Professional Documents

Culture Documents

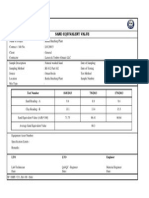

Asphalt Specification

Uploaded by

Rahil ShadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asphalt Specification

Uploaded by

Rahil ShadCopyright:

Available Formats

SECTION 321216 – ASPHALT PAVING 1

PART 1 GENERAL 1

1.1 RELATED DOCUMENTS 1

1.2 SUMMARY 1

1.3 DEFINITIONS 2

1.4 SUBMITTALS 2

1.5 QUALITY ASSURANCE 2

1.6 PROJECT CONDITIONS: 2

PART 2 - PRODUCTS 3

2.1 AGGREGATES: 3

2.2 ASPHALT MATERIAL AND ACCESSORIES 3

2.3 MISCELLANEOUS ITEMS TO COMPLETE SYSTEM 3

2.4 COATINGS 3

2.5 MIXES 4

PART 3 - EXECUTION 4

3.1 EXAMINATION 4

3.2 SURFACE PREPARATION 4

3.3 PAVING GEOTEXTILE INSTALLATION 5

3.4 COMPACTION 5

3.5 INSTALLATION TOLERANCES 5

3.6 FIELD QUALITY CONTROL 5

3.7 DISPOSAL 6

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 115 of: 321

SECTION 321216 – ASPHALT PAVING

PART 1 GENERAL

1.1 RELATED DOCUMENTS

A. General

1. Read this Section in conjunction with other related Sections, Division 01 General Requirements, the

Design Drawings and the Contract Conditions.

2. Refer also to the Technical Reference Sheet (TRS) which lists the reference codes and

accompanying descriptions used to reference and identify systems/ components/ products indicated

on the Design Drawings.

B. Section 321216 Asphalt Paving of the landscape specifications should be read and verified with ABU

DHABI QCC Standard Construction Specifications, Government of Abu Dhabi.

C. Latest editions of all relevant ASTM International Standards, British Standards and local standards shall

be used including those inter alia listed with current amendments and additions. In case of discrepancies

between standards, the ADG21 Standard construction Specs will govern.

D. Performance Specified Work

1. Refer to the Contractor's Responsibilities in Division 01 General Requirements for specific

requirements.

2. Supply, deliver, install and warrant the work in strict compliance with the materials and workmanship

requirements of the Landscape Specification.

3. Where required to prepare Shop Drawings, these shall be limited to final detailing of components,

systems indicated on the Design Drawings, necessary to demonstrate their safe installation.

4. Where products are offered by the Contractor for acceptance by the Engineer, provide full supporting

documentation in respect of the complete system or installation.

1.2 SUMMARY

A. Provide all labor, materials and equipment as necessary to complete all work as indicated on the Drawings

and specified herein.

B. This Section includes:

1. Cold milling of existing hot-mix asphalt pavement.

2. Hot-mix asphalt patching.

3. Hot-mix asphalt paving.

4. Hot-mix asphalt paving overlay.

5. Asphalt surface treatments.

6. Pavement-marking paint.

7. Traffic-calming devices.

C. Included systems / products:

1. Sports Court

2. Cycle Track

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 116 of: 321

D. Related Sections:

1. Division 31 Section "Earth Moving" for aggregate subbase and base courses and for aggregate

pavement shoulders.

2. Division 32 Sections for other paving installed as part of crosswalks in asphalt pavement areas.

3. Section 321823.43 Recreational Court Surfacing of the Landscape specifications for SF05 Sports

Court.

4. Section 321723 Pavement Markings of the Landscape specifications for SF06 Cycle Track.

1.3 DEFINITIONS

A. Hot-Mix Asphalt Paving Terminology: Refer to ASTM D 8 for definitions of terms.

1.4 SUBMITTALS

A. Product Data: For each type of product indicated. Include technical data and tested physical and

performance properties.

1. Job-Mix Designs: Certification, by authorities having jurisdiction, of approval of each job mix proposed

for the Work.

B. Qualification Data: For qualified manufacturer and Installer.

C. Material Certificates: For each paving material, from manufacturer.

D. Material Test Reports: For each paving material.

1.5 QUALITY ASSURANCE

A. Manufacturer Qualifications: A paving-mix manufacturer registered with and approved by authorities in

Abu Dhabi.

B. Testing Agency Qualifications: Qualified according to ASTM D 3666 for testing indicated.

C. Regulatory Requirements: Comply with materials, workmanship, and other applicable requirements of the

ABU DHABI QCC Standard Construction Specifications, Government of Abu Dhabi for asphalt paving

work.

1. Measurement and payment provisions and safety program submittals included in standard

specifications do not apply to this Section.

1.6 PROJECT CONDITIONS:

A. Regulatory Requirements: Comply with materials, workmanship, and other applicable requirements of

ABU DHABI QCC Standard Construction Specifications, Government of Abu Dhabi for asphalt paving

work.

B. Environmental Limitations: Do not apply asphalt materials if subgrade is wet or excessively damp, if rain is

imminent or expected before time required for adequate cure, or if the following conditions are not met:

1. HMA Temperature: Delivered between 250 deg F and 350 deg F.

2. Prime Coat: Minimum surface temperature of 60 deg F.

3. Slurry Coat: Comply with weather limitations in ASTM D 3910.

4. Asphalt Base Course: Minimum surface temperature of 40 deg F in the shade and rising at time of

placement.

5. Asphalt Surface Course: Minimum surface temperature of 45 deg F in the shade at time of placement

and rising at time of placement.

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 117 of: 321

C. Pavement-Marking Paint: Proceed with pavement marking only on clean, dry surfaces and at a minimum

ambient or surface temperature of 55 deg F for water-based materials, and not exceeding 95 deg F. When

more restrictive, manufacturer limits shall be adhered to.

PART 2 - PRODUCTS

2.1 AGGREGATES:

A. General: Use materials and gradations that have performed satisfactorily in previous installations.

B. Coarse Aggregate: ASTM D 692, sound; angular crushed stone, crushed gravel.

C. Fine Aggregate: ASTM D 1073, sharp-edged natural sand or sand prepared from stone, gravel, or

combinations thereof.

D. For hot-mix asphalt, limit natural sand to a maximum of 20 percent by weight of the total aggregate mass.

E. Mineral Filler: ASTM D 242, rock or slag dust, hydraulic cement, or other inert material.

2.2 ASPHALT MATERIAL AND ACCESSORIES

A. Asphalt Binder: AASHTO M 320 and AASHTO MP 1a, PG 58-28, PG58-22, PG64-22

B. Prime Coat: ASTM D 2027, medium-curing cutback asphalt matching IDOT MC-30 per Section 1032 of

the Standard Specifications for Road and Bridge construction.

C. Tack Coat: IDOT SS-1, SS-1hP, CSS-1, CSS-1hP, emulsified asphalt or cationic emulsified asphalt, slow

curing, diluted in water, in accordance with ABU DHABI QCC Standard Construction Specifications,

Government of Abu Dhabi and of suitable grade and consistency for application.

D. Tack Coat: Where Paving Geotextile as an interlayer is used; Performance Grade asphalt binder of the

same grade as the overlaying pavement.

E. Fog Seal: AASHTO M 140, emulsified asphalt, or AASHTO M 208 cationic emulsified asphalt, slow curing,

factory diluted in water, of suitable grade and consistency for application.

F. Water: Potable.

2.3 MISCELLANEOUS ITEMS TO COMPLETE SYSTEM

A. Herbicide: Commercial chemical for weed control, registered by the EPA. Provide in granular, liquid, or

wettable powder form.

B. Sand: AASHTO M 29 Grade Nos. 2 or 3.

C. Paving Geotextile (Reflective Crack Control): AASHTO M 288-06, nonwoven polypropylene; resistant to

chemical attack, rot, and mildew; and specifically designed for paving applications.

1. Weight: ASTM D1910, minimum 4.1 oz/sq. yd.

2. Grab Tensile Strength: ASTM D4632, minimum 101 lbs

3. Asphalt Retention: ASTM 6140, minimum 0.20 gal/sq. yd.

D. Joint Sealant: ASTM D 6690 or AASHTO M 324 Type II or III Type II Type IV, hot-applied, single-

component, polymer-modified bituminous sealant.

E. Pavement-Marking Paint

1. Refer to Section 321823.43 Recreational Court Surfacing of the Landscape specifications for SF05

Sports Court.

2. Refer to Section 321723 Pavement Markings of the Landscape specifications for SF06 Cycle Track.

F. Dowels: Reinforcing Bars: ASTM A 615, Grade 60; deformed

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 118 of: 321

2.4 COATINGS

A. Coating System: Imprinted-asphalt manufacturer's standard system formulated for exterior application on

asphalt paving surfaces.

1. Base Coating: Portland cement and epoxy-modified acrylic polymer blended with sand and

aggregate, formulated for exterior application on asphalt paving surfaces.

2. Top Coating: Epoxy-modified acrylic polymer blended with sand and aggregate, formulated for

exterior application on asphalt paving surfaces.

3. Colorant: UV-stable pigment blend, added to each coating layer.

4. Color: As indicated on Design Drawings.

2.5 MIXES

A. Hot-Mix Asphalt: Dense, hot-laid, hot-mix asphalt plant mixes designed according to the Illinois Modified

Strategic Highway Research Program criteria and the IDOT Special Provision “Superpave Bituminous

Concrete Mixtures”.

B. Binder Course Mixture N50, IL-19.0, Surface Course Mixture N50, IL-9.5, designed in accordance with

ABU DHABI QCC Standard Construction Specifications, Government of Abu Dhabi.

C. Provide mixes with a history of satisfactory performance in geographical area where Project is located.

D. Emulsified-Asphalt Slurry: ASTM D 3910, Type 1, consisting of emulsified asphalt, fine aggregate, and

mineral fillers.

PART 3 - EXECUTION

3.1 EXAMINATION

A. Verify that subgrade is dry and in suitable condition to begin paving.

B. Proof-roll subgrade below pavements with heavy pneumatic-tired equipment to identify soft pockets and

areas of excess yielding. Do not proof-roll wet or saturated subgrades.

1. Completely proof-roll subgrade in one direction, repeating proof-rolling in direction perpendicular to

first direction. Limit vehicle speed to 3 mph.

2. Proof roll with a loaded 10-wheel, tandem-axle dump truck weighing not less than 15 tons.

3. Excavate soft spots, unsatisfactory soils, and areas of excessive pumping or rutting, as deter-mined

by Architect, and replace with compacted backfill or fill as directed.

C. Proceed with paving only after unsatisfactory conditions have been corrected.

3.2 SURFACE PREPARATION

A. General: Immediately before placing asphalt materials, remove loose and deleterious material from

substrate surfaces. Ensure that prepared subgrade is ready to receive paving.

B. Prime Coat: Apply uniformly over surface of compacted unbound-aggregate base course at a rate of 0.15

to 0.50 gal./sq. yd. Apply enough material to penetrate and seal but not flood sur-face. Allow prime coat

to cure.

1. If prime coat is not entirely absorbed within 24 hours after application, spread sand over sur-face to

blot excess asphalt. Use enough sand to prevent pickup under traffic. Remove loose sand by

sweeping before pavement is placed and after volatiles have evaporated.

2. Protect primed substrate from damage until ready to receive paving.

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 119 of: 321

C. Tack Coat: Apply uniformly to surfaces of existing pavement at a rate of 0.05 to 0.15 gal./sq. yd.

1. Allow tack coat to cure undisturbed before applying hot-mix asphalt paving.

2. Avoid smearing or staining adjoining surfaces, appurtenances, and surroundings. Remove spillages

and clean affected surfaces.

3.3 PAVING GEOTEXTILE INSTALLATION

A. Apply tack coat uniformly to existing pavement surfaces at a rate of 0.20 to 0.30 gal./sq. yd.

B. Place paving geotextile promptly according to manufacturer's written instructions. Broom or roll geotextile

smooth and free of wrinkles and folds. Overlap longitudinal joints 4 inches and transverse joints 6 inches.

1. Protect paving geotextile from traffic and other damage and place hot-mix asphalt paving overlay the

same day.

3.4 COMPACTION

A. General: Begin compaction as soon as placed hot-mix paving will bear roller weight without excessive

displacement. Compact hot-mix paving with hot, hand tampers or with vibratory-plate compactors in areas

inaccessible to rollers.

1. Complete compaction before mix temperature cools to 185 deg F. Breakdown Rolling: Complete

breakdown or initial rolling immediately after rolling joints and outside edge. Examine surface

immediately after breakdown rolling for indicated crown, grade, and smoothness. Correct laydown

and rolling operations to comply with requirements.

B. Intermediate Rolling: Begin intermediate rolling immediately after breakdown rolling while hot-mix asphalt

is still hot enough to achieve specified density. Continue rolling until hot-mix asphalt course has been

uniformly compacted to the following density:

1. Average Density: 96 percent of reference laboratory density according to ASTM D 6927 but not less

than 94 percent nor greater than 100 percent.

2. Average Density: 92 percent of reference maximum theoretical density according to ASTM D 2041,

but not less than 90 percent nor greater than 96 percent.

C. Finish Rolling: Finish roll paved surfaces to remove roller marks while hot-mix asphalt is still warm.

D. Edge Shaping: While surface is being compacted and finished, trim edges of pavement to proper

alignment. Bevel edges while asphalt is still hot; compact thoroughly.

E. Repairs: Remove paved areas that are defective or contaminated with foreign materials and replace with

fresh, hot-mix asphalt. Compact by rolling to specified density and surface smoothness.

F. Protection: After final rolling, do not permit vehicular traffic on pavement until it has cooled and hardened.

G. Erect barricades to protect paving from traffic until mixture has cooled enough not to become marked.

3.5 INSTALLATION TOLERANCES

A. Pavement Thickness: Compact each course to produce the thickness indicated within the following

tolerances:

1. Base Course: Plus or minus 1/2 inch.

2. Surface Course: Plus 1/4 inch, no minus.

B. Pavement Surface Smoothness: Compact each course to produce a surface smoothness within the

following tolerances as determined by using a 10-foot straightedge applied transversely or longitudinally

to paved areas:

1. Base Course: 1/4 inch.

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 120 of: 321

2. Surface Course: 1/8 inch.

3. Crowned Surfaces: Test with crowned template centered and at right angle to crown. Maximum

allowable variance from template is 1/4 inch.

3.6 FIELD QUALITY CONTROL

A. Testing Agency: Engage a qualified testing agency to perform tests and inspections.

B. Thickness: In-place compacted thickness of hot-mix asphalt courses will be determined according to

ASTM D 3549.

C. Surface Smoothness: Finished surface of each hot-mix asphalt course will be tested for compliance with

smoothness tolerances.

D. In-Place Density: Testing agency will take samples of uncompacted paving mixtures and compacted

pavement according to ASTM D 979.

1. Reference maximum theoretical density will be determined by averaging results from four samples of

hot-mix asphalt-paving mixture delivered daily to site, prepared according to ASTM D 2041, and

compacted according to job-mix specifications.

2. In-place density of compacted pavement will be determined by testing core samples according to

ASTM D 1188 or ASTM D 2726.

a. One core sample will be taken for every 1000 sq. yd. or less of installed pavement, with no fewer

than 3 cores taken.

b. Field density of in-place compacted pavement may also be determined by nuclear method

according to ASTM D 2950 and correlated with ASTM D 1188 or ASTM D 2726.

E. Replace and compact hot-mix asphalt where core tests were taken.

F. Remove and replace or install additional hot-mix asphalt where test results or measurements indicate that

it does not comply with specified requirements.

3.7 DISPOSAL

A. Except for material indicated to be recycled, remove excavated materials from Project site and legally

dispose of them in an EPA-approved landfill. Contractor shall not allow milled materials to accumulate on-

site.

END OF SECTION

client: Fibrex Construction Group

Project: Design And Construction of Yas Living Development (Noya-2)

Title: Landscape Architecture Technical Specification Report

office: Abu Dhabi Project No. AET00688.01 document: rev: 0 sheet: 121 of: 321

You might also like

- Determining Flash & Fire Points of BitumenDocument11 pagesDetermining Flash & Fire Points of BitumenWily RustamNo ratings yet

- European Asphalt Standards - PresentationDocument17 pagesEuropean Asphalt Standards - PresentationCharles LangatNo ratings yet

- Design Controls and CriteriaDocument8 pagesDesign Controls and CriteriaMengstagegnewNo ratings yet

- Road Construction Materials GuideDocument98 pagesRoad Construction Materials GuideFrimini BeatusNo ratings yet

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091No ratings yet

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- Super PaveDocument20 pagesSuper PaveHashem EL-MaRimeyNo ratings yet

- Sydney Kerb and Gutter SpecificationsDocument17 pagesSydney Kerb and Gutter SpecificationsGeeta RamsinghNo ratings yet

- Worktips 31 Asphalt Paving Speed PDFDocument2 pagesWorktips 31 Asphalt Paving Speed PDFvamshi100% (1)

- Certification Policies For Concrete Field Testing Technician - Grade IDocument15 pagesCertification Policies For Concrete Field Testing Technician - Grade ISuhail P SakkeerNo ratings yet

- Superpave HMA: What is SuperpaveDocument2 pagesSuperpave HMA: What is SuperpaveMuhammad Waqar Aslam ChNo ratings yet

- PavementDocument11 pagesPavementelcivilengNo ratings yet

- Determining The Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk DiffusionDocument8 pagesDetermining The Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk DiffusionAhmed AlzubaidiNo ratings yet

- Flexible Pavement: Click To Edit Master Title StyleDocument13 pagesFlexible Pavement: Click To Edit Master Title StyleFaisal SharifNo ratings yet

- MOC Supplemental Specs for Ag RoadsDocument42 pagesMOC Supplemental Specs for Ag Roadsluismarcial01No ratings yet

- Earthwork ScopeDocument4 pagesEarthwork ScopeMax SchusterNo ratings yet

- ERA Standard Technical Specifications 2002Document759 pagesERA Standard Technical Specifications 2002Geby BridgeNo ratings yet

- Asphalt Materials and Uses: Section 1. NomenclatureDocument9 pagesAsphalt Materials and Uses: Section 1. Nomenclaturephoenix_12_No ratings yet

- Aci Method of Mix DesignDocument19 pagesAci Method of Mix DesignJuel Rahaman100% (1)

- حمامات السباحة - المقاولون العربDocument60 pagesحمامات السباحة - المقاولون العربAhd EssamNo ratings yet

- Determining The Flexural Creep Stiffness of Asphalt Binder Using The Bending Beam Rheometer (BBR)Document15 pagesDetermining The Flexural Creep Stiffness of Asphalt Binder Using The Bending Beam Rheometer (BBR)mohammed karasnehNo ratings yet

- Cement Bound Material Road Construction GuideDocument34 pagesCement Bound Material Road Construction GuideJawad Ghauri100% (1)

- Aggregates in Self-Consolidating Concrete: Research Report Icar 108-2FDocument362 pagesAggregates in Self-Consolidating Concrete: Research Report Icar 108-2FMichael GelongNo ratings yet

- Asphalt Technology in MyanmarDocument53 pagesAsphalt Technology in Myanmarကိုနေဝင်း100% (1)

- Ch3 Crack SealingDocument26 pagesCh3 Crack SealingWinengkuNo ratings yet

- Hot Mix Asphalt Construction Certification and Accreditation ProgramsDocument113 pagesHot Mix Asphalt Construction Certification and Accreditation Programsvrushankhallayrock100% (2)

- Intro & Subgrade CompactionDocument27 pagesIntro & Subgrade CompactionCarlos Ramos GuerraNo ratings yet

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignGemechu100% (1)

- Astm 2487Document1 pageAstm 2487paul sanchezNo ratings yet

- Basic Civil NotesDocument43 pagesBasic Civil Notessyedaleem1167100% (2)

- Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 FT-LBF/FT (600 KN-M/M) )Document13 pagesLaboratory Compaction Characteristics of Soil Using Standard Effort (12 400 FT-LBF/FT (600 KN-M/M) )grats_singcoNo ratings yet

- Repairing Asphelt Cracks PDFDocument49 pagesRepairing Asphelt Cracks PDFAhmed AlsadoonNo ratings yet

- DBM 507Document7 pagesDBM 507Mark Moni Mary ManoNo ratings yet

- Malaysia ReportDocument47 pagesMalaysia ReportAgim Derguti100% (1)

- Introduction To Pavement DesignDocument23 pagesIntroduction To Pavement DesignDaniel Berhane100% (1)

- Modified Binders and Superpave Plus SpecificationsDocument2 pagesModified Binders and Superpave Plus Specificationsingmdtz_1No ratings yet

- Utilisation of Warm Mix Asphalt Technology To Improve Bituminous Mixtures Containing Reclaimed Asphalt PavementDocument31 pagesUtilisation of Warm Mix Asphalt Technology To Improve Bituminous Mixtures Containing Reclaimed Asphalt PavementdaniNo ratings yet

- GITAM Placement DetailsDocument5 pagesGITAM Placement DetailspremsempireNo ratings yet

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDocument1 pageC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- TOP DOWN CRACKING IN BITUMINOUS PAVEMENT by MD - IMTHIYAZDocument48 pagesTOP DOWN CRACKING IN BITUMINOUS PAVEMENT by MD - IMTHIYAZMd.imthiyaz40% (5)

- Introduction to Bituminous Mixes and Volumetric AnalysisDocument19 pagesIntroduction to Bituminous Mixes and Volumetric AnalysisShre BNo ratings yet

- AFCONS - DESIGN - Pavement Design (PK 50-75) - Anglais - 2021-03-08Document89 pagesAFCONS - DESIGN - Pavement Design (PK 50-75) - Anglais - 2021-03-08Adrian FrantescuNo ratings yet

- Sup Mix PTC.11 PDFDocument69 pagesSup Mix PTC.11 PDFMohamed AbbassyNo ratings yet

- SoilsDocument180 pagesSoilsAyman KandeelNo ratings yet

- D 6758 - 02 - Rdy3ntgDocument5 pagesD 6758 - 02 - Rdy3ntgAntonio Harry PonceNo ratings yet

- Concrete Roads WorkshopDocument7 pagesConcrete Roads WorkshopShelly Delhi0% (1)

- AASHTO Sets Transportation StandardsDocument3 pagesAASHTO Sets Transportation StandardsAndrea CastreNo ratings yet

- Muhammad Mudassir S CVDocument10 pagesMuhammad Mudassir S CVMuhammad TahirNo ratings yet

- Resumen SuperpaveDocument60 pagesResumen SuperpaveFranklinNo ratings yet

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocument75 pagesHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNo ratings yet

- Properties Concrete Dune SandDocument6 pagesProperties Concrete Dune SandAlanSamNo ratings yet

- 10-000000-0000100595-ACM-ENG-SPC-000430 - Section 032000Document20 pages10-000000-0000100595-ACM-ENG-SPC-000430 - Section 032000ahmad.suliman.saeedNo ratings yet

- Section 089000 - Louvers and VentsDocument17 pagesSection 089000 - Louvers and VentsNeeskens D'melloNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument24 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 10-000000-0000100595-ACM-ENG-SPC-000649 - Section 034105Document48 pages10-000000-0000100595-ACM-ENG-SPC-000649 - Section 034105ahmad.suliman.saeedNo ratings yet

- A2-30 Applied Finishes For Flat RoofsDocument23 pagesA2-30 Applied Finishes For Flat RoofsJacky TiongNo ratings yet

- Z-17 Diesel Topping PlantsDocument29 pagesZ-17 Diesel Topping Plantssfar yassine100% (1)

- Swivel Joist-Expansion Joints: (With/without Noise Reduction)Document48 pagesSwivel Joist-Expansion Joints: (With/without Noise Reduction)Tamaduianu IoanNo ratings yet

- Ufgs 09 97 13.27Document43 pagesUfgs 09 97 13.27Amir KhakzadNo ratings yet

- Fiber Distributed Data Interface [FDDI] Technology ReportFrom EverandFiber Distributed Data Interface [FDDI] Technology ReportRating: 5 out of 5 stars5/5 (1)

- TSRTC Student Bus Pass Application FormDocument2 pagesTSRTC Student Bus Pass Application Formjagan the streamerNo ratings yet

- Mushak-17 Sales RegisterDocument18 pagesMushak-17 Sales RegisterMd MahabubNo ratings yet

- Crane Backward Stability RisksDocument3 pagesCrane Backward Stability RisksEleazar Maldonado Rivera100% (1)

- Motibhai Group Newsletter - September 2017Document4 pagesMotibhai Group Newsletter - September 2017Motibhai GroupNo ratings yet

- Sdoc 09 13 SiDocument70 pagesSdoc 09 13 SiJhojo Tesiorna FalcutilaNo ratings yet

- Bridge Watch Monitoring SystemDocument104 pagesBridge Watch Monitoring SystemAnil KumarNo ratings yet

- Booking 11 02Document4 pagesBooking 11 02Bryan FitzgeraldNo ratings yet

- Electronic VSI and TCASDocument2 pagesElectronic VSI and TCASAnish ShakyaNo ratings yet

- ICAO SMS M 01 - SMS Course (R013) 09 (E) (Compatibility Mode) PDFDocument5 pagesICAO SMS M 01 - SMS Course (R013) 09 (E) (Compatibility Mode) PDFFaisal KhanNo ratings yet

- Malolos Clark Railway Project - Framework Financing Agreement 1 PDFDocument22 pagesMalolos Clark Railway Project - Framework Financing Agreement 1 PDFDeniell Joyce MarquezNo ratings yet

- Final - Lesson 6 Activities and AssessmentsDocument12 pagesFinal - Lesson 6 Activities and AssessmentsJongie LaurianoNo ratings yet

- Ca002cb00320130228115350 (PMC Clutch Kit Promotion - 20130227) 1Document3 pagesCa002cb00320130228115350 (PMC Clutch Kit Promotion - 20130227) 1LUISGUILLERMOCC100% (1)

- Literature Review On The Study of Urban Heat Island Impacts On Building InteriorsDocument12 pagesLiterature Review On The Study of Urban Heat Island Impacts On Building InteriorsYeong Kam Loong100% (1)

- A319 Manual Handling - Training ManualDocument21 pagesA319 Manual Handling - Training ManualEvgeni StanevNo ratings yet

- SIP Trunking and Customisation Manual 1.0Document94 pagesSIP Trunking and Customisation Manual 1.0Javi KatzNo ratings yet

- ArgumentationDocument25 pagesArgumentationNingning DesaculaNo ratings yet

- Tesco Travel Policy BookletDocument64 pagesTesco Travel Policy Bookletuser001hNo ratings yet

- Iron Horse Brochure Web VersionDocument3 pagesIron Horse Brochure Web VersionMkpit Micu PiticuNo ratings yet

- Securing Roro CargoDocument2 pagesSecuring Roro CargoIlter KocamanNo ratings yet

- Trace Elliot V Type Preamp Schematic 1Document8 pagesTrace Elliot V Type Preamp Schematic 1Serhii HolykNo ratings yet

- Iloilo Airport and Port Expansion OpportunitiesDocument17 pagesIloilo Airport and Port Expansion OpportunitiesMarc Myer De AsisNo ratings yet

- Wire Rope Hoist 2 TonDocument5 pagesWire Rope Hoist 2 Tonafrozashirahatti20No ratings yet

- Indian RailwayDocument37 pagesIndian RailwayAnonymous 3BGW2XaXZeNo ratings yet

- FAA Drone DataDocument44 pagesFAA Drone DatamacmoonNo ratings yet

- Teodoro & Perena v. Nicolas & ZarateDocument2 pagesTeodoro & Perena v. Nicolas & Zaratemiles1280No ratings yet

- COURSE SYLLABUS (Transportation Management)Document9 pagesCOURSE SYLLABUS (Transportation Management)Sir John JosephNo ratings yet

- Dwnload Full Fraud Examination 6th Edition Albrecht Test Bank PDFDocument36 pagesDwnload Full Fraud Examination 6th Edition Albrecht Test Bank PDFpavierdegust.3thj2k100% (8)

- PT INSMART Oil & Gas Speaker Sudibyo ExperienceDocument1 pagePT INSMART Oil & Gas Speaker Sudibyo ExperienceSidik Kunto BNo ratings yet

- GX270 (GCAB) Parts DiagramDocument394 pagesGX270 (GCAB) Parts DiagramRusmiyanto YantoNo ratings yet

![Fiber Distributed Data Interface [FDDI] Technology Report](https://imgv2-1-f.scribdassets.com/img/word_document/282658933/149x198/df3dc47c73/1699545009?v=1)