Professional Documents

Culture Documents

Gears EN

Uploaded by

Jesús MarínOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gears EN

Uploaded by

Jesús MarínCopyright:

Available Formats

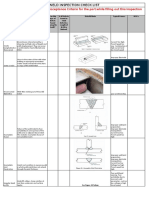

GEAR FAILURE MODES

Tanslated from Edgar Espero Mora y Juan Carlos Martinez Romero, Universidad Nacional de Colombia, September 2011

DUCTIL FRACTURE PARTIAL OR TOTAL FRACTURE OF THE TOOTH FATIGUE

Presence of shear of the tooth FRAGILE FRACTURE Progressive fracture that spreads

accompanied by a large plastic Fracture of granular aspect brilliant Elliptical fatigue striations during the work of the gear. Its

deformation. and without apparent plastic surface is smooth and normally has

deformation. concentric elliptical marks at the

SOME CAUSES origin.

- Overload due to high torque SOME CAUSES

- Overload due to high torque. SOME CAUSES

Hardness of the surface layer and / or

low gear core. Hardness of the hardened layer and / - Continuous operation torque higher

- Low thickness of the hardened or high toothing. than recommended.

layer. - High thickness of the hardened Hardness at heart and / or layer with

- Absence of hardened layer. layer. little hardening and / or insufficient

Origin

thickness.

WEAR

GEOMETRIC DEFORMATION OF THE TOOTH CORROSION

WEAR

ABRASIVE WEAR ADHESIVE WEAR CORROSION

When the tooth surface of a gear is Deterioration of the surface by

When the metal is transferred between

machined or polished in service. chemical action, or pitting and / or

two gears, because they come in direct

deposits on the teeth.

contact because the lubricant layer

SOME CAUSES breaks. SOME CAUSES

- Lubricant with particles. SOME CAUSES - Contamination of the lubricant with

- Low viscosity or high torque. chemicals or water.

- Deficiency of EP * additives. - Absence or deficiency of

- Low speed. Hardness in hardened layer.

Hardness in hardened layer. The attack can be generalized anticorrosive additive.

- High speed or temperature. by concentration gradient or - Mix the oil marks.

- High hardness difference between *EP : Additifs de pressions extrêmes - Low viscosity or high torque. slit; with uniform or puncture - Use a lubricant that is not suitable

the coupled gears. contenus dans certains lubrifiants

- Failure of the lubrication system. mechanism. for bronze gears.

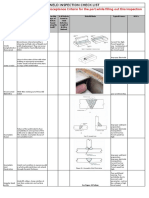

SUPERFICIAL FATIGUE PLASTIC DEFORMATION IN THE ROOT AREA PLASTIC DEFORMATION IN THE TOP AREA

PITTING CREASE NOTCH

This is a localized loss of material, It has the form of waves or ladders Due to a foreign body that is caught

usually in the form of small cavities. perpendicular to the sliding direction. in the mating of teeth and destroys

its profile during operation.

SOME CAUSES SOME CAUSES

- Low hardness in the hardened layer. - Low viscosity of the lubricant. SOME CAUSES

- Low viscosity of the lubricant. - Continuous operation torque higher - Presence of foreign elements

- Continuous operation torque higher than recommended. between the gears.

than recommended. - Absence or deficiency of EP * - Consequence of tooth fracture or

* EP: Extreme pressure additives

- Absence or deficiency of EP * * EP: Extreme pressure additives additive in the lubricant. macro-pitting.

contained in some lubricants

additive in the lubricant. contained in some lubricants

DEVELOPMENT OF SILLONS FLATTENING, SHARPENING AND RETRACTION

MACRO-PITTING OR UNLOADING Deformation of the teeth resulting in

Serious pitting, in which large The grooves follow the direction of triangular shapes and / or lateral flow

pieces of material come off the sliding on the surface of the tooth. generating chips.

surface. SOME CAUSES SOME CAUSES

SOME CAUSES

- Low viscosity of the lubricant. - Low viscosity and / or speed.

Hardness at heart and / or low - Continuous operation torque higher Hardness at heart and / or layer with

hardness layer and / or insufficient than recommended. little hardening and / or insufficient

thickness thereof. - Low speed. thickness.

- The same things as pitting but * EP: Extreme pressure additives - Absence or deficiency of EP * additive in - Continuous operation torque higher

more serious. contained in some lubricants the lubricant. than recommended.

CRACKING RISK FACTORS

OVERHEATING

CRACKS FACING TEETH CRACKS IN THE CENTER OR ON THE EDGES The affected teeth or area have a

Initial phase of partial tooth loss due The cracks start at the foot of the range of colors. Yellow (200 ° C), Blue

to fatigue. tooth and go to the center of the (300 ° C) and Dark Brown DD (400 ° C)

tooth. Usuallly formed by fatigue. approx***.

SOME CAUSES

SOME CAUSES

- Inadequate surface condition of the SOME CAUSES

teeth. - Leads quickly to adhesive wear.

- Cracks can start from macro-pitting. - Inadequate design due to the - The lubricant is degraded and the

*** The maximum operating

thinness of the border. temperatures of the lubricants other failure mechanisms described

See also the causes of total or partial tooth

breakage due to fatigue. vary between 85 ° C and 120 ° C in this guide are accelerated.

CRACKS IN THE ROOT AREA CRACKS IN THE DISCONTINUITIES PROBLEMS IN RECONSTRUCTION

Because of the dimensional accuracy,

Initial stage of total or partial tooth Fatigue cracks are normally formed in the

surface treatment, hardness and chemical

crack due to ductile, fragile or fatigue lubrication holes, shim housings, grooves,

composition of the steels used in the gears,

fracture. lightening holes or other concentrators. it is not advisable to repair them by

welding.

SOME CAUSES SOME CAUSES

SOME CONSEQUENCES

See also the causes of total or partial - Holes, wedges, grooves, etc., poorly sized - Dimensional differences.

tooth breakage. - High overload or continuous operation - Hardness less than required.

torque higher than recommended. - Accelerates the failure mechanisms

described in this guide.

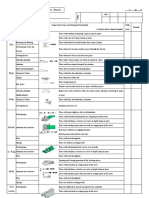

IRREGULAR GEARS RISK FACTORS GENERAL CONSIDERATIONS

- In the case of gears, choose the material, the thickness of the hardened layer, the

STRESS CONCENTRATION INTERFERENCE hardness, the dimensions, the tolerances and the finishes of the toothing, as

specified by the specialized standards such as ISO.

The gear shows signs that the In the root arae, there is

- When replacing gears, it is best to do it in pairs.

entire side of the tooth is not abnormal wear generated during

- Misalignment, tightness or excessive play between the gears will accelerate the

working evenly. operation.

appearance of the failure mechanisms described in this guide.

CAUSES: Reduced number of - Use the appropriate viscosity, additive group and type of lubricant in each case

teeth, misalignment, high radial according to the equipment manufacturer's recommendations.

CAUSES: Misalignment of shaft pressure between the gears. - The described failure mechanisms result in vibration, noise and heat which, if

In this case the stress deflection, deformation due to detected in time, can prevent catastrophic property damage or injury to the

concentration will promote heat treatment, improper CONSEQUENCES: Accelerates the operator.

macro-pitting. machining or assembly, etc. failure mechanisms described in - Sensitize operators, drivers and users in general to the importance of avoiding

CONSEQUENCES: Accelerates this guide. overloading the equipment under their load by torque and / or speed and / or

the failure mechanisms impacts.

described in this guide. - The common causes of the failure modes described here are only a general guide,

since each case of failure must be analyzed in a particular way to find other possible

causes.

- Under appropriate lubrication and loading conditions, that is, when proper

maintenance and operating procedures are followed, the service life of the gears is

conditioned by surface fatigue.

When oils of different brands are mixed, corrosive compounds can be generated by

reaction between incompatible additives.

You might also like

- PUB BU P4 13485 en ISO Classification of Bearing Damages PosterDocument1 pagePUB BU P4 13485 en ISO Classification of Bearing Damages PosterAlvaro Munoz100% (1)

- Sr. No. Item Effects Causes Functions / Requirements Failure ModeDocument6 pagesSr. No. Item Effects Causes Functions / Requirements Failure ModeAtul DahiyaNo ratings yet

- Hardfacing Overview MeltolitDocument1 pageHardfacing Overview MeltolitmercyNo ratings yet

- Cables ENDocument1 pageCables ENJesús MarínNo ratings yet

- Dove 1999Document12 pagesDove 1999faizan iqbalNo ratings yet

- Major Causes of Cracks Classification of Cracks: UNIT II: Cracks in BuildingsDocument6 pagesMajor Causes of Cracks Classification of Cracks: UNIT II: Cracks in BuildingsPriyankaNo ratings yet

- Weld Inspection ChecklistDocument9 pagesWeld Inspection ChecklistRavinesh SinghNo ratings yet

- Check List Inspección de SoldaduraDocument3 pagesCheck List Inspección de SoldaduraNestor De Jesus Pico TorresNo ratings yet

- Weld Inspection Check List: ChecklistDocument3 pagesWeld Inspection Check List: ChecklistMaheshkumar ManeNo ratings yet

- Weld Inspection Check ListDocument3 pagesWeld Inspection Check ListBGRLNo ratings yet

- STRUCTURAL RECTIFICATION GUIDELINES (For Cracks)Document3 pagesSTRUCTURAL RECTIFICATION GUIDELINES (For Cracks)vernileo pambidNo ratings yet

- Mason Industries, Inc.: ND MountsDocument2 pagesMason Industries, Inc.: ND MountsErwin MaldoNo ratings yet

- Burnt-On SandDocument2 pagesBurnt-On SandJOHNSONNo ratings yet

- 03 Aggregate 091312 (Compatibility Mode)Document35 pages03 Aggregate 091312 (Compatibility Mode)Netzoo FlixNo ratings yet

- Brosur Tensar Ground Stabilisation With Geogrid BiaxialDocument5 pagesBrosur Tensar Ground Stabilisation With Geogrid BiaxialIsparmoNo ratings yet

- C ASingDocument3 pagesC ASingGabriela MotaNo ratings yet

- Inspection Fiber RopeDocument1 pageInspection Fiber RopeRusdi BaccoNo ratings yet

- Weld DefectsDocument10 pagesWeld DefectsMUHAMMAD AFIQ IQWAN KAMARUL BADRINNo ratings yet

- Erosion, Erosion Corrosion, Flow Assisted Corrosion, : Differences and ConvergencesDocument55 pagesErosion, Erosion Corrosion, Flow Assisted Corrosion, : Differences and ConvergencesDede Si Engghe SurenggheNo ratings yet

- Reparir WorksDocument21 pagesReparir WorksGanesh NichalNo ratings yet

- Foreign Object Damage Uneven Wear Normal Wear: Radial and Bias TiresDocument1 pageForeign Object Damage Uneven Wear Normal Wear: Radial and Bias Tireshpulido33_390009144100% (1)

- Importance of Induction Hardening Case Depth PDFDocument5 pagesImportance of Induction Hardening Case Depth PDFKundan Kumar MishraNo ratings yet

- Types of CracksDocument14 pagesTypes of Cracksasl halNo ratings yet

- 4 - Afl WQT RecordDocument54 pages4 - Afl WQT RecordBilalNo ratings yet

- Pages From WorkPlans - Year2-Revised-Dec 08 - FHWA - DTFH61-07-H-00009-5 PDFDocument1 pagePages From WorkPlans - Year2-Revised-Dec 08 - FHWA - DTFH61-07-H-00009-5 PDFMEHDI FARROKHINo ratings yet

- Waste DumpsDocument122 pagesWaste DumpsAngNo ratings yet

- Introduction To Surface EngineeringDocument26 pagesIntroduction To Surface Engineeringdu.maximeNo ratings yet

- 16 ScabbingDocument4 pages16 Scabbingvivek13120% (1)

- Activity 5TECHDocument2 pagesActivity 5TECHMoises AtencioNo ratings yet

- Intrinsic and Extrinsic Properties of A RockDocument1 pageIntrinsic and Extrinsic Properties of A Rockanon00No ratings yet

- Deformation and Mechanical BehaviourDocument20 pagesDeformation and Mechanical Behaviourعبدالله المصريNo ratings yet

- Structural Geology: Joints, Folds, and FaultsDocument5 pagesStructural Geology: Joints, Folds, and FaultsMukhammad Nur SulaimanNo ratings yet

- 8 Gear-Damage PDFDocument1 page8 Gear-Damage PDFAditya PrajasNo ratings yet

- Common Defects On Concrete Deck SlabDocument3 pagesCommon Defects On Concrete Deck SlabliezelNo ratings yet

- Folds: Kinematics & MechanicsDocument5 pagesFolds: Kinematics & MechanicsRizwan UllahNo ratings yet

- Cryst: BoundaryDocument10 pagesCryst: Boundarysyed MahdiNo ratings yet

- Types of Avalanche Problems - Handout - 20180830Document10 pagesTypes of Avalanche Problems - Handout - 20180830Raveen SinghNo ratings yet

- Sand Control GuideDocument1 pageSand Control GuidesaeednorouziNo ratings yet

- AFA Overview WearDocument7 pagesAFA Overview WearMohamed HamdallahNo ratings yet

- CN-DT-003 - ENG - RC Walls vs. Terramesh System - Rev. 0 PDFDocument2 pagesCN-DT-003 - ENG - RC Walls vs. Terramesh System - Rev. 0 PDFszemianNo ratings yet

- Sheet Metal WorkingDocument5 pagesSheet Metal WorkingVikas KunduNo ratings yet

- Irc.82 2015Document2 pagesIrc.82 2015K&J Projects Pvt. Ltd. Pvt. Ltd.No ratings yet

- Advanced Scratch Testing For Evaluation of Coatings Slides PDFDocument36 pagesAdvanced Scratch Testing For Evaluation of Coatings Slides PDFPlínio Furtat100% (1)

- Lubrication and Oil Analysis 1698237450Document114 pagesLubrication and Oil Analysis 1698237450mariustresor997No ratings yet

- X-Ray Diffraction Provides Answers To Bearing Failures 1997 E4 enDocument7 pagesX-Ray Diffraction Provides Answers To Bearing Failures 1997 E4 enangel017No ratings yet

- Plain Bearing FailuresDocument7 pagesPlain Bearing FailuressourajpatelNo ratings yet

- Girth Gear Wear PDFDocument6 pagesGirth Gear Wear PDFRajib DuttaNo ratings yet

- Engine Bearing Failure Analysis GuideDocument1 pageEngine Bearing Failure Analysis GuideMahmoud AbdellatifNo ratings yet

- King Engine BearingsDocument1 pageKing Engine BearingsDanny BenderNo ratings yet

- Deformation and Mechanical BehaviourDocument15 pagesDeformation and Mechanical BehaviourSantanu Kumar SahooNo ratings yet

- Name: Term Unconfined Compressive Strength (MN / M) Field TestDocument1 pageName: Term Unconfined Compressive Strength (MN / M) Field TestRisal ZulfikarNo ratings yet

- 4 - Vibro Replacement & Stone ColumnsDocument2 pages4 - Vibro Replacement & Stone ColumnsAmw Mohamed AmwNo ratings yet

- Soporte AntivibratorioDocument2 pagesSoporte AntivibratorioGerman GinesNo ratings yet

- Types of Cracks in Reinforced ConcreteDocument5 pagesTypes of Cracks in Reinforced ConcretewidiaretnoNo ratings yet

- Safety Belts and Harnesses Inspection SheetDocument3 pagesSafety Belts and Harnesses Inspection SheetAdinda SekarNo ratings yet

- 02D PDFDocument28 pages02D PDFRoberta S.No ratings yet

- Module 1: Shear Strength of Soil: Engr. Vuangh Erick B. Barrantes, MSCDocument34 pagesModule 1: Shear Strength of Soil: Engr. Vuangh Erick B. Barrantes, MSCKenneth Bryan FontanillasNo ratings yet

- Bc8 Gear Box Recon. ReportDocument6 pagesBc8 Gear Box Recon. ReportRahmat Wahyu PratamaNo ratings yet

- Au - TB Xfe BrochureDocument2 pagesAu - TB Xfe Brochurekazem qareNo ratings yet

- Safelisting in Office 365Document5 pagesSafelisting in Office 365Brett ThomasNo ratings yet

- 6 Best Chainsaw Under 300: A Complete Buying Guide: What We LikeDocument5 pages6 Best Chainsaw Under 300: A Complete Buying Guide: What We LikeFahim WatsonNo ratings yet

- MaekawaDocument2 pagesMaekawabhaskar_chintakindiNo ratings yet

- Management From RamayanaDocument14 pagesManagement From Ramayanasaaket batchuNo ratings yet

- Classification by Depth Distribution of Phytoplankton and ZooplanktonDocument31 pagesClassification by Depth Distribution of Phytoplankton and ZooplanktonKeanu Denzel BolitoNo ratings yet

- Step Buying Process in LazadaDocument4 pagesStep Buying Process in LazadaAfifah FatihahNo ratings yet

- Naaladiyar: Watch Free MoviesDocument6 pagesNaaladiyar: Watch Free MoviesVijayaLakshmi IyerNo ratings yet

- Water Cement RatioDocument5 pagesWater Cement RatioCastro FarfansNo ratings yet

- EHS Audit - Review PaperDocument5 pagesEHS Audit - Review PaperYousef OlabiNo ratings yet

- Final Exam Tle Grade 8Document4 pagesFinal Exam Tle Grade 8John leo Claus67% (3)

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- Cebex 305: Constructive SolutionsDocument4 pagesCebex 305: Constructive SolutionsBalasubramanian AnanthNo ratings yet

- English Grammar Class 2 Sentences and Phrases - Learn and Practice - Download Free PDFDocument8 pagesEnglish Grammar Class 2 Sentences and Phrases - Learn and Practice - Download Free PDFSlesha SinhaNo ratings yet

- Too Early! by Anton Pavlovich ChekhovDocument4 pagesToo Early! by Anton Pavlovich Chekhovapi-19787590No ratings yet

- 500KVA Rigsafe Framed Generator (8900Kgs)Document1 page500KVA Rigsafe Framed Generator (8900Kgs)Elsad HuseynovNo ratings yet

- Lecture - 1 - UNDERGROUND MINE DESIGNDocument59 pagesLecture - 1 - UNDERGROUND MINE DESIGNRahat fahimNo ratings yet

- Tata Steel LTD.: Elements Unit Min Max RemarksDocument2 pagesTata Steel LTD.: Elements Unit Min Max RemarksPavan KumarNo ratings yet

- Wireless Cellular and LTE 4g Broadband PDFDocument26 pagesWireless Cellular and LTE 4g Broadband PDFAE videosNo ratings yet

- ESET TechnologyDocument21 pagesESET TechnologyValentin SalcianuNo ratings yet

- Initial 2Document6 pagesInitial 2Asad HoseinyNo ratings yet

- Arid Agriculture University, RawalpindiDocument4 pagesArid Agriculture University, RawalpindiIsHa KhAnNo ratings yet

- Reflective EssayDocument4 pagesReflective Essayapi-385380366No ratings yet

- CREDEDocument10 pagesCREDEDaffodilsNo ratings yet

- Alternative Refrigerants Manny A PresentationDocument29 pagesAlternative Refrigerants Manny A PresentationEmmanuel Zr Dela CruzNo ratings yet

- 2946 1308 00 Leroy Somer LSA47.2 Installation & MaintenanceDocument20 pages2946 1308 00 Leroy Somer LSA47.2 Installation & MaintenanceJORGE ARMANDO CARRASCO TICLLENo ratings yet

- AspenTech Awareness & Workshop Ebook - 2020 PDFDocument20 pagesAspenTech Awareness & Workshop Ebook - 2020 PDFĐậu BắpNo ratings yet

- Case Presentation On Management of Depressive Disorders-1Document40 pagesCase Presentation On Management of Depressive Disorders-1Fatima MuhammadNo ratings yet

- Chapter 12 Fraud and ErrorsDocument3 pagesChapter 12 Fraud and ErrorsMajoy BantocNo ratings yet

- Āyāt Al-Aḥkām, Ayat Al-AhkamDocument6 pagesĀyāt Al-Aḥkām, Ayat Al-AhkamRasoul NamaziNo ratings yet

- Pricelist LV Siemens 2019 PDFDocument96 pagesPricelist LV Siemens 2019 PDFBerlianiNo ratings yet