This symbol is displayed when more than 24 hours have elapsed

since the last successful zero procedure was performed (O2

models) or indicates a sensor calibration is due (H2S, CO and SO2

models).

indicates a failed calibration (H2S, CO and SO2 models) or a

failed zero procedure (O2 models).

Operating life remaining in months (MM) or days (DD).

B W Cl i p Re a l Ti m e

2 OR 3 YEAR H2S, CO, O2, SO2 SINGLE-GAS DETECTOR

Activate a New Detector Over-Limit and Under-Limit Alarms

1. Move to a normal atmosphere (20.9% v/v O2) that is free of hazardous gas.

If the gas concentration is beyond the sensor range, OL (over-limit) or

2. Press and hold the pushbutton until a 5 second countdown is displayed, and then

-OL (under-limit) is displayed.

continue to hold until the countdown is complete.

3. When the countdown is complete, the LCD and LEDs turn on and then turn off. The Audible: 2 beeps per second

detector performs an internal diagnostic test.

Visual: 2 Àashes per second

4. When the diagnostic test is successful, the alarm setpoints are displayed and the LEDs

Àash. Vibration: 2 vibrations per second

5. The sensor stabilization countdown is displayed. During the countdown, the detector

vibrates continuously for 20 seconds. The time required to stabilize varies depending

on sensor type. When the countdown reaches 0, the LEDs Àash and the audible alarm

beeps.

Automatic Zero Reminder for O2 Models

6. The detector is in normal operating mode when the gas type and concentration are For O2 models only, the Automatic Zero Reminder is displayed when

displayed. more than 24 hours have elapsed since the last successful zero

procedure was performed.

Normal Operating Mode

When the detector is in normal operating mode, the type of gas

Peak Readings

detected is permanently displayed. The detected concentration of the

The peak readings symbol is displayed when the sensor is exposed to

gas is displayed until it is disrupted by a pushbutton action, gas alarm,

a gas concentration that exceeds the alarm setpoints. It is no longer

or error event.

displayed when more than 24 hours have passed since the last alarm,

Operating Life or when a successful bump test is performed via an IntelliDoX or

When the detector is activated for the ¿rst time, the operating life MicroDock II station.

countdown is displayed. Press the pushbutton to display remaining

Non-compliance Symbol and LED Indicators

operating life.

The non-compliance warning symbol is displayed when:

• an internal diagnostic test fails;

90 Days or Less Remaining • a bump test, calibration or zero procedure fails;

When the operating life countdown reaches 90 days or less before • a bump test or calibration is due, if enabled;

expiry, the countdown display changes to days. The countdown • the sensor is exposed to a gas concentration that exceeds alarm setpoints, if enabled.

displays the remaining operating life in days until the countdown The non-compliance warning symbol is no longer displayed when more than 24 hours have

reaches 24 hours or less before expiry. passed since the last alarm, or when a successful bump test or calibration is performed

24 Hours or Less Remaining (manual calibration or via an IntelliDoX or MicroDock II station). The non-compliance

When the operating life countdown reaches 24 hours or less before warning symbol is permanently displayed when the service-life countdown reaches 24 hours

expiry, the countdown display changes to hours, and the EXPIRY! or less before expiry, and for up to 30 days after expiry.

warning and non-compliance symbol are displayed.

When Non-compliance after gas exposure is enabled through Fleet Manager II via

an IntelliDoX station, the LEDs Àash in an alternating pattern when the non-compliance

End of Operating Life warning symbol is displayed. When the symbol is ¿rst displayed, the top LEDs Àash. After

When the operating life countdown ends, the detector deactivates and 30 seconds, the side LEDs Àash. After 30 seconds, the pattern repeats until the non-

detector safety functions are disabled. It is possible to retrieve event compliance warning symbol is no longer displayed.

logs for a limited time after expiry. The EXPIRY! warning and

NOTE: When the detector is bump tested via a MicroDock II station, an abnormal test

non-compliance symbol are displayed for up to 30 days after expiry.

result may occur if non-compliance LEDs are Àashing. To suspend the Àashing for up to 10

Internal Diagnostic Tests minutes, press and release the pushbutton. When the Àashing stops, insert the detector and

Activated detectors automatically perform one internal diagnostic test every 24 hours. If the perform the test. If the bump test fails, the LEDs resume Àashing.

internal diagnostic test fails, the diagnostic fail-safe begins.

Recall Events and Settings

Diagnostic Fail-Safe When the detector is in normal operating mode, press the pushbutton at any time to scroll

1. The EXPIRY! warning and non-compliance symbol are displayed.

through events and settings that are not empty or disabled through Fleet Manager II via an

2. The detector beeps and vibrates.

3. The LEDs Àash 2 times per second for 15 seconds. IntelliDoX station. BW Clip Real Time Àashes, vibrates and beeps.

4. OFF or an error code is displayed. The detector is deactivated. While an event or setting is displayed, press the pushbutton to scroll to the next available

It is possible to retrieve the event logs for a limited time after expiry. If you are unable to event or setting. If you do not press the pushbutton, or if you have reached the last available

retrieve the event logs, contact BW. event or setting, the detector returns to normal operation. Events and settings are displayed

in this order:

Alarms and Warnings 1. Peak Reading, if available, and when a maximum gas exposure event has occurred

An alarm is initiated when the sensor is exposed to a gas concentration that exceeds alarm within the past 24 hours.

setpoints. The alarm persists until the alarm gas concentration returns to an acceptable 2. Time of Peak Reading, if Real-time Clock display is enabled.

range. Battery life decreases rapidly when the detector is in alarm condition. 3. Operating Life, the remaining operating life of the detector in months, days or hours.

4. Low Alarm Setpoint

Low Alarm

5. High Alarm Setpoint

Audible: 1 beep per second 6. Real-time Clock, if enabled.

Visual: 1 flash per second 7. Firmware Version

Vibration: 1 vibration per second 8. Next Bump Due, if enabled.

9. Next Calibration Due, if enabled.

10. Hibernation, for 2-year H2S and CO models only.

High Alarm

Audible: 2 beeps per second

Visual: 2 Àashes per second

Vibration: 2 vibrations per second

Zero the Sensor Event Logs

Over time and through use, the sensor baseline at zero exposure may drift from the The detector stores the last 35 events that occurred, including peak readings, bump tests,

manufacturer’s baseline. For optimal performance of O2 models, BW recommends that calibrations and auto zeros. Each record contains:

you zero the O2 sensor once every 24 hours or when the Automatic Zero Reminder is • detector serial number, sensor type and life-remaining;

displayed. For all other models, BW recommends that you zero the sensor periodically. • total number of events that have occurred;

Zero Procedure • event type and duration;

• alarm level(s) in ppm or %;

1. Move to a normal atmosphere (20.9% v/v O2) that is free of

• time elapsed since the alarm occurred in days/hours/minutes;

hazardous gas.

• duration of the alarm (minutes/seconds).

2. Press and hold the pushbutton until a 5 second countdown

is displayed, and then continue to hold until the countdown is Use Fleet Manager II via an IntelliDoX or MicroDock II station to transfer event logs from the

complete. detector to a computer. When logs are transferred via an IntelliDoX station, the most recent

3. When the countdown is complete, the Zero procedure begins and 35 events are transferred. When logs are transferred via a MicroDock II station, the most

ZErO is displayed. recent 10 events are transferred.

4. When Zero is successful, PASS and then CAL ? is displayed.

Press the pushbutton to calibrate, or wait for the detector to enter Optional Settings

normal operating mode after a 5 second countdown. Use Fleet Manager II via an IntelliDoX station to enable the following optional settings for

5. If Zero is not successful, the non-compliance LED Àashes. FAIL BW Clip Real Time detectors.

and the non-compliance warning symbol are displayed. Press

the pushbutton to acknowledge the result and return to normal

Non-compliance After Gas Exposure

operation. The non-compliance warning symbol is displayed and When Non-compliance after gas exposure is enabled, the LEDs Àash in an alternating

the non-compliance LED Àashes. Perform the Zero procedure pattern when the sensor is exposed to a gas concentration that exceeds alarm setpoints.

again. If the procedure fails again, contact BW. When the gas exposure is detected, the top LEDs Àash. After 30 seconds, the side LEDs

Àash. After 30 seconds, the pattern repeats until more than 24 hours have passed since the

Bump Tests last alarm, or when a successful bump test is performed via an IntelliDoX or MicroDock II

When the detector is con¿gured to display a bump test reminder, the bump test symbol is station.

displayed when a bump test is due. For best results, bump test the detector via an IntelliDoX

or MicroDock II station. Bump tests performed via an IntelliDoX or MicroDock II station are Real-time Clock Display

logged as bump tests. Manual bump tests are logged as unsafe gas concentrations. When real-time Clock Display is enabled, you can display the current

time by pressing the pushbutton to Recall Events and Settings, and

Calibration then continuing to press the pushbutton until the time is displayed.

By default, BW Clip Real Time is con¿gured to use the following calibration gas mixtures: Time may be displayed in 12-hour or 24-hour clock format.

H2S: 20 ppm CO: 100 ppm SO2: 20 ppm O2: 18.0 % v/v O2

balance N2 balance N2 balance N2

Hibernation

Hibernation is a factory installed feature that is available for 24-month H2S and CO

You can use Fleet Manager II software via an IntelliDoX station to change a detector’s

detectors. When Hibernation is activated, the operating life countdown is suspended. Use

default calibration gas mixtures. If the detector’s default calibration mixtures were changed,

Hibernation to deactivate the detector for 7 days or longer, up to a maximum of 12 months.

use the gas mixture values from Fleet Manager II to calibrate the

When Hibernation is activated, all detector safety functions are disabled.

detector.

1. Move to a normal atmosphere (20.9% v/v O2 ) that is free of

hazardous gas.

Activate Hibernation via BW Clip Real Time

2. Connect the calibration hose to the gas cylinder and to the intake Hibernation Case

inlet on the calibration cap. 1. Have ready a BW Clip Hibernation Case. To purchase a Case,

3. Press and hold the pushbutton until a 5 second countdown contact BW or an authorized distributor.

is displayed, and then continue to hold until the countdown is 2. Move to a normal atmosphere (20.9% v/v O2) that is free of

complete. The zero procedure begins and ZErO is displayed. hazardous gas.

When Zero is successful, PASS is displayed. 3. Verify that the detector is in normal operating mode.

4. When CAL ? is displayed, press the pushbutton to begin 4. Press the pushbutton to Recall Events and Settings, and then

calibration. continue to press the pushbutton until Hib is displayed.

5. Put the calibration cap on the sensor grill.

6. When GAS ? is displayed, apply calibration gas for two minutes

at a recommended Àow rate of 500 ml/min. When calibration is 5. While Hib is displayed, press the pushbutton until a 5 second countdown is displayed.

successful, PASS is displayed and the detector returns to normal When the countdown is complete, the 20-second Hibernation counter is displayed.

operating mode. 6. While the Hibernation counter is displayed, place the detector into a BW Clip Real

If calibration fails, non-compliance warning symbols are displayed. Press the pushbutton to Time Hibernation Case and then close the case ¿rmly. The detector enters Hibernation

acknowledge. Repeat calibration. If it fails again, contact BW. mode. All detector safety functions are disabled.

7. To reactivate the detector, open the case and remove the detector.

Activate Hibernation through Fleet Manager II

via IntelliDoX

1. Use Fleet Manager II to activate Hibernation on Insertion via an IntelliDoX station, and

then insert the detector in the con¿gured station. The detector event logs are retrieved,

and the detector enters Hibernation mode. All safety functions are disabled, and the

detector may be removed from the IntelliDoX station.

2. To reactivate the detector, press and hold the pushbutton until a 5 second countdown

is displayed, and then continue to hold until the LCD and LEDs turn on and off. The

detector performs a self-diagnostic test. When the test is successful, the type of gas

detected and the remaining operating life are displayed. The detector is in normal

operating mode.

3. For more information, refer to the operator manuals for the IntelliDoX station and Fleet

Manager II software version 4.2 or higher.

You might also like

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- 1 ST Quater Drill ScenarioDocument2 pages1 ST Quater Drill ScenarioSk MehbobNo ratings yet

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruNo ratings yet

- Planets, Luminaries, Asteroids, and Points in AstrologyDocument3 pagesPlanets, Luminaries, Asteroids, and Points in AstrologySushant ChhotrayNo ratings yet

- HITRA For PiggingDocument6 pagesHITRA For PiggingAhmedNo ratings yet

- Book Review When We Cease To Understand The World,' by Benjamín Labatut - The New York TimesDocument4 pagesBook Review When We Cease To Understand The World,' by Benjamín Labatut - The New York Timeselias100% (1)

- P1501-TOS-70000-PP-RP-0002 - Revb0 Piping Stress Analysis Design BasisDocument49 pagesP1501-TOS-70000-PP-RP-0002 - Revb0 Piping Stress Analysis Design BasisBharuk Mech50% (2)

- 059 Vacuum Truck SafetyDocument6 pages059 Vacuum Truck Safetyichal_zaidanNo ratings yet

- EPM EHS SP F 040 Boom Truck ChecklistDocument2 pagesEPM EHS SP F 040 Boom Truck ChecklistTamoor MirzaNo ratings yet

- Inflatable Life JacketsDocument6 pagesInflatable Life Jacketsade maulanaNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- HIRAC - Work - at - Height - Template PDFDocument8 pagesHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Purpose:: Method StatementDocument10 pagesPurpose:: Method StatementIrfan ashrafNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

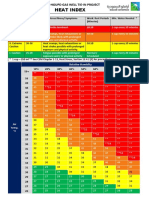

- Aramco Heat Index A4Document1 pageAramco Heat Index A4DLPS HSENo ratings yet

- Fluid and Electrolytes Lecture NotesDocument85 pagesFluid and Electrolytes Lecture NotesVince Peliño De MesaNo ratings yet

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Water Pump JsaDocument2 pagesWater Pump JsajvmspNo ratings yet

- 41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFDocument10 pages41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFFarhan MNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Gi-0006 011Document2 pagesGi-0006 011malika_00No ratings yet

- Short Employee Service AssessmentDocument2 pagesShort Employee Service Assessmentdennisjuntak100% (1)

- Physics - ANSWERS - David Homer and Michael Bowen-Jones - Oxford 2014Document39 pagesPhysics - ANSWERS - David Homer and Michael Bowen-Jones - Oxford 2014Proleteriat Dictatorship of Koperia100% (1)

- SSP 639 - Audi 10l 3 Cylinder TFSI Engine EA211 SeriesDocument36 pagesSSP 639 - Audi 10l 3 Cylinder TFSI Engine EA211 SeriesFran Rosales Tovar100% (3)

- A Practical Guide To Gas Detection: DET TronicsDocument48 pagesA Practical Guide To Gas Detection: DET TronicsforuzzNo ratings yet

- TBT Attendance Format - NRP WorkersDocument2 pagesTBT Attendance Format - NRP WorkersIsrael Raja AbhilashNo ratings yet

- TPF RAG Violation AnalysisDocument2 pagesTPF RAG Violation AnalysisImran Khan100% (1)

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- Buku IstighfarDocument1 pageBuku IstighfarAfif MudzakkirNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- DevicorebbtDocument1 pageDevicorebbtDaviss Pauca Morón100% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Job Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksDocument1 pageJob Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksAdel AlKhedawyNo ratings yet

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rFNo ratings yet

- Method Statement For Light Beacons and Buoys C04Document93 pagesMethod Statement For Light Beacons and Buoys C04Olugbemiga James OlalekanNo ratings yet

- Scaffold TowerDocument20 pagesScaffold TowerAndhika HerdiawanNo ratings yet

- Mod10 Work at Height QuizDocument11 pagesMod10 Work at Height QuizMhanna AYNo ratings yet

- Bnwas KBJ-3Document11 pagesBnwas KBJ-3SergeyNo ratings yet

- NX300 Operator's Manual PDFDocument65 pagesNX300 Operator's Manual PDFBhavin DoshiNo ratings yet

- Hot Work - Definition, Responsibility, Process and Risks On-Board ShipsDocument6 pagesHot Work - Definition, Responsibility, Process and Risks On-Board ShipsGiorgi KandelakiNo ratings yet

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- Appendix-AC, Guide For Working at HeightsDocument23 pagesAppendix-AC, Guide For Working at HeightsApm FoumilNo ratings yet

- Generic RA Gas CylindersDocument6 pagesGeneric RA Gas CylindersShahid RazaNo ratings yet

- 658 - Eng - Sigma Phenguard 935 BaseDocument1 page658 - Eng - Sigma Phenguard 935 BasetariqueNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Excavation ManuallyDocument1 pageExcavation ManuallyJack PNo ratings yet

- JSA - EDDY CURRENRT - AmendedDocument1 pageJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Aramco Emergency PlanDocument1 pageAramco Emergency Planengrabbas75No ratings yet

- HOT WORK PERMIT Cutting & Grinding of GRP PipesDocument1 pageHOT WORK PERMIT Cutting & Grinding of GRP Pipesadil khanNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Conbextra EP120 TDS PDFDocument3 pagesConbextra EP120 TDS PDFzulfikarNo ratings yet

- Jha Miura Z-Steam Boilers Intallation2Document8 pagesJha Miura Z-Steam Boilers Intallation2perquino oasanNo ratings yet

- PTWC IssueDocument4 pagesPTWC IssueSajjad AfzalNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- HazardsDocument17 pagesHazardsNavin DipaliNo ratings yet

- Fire Hydrant AccessoriesDocument8 pagesFire Hydrant AccessoriesDan Nicole Dadivas100% (1)

- Fire Safety Plan BookletDocument40 pagesFire Safety Plan BookletSofiqNo ratings yet

- Conined Space Entry ChecklistDocument2 pagesConined Space Entry ChecklistJoelNo ratings yet

- SHEM-SP-08.01 - OMS-316.01General SHE RulesDocument40 pagesSHEM-SP-08.01 - OMS-316.01General SHE RulesAjith Kumar AjithNo ratings yet

- BW Clip Operators ManualDocument4 pagesBW Clip Operators ManualSanthosh MechNo ratings yet

- Goldscmidt AlgoDocument4 pagesGoldscmidt AlgochayanpathakNo ratings yet

- Jay BirdDocument37 pagesJay Birdvlcmstne04100% (1)

- MP Module 2 - Modified - CorrectDocument24 pagesMP Module 2 - Modified - Correctakhil krishnanNo ratings yet

- Manual Montaj Cobra 600iDocument130 pagesManual Montaj Cobra 600iDdanaa DanaNo ratings yet

- Analysis of Cost Control, Time, and Quality On Construction ProjectDocument12 pagesAnalysis of Cost Control, Time, and Quality On Construction ProjectDeryta FlorentinusNo ratings yet

- AGN 234 - Generating Set Assembly - AlignmentDocument6 pagesAGN 234 - Generating Set Assembly - AlignmentbaljeetjatNo ratings yet

- Lesson 5 - Web DevelopmentDocument25 pagesLesson 5 - Web DevelopmentJoshua OmolewaNo ratings yet

- Lab PDFDocument8 pagesLab PDFAnonymous HZXRbzPkzNo ratings yet

- SEAWEEDDocument118 pagesSEAWEEDJeromeGenilanNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- 02-Continental Drift TheoryDocument22 pages02-Continental Drift Theoryapi-242405009No ratings yet

- DSS Module-2 Backbencher - ClubDocument131 pagesDSS Module-2 Backbencher - ClubPuneeth hr2No ratings yet

- Chapter 7Document23 pagesChapter 7enes_ersoy_3No ratings yet

- RD Sharma Solutions For Class 10 Chapter 2 Polynomials Exercise 2.1Document10 pagesRD Sharma Solutions For Class 10 Chapter 2 Polynomials Exercise 2.1Ruturaj ParidaNo ratings yet

- VB Exercises LoopsDocument6 pagesVB Exercises LoopsS Ahmad1311993No ratings yet

- Che Vol1Document139 pagesChe Vol1abiramanNo ratings yet

- Chapter 1 - Systems of Linear Equations and InequalitiesDocument7 pagesChapter 1 - Systems of Linear Equations and InequalitiesRonald AlmagroNo ratings yet

- VSM Blue)Document4 pagesVSM Blue)api-27411749No ratings yet

- EMV Multi Cable Transit Modular System (EMC-System) : PDFDocument7 pagesEMV Multi Cable Transit Modular System (EMC-System) : PDFbakien-canNo ratings yet

- Assignment 7.3: Double-Angle, Half-Angle, and Reduction FormulasDocument3 pagesAssignment 7.3: Double-Angle, Half-Angle, and Reduction FormulasCJG MusicNo ratings yet

- 878Document47 pages878IulianCiobanuNo ratings yet

- Elbi Vessel Data SheetDocument20 pagesElbi Vessel Data SheetMAZENNo ratings yet

- 1 CathDocument12 pages1 CathHashem AlsmadiNo ratings yet

- Rubrics Vital Signs TakingDocument6 pagesRubrics Vital Signs TakingRichard SluderNo ratings yet