Professional Documents

Culture Documents

Aei2883 24.12.2021.

Uploaded by

quality fluconOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aei2883 24.12.2021.

Uploaded by

quality fluconCopyright:

Available Formats

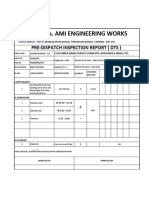

ASCON ENGINEERING INDUSTRIES

PLOT NO. D-97-98, D-87 & E-4,E-5 FOCAL POINT, RAJPURA -1 40 401 (PUNJAB)

(DOC. NO.: AEI/D/QPP-15)

PRE DISPATCH MATERIALS INSPECTION REPORT

BUYER'S NAME M/S. FLUCON COMPONENTS PVT. LTD., MAHARASHTRA.

CONSIGNEE NAME M/S. FLUCON COMPONENTS PVT. LTD., MAHARASHTRA.

PURCHASE ORDER REF. 21060707/DT.23.12.2021.

OUR BILL/CHALLAN REF. 2021-22/2883 DT.24.12.2021.

STANDARD/GTP/DRG.REF RCF Spec. Ref: EDTS-200, REV.NIL, AM-1, CORR.-2.

ITEM DESCRIPTION Copper Crimping Sockets Suitable for 95 mm2 Cable M12, Item No.4

LOT SIZE 900 Nos.

SAMPLE LOT SIZE 80 Nos. As per IS 2500 (Part-1),2000

MATERIAL Copper Tube To BS-1977/IS 191 Part -V, IS 2501

SURFACE FINISH Electro Tinned Plated

Identification Marking Manufacturer's Brand name & Cable size

TESTS CONDUCTED

1- Visual Examination Materials examined and found free from Flaws, Rust, Crevices,

Cracks and any other defect which is harmful for the joints. Overall

Finish found Satisfactory.

2- Dimensions Dimensions are in mm. (Tolerance as per IS 2102 (Part-1)1993 ISO 2768-1)

Specified Tolerance Observed Value Remarks

Nomenclature

Value Value (mm) Min. Max.

Stud Hole Dia E 13.0 mm ±0.2 12.93 13.06 Satisfactory

Barrel Inner Dia A 13.5 mm ±0.2 13.46 13.58 Satisfactory

Barrel Outer Dia C 20.0 mm ±0.2 19.92 20.03 Satisfactory

Palm Width D 27.8 mm ±0.5 27.75 27.84 Satisfactory

Palm Thickness F 6.5 mm ±0.5 6.43 6.58 Satisfactory

Barrel Length B 24.0 mm ±0.5 23.91 24.10 Satisfactory

Stud Center Distance from Barrel H 17.0 mm ±0.5 16.94 17.12 Satisfactory

Stud center Distance from Top G 15.0 mm ±0.5 14.95 15.02 Satisfactory

Total Length J 62.0 mm ±0.8 61.92 62.20 Satisfactory

Inspection Hole 4.0 mm ±0.2 3.98 4.02 Satisfactory

DESTRUCTIVE TESTS Specified Value Observed Value Remarks

3-Electrical Conductivity Min : 97% I.A.C.S. 99.3-99.5%IACS Satisfactory

4-Tin Electroplating Thk. Min : 5 Microns 6-7 Microns Satisfactory

5-Crimping Test No flaring after Crimping OK Satisfactory

6-Flattening Test No signs of Cracks OK Satisfactory

7-Chemical Analysis of Cu. Cu. 99.9% 99.92% RMC Reviewed

8-Determinaton of Pull Out Force 5700 Ns With Stood Satisfactory

9-OVERALL DECISION Accepted/Rejected Lot Accepted.

Inspected By : QA/QC Approved By : QC Manager

ASCON ENGINEERING INDUSTRIES

PLOT NO. D-97-98, D-87 & E-4,E-5 FOCAL POINT, RAJPURA -1 40 401 (PUNJAB)

(DOC. NO.: AEI/D/QPP-15)

PRE DISPATCH MATERIALS INSPECTION REPORT

BUYER'S NAME M/S. FLUCON COMPONENTS PVT. LTD., MAHARASHTRA.

CONSIGNEE NAME M/S. FLUCON COMPONENTS PVT. LTD., MAHARASHTRA.

PURCHASE ORDER REF. 21060707/DT.23.12.2021.

OUR BILL/CHALLAN REF. 2021-22/2883 DT.24.12.2021.

STANDARD/GTP/DRG.REF RCF Spec. Ref: EDTS-200, REV.NIL, AM-1, CORR.-2.

ITEM DESCRIPTION Copper Crimping Sockets Suitable for 70 mm 2 Cable M12, Item No.7

LOT SIZE 1800 Nos.

SAMPLE LOT SIZE 125 Nos. As per IS 2500 (Part-1),2000

MATERIAL Copper Tube To BS-1977/IS 191 Part -V, IS 2501

SURFACE FINISH Electro Tinned Plated

Identification Marking Manufacturer's Brand name & Cable size

TESTS CONDUCTED

1- Visual Examination Materials examined and found free from Flaws, Rust, Crevices,

Cracks and any other defect which is harmful for the joints. Overall

Finish found Satisfactory.

2- Dimensions Dimensions are in mm. (Tolerance as per IS 2102 (Part-1)1993 ISO 2768-1)

Specified Tolerance Observed Value Remarks

Nomenclature

Value Value (mm) Min. Max.

Stud Hole Dia E 13.0 mm ±0.2 12.89 13.11 Satisfactory

Barrel Inner Dia A 12.0 mm ±0.2 11.92 12.03 Satisfactory

Barrel Outer Dia C 17.8 mm ±0.2 17.75 17.84 Satisfactory

Palm Width D 25.0 mm ±0.5 24.95 25.10 Satisfactory

Palm Thickness F 5.8 mm ±0.3 5.74 5.88 Satisfactory

Barrel Length B 24.0 mm ±0.5 23.91 24.10 Satisfactory

Stud Center Distance from Barrel H 15.0 mm ±0.5 14.95 15.11 Satisfactory

Stud center Distance from Top G 13.0 mm ±0.5 12.93 13.06 Satisfactory

Total Length J 58.0 mm ±0.8 57.94 58.20 Satisfactory

Inspection Hole 3.0 mm ±0.2 2.98 3.02 Satisfactory

DESTRUCTIVE TESTS Specified Value Observed Value Remarks

3-Electrical Conductivity Min : 97% I.A.C.S. 99.3-99.5%IACS Satisfactory

4-Tin Electroplating Thk. Min : 5 Microns 6-7 Microns Satisfactory

5-Crimping Test No flaring after Crimping OK Satisfactory

6-Flattening Test No signs of Cracks OK Satisfactory

7-Chemical Analysis of Cu. Cu. 99.9% 99.92% RMC Reviewed

8-Determinaton of Pull Out Force 4200 Ns With Stood Satisfactory

9-OVERALL DECISION Accepted/Rejected Lot Accepted.

Inspected By : QA/QC Approved By : QC Manager

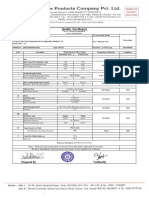

ASCON ENGINEERING INDUSTRIES

PLOT NO. D-97-98, D-87 & E-4,E-5 FOCAL POINT, RAJPURA -1 40 401 (PUNJAB)

(DOC. NO.: AEI/D/QPP-15)

PRE DISPATCH MATERIALS INSPECTION REPORT

BUYER'S NAME M/S. FLUCON COMPONENTS PVT. LTD., MAHARASHTRA.

PURCHASE ORDER REF. 21060707/DT.23.12.2021.

OUR BILL/CHALLAN REF. 2021-22/2883 DT.24.12.2021.

STANDARD/GTP/DRG.REF As Per Drawing No-LW71245 (Item no-1)

ITEM DESCRIPTION Copper Terminal Reducer Type Suitable for 95 mm 2 Cable12

LOT SIZE 300 Nos.

SAMPLE LOT SIZE 50 Nos. As per IS 2500 (Part-1),2000

MATERIAL Copper Tube To BS-1977/IS 191 Part -V, IS 2501

SURFACE FINISH Electro Tinned Plated

Identification Marking Manufacturer's Brand name & Cable size

TESTS CONDUCTED

1- Visual Examination Materials examined and found free from Flaws, Rust, Crevices,

Cracks and other defect which is harmful for the joints. Overall

Finish found Satisfactory.

2- Dimensions Dimensions are in mm. (Tolerance as per IS 2102)

Specified Tolerance Observed Value Remarks

Nomenclature

Value Value (mm) Min. Max.

Stud Hole Dia E 10.5 mm ±0.5 10.45 10.55 Satisfactory

Barrel Inner Dia A 13.0 mm ±0.5 12.93 13.06 Satisfactory

Barrel Outer Dia C 17.0 mm ±0.5 16.94 17.10 Satisfactory

Palm Width D 17.0 mm ±0.5 16.88 17.09 Satisfactory

Palm Thickness F 6.5 mm ±0.5 6.43 6.58 Satisfactory

Barrel Length B 29.0 mm ±0.5 28.94 29.20 Satisfactory

Total Length J 60.0 mm ±0.8 59.90 60.16 Satisfactory

DESTRUCTIVE TESTS Specified Value Observed Value Remarks

3-Electrical Conductivity Min : 97% I.A.C.S. 97.2-97.5%IACS Satisfactory

4-Tin Electroplating Thk. Min : 6 Microns 6-7 Microns Satisfactory

5-Crimping Test No flaring after Crimping OK Satisfactory

6-Flattening Test No signs of Cracks OK Satisfactory

7-Chemical Analysis of Cu. Cu. 99.9% 99.92% RMC Reviewed

8-OVERALL DECISION Accepted/Rejected Lot Accepted.

Inspected By : QA/QC Approved By : QC Manager

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- TolerancesDocument12 pagesTolerancesmahmoudNo ratings yet

- Nefit Butt Welf FittingsDocument20 pagesNefit Butt Welf FittingsFaiyaz Bin Mazid AhmedNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- M12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Document1 pageM12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Athul T.NNo ratings yet

- P 1717 Quality Certificate Lot 1Document6 pagesP 1717 Quality Certificate Lot 1Adink M AlwiNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- TPE - DOP.008 İSK EN 10255 Performans BeyanıDocument4 pagesTPE - DOP.008 İSK EN 10255 Performans BeyanıMBMNo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- Cold Rolled Steel Sheets SpecificationDocument10 pagesCold Rolled Steel Sheets Specificationsingaravelan narayanasamyNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Visual Inspection HRSG # 02Document2 pagesVisual Inspection HRSG # 02Muhammad RezaNo ratings yet

- Norm Cıvata inspection certificateDocument3 pagesNorm Cıvata inspection certificateömer cılızNo ratings yet

- Yonks Tubing A Inox 3-8Document1 pageYonks Tubing A Inox 3-8Fercomil S.A.SNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- AMBICA 36mm Rod SS316L MTCDocument2 pagesAMBICA 36mm Rod SS316L MTCmetalexinNo ratings yet

- Saudi Pipe System Co. Mold Final Inspection ReportDocument8 pagesSaudi Pipe System Co. Mold Final Inspection ReportNADEEM AHMEDNo ratings yet

- TC For Screws Akil Rfx018201Document2 pagesTC For Screws Akil Rfx018201PAVAN YADAVNo ratings yet

- LAD8N20 Product Data SheetDocument2 pagesLAD8N20 Product Data SheetLin ZawNo ratings yet

- 3x50 RM N2xSEYFGbY (24.09.2020)Document1 page3x50 RM N2xSEYFGbY (24.09.2020)Jamil SharifNo ratings yet

- TEST REPORT FINDINGSDocument1 pageTEST REPORT FINDINGSAbhinav SinghNo ratings yet

- Ashirvad Pipes Pvt. LTD.: Test Report of Upvc Agri Pipes As Per Is 4985:2021Document6 pagesAshirvad Pipes Pvt. LTD.: Test Report of Upvc Agri Pipes As Per Is 4985:2021mohd shiraz100% (1)

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- Conexiones 3 SCH 160Document29 pagesConexiones 3 SCH 160RodolfoNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- Bs en 14399 Parts 1 To 8Document7 pagesBs en 14399 Parts 1 To 8ramonyk_003558100% (1)

- WS09TZ200052Document11 pagesWS09TZ200052sudeepNo ratings yet

- Inspection Report: Cu Flexibles For SWGR and TRF End. (Qty. 36 Nos.)Document4 pagesInspection Report: Cu Flexibles For SWGR and TRF End. (Qty. 36 Nos.)sanjayprakash1979No ratings yet

- CERT Usm GoDocument2 pagesCERT Usm Gotyo wibowoNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- QC 64256-1 Ring Spacer Inspection ReportDocument1 pageQC 64256-1 Ring Spacer Inspection ReportSenthil KumarNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- Tesys D Ladr2Document3 pagesTesys D Ladr2Electrical DistributionNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- 0.8 o.sDocument1 page0.8 o.sSaravana VelNo ratings yet

- GP 11127Document5 pagesGP 11127SHivaprasad APITNo ratings yet

- Specification Aa10109 1440410164 PDFDocument5 pagesSpecification Aa10109 1440410164 PDFParthi NatarajNo ratings yet

- Cylinder Head Group Inspection StandardsDocument9 pagesCylinder Head Group Inspection StandardsAntonius Bith, A.mdNo ratings yet

- F TC TapeDocument1 pageF TC Tapedoddi99No ratings yet

- TeSys D - LADT0Document3 pagesTeSys D - LADT0Syed Mohammad NaveedNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Certified Mill Test Report: S O L D T O S H I P T ODocument1 pageCertified Mill Test Report: S O L D T O S H I P T OMohamed RaafatNo ratings yet

- ÜNTEL cable quality control reportsDocument3 pagesÜNTEL cable quality control reportsomarNo ratings yet

- BREB Post-Landing Inspection Report of Power CablesDocument3 pagesBREB Post-Landing Inspection Report of Power CablesShahriar AhmedNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- Weld Mesh Panel ReportDocument1 pageWeld Mesh Panel ReportMahfooz AlamNo ratings yet

- Investment Castings, Surface Acceptance Standards, Visual ExaminationDocument2 pagesInvestment Castings, Surface Acceptance Standards, Visual ExaminationDarwin DarmawanNo ratings yet

- Tube InspectionDocument6 pagesTube InspectionaamirsaddiqNo ratings yet

- Magnetic Particle Testing ReportDocument1 pageMagnetic Particle Testing Reportaxis inspection solutionsNo ratings yet

- Scope of Work for Piston RepairDocument5 pagesScope of Work for Piston RepairM Ferry AnwarNo ratings yet

- WS09TZ200054Document11 pagesWS09TZ200054sudeepNo ratings yet

- 3x10 RM NYFGbY-FRLS (27.10.2020)Document1 page3x10 RM NYFGbY-FRLS (27.10.2020)Jamil SharifNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- Quarry Dust 2022Document3 pagesQuarry Dust 2022WilliamNo ratings yet

- PP Black Semi Glossy B.No. 7558Document2 pagesPP Black Semi Glossy B.No. 7558Andras StegerNo ratings yet

- Premium Nylon Cable Ties Certified to International StandardsDocument4 pagesPremium Nylon Cable Ties Certified to International Standardsquality fluconNo ratings yet

- Tax Invoice DetailsDocument2 pagesTax Invoice Detailsquality fluconNo ratings yet

- MahadevDocument36 pagesMahadevquality fluconNo ratings yet

- Sameer TandalekarDocument4 pagesSameer Tandalekarquality fluconNo ratings yet

- 95 SQ MMDocument1 page95 SQ MMquality fluconNo ratings yet

- Sixth CommandmentDocument26 pagesSixth CommandmentJewel Anne RentumaNo ratings yet

- Klee N Rite 50100Document24 pagesKlee N Rite 50100Nestor Marquez-DiazNo ratings yet

- Alpha Full CaseDocument5 pagesAlpha Full CaseAnonymous 4IOzjRIB1No ratings yet

- UK-India Coffee Market ReportDocument27 pagesUK-India Coffee Market ReportNikhil MunjalNo ratings yet

- Ureteral Trauma Profile in Soetomo Hospital January 2006 - December 2011Document9 pagesUreteral Trauma Profile in Soetomo Hospital January 2006 - December 2011Nurhafidin RamadhaniNo ratings yet

- SITHPAT006 Student LogbookDocument46 pagesSITHPAT006 Student LogbookÇrox Rmg PunkNo ratings yet

- TDS - Rheofinish 288 FDDocument2 pagesTDS - Rheofinish 288 FDVenkata RaoNo ratings yet

- If You Have Guts Then Dare To Be DIFFERENTDocument20 pagesIf You Have Guts Then Dare To Be DIFFERENTChirag Saiya (PHILOSOPHER) - SPIRITUAL Speaker and Writer100% (1)

- DAPHNE GREASE MP NO.2Document8 pagesDAPHNE GREASE MP NO.2sanusi.pdkmNo ratings yet

- Imagicle Solutions Available On Cisco DcloudDocument4 pagesImagicle Solutions Available On Cisco Dcloudchindi.comNo ratings yet

- Parasitic Draw ChartDocument9 pagesParasitic Draw Chartlionellin83No ratings yet

- CA Prostate by Dr. Musaib MushtaqDocument71 pagesCA Prostate by Dr. Musaib MushtaqDr. Musaib MushtaqNo ratings yet

- Goat anatomy and physiology guideDocument8 pagesGoat anatomy and physiology guideLochi GmNo ratings yet

- Chemical Manual L PDFDocument160 pagesChemical Manual L PDFИгорьNo ratings yet

- Human Papillomavirus (HPV) Test and PAP Smear As Predictors of Outcome in Conservatively Treated Adenocarcinoma in Situ (AIS) of The Uterine CervixDocument7 pagesHuman Papillomavirus (HPV) Test and PAP Smear As Predictors of Outcome in Conservatively Treated Adenocarcinoma in Situ (AIS) of The Uterine CervixodivarNo ratings yet

- 2000-03 Taconic Running Life March 2000Document24 pages2000-03 Taconic Running Life March 2000TaconicArchiveNo ratings yet

- Dycaico Vs SssDocument1 pageDycaico Vs SssGladys Bustria OrlinoNo ratings yet

- Measuring Blood Pressure AccuratelyDocument2 pagesMeasuring Blood Pressure AccuratelyxmantestNo ratings yet

- 05 Building Laws Summary 11-03-21Document27 pages05 Building Laws Summary 11-03-21Lyka Mendoza MojaresNo ratings yet

- Wire Rope Slings Si 2 - 2 EmmDocument2 pagesWire Rope Slings Si 2 - 2 EmmheppyfaebanffNo ratings yet

- The Bone DreamingDocument3 pagesThe Bone DreamingastrozzNo ratings yet

- CFM56 3Document148 pagesCFM56 3manmohan100% (1)

- Axell Wireless Cellular Coverage Solutions BrochureDocument8 pagesAxell Wireless Cellular Coverage Solutions BrochureBikash ShakyaNo ratings yet

- Breast CancerDocument1 pageBreast CancerAdang FirmansyahNo ratings yet

- Manual Instlacion y Servicio Logix Magnum IT and CV ValvesDocument69 pagesManual Instlacion y Servicio Logix Magnum IT and CV ValvesmortifileNo ratings yet

- Chapter 3 - HTT547Document33 pagesChapter 3 - HTT547Faadhil MahruzNo ratings yet

- Instructional Materials: For K12Document17 pagesInstructional Materials: For K12Ram Jacob LevitaNo ratings yet

- PAES 422-1-2012 - Agricultural Structures - Poultry Dressing Slaughtering Plan - Part 1 Small Sca PDFDocument32 pagesPAES 422-1-2012 - Agricultural Structures - Poultry Dressing Slaughtering Plan - Part 1 Small Sca PDFJohn VelacioNo ratings yet

- Enppi EI BrochureDocument51 pagesEnppi EI Brochurenithin spNo ratings yet

- Department of Education Region X-Northern Mindanao 3rd Quarter Exam Cookery SY 2022-2023Document10 pagesDepartment of Education Region X-Northern Mindanao 3rd Quarter Exam Cookery SY 2022-2023SORAHAYDA ENRIQUEZNo ratings yet