Professional Documents

Culture Documents

7 Eec 9 B

Uploaded by

Achref MmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Eec 9 B

Uploaded by

Achref MmaCopyright:

Available Formats

As

Flexible

as You

Need us

to be

DFS DMP Magnetostrictive

Flex Probe

Visit Website

DOVER FUELING SOLUTIONS

Dispensers & Payment

Co

n

cy

su

ien

me

ffic

rE

xp

eE

eri

Sit

en

ce

Fle

y

vit

et

cti

S olu

ne

n

tio

Co

ns

Retail Systems & Pricing

Practical, Cost-Effective

and Adaptable

Need a flexible, global solution for monitoring

your aboveground storage tanks? Then look no

further than the DFS DMP Flex Probe, a practical,

cost-effective and adaptable product that relays

incredibly precise readings of the fuel and other liquids

inside your tank. This probe is perfectly engineered

to fit more challenging environments, such as tight or

difficult-to-access spaces or tall outdoor tanks. Pair the

DMP Flex Probe with one of our industry-leading tank

gauge consoles for unbeatable wetstock monitoring.

DOVER FUELING SOLUTIONS

Magnetostrictive

Technology

Using magnetostrictive technology, our

probes provide continuous and highly

accurate readings of liquids inside of the

tank. By transmitting a high frequency

electrical impulse that travels at the speed

of sound, the advanced technology within

the probes is able to measure the time

elapsed between the initial sending of the

signal and its return to the float, giving an

unbeatably accurate fuel reading which

is then relayed to the console on site or

directly to the point-of-sale (POS). Available

as both wired and wireless units, you can be

sure that whatever your site configuration,

you are receiving the best service.

Density Float

Using magnetostrictive technology, our

probes provide continuous and highly

accurate readings of liquids inside of the

tank. By transmitting a high frequency

electrical impulse that travels at the speed

of sound, the advanced technology within

the probes is able to measure the time

elapsed between the initial sending of the

signal and its return to the float, giving an

unbeatably accurate fuel reading which

is then relayed to the console on site or

directly to the POS.

AEF Sensor

The Aqueous Ethanol Float (AEF) sensor

from DFS provides early detection

of unstable water levels inside of

ethanol-blended fuel tanks, by indicating

potential phase separation. By measuring

the changes in density, the AEF sensor

provides an early warning of the presence

of water, notifying the retailer to stop

selling fuel whilst investigations are carried

out. Programmable thresholds and alarm

settings also allow corrective actions to

be deployed before phase separation

occurs, and subsequent costly fuel loss.

DFS DMP Magnetostrictive Flex Probe

Standard Technical Specifications

Intrinsically safe

Features Stainless steel enclosure Ø 50 mm IP68 (submersible up to 1.2

m per 24 hours)

In 2 inch riser installation (with sliding connection 3/4” only)

• Magnetostrictive technology 7/8 inch circular connector with standard cable length

• Supports diagnostic and maintenance functions 2 m (Ø 9 mm, hydrocarbon resistant in accordance with ENI

specification)

• Single float monitors both petroleum and diesel

• Remote configuration of operation parameters Power supply: 12 VDC

• Adjustable connection to the tank No. 4 digital inputs

• Probe length 5m - 12m RS485 Output

• Calculation of data relating to: OPW FMS Compatible (1 Wire Interface)

• product level, given in measurements of 0.01mm

• water presence, given in measurements of 0.01mm

• product temperature

• Measuring and resolution accuracy:

• standard measuring accuracy: +/- 0.01% full scale

• standard resolution: +/- 0.01mm

• operating temperature -40 + 60°C: +/- 0.2°C

• temperature resolution: + 0.0625°C

• density accuracy +/- 3kg

Certifications

©2022 Dover Fueling Solutions. All rights reserved. DOVER, the DOVER D Design, DOVER FUELING SOLUTIONS, and other trademarks referenced herein are trademarks of Delaware Capital Formation

Inc., Dover Corporation, Dover Fueling Solutions UK. Ltd., and their affiliated entities, registered or claimed in the United States and various other countries. 22-09-22

You might also like

- 7 Eec 9 BDocument4 pages7 Eec 9 BAchref MmaNo ratings yet

- Chute MasterDocument8 pagesChute Mastermathan_aeNo ratings yet

- Application of Ultrasonic WaveDocument3 pagesApplication of Ultrasonic WaveDeelNo ratings yet

- p38 PDFDocument8 pagesp38 PDFsamandondonNo ratings yet

- Accepted Manuscript: Sensors and Actuators ADocument12 pagesAccepted Manuscript: Sensors and Actuators ASiddharth MankarNo ratings yet

- Ultrasonic Sensor For Liquid-Level Inspection in Bottles: PH CalDocument4 pagesUltrasonic Sensor For Liquid-Level Inspection in Bottles: PH CalAkram Al-muharamiNo ratings yet

- Yao 2001Document10 pagesYao 2001Amin ZoljanahiNo ratings yet

- MPFM Virtual Training June 2021 All Slides-1Document247 pagesMPFM Virtual Training June 2021 All Slides-1hussein.talib.kadumNo ratings yet

- Power Management in High Definition!: EPMS-HD-Reliable Power Starts With Precision TimingDocument6 pagesPower Management in High Definition!: EPMS-HD-Reliable Power Starts With Precision TimingAtsiraz Eoni Inoe ZaristaNo ratings yet

- Telescope: More Data, Delivered FasterDocument3 pagesTelescope: More Data, Delivered FasterPatou PatriceNo ratings yet

- Introduction To Brukers ScanAsyst and PeakForce Tapping Atomic Force Microscopy Technology - AN133Document12 pagesIntroduction To Brukers ScanAsyst and PeakForce Tapping Atomic Force Microscopy Technology - AN133Fabien CazesNo ratings yet

- A Hybrid Analog-Digital Phase-Locked Loop For Frequency Mode Non-Contact Scanning Probe MicrosDocument8 pagesA Hybrid Analog-Digital Phase-Locked Loop For Frequency Mode Non-Contact Scanning Probe Microsblake birminghamNo ratings yet

- Using The FFT As An Arbitrary Function GeneratorDocument5 pagesUsing The FFT As An Arbitrary Function GeneratorJaime Andres Aranguren CardonaNo ratings yet

- Experimental Results Obtained in The Vibrating Intrinsic Reverberation ChamberDocument6 pagesExperimental Results Obtained in The Vibrating Intrinsic Reverberation Chamberjohn BronsonNo ratings yet

- Gear InspectionDocument2 pagesGear InspectiontaghdirimNo ratings yet

- Transient Simulaton of Flow Noise in MufflersDocument8 pagesTransient Simulaton of Flow Noise in MufflersRaimundo OtávioNo ratings yet

- HydroVision Brochure Mobile Flow Profiler AquaProfilerMPro e 2017Document4 pagesHydroVision Brochure Mobile Flow Profiler AquaProfilerMPro e 2017wfenix777No ratings yet

- Downhole Fluid Analysis With Lab-Quality ResultsDocument5 pagesDownhole Fluid Analysis With Lab-Quality Results'Aditz Nento S'No ratings yet

- (English) EMF-300E Series Flowmeter User ManualDocument21 pages(English) EMF-300E Series Flowmeter User ManualMario PazNo ratings yet

- Brochure en Knick PDFDocument8 pagesBrochure en Knick PDFbango7886No ratings yet

- Windows Used or Impact TestingDocument5 pagesWindows Used or Impact TestingAhmed El TayebNo ratings yet

- Measuring Up An Audio Transformer - Norman H. Crowhurst (Audio Engineering, Nov 1952)Document4 pagesMeasuring Up An Audio Transformer - Norman H. Crowhurst (Audio Engineering, Nov 1952)jimmy67music100% (2)

- Subcontract Process PricingDocument1 pageSubcontract Process PricingGlobal QualityNo ratings yet

- Wang 2007Document8 pagesWang 2007jonhNo ratings yet

- Ultramicroscopy: Lenard M. Voortman, Sjoerd Stallinga, Remco H.M. Schoenmakers, Lucas J. Van Vliet, Bernd RiegerDocument8 pagesUltramicroscopy: Lenard M. Voortman, Sjoerd Stallinga, Remco H.M. Schoenmakers, Lucas J. Van Vliet, Bernd RiegerKobi ZadaNo ratings yet

- Acoustic Emission Weld Monitoring of Nuclear ComponentsDocument7 pagesAcoustic Emission Weld Monitoring of Nuclear ComponentsjudarangocaNo ratings yet

- PXS EVO Communication Folder v2Document2 pagesPXS EVO Communication Folder v2MamunNo ratings yet

- 4 100593163mergedDocument5 pages4 100593163mergedVarad KeniNo ratings yet

- SSP 186 The CAN DatabusDocument29 pagesSSP 186 The CAN DatabusЕвгений МорокоNo ratings yet

- Foxboro Flow-Through Conductivity: Boiler Blowdown Analysis and ControlDocument2 pagesFoxboro Flow-Through Conductivity: Boiler Blowdown Analysis and ControlPhaniNo ratings yet

- Wireless InstrumentDocument12 pagesWireless Instrumenta_salehi100% (2)

- A Simplfied Workflow For Accurate Time-To-Depth ConversionDocument5 pagesA Simplfied Workflow For Accurate Time-To-Depth ConversionAlfian AminNo ratings yet

- Encoding by Time Ratio Discrimination - Consumer ElectronicsDocument1 pageEncoding by Time Ratio Discrimination - Consumer ElectronicsalexanderjfernandesNo ratings yet

- STUDIES AND POSSIBLE MITIGATION OF ELECTRON CLOUD EFFECTS IN FCC-eeDocument5 pagesSTUDIES AND POSSIBLE MITIGATION OF ELECTRON CLOUD EFFECTS IN FCC-eeFatihNo ratings yet

- Signals 2000 ExamDocument2 pagesSignals 2000 ExamYousef AkkadNo ratings yet

- Long-Term Reliability of Fiber-Optic Current SensorsDocument10 pagesLong-Term Reliability of Fiber-Optic Current SensorsL oNo ratings yet

- Refrigerated Tank TestingDocument2 pagesRefrigerated Tank TestingAnonymous 1XHScfCINo ratings yet

- Chapter 11Document5 pagesChapter 11selasenuapahNo ratings yet

- HEPA Filter TestingDocument2 pagesHEPA Filter TestingTomas KhunNo ratings yet

- Car Plate Recognition by Neural Networks and Image Processing Using Integration of WaveletsDocument5 pagesCar Plate Recognition by Neural Networks and Image Processing Using Integration of Waveletsjamal fathiNo ratings yet

- Prof Paul - The Basics of Multicolor Flow CytometryDocument70 pagesProf Paul - The Basics of Multicolor Flow CytometryVIANA ROJANI AL AWWALIYAHNo ratings yet

- Gearbox Damage Diagnosis Using Wavelet Transform TechniqueDocument8 pagesGearbox Damage Diagnosis Using Wavelet Transform TechniqueDavid TorresNo ratings yet

- Adobe Scan Jul 07, 2021Document23 pagesAdobe Scan Jul 07, 2021ChristianNo ratings yet

- Decagon EC-5 Moisture: Easy InstallationDocument5 pagesDecagon EC-5 Moisture: Easy InstallationJohanna Sofia Maldonado VillamizarNo ratings yet

- How Develop - Validate MethodsDocument554 pagesHow Develop - Validate MethodsAdriana CiroNo ratings yet

- ESRT: Event-To-Sink Reliable Transport in Wireless Sensor NetworksDocument12 pagesESRT: Event-To-Sink Reliable Transport in Wireless Sensor NetworksNicole SalasNo ratings yet

- Fabry PerotDocument11 pagesFabry PerotG. P HrishikeshNo ratings yet

- Digital Audio Recording Analysis The Electric Network Frequency CriterionDocument4 pagesDigital Audio Recording Analysis The Electric Network Frequency CriterionELIAS FERRREIRA DE MORAESNo ratings yet

- Characterization of GaAs-AlGaAs Structures Using Scanning PhotoluminescenceDocument7 pagesCharacterization of GaAs-AlGaAs Structures Using Scanning PhotoluminescencetlmorettiNo ratings yet

- Mass Transfer and PDFDocument4 pagesMass Transfer and PDFJhon GarciaNo ratings yet

- I P Based Smoke Detecti On: Network Moni Tori NGDocument3 pagesI P Based Smoke Detecti On: Network Moni Tori NGSahibzada NizamuddinNo ratings yet

- 020501C Communicating With Daniel Ultrasonic Gas Flowmeter Model 3400 SeniorSonic PDFDocument18 pages020501C Communicating With Daniel Ultrasonic Gas Flowmeter Model 3400 SeniorSonic PDFSofyan HadiNo ratings yet

- Evaluation Method For Arc Fault Detection Algorithms PDFDocument6 pagesEvaluation Method For Arc Fault Detection Algorithms PDFandrea santNo ratings yet

- Save Decoder: Part 1: Operation and Technical BackgroundDocument6 pagesSave Decoder: Part 1: Operation and Technical BackgroundAg CristianNo ratings yet

- Spectrum Analyzer PDFDocument18 pagesSpectrum Analyzer PDFAgus SantosaNo ratings yet

- Encoder and Decoder Optimization For Source-Channel Prediction in Error Resilient Video TransmissionDocument4 pagesEncoder and Decoder Optimization For Source-Channel Prediction in Error Resilient Video TransmissionArvind SinghNo ratings yet

- Asset 1216Document12 pagesAsset 1216Soma GhoshNo ratings yet

- Absolute Virtual Instrument TCHDocument6 pagesAbsolute Virtual Instrument TCHNAdreaNo ratings yet

- The Beta Equilibrium, Stability, and Transport Codes: Applications of the Design of StellaratorsFrom EverandThe Beta Equilibrium, Stability, and Transport Codes: Applications of the Design of StellaratorsFrances BauerNo ratings yet

- CueTrans IVMSDocument4 pagesCueTrans IVMSAchref MmaNo ratings yet

- Telematics BrochureDocument4 pagesTelematics BrochureAchref MmaNo ratings yet

- PetroDocument13 pagesPetroAchref MmaNo ratings yet

- Dfs I Fusion v3 I Sep '22Document8 pagesDfs I Fusion v3 I Sep '22Achref MmaNo ratings yet

- TQC ConfDocument43 pagesTQC ConfAchref MmaNo ratings yet

- Drug StudyDocument4 pagesDrug Studysnowyfingers100% (1)

- SC4622 (CX) G3-399-04 - Ship Structural Access ManualDocument40 pagesSC4622 (CX) G3-399-04 - Ship Structural Access ManualBen TanNo ratings yet

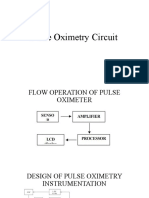

- Pulse Oximetry CircuitDocument19 pagesPulse Oximetry Circuitنواف الجهنيNo ratings yet

- CGG Book 1Document34 pagesCGG Book 1api-245318709No ratings yet

- The Theory of Motivation in Dog Training: By: Ed FrawleyDocument30 pagesThe Theory of Motivation in Dog Training: By: Ed Frawleyrodrigue angbohNo ratings yet

- Paramagnetic Article PDFDocument5 pagesParamagnetic Article PDFJonathan SinclairNo ratings yet

- Monthly Hse Report Nhai Org inDocument12 pagesMonthly Hse Report Nhai Org inPhilip S. GongarNo ratings yet

- Tokyo Fact SheetDocument17 pagesTokyo Fact Sheethoangnguyen2401No ratings yet

- Blood Anatomy and Physiology ReviewDocument20 pagesBlood Anatomy and Physiology ReviewStacey CamilleNo ratings yet

- Bradycardia AlgorithmDocument1 pageBradycardia AlgorithmGideon BahuleNo ratings yet

- Geostats Pty LTD: Base Metal AnalysesDocument1 pageGeostats Pty LTD: Base Metal AnalysesJhony Enrique Morales LauraNo ratings yet

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- TNEB Thermal Power PlantDocument107 pagesTNEB Thermal Power Plantvicky_hyd_130% (1)

- Brief Psychological Interventions For Borderline Personality Disorder. A Systematic Review and Meta-Analysis of Randomised Controlled TrialsDocument9 pagesBrief Psychological Interventions For Borderline Personality Disorder. A Systematic Review and Meta-Analysis of Randomised Controlled TrialsFELIPE ROJAS TRAVERSONo ratings yet

- War RoomDocument88 pagesWar RoomDada Sasa100% (1)

- TruEarth Case SolutionDocument6 pagesTruEarth Case SolutionUtkristSrivastavaNo ratings yet

- Disease PreventionDocument14 pagesDisease PreventionJoan InsonNo ratings yet

- Assignment 1 Front SheetDocument9 pagesAssignment 1 Front SheetBách PhạmNo ratings yet

- Switchyard Equipments, Switching Schmes & LayoutsDocument66 pagesSwitchyard Equipments, Switching Schmes & LayoutsPraveen Kumar88% (17)

- Anti Vawc PrimerDocument6 pagesAnti Vawc PrimerCiddy Montemayor100% (1)

- MCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersDocument30 pagesMCQ Questions For Class 10 Science Periodic Classification of Elements With AnswersAymen WaelNo ratings yet

- Life Everlasting 2021001Document11 pagesLife Everlasting 2021001realangelinemylee2020721001No ratings yet

- BS Pharmacy - ProspectusDocument9 pagesBS Pharmacy - ProspectusDomz BucadNo ratings yet

- BMP (Class 14 - Class-17) WeldingDocument24 pagesBMP (Class 14 - Class-17) WeldingAsesh PramanikNo ratings yet

- Sugarcane JuiceDocument21 pagesSugarcane JuiceOk HqNo ratings yet

- ASTM C-1116 - 03 - Standard Specification For Fiber-Reinforced Concrete and ShotcreteDocument8 pagesASTM C-1116 - 03 - Standard Specification For Fiber-Reinforced Concrete and ShotcretemordeauxNo ratings yet

- Saving AccountDocument9 pagesSaving AccountpalkhinNo ratings yet

- 2017-12-27 Final Alcohol Task Force ReportDocument288 pages2017-12-27 Final Alcohol Task Force ReportShira SchoenbergNo ratings yet

- The Zombie in The Brain and The Woman Who Died LaughingDocument40 pagesThe Zombie in The Brain and The Woman Who Died Laughingcory_ruda100% (1)

- Affidavit Format FOR ART LEVEL 1 CLINIC RegistrationDocument2 pagesAffidavit Format FOR ART LEVEL 1 CLINIC Registrationward fiveNo ratings yet