Professional Documents

Culture Documents

Method Statement - GI and PVC Conduits

Method Statement - GI and PVC Conduits

Uploaded by

amenmohdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement - GI and PVC Conduits

Method Statement - GI and PVC Conduits

Uploaded by

amenmohdCopyright:

Available Formats

Installation of GI and PVC Conduits

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 1 of 7

1. Purpose

This method statement is applicable to define the step-by-step procedures and to

implement the correct practices for the Installation of GI and PVC Conduits through the

guidelines contained herein to ensure that the job execution complies with the

requirements of the contract documents and serves the intended function to be satisfactory

and to ensure that the safe working procedures for this operation are detailed and

implemented throughout the execution of the work activities.

2. Objective

The objective of this method of work is to provide and document a safe working procedure

for employees of the company and Consideration has also been given in respect of persons

who may be affected by the work.

3. Scope of Work

This method statement serves to outline the steps and actions that FFTS will adopt to

undertake the Installation of Installation of GI and PVC as set out in the project

specifications and drawings.

1. Responsibility:

1) FFTS will be responsible for the supervision and execution of all of the above works.

2) Project Manager

Review, Approval and Monitoring of Method Statement implementation.

3) Site Engineer:

Responsible for day-to-day project requirements for execution, quality, and safety.

Record and monitor activities, and maintain progress and coordination with the Main

Contractor.

4) HSE Officer:

Implementing and monitoring the site’s HSE aspect as per FFTS requirements, in

coordination with the Main contractor.

4. Procedure:

Documentation and Preliminary site pre-check

1. Make sure that the drawings are approved before commencing the work.

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 2 of 7

2. Any works in confined spaces will be subject to a separate risk assessment and a

permit will be requested by FFTS to the Main Contractor prior to the

commencement of any works.

3. All materials are subjected to Material Inspection Request (MIR) approval before

site usage.

4. All safety work permits (Working at height Permit / Working on floor edge

permit / Shaft permit) must be obtained prior to the commencement of work

and all workers must be safety inducted as per Main Contractor’s HSE plan.

5. Works must be coordinated, Obtain clearance from the Main Contractor Civil

team prior to the commencement of installation at site.

6. Prior to start any works inside shaft permit will be requested by FFTS to the

Main Contractor prior to the commencement of any works to follow the safety

precautions.

7. Ensure proper working platform and safe access prior in entering the working

area must be provided. Ensure that lifeline, hand gloves and safety goggles is

available for workers. (If required) Scaffolds / platform (by Civil) shall be

coordinate and safety tag shall be available prior to its usage.

8. The Electrical Site Engineer confirms that all necessary documentation is in-

place to proceed, and identifies if there are any special requirements needed to

undertake the work; if everything is acceptable to proceed, the Electrical Site

Engineer then issue an instruction to the Construction team to carry out the

work.

9. All workers must wear PPE prior to start the Installation of Wiring Accessories.

Storage and Handling

1. Upon receipt of materials at site, all materials are stored in a safe, covered and

secured manner as per manufacturer’s recommendations.

2. All materials shall be carefully off-loaded at site using the necessary manpower,

appropriate shifting machinery and equipment to ensure that no damage will incur

to the materials.

3. Correct storage is vital for all materials as per manufacturer recommendations.

Reasonable care should be taken at all times and during offloading. Wiring

Accessories should be lowered carefully and not dropped to the ground.

4. Only the required quantity of Wiring Accessories for the specific task will be

transported from FFTS store to the work place. For temporary storage in the field,

where racks are not provided, the ground should be level and free from loose

stones.

5. All Wiring Accessories must be stored as per the manufacturer’s recommendations.

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 3 of 7

Installation Methodology:

Installation of GI and PVC Conduits

The electrical supervisor shall identify the start and endpoints of each circuit by

seeing the approved shop drawings, to lay the GI and PVC conduits.

Routing shall be marked the electrical points on the slab/wall as per the latest

approved shop drawings.

The route of GI and PVC conduits shall be checked to make sure that it is free

from debris and any other services. All cut edges burrs shall be removed, and

touch‐up paint will be applied.

Solvents shall be used for joining couplers while installing GI and PVC conduits.

The size of electrical conduits shall be a minimum of 20mm dia for lighting

circuits and 25mm for other electrical power circuits.

Conduit shall be installed with a maximum of two 90º bends

The minimum internal radius of any bend or elbow fitting in a conduit shall be 2.5

times the diameter of the conduit.

Technicians shall make holes on the wall/ceiling using drilling machines for fixing

Rawal plugs inside these holes. Saddles of appropriate sizes shall be fixed to the

Rawal plugs using screws. Saddles shall be fixed at every one‐meter span.

PVC conduits shall not be laid below water services, crossing vents, and

disturbing any wall/slab openings.

Where a GI and PVC conduit is installed within a wall, floor, or ceiling it must be

at a minimum depth of 50 mm from the surface.

Couplers and circular boxes of suitable sizes shall be used to join the conduits.

Where conduits are connected to GI trunking or Distribution Boards conduits

shall be connected using threaded adaptors.

Conduits shall be run neatly either horizontal or vertical. Overlapping of conduits

shall be avoided as much as possible.

In case of concrete pouring, the installation of PVC conduits shall be inspected by

consultant and approval to be obtained for the same.

At the time of concrete pouring, electricians shall be provided for taking care of

conduits to avoid any damage or dislocation.

Proper labelling shall be done after installation of tray/trucking, indicating the

service which it has been provided for.

The ends and other finished ends of tray/trucking shall be provided with bushes

such that cables/wires do not sustain damage at the time of installation.

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 4 of 7

5. Labour, Plant & Material Requirement Material

In compiling this method statement, it has been assumed that materials to be used

in the defined process have been subjected to an approval process and

subsequently approved by the Client’s nominated representative, as per the

contractual requirements.

- Installation of GI and PVC Conduits

Tools / Equipment

1. Hand Tools

2. Drill Machine

3. Measuring Equipments

4. Hacksaw

5. Pipe wrenches, Spanners etc.

1.0 Supervision Arrangements

1. The team of experienced supervisors, foreman, and technicians under the guidance of

the Site Engineer shall ensure the quality of the work and conforms to the latest

approved drawings.

2. The work shall be carried out under the supervision of a supervisor. The Site Engineer

will monitor the quality/work progress. The Site engineer shall be responsible for the

overall quality and progress of the work.

3. The Site Engineer shall inform QA/QC Engineer, of the readiness of the site. The work

further shall be checked and approved by the QA/QC Engineer.

4. The QA/QC Engineer shall raise all inspections to the Client to carry out a joint

inspection. The works are subject to the Consultant’s approval.

2.0 Health & Safety Requirements

HSE

1. All works are to be commenced by the FFTS HSE plan and the local HSE

regulations.

2. All Method statements and risk assessments are to be

addressed/communicated via briefing before commencing site work.

3. FFTS will comply with all local and UAE environmental procedures as per FFTS

Environmental policy

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 5 of 7

Fire

1. In the event of the occurrence of a fire outbreak during the course of the works, the

deployment of the first aid firefighting equipment shall be such as to be able to

contain and neutralize a minor outbreak. The Foreman/Supervisor shall determine if

the site-wide fire alarm system(s) should be activated in line with the assigned site

procedures.

2. Should it not be possible to extinguish the fire with the available equipment, then the

Foreman/Supervisor shall initiate the procedure for the safe evacuation of the site, as

defined within the Project Emergency Response Plan.

3. It shall be the responsibility of the Foreman/Supervisor to report the incident to the

designated Works Safety Officer. The Project HSE Manager shall compile an Incident

Report and issue the report to their immediate Project / Construction Manager for

onward submission to the Client’s Construction Managers (if applicable).

Accident

1. In the event of an accident the Foreman / Supervisor shall assess the situation and

determine the most appropriate action to take to ensure that the injured party is

safe. If the injury is minor, the Foreman / Supervisor shall assign another operative to

accompany the injured person to the designated site first aid facility.

2. All accidents occurring on the site shall be reported to the designated HSE Officer and

recorded in the Incident Register.

Emergency site evacuation

The evacuation of the site during an emergency shall be dictated by the FFTS project

HSE plan and Project Emergency Response Plan.

Training

1. Full training about mandatory and job-specific PPE will be conducted (hard hat,

gloves, eye protection, harness, and safety shoes) on how to properly use, store and

dispose of.

2. Daily briefings shall be conducted on daily basis and before any execution of work (a

full briefing about the daily task to be communicated with all).

3.0 Environmental Requirements

1. FFTS will comply with all local and international regulations and standards as required

company’s HSE plan.

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 6 of 7

2. All works to be conducted by FFTS Sustainability Plan.

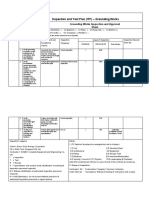

6. Inspection and Approval

1. On satisfactory completion of the installation the relevant internal inspection

will be carried out to ensure correct installation (as per the approved drawing,

specifications & method statement) before offering for client inspection.

2. On satisfactory completion of the internal inspection, a client inspection

request will be raised through Work Inspection Request, and a formal

inspection of the works carried out.

Method Statement-Installation of GI and PVC Conduits

Revision -R0 Page 7 of 7

You might also like

- Testing and Commissioning Split ACDocument2 pagesTesting and Commissioning Split ACNuratiqah SharifahNo ratings yet

- Method Statement DuctingDocument7 pagesMethod Statement DuctingamenmohdNo ratings yet

- Risk Assessment For Installation of GI and PVC ConduitsDocument2 pagesRisk Assessment For Installation of GI and PVC ConduitsamenmohdNo ratings yet

- SCP109 - Risk Assessment For Glass Partition EditedDocument4 pagesSCP109 - Risk Assessment For Glass Partition EditedamenmohdNo ratings yet

- Method Statement and Risk Assessment For Installation of Cable Ladders & Perforated TraysDocument11 pagesMethod Statement and Risk Assessment For Installation of Cable Ladders & Perforated TraysImran Khan100% (1)

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Ms For Facade Light InstallationDocument14 pagesMs For Facade Light InstallationAdnan AbdulNo ratings yet

- Electrical Method of Statement For Installation & Termination of Cables and Wires - Method Statement HQDocument6 pagesElectrical Method of Statement For Installation & Termination of Cables and Wires - Method Statement HQRahul Raj SinghNo ratings yet

- Method Statement For Audio Visual System InstallationDocument8 pagesMethod Statement For Audio Visual System InstallationArshad PcNo ratings yet

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- Toolbox TalkDocument15 pagesToolbox TalkamenmohdNo ratings yet

- BEW - Method Statement For Electrical Conduiting in Concealed WallDocument9 pagesBEW - Method Statement For Electrical Conduiting in Concealed WallArun UdayabhanuNo ratings yet

- Method Statement WDocument10 pagesMethod Statement WAkila SarkunanNo ratings yet

- List of Method Satement (MS)Document7 pagesList of Method Satement (MS)Imho Tep100% (1)

- RDF REMOVAL METHOD STATEMENT - Civil WorksDocument7 pagesRDF REMOVAL METHOD STATEMENT - Civil WorksamenmohdNo ratings yet

- Pre-Commissioning and Commissioning For Fire Hosr Rack and Hose ReelDocument1 pagePre-Commissioning and Commissioning For Fire Hosr Rack and Hose Reelsoe_thumoeNo ratings yet

- Checklist For Wall Panels InstallationDocument2 pagesChecklist For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Table OF: Method Statement FOR Wires AND Cables InstallationDocument235 pagesTable OF: Method Statement FOR Wires AND Cables InstallationMuhammad Jamil Khan100% (1)

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 pageCHECKLIST For Installation of Electrical UPVC DuctskevinNo ratings yet

- MET HangersDocument5 pagesMET Hangersjay mamucayNo ratings yet

- Method Statement Lamps, Switches and Socket Outlets InstallationDocument2 pagesMethod Statement Lamps, Switches and Socket Outlets InstallationVõ Khắc GhiNo ratings yet

- METHOD STATEMENT Installation of HV Switch Gear 11kv PanelsDocument2 pagesMETHOD STATEMENT Installation of HV Switch Gear 11kv Panelsanuraj arackalNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Erection of LV Switchgears (PCC, MCC, Aux PDB'S)Document6 pagesErection of LV Switchgears (PCC, MCC, Aux PDB'S)Sutanu BiswasNo ratings yet

- p021.46 Db54 Mat Mep Mech 022 Ventilation FansDocument95 pagesp021.46 Db54 Mat Mep Mech 022 Ventilation Fansp4p7 projectsNo ratings yet

- Metherd Statement For Wiring & Cable-R0Document11 pagesMetherd Statement For Wiring & Cable-R0Ahmad Saqqa100% (1)

- 014 - G.I Duct, Accessories and FittingsDocument14 pages014 - G.I Duct, Accessories and FittingsJomy JohnyNo ratings yet

- Method Statement - CCTVDocument7 pagesMethod Statement - CCTVamenmohd100% (1)

- Instrument Installation ChecklistDocument1 pageInstrument Installation ChecklistAli AkbarNo ratings yet

- Mos Ups 1Document4 pagesMos Ups 1MohamedAhmedFawzyNo ratings yet

- Method Statement For Installation of DBsDocument11 pagesMethod Statement For Installation of DBstristan guarinoNo ratings yet

- Plexo Catalog PDFDocument20 pagesPlexo Catalog PDFMeylia RodiawatiNo ratings yet

- CHECKLIST For Installation of MICC CableDocument2 pagesCHECKLIST For Installation of MICC CableTHEOPHILUS ATO FLETCHERNo ratings yet

- Electrical Rooms DesignDocument93 pagesElectrical Rooms Designahmad shakeebNo ratings yet

- Method Statement - Installation CCTVDocument1 pageMethod Statement - Installation CCTVMuhammad Syadham100% (1)

- Saudi Aramco Pre-Commissioning Form: Outdoor SubstationsDocument2 pagesSaudi Aramco Pre-Commissioning Form: Outdoor SubstationsHaleem Ur Rashid BangashNo ratings yet

- Inspection and Test Plan (ITP) - Grounding WorksDocument2 pagesInspection and Test Plan (ITP) - Grounding WorksElisco Pher SalmasanNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- Inspection & Test Check ListDocument1 pageInspection & Test Check ListPRAKTISINo ratings yet

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaNo ratings yet

- Work Methodolgy For The Installation of Video-WallDocument17 pagesWork Methodolgy For The Installation of Video-WallDani SalimiNo ratings yet

- Method Statement For Installation of Cable Tray or TrunkingDocument9 pagesMethod Statement For Installation of Cable Tray or TrunkingEmmanuel TamayoNo ratings yet

- Relocation of Device On Concrete SlabDocument1 pageRelocation of Device On Concrete SlabBento BoxNo ratings yet

- MS Boiler & CalorifierDocument14 pagesMS Boiler & CalorifierSanto ENo ratings yet

- Method of Statement For Installation of Wires and Cables PDF FreeDocument6 pagesMethod of Statement For Installation of Wires and Cables PDF Freetristan guarinoNo ratings yet

- Qcs 2010 Section 21 Part 1 General Provisions For Electrical InstallaDocument15 pagesQcs 2010 Section 21 Part 1 General Provisions For Electrical Installabryanpastor106100% (1)

- Method of Statement - Pa SystemDocument15 pagesMethod of Statement - Pa SystemashifNo ratings yet

- Fiber ITPDocument17 pagesFiber ITPDennis DahlNo ratings yet

- PlenaVAS-SW3 00 01 (V0 2) enDocument50 pagesPlenaVAS-SW3 00 01 (V0 2) enpnh mcsaNo ratings yet

- Qcs 2014 - Sec21 p8 - TrunkingDocument7 pagesQcs 2014 - Sec21 p8 - TrunkingchandraNo ratings yet

- Havells Combined Price List Modular SwitchDocument12 pagesHavells Combined Price List Modular SwitchRakesh VermaNo ratings yet

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Document6 pagesAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasNo ratings yet

- Ofc Laying ProcedureDocument6 pagesOfc Laying ProcedureAnonymous DIFDo05GfSNo ratings yet

- Parking Guidance System (PGS)Document23 pagesParking Guidance System (PGS)Pimen AjjahNo ratings yet

- Master Clock SystemDocument4 pagesMaster Clock SystemAli SaifNo ratings yet

- Transformer 1 MosDocument5 pagesTransformer 1 MosMohamedAhmedFawzyNo ratings yet

- Method Statement For Dressing of Steel PoleDocument3 pagesMethod Statement For Dressing of Steel PoleMary Grace LagundinoNo ratings yet

- Method Statement For Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverNo ratings yet

- O&m Manual For Landscapeing LightDocument104 pagesO&m Manual For Landscapeing Lightmukilanarul12No ratings yet

- 240-70413681 POE Rev 3Document72 pages240-70413681 POE Rev 3Thulani Dlamini100% (1)

- 2.field Inspection Formats-Survey ChecklistDocument9 pages2.field Inspection Formats-Survey ChecklistGopal SauNo ratings yet

- Installation of Aluminium Busbar JMSDocument14 pagesInstallation of Aluminium Busbar JMSadrianNo ratings yet

- Inventory Lis1Document7 pagesInventory Lis1amenmohdNo ratings yet

- Hse Report SCP083-02Document1 pageHse Report SCP083-02amenmohdNo ratings yet

- RDF REMOVAL METHOD STATEMENT - Fire FightingDocument7 pagesRDF REMOVAL METHOD STATEMENT - Fire FightingamenmohdNo ratings yet

- HSE REPORT - SCP094 - Salim Jewellery - 21-11-2022Document1 pageHSE REPORT - SCP094 - Salim Jewellery - 21-11-2022amenmohdNo ratings yet