Professional Documents

Culture Documents

Jishu Hozen

Uploaded by

ngrlean whCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jishu Hozen

Uploaded by

ngrlean whCopyright:

Available Formats

Jishu Creation date: /

TPM Promotion Office

/

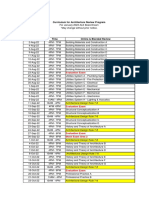

Hozen List of Jishu Hozen (AM) Registered Machines

(AM)

Introdu

ction

Educati

on

Schedul

e

Sche

No. Main Item Sub-Item Instructor Time dule

Application Section Leader

date Manager

Diagnosis Autonomous Section Top Step points Pass Fail

Manager Executive

Section/Team

name

Equipment No.

Desired diagnosis //

date

Diagnosis date //

and time :-:

Diagnosed by

Application Form for Autonomous Maintenance

Diagnosis

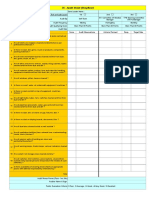

Autonomous Maintenance Diagnosis Sheet

Step 1: Initial Cleaning

(Equipment)

Autonomous Section Top

Manager Executive

90 points or 85 points or 80 points

more more or more

Level passed (level points in table below

+ evaluation score)Sum of (level points in items 1-5) + evaluation score (item 6)

Diagnosis item Points of Bad Poor Fair

Somewhat Good Sugges-

diagnosis good tions

1 point 2 points 3 points 4 points 5 points

1. Cleaning of machine • Are waste, dust, oil contamination and scraps at acceptable levels,

main body and are work and tools in good condition?

(Jig parts, chuck parts, sliding parts, chute parts, frame, bed , piping,

wiring parts, etc.)

• Are looseness, play, vibration, wear and heat generation at

acceptable levels?

(Bolts, nuts, jig parts, rotating parts, sliding parts, chutes, etc.)

2. Cleaning of auxiliary • Are waste, dust, oil contamination, adherence of foreign matter, etc.

equipment at acceptable levels?

• Circulatory systems (Cylinders, solenoids, 3-point sets, motors, limit switches, belts, proximity

such as oil, switches, photoelectric tubes, inside and outside control boxes,

pneumatic and water measuring equipment, etc.)

• Electrical • Are looseness, play, vibration, wear, whining noise, and heat

control generation at acceptable levels?

• Other (Motors, solenoids, fastening plate of limit switches, relays, wiring,

bolts, nuts, etc.)

3. Lubrication • Are waste, dust and oil contamination at acceptable levels?

conditions (Lubricator, oil cup, measuring gauges, cover of oil spout, lubrication

piping)

• Are oil quantity, drip quantity, looseness, play, and vibration

at acceptable levels?

(Contamination of the oil itself, deterioration, piping joints, valves,

speed controls, oil temperature, etc.)

4. Status of • Are ordering of tools, gauges, and spare parts in good condition?

cleaning • Are indicators, such as covers, name plates and labels, in

machine good condition?

vicinity • Are unneeded parts and necessary products and parts in

good

• Are quality products and defective products separated?

• Are passageways secured?

• Is there any scattering of dust from other equipment?

5. Counter- • Is there a future plan to create a list for generating sources and

measures for difficult- to-access cleaning locations for waste, dust and oil leakage?

difficult-to- clean • Have improvements been made for covers and cleaning tools?

locations, • Are there items to be inspected while cleaning?

• Are cleaning locations divided up and apportioned?

6. Status of TPM efforts • Do all personnel understand Evaluation 10 points 20 points 30 points 40 points 50 points

TPM and participate in score

activities? Diagnosis

1 point 2 points 3 points 4 points 5 points

(10 points) (20 points) (30 points) (40 points) (50 points)

1~5 Equip- Almost Implemented Implemented as far as Implemented even for Cleaning and inspection are thoroughly

Evalua- tion ment completely insofar as can be specified locations, such as parts that cannot be implemented, and proceeding with difficult-

level un- seen sliding parts and chutes seen to-access locations

implemented

6 Per- All personnel Only those in Operators are active only in Being implemented by Division of roles is clear and well

son- are indifferent maintenance and some simple areas nearly all operators implemented

nel management are

active

Diagnos

is Sheet

Application Form for Top Executive Diagnosis of

(Step 1) Jishu Hozen (AM)

(Step No. )

Applic

ation

Form

for Top

Execut

ive

Diagno

sis

Applying department: Circle Subsection

Section Department Section Manager

Target equipment:

Since the Autonomous Maintenance Step No. activities are proceeding as shown below, I would like to

apply for a top executive diagnosis.

1. Status of activities (progress, details, results, policies, etc.)

2. Autonomous diagnosis results

Date implemented: / / Section Manager comments:

Diagnosis evaluation: points

Diagnosed by:

3. Desired diagnosis date and time

/ / : - :

Promotion Promotion

4. Top executive diagnosis date (decision) Office Office Receptionist

/ / : - : Manager

5. Application route

Circle Subsection Section Department TPM Promotion Office (Reception)

Leader Manager Manager Manager (Coordinates diagnosis schedule)

Contact regarding diagnosis d

You might also like

- BobcatTroubleshooting Method 2018Document17 pagesBobcatTroubleshooting Method 2018Ayman Esa100% (1)

- 5S Audit Scorecard ResultsDocument5 pages5S Audit Scorecard ResultsGauravNo ratings yet

- Economies of Scale CluffDocument8 pagesEconomies of Scale CluffJackson CluffNo ratings yet

- Failure Analysis: Key Concepts and Benefits of FMECADocument72 pagesFailure Analysis: Key Concepts and Benefits of FMECAbrucemartin3100% (1)

- Autonomous Maintenance Webinar GuideDocument37 pagesAutonomous Maintenance Webinar GuideMadhavaKrishnaNo ratings yet

- Slickline - Lectures. Tools. OperationsDocument44 pagesSlickline - Lectures. Tools. OperationsOmer Abuzeid100% (1)

- Plating Process Audit Checksheet 9332E-XDocument3 pagesPlating Process Audit Checksheet 9332E-Xabhionlyster63% (8)

- Internal Quality Audit at Isuzu PlantDocument8 pagesInternal Quality Audit at Isuzu Plantgharba putraNo ratings yet

- TPM Maintenance Philosophy for Zero BreakdownsDocument35 pagesTPM Maintenance Philosophy for Zero BreakdownsGURMUKH SINGH100% (1)

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Document1 pageAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNo ratings yet

- 01 - Layered Process Audit Example B 2011Document7 pages01 - Layered Process Audit Example B 2011RN XaverNo ratings yet

- Chapter 3 SolmanDocument23 pagesChapter 3 SolmanUchayyaNo ratings yet

- TPM FormsDocument15 pagesTPM FormscivanusNo ratings yet

- Autonomous Operator Training Step 0 PDFDocument17 pagesAutonomous Operator Training Step 0 PDFjesusmemNo ratings yet

- FMEA Analysis and ImprovementDocument87 pagesFMEA Analysis and ImprovementArijitMalakarNo ratings yet

- Effective Maintenance PDFDocument59 pagesEffective Maintenance PDFEkopribadiNo ratings yet

- JH TrainingDocument218 pagesJH TrainingMAngesh GadeNo ratings yet

- Condition Monitoring & Assessment For Rotating Machinery by Using Risk-Based Inspection and Quick Inspection SystemDocument19 pagesCondition Monitoring & Assessment For Rotating Machinery by Using Risk-Based Inspection and Quick Inspection SystemMohamed saleh100% (1)

- 5S AuditDocument7 pages5S Auditjorge.kemelNo ratings yet

- Soft Furnishing SpecsDocument11 pagesSoft Furnishing SpecsMiguel EllaNo ratings yet

- Paradise IATF IA Presentation PDFDocument211 pagesParadise IATF IA Presentation PDFSameer SaxenaNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Autonomous MaintenanceDocument455 pagesAutonomous MaintenanceBrian Job Malonzo100% (4)

- FTMO Passing StrategiesDocument7 pagesFTMO Passing Strategiesabsar ahmed100% (1)

- FMEADocument9 pagesFMEADhivakar S K100% (1)

- QM Pillar: (Quality Maintenance)Document17 pagesQM Pillar: (Quality Maintenance)G K MohanNo ratings yet

- The Economic Cost of The Pandemic: State by StateDocument12 pagesThe Economic Cost of The Pandemic: State by StateHoover Institution100% (1)

- Procedure Vs InstructionDocument2 pagesProcedure Vs Instructionkendall0609No ratings yet

- 01 Jipm Am Audit Step by StepDocument10 pages01 Jipm Am Audit Step by StepDũng Tây NinhNo ratings yet

- Jishu Hozen (Autonomous Maintenance)Document118 pagesJishu Hozen (Autonomous Maintenance)Harshit Modhia100% (2)

- Autonomous Maintenance Review RequestDocument15 pagesAutonomous Maintenance Review Requestsuzhou cNo ratings yet

- 6s Audit Workshop FormDocument22 pages6s Audit Workshop FormGman0% (1)

- Bug Defect Triage ProcessDocument20 pagesBug Defect Triage Processraulnq50% (2)

- Saif Powertec Limited Battery Division: Awarness SessionDocument47 pagesSaif Powertec Limited Battery Division: Awarness SessionNadeem NafisNo ratings yet

- 3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1Document1 page3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNo ratings yet

- JH Step-1 & 2activitiesDocument34 pagesJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNo ratings yet

- Total Preventative Maintenance Program InitiationDocument20 pagesTotal Preventative Maintenance Program InitiationAji Beni LastomoNo ratings yet

- Quality CircleDocument49 pagesQuality CircleAbdul Wahid AnsariNo ratings yet

- Waste Management GuideDocument5 pagesWaste Management GuidejamilvoraNo ratings yet

- Benefits and Limitations of Vibration Monitoring at Turbine Generators Carlo NobusDocument34 pagesBenefits and Limitations of Vibration Monitoring at Turbine Generators Carlo NobusFitas MounirNo ratings yet

- Training JH PillarDocument41 pagesTraining JH PillarSelvamNo ratings yet

- Fault Tracing IntroductionDocument4 pagesFault Tracing IntroductionjgkuchhadiyaNo ratings yet

- 20bba0194 TQM Da 1 FmeaDocument9 pages20bba0194 TQM Da 1 Fmeavani sureshNo ratings yet

- TPMDocument9 pagesTPMdmaticsc1No ratings yet

- 5s ShortDocument24 pages5s ShortSMAKNo ratings yet

- LEAN SIX SIGMA PROCESS IMPROVEMENTDocument27 pagesLEAN SIX SIGMA PROCESS IMPROVEMENTbcitilciNo ratings yet

- Internship ReportDocument93 pagesInternship ReportBabar Bilal100% (1)

- Implementation Manual - 3 Quality Maintenance Qs. 1 What Kind of Data Is Required? Ans: Quality Defects - In-House and at Customer EndDocument8 pagesImplementation Manual - 3 Quality Maintenance Qs. 1 What Kind of Data Is Required? Ans: Quality Defects - In-House and at Customer Endagus wahyudiNo ratings yet

- Layered Process Audit ChecklistDocument1 pageLayered Process Audit ChecklistMuniyappan TNo ratings yet

- 6S Scan Diagnostic Sheet-Print For ExerciseDocument2 pages6S Scan Diagnostic Sheet-Print For ExerciseHardi BanuareaNo ratings yet

- Machine Maintenance 3Document35 pagesMachine Maintenance 3Tariku HabteselassieNo ratings yet

- Industrial Hazard IdentificationDocument117 pagesIndustrial Hazard IdentificationAll movies trailers and linkNo ratings yet

- 5 S Audit Checklist ANIMADocument1 page5 S Audit Checklist ANIMAMd Gulam SafiNo ratings yet

- An Overview of Quantitative Risk Assessment Methods Fayssal Safie/MSFC August 1, 2000Document68 pagesAn Overview of Quantitative Risk Assessment Methods Fayssal Safie/MSFC August 1, 2000suman pandianNo ratings yet

- MEFD1012 - Labsheet Drilling S22021Document8 pagesMEFD1012 - Labsheet Drilling S22021Wan Aiman Wan Kamarul AzwanNo ratings yet

- TPMDocument69 pagesTPMOswaldo VallesNo ratings yet

- Introduction To: Resonant Inspection: MagnafluxDocument23 pagesIntroduction To: Resonant Inspection: MagnafluxChiqui dripiNo ratings yet

- Zero Defects Implementation ManualDocument8 pagesZero Defects Implementation ManualCleber RochaNo ratings yet

- Introduction To Environmental Engineering Technology LaboratoryDocument34 pagesIntroduction To Environmental Engineering Technology LaboratorySYaz WAniNo ratings yet

- Fmea para RiesgoDocument68 pagesFmea para RiesgoVERONICA ROSALES GONZALEZNo ratings yet

- Error Proofing TechniquesDocument41 pagesError Proofing TechniquesMahmadah KhuryatiningsihNo ratings yet

- Failure Modes Effect Analysis (FMEA)Document22 pagesFailure Modes Effect Analysis (FMEA)Mujammil ChoudhariNo ratings yet

- Pfmea: Why Use It? How To Do It?Document7 pagesPfmea: Why Use It? How To Do It?imNo ratings yet

- FMEADocument88 pagesFMEAdspquality2023No ratings yet

- Breakdown Training WorkshopDocument49 pagesBreakdown Training WorkshopOsinachukwu NwosuNo ratings yet

- Find Question 4Document2 pagesFind Question 4hasgonde123No ratings yet

- XYZ CompanyDocument2 pagesXYZ Companysheetal2324No ratings yet

- Assignment RC IDocument2 pagesAssignment RC Iabrhamfikadie676No ratings yet

- Aims Annual Report 2020Document122 pagesAims Annual Report 2020Felicia IvenaNo ratings yet

- Animal Census Rajasthan 2019 DataDocument2 pagesAnimal Census Rajasthan 2019 DataPAHAL PYARENo ratings yet

- FSAV 6e - Errata 092022Document28 pagesFSAV 6e - Errata 092022Aruzhan TanirbergenNo ratings yet

- Direct Demand FunctionsDocument5 pagesDirect Demand FunctionsLagopNo ratings yet

- Management AccountingDocument68 pagesManagement AccountingNekibur DeepNo ratings yet

- Statistics & Probability: Quarter 3 - Week 5Document4 pagesStatistics & Probability: Quarter 3 - Week 5MichelJoy De GuzmanNo ratings yet

- Booklet 3er Grado 2023Document24 pagesBooklet 3er Grado 2023impresionespribianNo ratings yet

- PG TRB Commerce Question Paper 2004Document22 pagesPG TRB Commerce Question Paper 2004julie jasmineNo ratings yet

- Gantrex Pad Mk6Document4 pagesGantrex Pad Mk6reza nasiriNo ratings yet

- 30-April-2021 Weekly UpdateDocument11 pages30-April-2021 Weekly UpdateShamraiz KhanNo ratings yet

- Garment Manufacturing Lab Manual Parts GuideDocument67 pagesGarment Manufacturing Lab Manual Parts GuideHammad MustafaNo ratings yet

- ReportTransactionStatement - Do - 1522Document4 pagesReportTransactionStatement - Do - 1522Shaikh Hassan AtikNo ratings yet

- Business Cycle EconomicsDocument2 pagesBusiness Cycle EconomicsRitvik Anuraag JanarajupalliNo ratings yet

- sss-foreclosed-properties-HAA For Sale As of July 31 2020 PDFDocument18 pagessss-foreclosed-properties-HAA For Sale As of July 31 2020 PDFFrances PaulineNo ratings yet

- Common Statistical Tests Are Linear ModelsDocument1 pageCommon Statistical Tests Are Linear ModelsLourrany BorgesNo ratings yet

- Comparing banana and watermelon production between countriesDocument5 pagesComparing banana and watermelon production between countriesAkai GunnerNo ratings yet

- Causes of Delay in Construction Projects of Punjab-Pakistan: An Empirical StudyDocument10 pagesCauses of Delay in Construction Projects of Punjab-Pakistan: An Empirical StudysijixingNo ratings yet

- Ale Jan 2023 - ScheduleDocument6 pagesAle Jan 2023 - ScheduleBenjie LatrizNo ratings yet

- Multiple Choice Answers and Solutions: Franchise Accounting 177Document11 pagesMultiple Choice Answers and Solutions: Franchise Accounting 177Mazikeen DeckerNo ratings yet

- U3 Regional Integration & Trade ArrangementsDocument40 pagesU3 Regional Integration & Trade ArrangementsArun MishraNo ratings yet

- Examples EconometricsDocument9 pagesExamples EconometricsAhihiNo ratings yet