Professional Documents

Culture Documents

Case Study Grain Drying CHP

Uploaded by

Jupinu Nelu MariusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study Grain Drying CHP

Uploaded by

Jupinu Nelu MariusCopyright:

Available Formats

CASE STUDY: GRAIN DRYING, FINLAND

Energy costs

BOWMAN significantly

HEAT reduced in

TRANSFER

TECHNOLOGY new grain

IN ACTION drying solution.

Project

Drying is an essential part of the grain production

process in Nordic countries such as Finland. After

harvesting, the grain has to be dried to reduce

its moisture content from around 25% to 12-

14% for storage. Large grain dryers blow hot air

through the grain, usually via an oil or gas burner.

However, the energy costs involved are significant

and directly impact on food production costs.

During the drying process, warm air, which has passed

through the grain, is exhausted to outside atmosphere,

in a ‘total loss’ cycle. Typically this exhaust air still

has a temperature of 35º C and 50-75% humidity,

so a valuable energy source is lost. It takes up to

24 hours to achieve the required moisture level in a

30 ton batch of grain, so a farms typical drying season

can last for up to 2 months, consuming between

25,000 and 40,000 litres of oil during that time.

A Bowman exhaust gas heat exchanger has been

used as part of a new heat recovery system that

dramatically reduces the amount of energy required

and the emissions produced during the grain drying

process.

Heat Exchanger Technology by

A World Leader in Heat Exchanger Technology

CASE STUDY: GRAIN DRYING, FINLAND

Solution

The drying solution has been successfully installed at the

Ronimus Farm in Litti, Southern Finland, which is a well-

established arable business. It is the first time this kind of

installation has been undertaken in Finland, and possibly the

first of its type in the world.

The system works by recovering a significant proportion of the

warm exhaust air that is traditionally expelled from the farm’s

grain dryer to atmosphere. Any contaminants and grain debris

are removed from the exhaust air prior to it being recirculated

and the ‘cleaned’ air transferred through a high efficiency

Bowman exhaust gas heat exchanger in the main heat pump The system is designed to operate with outside air temperatures

container, where it is heated back up to 65º C. between -5º C to +30º C which is the typical outside air

temperatures in the Nordic drying season. It can be retrofitted

The CHP system has been set up to recover heat energy from half very easily to existing grain drying systems as well as new

of the exhaust air that would normally exhaust to atmosphere. installations. As an additional bonus, the diesel engine is fitted

In the first year of operation, it has reduced the farm’s fuel oil with a generator with a shaft power of 55kW - enabling it to

consumption by half, saving around 18,000 litres of fuel and provide power to the pumps and other actuators of the heat

halving its CO2 emissions. recovery system.

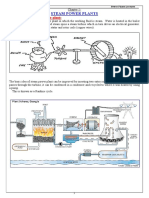

System Overview

1: a closing damper channels warm

Grain Drying

Facility exhaust air from the drier to an inside duct.

1 2: warm air is blown into a cyclone at high

7 speed.

3rd Heat: External Air

Diesel Engine 3: the warmed air is cleaned of debris in the

Exhaust Gas cyclone.

Warm air

for grain 2 4: heat from the warmed air is transferred to

drying a water-glycol mixture and piped to the

BOWMAN Exhaust 3 heat pump container.

6 Gas Heat Exchanger

5: the transferable heat pump container

2nd Heat:

Heat Pump 4 Warm air houses the diesel engine, compressor and

Diesel raises Heat a generator.

Engine temperature Exchanger

level Dust etc. 6: The diesel powered heat pump increases

Coil

Condensation the temperature of the water/glycol

mixture from around 35º C to around 65º C

Condenser

Evaporator

Compressor using heat recovered from the diesel

Water-Glycol 1st Heat:

Energy from engine via the Bowman EGHE.

Throttling Mixture warm air is 7: the water/glycol mixture is then transferred

Device 5 transferred to

the liquid to a pre-heating coil and from there to the

dryer inlet air stream.

Grain Drying from Diesel-Powered

Air Source Heat Pump

EJ Bowman (Birmingham) Ltd

Chester Street, Birmingham B6 4AP, UK

Tel: +44 (0) 121 359 5401 Fax: +44 (0) 121 359 7495

BS EN ISO 9001-2008

Email: info@ejbowman.co.uk www.ejbowman.co.uk Reg. No. FM38224 A A World Leader in Heat Exchanger Technology

You might also like

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Renewable Heat Pumps: A Guide For The Technically Minded How Do Heat Pumps Work ?Document12 pagesRenewable Heat Pumps: A Guide For The Technically Minded How Do Heat Pumps Work ?Nate SheaNo ratings yet

- Steam Power Plant PDFDocument47 pagesSteam Power Plant PDFSandeep Gupta100% (1)

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganNo ratings yet

- TemplifierDocument8 pagesTemplifiermdalt9180100% (1)

- Pipe Refresher CourseDocument5 pagesPipe Refresher CourseBanilo BanilaNo ratings yet

- HVAC & Refrigeration SystemDocument22 pagesHVAC & Refrigeration SystemSivakumar NadarajaNo ratings yet

- The Definitive Guide To Cryogenic EngineeringDocument21 pagesThe Definitive Guide To Cryogenic EngineeringSamanthaPereraNo ratings yet

- Heat PumpsDocument2 pagesHeat PumpsD.V.S.S Ram PrasadNo ratings yet

- Study of Vapour Absorption System Using Waste Heat-F0283439Document6 pagesStudy of Vapour Absorption System Using Waste Heat-F0283439Anonymous NGXdt2BxNo ratings yet

- WPCE Wireline Lubricator With Threaded UnionsDocument1 pageWPCE Wireline Lubricator With Threaded UnionsMARIONo ratings yet

- Heat Pumps: Solving Energy and Environmental ChallengesFrom EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoNo ratings yet

- GEA18457ADocument20 pagesGEA18457AEdGouramiNo ratings yet

- Vapor Power CyclesDocument18 pagesVapor Power CyclesParmeshwarPaulNo ratings yet

- Upload 48990ijrdtvlis22 142204 150118011549 Conversion Gate01 PDFDocument5 pagesUpload 48990ijrdtvlis22 142204 150118011549 Conversion Gate01 PDFVignesh VickyNo ratings yet

- Heat Recovery From Air-Cooled ChillersDocument17 pagesHeat Recovery From Air-Cooled ChillersRahmat JunaidiNo ratings yet

- Heat Recovery White Paper - Version 2Document9 pagesHeat Recovery White Paper - Version 2saNo ratings yet

- Advantages and Disadvantages of Using Absorption Chillers ToDocument4 pagesAdvantages and Disadvantages of Using Absorption Chillers Toأحمد صلاحNo ratings yet

- Heat PipeDocument7 pagesHeat PipeĐinh QuyetNo ratings yet

- Development and Evaluation of Solar Based Vapour Compression Refrigeration SystemDocument6 pagesDevelopment and Evaluation of Solar Based Vapour Compression Refrigeration SystemEugine BalomagaNo ratings yet

- Heat Pipe Heat ExchangersDocument7 pagesHeat Pipe Heat Exchangerssahilnayyar77No ratings yet

- Chapter 7 PDFDocument46 pagesChapter 7 PDFOnur ÖZÇELİKNo ratings yet

- Steam Theory - Waste Heat RecoveryDocument7 pagesSteam Theory - Waste Heat Recoverydarshan.dhonsiNo ratings yet

- The Influence Comparison of The Mass Refrigerant Towards Coefficient of Performance Car Air - Conditioning Systems With Refrigerant R-134ADocument7 pagesThe Influence Comparison of The Mass Refrigerant Towards Coefficient of Performance Car Air - Conditioning Systems With Refrigerant R-134Aanon_630820255No ratings yet

- Thermal Power Plant: Prepared by Mr.M.Boominathan, Maintenance Engineer, Mrungtamines LTD, OdishaDocument22 pagesThermal Power Plant: Prepared by Mr.M.Boominathan, Maintenance Engineer, Mrungtamines LTD, OdishaAnonymous JgPHsDNo ratings yet

- DesuperheaterDocument15 pagesDesuperheaterAVI_ROHINI100% (5)

- Advanced Heat Recovery: Source: HVAC Pump HandbookDocument12 pagesAdvanced Heat Recovery: Source: HVAC Pump HandbookDaring CodybillyNo ratings yet

- ME 403 CycleDocument40 pagesME 403 CyclesaquibNo ratings yet

- Refrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusDocument22 pagesRefrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusEmmanuel PlazaNo ratings yet

- Heat Pump 1Document6 pagesHeat Pump 1robert robNo ratings yet

- 6 Refrigeration Cycles EditedDocument31 pages6 Refrigeration Cycles EditederioNo ratings yet

- ESO 201A: Thermodynamics: Vapor and Combined Power CyclesDocument22 pagesESO 201A: Thermodynamics: Vapor and Combined Power CyclesamanNo ratings yet

- CHPC PDFDocument6 pagesCHPC PDFsaliyarumesh2292No ratings yet

- Vapour Absorption Refrigeration SystemDocument4 pagesVapour Absorption Refrigeration SystemAmith KumarNo ratings yet

- Cleaver Brooks - Design Considerations For Small Scale HRSGsDocument16 pagesCleaver Brooks - Design Considerations For Small Scale HRSGsLiu YangtzeNo ratings yet

- Challenges - Diesel Exhaust Gas RecoveryDocument5 pagesChallenges - Diesel Exhaust Gas RecoveryAiman AliNo ratings yet

- Chapter - 06 - Second Law-8Document38 pagesChapter - 06 - Second Law-8Marviandi EkoNo ratings yet

- Boiler Performance ImproveDocument5 pagesBoiler Performance Improvehwang2No ratings yet

- Steam Absorption ChillerDocument3 pagesSteam Absorption ChillerAbd AbdulNo ratings yet

- Pompe de Caldura PDFDocument21 pagesPompe de Caldura PDFLiviuNo ratings yet

- Lecture 4 Capter 11 (Refrigeration Cycle)Document9 pagesLecture 4 Capter 11 (Refrigeration Cycle)Yato SenkaiNo ratings yet

- Powr PlantDocument10 pagesPowr PlantSajjad Ibraheem100% (1)

- Cogeneration PlantDocument32 pagesCogeneration PlantSujeet SalunkheNo ratings yet

- Uebersetzung EnglischDocument4 pagesUebersetzung Englischduddu_nageshNo ratings yet

- Module 2 RefrigerationDocument37 pagesModule 2 Refrigerationsindhujaj6No ratings yet

- Nonconventional Methods of Gas LiquefactionDocument45 pagesNonconventional Methods of Gas LiquefactionImtisal E NoorNo ratings yet

- Emerging Trends in Mechanical Engineering: Course Code - 22652 (AE/PG/PT/ME) Unit 2 - Process EngineeringDocument15 pagesEmerging Trends in Mechanical Engineering: Course Code - 22652 (AE/PG/PT/ME) Unit 2 - Process EngineeringKunal AhiwaleNo ratings yet

- Ijpam - Eu: ISSN: 1311-8080 (Printed Version) ISSN: 1314-3395 (On-Line Version) Url: HTTP://WWW - Ijpam.eu Special IssueDocument8 pagesIjpam - Eu: ISSN: 1311-8080 (Printed Version) ISSN: 1314-3395 (On-Line Version) Url: HTTP://WWW - Ijpam.eu Special Issuewill14No ratings yet

- Waste Heat RecoveryDocument25 pagesWaste Heat RecoveryJoeb DsouzaNo ratings yet

- Part 4Document28 pagesPart 4Mhr IzadNo ratings yet

- Vapor and Combined Power Cycles: Mehmet KanogluDocument22 pagesVapor and Combined Power Cycles: Mehmet Kanogluichig0_89No ratings yet

- Mechanical Heat PumpDocument8 pagesMechanical Heat PumpClara SariNo ratings yet

- Heating CrudeDocument2 pagesHeating Crudefawmer61No ratings yet

- Industrial Waste Heat Recovery: Alfred PiggottDocument9 pagesIndustrial Waste Heat Recovery: Alfred PiggottNandha KumarNo ratings yet

- Simple Thermal Power PlantDocument25 pagesSimple Thermal Power Plantdanielroldan100% (1)

- 2012 - Thermodynamic Evaluation of Heat Recovery Through A Canopus Heat Exchanger For Vapor Compression Refrigeration (VCRDocument7 pages2012 - Thermodynamic Evaluation of Heat Recovery Through A Canopus Heat Exchanger For Vapor Compression Refrigeration (VCRBradley JohnsonNo ratings yet

- PGD 161018125619 PDFDocument47 pagesPGD 161018125619 PDFveerchetan007No ratings yet

- 24VDC For DiplomaDocument62 pages24VDC For DiplomaSaikrishna ChalamalaNo ratings yet

- Heat RecoveryDocument28 pagesHeat RecoveryalbertusngNo ratings yet

- WSHP - Sizing GuideDocument5 pagesWSHP - Sizing GuideMinh TranNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Tecumseh Description1Document7 pagesTecumseh Description1Wiraindo AirconNo ratings yet

- 5090b-Excavator Hydraulic SystemDocument2 pages5090b-Excavator Hydraulic SystemAlex Franklin Camaña JiménezNo ratings yet

- Hydraulic SystemDocument7 pagesHydraulic SystemHamza Munir100% (1)

- Geothermal EnergyDocument36 pagesGeothermal EnergyFarrah MadrioNo ratings yet

- Haier Biomedical Catalog - Vaccine Storage Solution1557741169Document15 pagesHaier Biomedical Catalog - Vaccine Storage Solution1557741169Aiman AliNo ratings yet

- Systems & Solutions: Renewable Energy Geothermal PowerDocument5 pagesSystems & Solutions: Renewable Energy Geothermal PowerBRIGHT TECH INDUSTRIALS INDIA PVT LTDNo ratings yet

- Components of Hydroelectric PlantDocument13 pagesComponents of Hydroelectric PlantHarun Rasul100% (1)

- 4 - RenewablePower - ValmetSolutions - Nelson KohDocument20 pages4 - RenewablePower - ValmetSolutions - Nelson KohĐặng Trung AnhNo ratings yet

- 614 - Dump Tube SystemDocument4 pages614 - Dump Tube SystemShivakumarNo ratings yet

- Exam Assessment Level Full Marks Program BCT A Pass Marks Year/Part I/II TimeDocument4 pagesExam Assessment Level Full Marks Program BCT A Pass Marks Year/Part I/II Timeविशाल पुडासैनीNo ratings yet

- Booster Regulator/Air Tank: Vba/VbatDocument24 pagesBooster Regulator/Air Tank: Vba/VbatShahabNo ratings yet

- Lampiran 1 Critical Line List - DDocument5 pagesLampiran 1 Critical Line List - DAfif FadhliNo ratings yet

- F300c-Experimental Impulse TurbineDocument2 pagesF300c-Experimental Impulse TurbineUzair BukhariNo ratings yet

- Gas Technology Institute PresentationDocument14 pagesGas Technology Institute PresentationAris KancilNo ratings yet

- SIB 121009 E90, E70 M57Y Diesel - Diagnosis For DDE FC 4521 or 4530Document2 pagesSIB 121009 E90, E70 M57Y Diesel - Diagnosis For DDE FC 4521 or 4530Manea DaianaNo ratings yet

- Cavins Double Action Tubing PumpDocument2 pagesCavins Double Action Tubing PumpHassan KhalidNo ratings yet

- Air Comp. MCCDocument19 pagesAir Comp. MCCMohammad Reza NajafiNo ratings yet

- Energetic and Exergetic Analysis of Combined Cycle Power Plant: Part-1 Operation and PerformanceDocument18 pagesEnergetic and Exergetic Analysis of Combined Cycle Power Plant: Part-1 Operation and Performanceilya danisyahNo ratings yet

- Unit 1. Fluid and Fluid PropertiesDocument9 pagesUnit 1. Fluid and Fluid PropertiesNirmal PatelNo ratings yet

- Unfired HRSGs For Solar TurbinesDocument2 pagesUnfired HRSGs For Solar Turbineshermit445350% (1)

- Examen Final ACBS CGA Sys AlumnoDocument15 pagesExamen Final ACBS CGA Sys AlumnoDanny_P123No ratings yet

- 4.DOING Waste Oil Distillation Project ReportDocument24 pages4.DOING Waste Oil Distillation Project ReportPranav Tubaji100% (1)

- Chapter 5 - CavitationDocument44 pagesChapter 5 - CavitationSiraj MohammedNo ratings yet

- Heating Coil in The Main Air Handling UnitDocument13 pagesHeating Coil in The Main Air Handling UnitApurv GoyalNo ratings yet

- Name-Pranshy Singha: MoroideDocument5 pagesName-Pranshy Singha: MoroidePranshu SinghalNo ratings yet

- Uip JBB Upp Pjbb1: Lead Pipe and OLV Pipe Issue 5th To: Project Manager Consortium SC - BVI - SSPDocument3 pagesUip JBB Upp Pjbb1: Lead Pipe and OLV Pipe Issue 5th To: Project Manager Consortium SC - BVI - SSPAswindana Ibnu SenaNo ratings yet