Professional Documents

Culture Documents

AI070386451887en 010301

Uploaded by

mohamadhosein mohamadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AI070386451887en 010301

Uploaded by

mohamadhosein mohamadiCopyright:

Available Formats

Data sheet

Oil Nozzles Type H, S-S and B

Application Danfoss Hago oil nozzles are designed for

domestic and commercial high pressure oil

burners operating with light or heavy fuel.

An optimal combustion process is only achieved

by a perfect match between nozzle capacity and

spray pattern, air supply and air distribution and

the design of combustion chamber.

Danfoss Hago offers a very broad range of

nozzles with different capacity and spray

patterns – which means that it is possible to

cover all demands in the market.

Features: Light and heavy fuel.

Identification The nozzles are marked with the following

information (example):

0.65 60°B SOLID 12345

Stamped on the flats

0.65 GPH at 100 psi, (~ 7 bar) 35 SSU (2.7 cSt)

60°B Spray angle and pattern: B Solid, S-S Semi Solid and H Hollow

SOLID SOLID for “Solid” spray pattern. Only on B nozzles

12345 Batch code

Technical Data Material and construction

Nozzle tip and disc AISI 416 grade stainless steel Filters

filters size dependent

Recommended and maximum tightening

torque

Recommended 200-310 in-lbs (25-30 Nm) and Capacity 0.40 – 1.35 GPH

max. 310 in-lbs (35 Nm).for steel and nickel 30-40 μm sintered bronze filter

plated adapters.

Recommended 130-180 in-lbs (15-20 Nm) and

max. 220 in-lbs (25 Nm).for brass adapters.

Capacity from 1.50 GPH

120 mesh stainless steel strainer

© Danfoss | 2018.01 VD.CE.Y3.02 | 1

Data sheet Oil Nozzles Type H, S-S and B

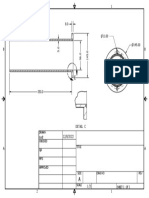

Design and dimensions A: Tip

B: Disc

C: Bronze filter or strainer

D: Locknut

C D A B C D A B

Available spray patterns: B: Solid Cone (black caps)

Even distributed spray pattern – well suited for

H: Hollow Cone (red caps) burners with even distributed air pattern. Well

Hollow spray pattern with higher volume suited for high static pressure flame retention

concentration in the periphery of the spray. burners.

Well suited for low firing rates and burners with

hollow air pattern.

S-S: Semi Solid Cone (blue caps)

Semi solid spray pattern which is the optimal

choice for applications where exact air pattern or

spray pattern requirements can’t be established.

Spray angles Schematic spray patterns

45

60

80

H series S-S series B series 0.50 B series 2.25

to 2.00 USgal/h to 6.00 USgal/h

2 | VD.CE.Y3.02 © Danfoss | 2018.01

Data sheet Oil Nozzles Type H, S-S and B

Design and dimensions

(continuous) Dimensions for reference only.

Program

Reference Hollow Semi Solid Solid

capacity

(Usgal/h) 45° 60° 80° 45° 60° 80° 45° 60° 80°

0.50 - - - - - - - 030G6408 030G6508

0.60 - - - - - - 030G6312 030G6412 030G6512

0.65 030G6014 030G6114 030G6214 030G6614 030G6714 030G6814 030G6314 030G6414 030G6514

0.70 030G6015 030G6115 030G6215 - - - - - -

0.75 030G6016 030G6116 030G6216 030G6616 030G6716 030G6816 030G6316 030G6416 030G6516

0.85 030G6018 030G6118 030G6218 030G6618 030G6718 030G6818 030G6318 030G6418 030G6518

0.90 - - - - - - 030G6319 030G6419 030G6519

1.00 030G6020 030G6120 030G6220 030G6620 030G6720 030G6820 030G6320 030G6420 030G6520

1.10 030G6022 030G6122 030G6222 030G6622 030G6722 030G6822 030G6322 030G6422 030G6522

1.20 - - - 030G6623 030G6723 030G6823 - - -

1.25 030G6024 030G6124 030G6224 030G6624 030G6724 030G6824 030G6324 030G6424 030G6524

1.35 - - - - - - 030G6326 030G6426 030G6526

1.50 030G6028 030G6128 030G6228 030G6628 030G6728 030G6828 030G6328 030G6428 030G6528

1.65 030G6029 030G6129 030G6229 - 030G6729 030G6829 - - -

1.75 030G6030 030G6130 030G6230 030G6630 030G6730 030G6830 030G6330 030G6430 030G6530

2.00 030G6032 030G6132 030G6232 030G6632 030G6732 030G6832 030G6332 030G6432 030G6532

2.25 030G6034 030G6134 030G6234 030G6634 030G6734 030G6834 030G6334 030G6434 030G6534

2.50 030G6036 030G6136 030G6236 030G6636 030G6736 030G6836 030G6336 030G6436 030G6536

2.75 - - - 030G6638 030G6738 030G6838 030G6338 030G6438 030G6538

3.00 030G6040 030G6140 030G6240 030G6640 030G6740 030G6840 030G6340 030G6440 030G6540

3.25 - - - 030G6641 030G6741 030G6841 030G6341 030G6441 030G6541

3.50 030G6042 030G6142 030G6242 030G6642 030G6742 030G6842 030G6342 030G6442 030G6542

3.75 - - 030G6243 - - - 030G6343 030G6443 030G6543

4.00 030G6044 030G6144 030G6244 030G6644 030G6744 030G6844 030G6344 030G6444 030G6544

4.50 030G6046 030G6146 030G6246 030G6646 030G6746 030G6846 030G6346 030G6446 030G6546

5.00 030G6048 030G6148 030G6248 030G6648 030G6748 030G6848 030G6348 030G6448 030G6548

5.50 030G6050 030G6150 030G6250 030G6650 030G6750 030G6850 030G6350 030G6450 030G6550

6.00 030G6052 030G6152 030G6252 030G6652 030G6752 030G6852 030G6352 030G6452 030G6552

6.50 - - - 030G6653 030G6753 - - - -

7.00 - - - 030G6654 030G6754 030G6854 - - -

7.50 - - - 030G6655 030G6755 - - - -

8.00 - - - 030G6656 030G6756 030G6856 - - -

8.50 - - - 030G6657 030G6757 - - - -

9.00 - - - 030G6658 030G6758 030G6858 - - -

10.0 - - - 030G6660 030G6760 030G6860 - - -

11.0 - - - 030G6662 030G6762 030G6862 - - -

12.0 - - - 030G6664 030G6764 030G6864 - - -

© Danfoss | 2018.01 VD.CE.Y3.02 | 3

Data sheet Oil Nozzles Type H, S-S and B

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | VD.CE.Y3.02 © Danfoss | DHS-SRMT/SI | 2018.01

You might also like

- HP Catalog PDFDocument36 pagesHP Catalog PDFnalong hebatNo ratings yet

- Syp 029048Document20 pagesSyp 029048testNo ratings yet

- DFN NozzlesDocument2 pagesDFN NozzlesIraj AmiriNo ratings yet

- Full Cone Series 490Document4 pagesFull Cone Series 490erdi.eksiNo ratings yet

- BB4-Catalogue 2015Document11 pagesBB4-Catalogue 2015nima hasanzadehNo ratings yet

- Manual de BombasDocument10 pagesManual de BombasCalcetinNo ratings yet

- Oil Nozzles Leaflet Hago Steel Nozzles Vbcea322 2012Document2 pagesOil Nozzles Leaflet Hago Steel Nozzles Vbcea322 2012api-221502147No ratings yet

- Large Bore High Pressure Hydraulic Cylinders SeriesDocument18 pagesLarge Bore High Pressure Hydraulic Cylinders SeriesHYDRAULICGURUNo ratings yet

- H2 Family of Chokes: For Pressure and Flow ControlDocument16 pagesH2 Family of Chokes: For Pressure and Flow ControlDEATH ASSASSIN GAMERNo ratings yet

- Senior Dual-Chamber Orifice Fitting - DanielsDocument30 pagesSenior Dual-Chamber Orifice Fitting - DanielsJoseVillanuevaNo ratings yet

- Yu13 EndmilDocument446 pagesYu13 EndmilBrian FloresNo ratings yet

- MODELS-2030 Series: All Stainless Steel Construction Chemical Seal Pressure GaugesDocument4 pagesMODELS-2030 Series: All Stainless Steel Construction Chemical Seal Pressure GaugesAnonymous Dp4DdscGSNo ratings yet

- Hole Making Tools IscarDocument449 pagesHole Making Tools IscarMarcosNo ratings yet

- Claculation of Area Center of Gravity and Sectional Secondary MomentDocument28 pagesClaculation of Area Center of Gravity and Sectional Secondary MomentĐức Nguyễn VănNo ratings yet

- Brochure Isolation Valves Product Overview en en 5253576Document36 pagesBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RNo ratings yet

- Merkel Guide Strip KF: Design NotesDocument2 pagesMerkel Guide Strip KF: Design NotesCAT CYLINDERNo ratings yet

- Molecular Sieve Desiccant Dehydrator For Natural Gas: Bettis Model DD (Standard Service) Bettis Model DD-S (Sour Service)Document4 pagesMolecular Sieve Desiccant Dehydrator For Natural Gas: Bettis Model DD (Standard Service) Bettis Model DD-S (Sour Service)Alina SmochinaNo ratings yet

- TECHNICAL VOGEL L Series - English Only ITT 1 PDFDocument94 pagesTECHNICAL VOGEL L Series - English Only ITT 1 PDFadamNo ratings yet

- AI000086447469en 010101Document2 pagesAI000086447469en 010101mohamadhosein mohamadiNo ratings yet

- High Pressure Hose 18974ENDocument8 pagesHigh Pressure Hose 18974ENFotolag JrNo ratings yet

- DocumentDocument12 pagesDocumentArunprasad MurugesanNo ratings yet

- Dan Sof TG 0122Document30 pagesDan Sof TG 0122Erick Trujillo100% (1)

- H Seri̇si̇ Bi̇lgi̇Document4 pagesH Seri̇si̇ Bi̇lgi̇Jose RoseNo ratings yet

- cat75HYD Us Hollow-Cone DDocument32 pagescat75HYD Us Hollow-Cone DEmanuelNo ratings yet

- Heavy Duty Shock Absorbers HD, HDA SeriesDocument20 pagesHeavy Duty Shock Absorbers HD, HDA SeriesKarimZianiNo ratings yet

- BIFRM-0022-US Act. NeumDocument16 pagesBIFRM-0022-US Act. NeumOlegario PalmaNo ratings yet

- Bicos Spray SprayingDocument40 pagesBicos Spray SprayingAntônio MiguelNo ratings yet

- Jenis Jenis Mata BorDocument92 pagesJenis Jenis Mata BorRendy Adam FarhanNo ratings yet

- Lovex Load DataDocument48 pagesLovex Load DataolexandrNo ratings yet

- Notes For - Process Level GaugesDocument8 pagesNotes For - Process Level GaugesDavid BaughNo ratings yet

- Technical Information ASSET DOC LOC 3996075Document23 pagesTechnical Information ASSET DOC LOC 3996075Alexandre Massahiro KanashiroNo ratings yet

- Re17332 2017-07Document76 pagesRe17332 2017-07ControlNo ratings yet

- 4 D.S. ManómetroDocument2 pages4 D.S. ManómetroMiguel Arocha FuentesNo ratings yet

- Merkel Wiper P 6Document4 pagesMerkel Wiper P 6kocho79No ratings yet

- Blue Rhino SWSI - Centrifugal FansDocument4 pagesBlue Rhino SWSI - Centrifugal FansPhelan RoqueNo ratings yet

- Elementos de HPDocument8 pagesElementos de HPAndres Elias Fernandez PastorNo ratings yet

- 1.00 BookletDocument8 pages1.00 BookletKalpana BansalNo ratings yet

- Cat75HYD Metric Fine-Spray EDocument12 pagesCat75HYD Metric Fine-Spray Edavide scamardellaNo ratings yet

- Technical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Document42 pagesTechnical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Kovacs Zsolt-Istvan100% (1)

- Submersible Catalogue - Cosmos PumpsDocument8 pagesSubmersible Catalogue - Cosmos PumpsraviNo ratings yet

- Butterly Valves A6..HDocument2 pagesButterly Valves A6..HstomakosNo ratings yet

- SK SDW20 Web 201605 ENDocument4 pagesSK SDW20 Web 201605 ENmehdiNo ratings yet

- B747C HP FogJet HP MultiPoint FogJet NozzlesDocument4 pagesB747C HP FogJet HP MultiPoint FogJet NozzlesRidho SprayNo ratings yet

- DODGE Plummer BlocksDocument40 pagesDODGE Plummer Blocksgrupa2904100% (2)

- Coromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaDocument4 pagesCoromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaazharzebNo ratings yet

- Paint Data SheetDocument2 pagesPaint Data SheetdidiNo ratings yet

- Fulljet MD WideDocument2 pagesFulljet MD Widechris110No ratings yet

- Polaris: Hydraulic Gear Pumps and Motors Hydraulic Gear Pumps and MotorsDocument47 pagesPolaris: Hydraulic Gear Pumps and Motors Hydraulic Gear Pumps and MotorsMichel BrassardNo ratings yet

- LHA 25 Double Action Hydraulic Cylinder - For High DemandsDocument20 pagesLHA 25 Double Action Hydraulic Cylinder - For High DemandsMarcel StoianNo ratings yet

- Duza Silentioasa SIEMENSDocument6 pagesDuza Silentioasa SIEMENSIonut DeaconuNo ratings yet

- HR 500Document20 pagesHR 500george000023No ratings yet

- ECP - Paper, Pulp & Process Pumps ENGDocument56 pagesECP - Paper, Pulp & Process Pumps ENGIwan KurniawanNo ratings yet

- Ti Be PDFDocument30 pagesTi Be PDFPascual Ronald PatrickNo ratings yet

- General Hss End Mills Yg1Document60 pagesGeneral Hss End Mills Yg1bayuwiroNo ratings yet

- BPW32 Balanced Pressure Wafer Pattern Steam TrapDocument4 pagesBPW32 Balanced Pressure Wafer Pattern Steam Trapmember1000No ratings yet

- Heat Exchangers Course Baher Part04Document32 pagesHeat Exchangers Course Baher Part04Baher ElsheikhNo ratings yet

- Piston Bumper Seal Option Now Available For Series 2A & 2AN: Sound Level ComparisonDocument2 pagesPiston Bumper Seal Option Now Available For Series 2A & 2AN: Sound Level ComparisonGonzalo AlvarezNo ratings yet

- 36 Petroland PD Serie DKDocument7 pages36 Petroland PD Serie DKBayu RahmansyahNo ratings yet

- Endress-Hauser Proline Promass F 300 8F3B enDocument20 pagesEndress-Hauser Proline Promass F 300 8F3B enNafis TaqiyuddinNo ratings yet

- Part 40Document1 pagePart 40mohamadhosein mohamadiNo ratings yet

- V005t14a005 88 GT 113Document13 pagesV005t14a005 88 GT 113mohamadhosein mohamadiNo ratings yet

- NASA TM X-71638 MemorandumDocument15 pagesNASA TM X-71638 Memorandummohamadhosein mohamadiNo ratings yet

- P RP 0186Document6 pagesP RP 0186mohamadhosein mohamadiNo ratings yet

- TemperatureSensors CAT1667SSiDocument38 pagesTemperatureSensors CAT1667SSiLaurentiu ZgripceaNo ratings yet

- AI279137114292en 010102Document2 pagesAI279137114292en 010102mohamadhosein mohamadiNo ratings yet

- AI000086447469en 010101Document2 pagesAI000086447469en 010101mohamadhosein mohamadiNo ratings yet

- Technical Data HV-P 100 - 60000/9Document2 pagesTechnical Data HV-P 100 - 60000/9mohamadhosein mohamadiNo ratings yet

- Welding Jack Stand: KT No. Capacity (T) Adjustable Height (MM) Min Height (MM) Max Height (MM) N.W (KG) G.W (KG) CuftDocument1 pageWelding Jack Stand: KT No. Capacity (T) Adjustable Height (MM) Min Height (MM) Max Height (MM) N.W (KG) G.W (KG) Cuftmohamadhosein mohamadiNo ratings yet

- Oil Burner GuideDocument44 pagesOil Burner GuideIrshad KhNo ratings yet

- FTT20Document2 pagesFTT20mohamadhosein mohamadiNo ratings yet

- DNVGL ST 0373Document25 pagesDNVGL ST 0373mohamadhosein mohamadiNo ratings yet

- Ds Pe8161 en CoDocument13 pagesDs Pe8161 en Comohamadhosein mohamadiNo ratings yet

- Kstta KSTTHDocument1 pageKstta KSTTHmohamadhosein mohamadiNo ratings yet

- Combination Probes For Stagnation Pressure and Temperature Measurements in Gas Turbine EnginesDocument23 pagesCombination Probes For Stagnation Pressure and Temperature Measurements in Gas Turbine Enginesmohamadhosein mohamadiNo ratings yet

- Vision 2000 en 13Document5 pagesVision 2000 en 13mohamadhosein mohamadiNo ratings yet

- Ac 33 64-1Document4 pagesAc 33 64-1mohamadhosein mohamadiNo ratings yet

- AI279140707296en US0101Document2 pagesAI279140707296en US0101mohamadhosein mohamadiNo ratings yet

- Kkp1000m 407 Test Stand For Fuel Pumps and Components eDocument4 pagesKkp1000m 407 Test Stand For Fuel Pumps and Components emohamadhosein mohamadiNo ratings yet

- d39361 Apu Fuel Control Unit Test StandDocument1 paged39361 Apu Fuel Control Unit Test Standmohamadhosein mohamadiNo ratings yet

- 96 GT 032Document7 pages96 GT 032mohamadhosein mohamadiNo ratings yet

- Study and Optimization of Ramjet Fuel System Control Rule Based On Internal Model ControlDocument5 pagesStudy and Optimization of Ramjet Fuel System Control Rule Based On Internal Model Controlmohamadhosein mohamadiNo ratings yet

- GT2010 22920 - Final With Cover Page v2Document12 pagesGT2010 22920 - Final With Cover Page v2mohamadhosein mohamadiNo ratings yet

- (2012) Evaluation - Modeling - and - Analysis - of - Shipping - Container - Building - Structures PDFDocument10 pages(2012) Evaluation - Modeling - and - Analysis - of - Shipping - Container - Building - Structures PDFSergio OrozcoNo ratings yet

- Mixing and Chemical Reaction in Steady Confined Turbulent FlamesDocument9 pagesMixing and Chemical Reaction in Steady Confined Turbulent Flamesmohamadhosein mohamadiNo ratings yet

- United States Patent: (10) Patent No.: US 8.479,492 B2Document8 pagesUnited States Patent: (10) Patent No.: US 8.479,492 B2mohamadhosein mohamadiNo ratings yet

- Factors Affecting - Altitude Relight Performance of A Double-Annular Ram-Induction CombustorDocument29 pagesFactors Affecting - Altitude Relight Performance of A Double-Annular Ram-Induction Combustormohamadhosein mohamadiNo ratings yet

- S3 Modane: Grands Moyens TechniquesDocument4 pagesS3 Modane: Grands Moyens Techniquesmohamadhosein mohamadiNo ratings yet

- 800 Product Brochure - Rev 022118 PDFDocument4 pages800 Product Brochure - Rev 022118 PDFeliasjosecNo ratings yet

- Tensile PropertiesDocument2 pagesTensile PropertiesSh.nasirpurNo ratings yet

- Recommendations Annexure 2Document13 pagesRecommendations Annexure 2Structform ConsultantNo ratings yet

- Mit 185UD5Document2 pagesMit 185UD5Pakito ChocolateroNo ratings yet

- E7604-1!05!09 Practical Contamination Management enDocument45 pagesE7604-1!05!09 Practical Contamination Management enAlie Bhin Abhu DhabiNo ratings yet

- Manual Masina Spalat Rufe Incarcare Verticala WhirlpoolDocument2 pagesManual Masina Spalat Rufe Incarcare Verticala WhirlpoolReviewuri100% (1)

- TRI SHiELD Brochure FLTR Purple Engineering 1Document6 pagesTRI SHiELD Brochure FLTR Purple Engineering 1FLTR PURPLE E.No ratings yet

- Lab PDFDocument4 pagesLab PDFBehairy AhmedNo ratings yet

- 2021 Korea Make-Up TrendDocument31 pages2021 Korea Make-Up TrendLIANo ratings yet

- 9781464811746Document255 pages9781464811746Tong Yee SiongNo ratings yet

- Load Combination To Euro CodeDocument5 pagesLoad Combination To Euro CodeAbdul Hameed HatemNo ratings yet

- Triple Only Static ElectricityDocument32 pagesTriple Only Static ElectricityMary Ann MaherNo ratings yet

- Muzaffarpur Thermal Power Project (2 X 195 MW) : Sr. Description by by No Vendor BHEL A MechanicalDocument3 pagesMuzaffarpur Thermal Power Project (2 X 195 MW) : Sr. Description by by No Vendor BHEL A MechanicalHimadri SNo ratings yet

- Válvula de Retención - Clase 600 - CAMERONDocument9 pagesVálvula de Retención - Clase 600 - CAMERONiMaJeniDeasNo ratings yet

- Wiring DevicesDocument6 pagesWiring DevicesMohammed Hussain OMNo ratings yet

- Golding IV BootmakingDocument272 pagesGolding IV Bootmakingrhoob2002100% (3)

- Atlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90Document16 pagesAtlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90mahdiNo ratings yet

- Tubingal HwsDocument3 pagesTubingal Hwsasebaei95No ratings yet

- ACT Lab ManualDocument55 pagesACT Lab ManualDusk Slayer100% (1)

- Understanding Motor Controls 3rd Edition Herman Solutions ManualDocument2 pagesUnderstanding Motor Controls 3rd Edition Herman Solutions Manuala471886600No ratings yet

- HLLDocument40 pagesHLLClinton ThomsonNo ratings yet

- Trade: Fitter: Syllabus For The SubjectDocument29 pagesTrade: Fitter: Syllabus For The SubjectPrabhuNo ratings yet

- PCI Chapter 14Document20 pagesPCI Chapter 14Sergio Adolfo ParedesNo ratings yet

- Control Valve SizingDocument21 pagesControl Valve Sizingamarnath982520% (1)

- Chapter 4 Jobbing and BatchDocument39 pagesChapter 4 Jobbing and BatchDavid HồNo ratings yet

- Consolidated - Catalog 1900 P Series PDFDocument54 pagesConsolidated - Catalog 1900 P Series PDFAdnen GuedriaNo ratings yet

- Introduction To Industrial Wastewater Treatment SystemsDocument50 pagesIntroduction To Industrial Wastewater Treatment SystemsKaladorNo ratings yet

- EHC1Document30 pagesEHC1Jagadeesan SaiNo ratings yet

- Manual SwitchgearDocument48 pagesManual SwitchgearVinícius MartinsNo ratings yet