Professional Documents

Culture Documents

Engine Bearing Failure Analysis Guide

Uploaded by

Mahmoud AbdellatifCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Bearing Failure Analysis Guide

Uploaded by

Mahmoud AbdellatifCopyright:

Available Formats

Engine Bearing Failure Analysis Guide

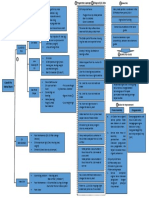

Fatigue of Aluminum Fatigue of Babbitt Fatigue of Bronze Edge Wear Due to

Lining Overlay Intermediate Layer Surface Wear Distorted Connecting Rod

Appearance: Appearance: Appearance: Appearance: Appearance:

Cracks, cratered & distressed bearing surface due to Irregular spider web-like cracks and craters in the overlay. Babbitt surface missing and intermediate layer cracked Accelerated wear - shiny surface Localized excessive wear of the bearing surface along the

loss of aluminum lining material. Fatigue may lead to partial flaking of the overlay, followed and cratered. Fragments are detached from the steel Heavy wear - signs of overheating (blackening), partial bearing edge. Possibility of fatigue cracks in the affected area.

by fatigue of the copper-lead intermediate layer. back causing imminent bearing failure. melting/removal of overlay (top shell)

Severe wear - torn surface, heavy overheating, Possible causes:

Possible causes: melted/missing overlay and lining material (bottom shell) Rod distortion caused by:

Possible causes: Possible causes:

Overloading

Wrong selection of engine bearing material

Wrong selection of engine bearing material Wrong selection of engine bearing material Possible causes:

Detonation

Engine power increased beyond original design Insufficient oil supply (starvation)

Engine power increased beyond original design Engine power increased beyond original design Excessive torque

Excessive clearance Non-uniform/unstable oil film (due to bearing fatigue)

Excessive clearance Excessive clearance Distorted rod produces non-parallel orientation of the

Fuel detonation/advanced ignition Geometrical irregularities or poor journal surface finish

Fuel detonation/advanced ignition Fuel detonation/preignition bearing and journal surfaces

Geometry defects causing localized bearing overloading Grinding chatter marks and lobing Metal-to-metal contact occurs along the bearing edge

Geometry defects causing localized bearing overloading Geometry defects causing localized bearing overloading

Contaminated oil

Corrective actions: Corrective actions:

Corrective actions: Corrective actions: Corrective actions:

Check oil supply system, prevent oil dilution/contamination Replace the distorted parts

Select a bearing material with higher load capacity Select a bearing material with higher load capacity Select a bearing material with higher load capacity Change bearing material Prevent engine detonation and pre-ignition (check

Check: clearances and component geometry Check: clearances and component geometry Check: clearances and component geometry Verify proper grinding/polishing procedures cooling system, air-fuel ratio, ignition timing, knock

Retard ignition or use fuel with higher octane number Retard ignition or use fuel with higher octane number Retard ignition or use fuel with higher octane number Improve cleaning procedures, replace oil and filter more sensor, octane number of fuel)

Repair/replace distorted parts Repair/replace distorted parts Repair/replace distorted parts frequently Choose higher strength connecting rods

Imperfect Journal Cavitation Erosion Spinning of the Bearing Fatigue in the Crush Damage Caused

Geometry in the Housing Relief Area by Foreign Particles

Appearance: Appearance: Appearance: Appearance: Appearance:

Localized wear in parts of the bearing surface. Erosion damaged areas on the overlay due to sharp Highly polished area on the bearing back caused by Fatigue cracks in the area of crush relief. Circumferential scores or scratches on the bearing

Fatigue cracks may occur in these areas. changes of pressure in the oil film. bearing spinning in the housing. surface.

Possible causes: Possible causes:

Possible causes:

Possible causes: Possible causes: Excessive crush height - upon torqueing the housing,

Vapor cavities (bubbles) in the oil – when the load applied Particles of grinding abrasive entrapped in crankshaft

the parting line region of the bearings deflects inward.

Inconsistent journal diameter. Areas of greater diameter to a bearing fluctuates at high frequency (high RPM). Insufficient crush height oil passages and/or other engine block components

This reduces the gap between the journal and bearing

produce metal-to-metal contact with the bearing The oil pressure can instantly fall, causing vapor cavities Oil starvation/lugging the engine causing seizure Ambient dirt, sand or dust

surfaces. Such change of bearing profile at the parting

surface, causing local wear Housing diameter greater than specified value Metal particles (e.g. fragments of fatigued material

(bubbles) due to fast evaporation (boiling). When the line region produces localized peak oil film pressure,

Use of worn or improperly dressed grinding wheel from failed components)

pressure rises, vapor cavities (cavitation bubbles) contract which can cause fatigue of the bearing material.

when resizing the crankshaft. Journals may result as at high velocity. Such collapse results in impact pressure, Excessive RPM producing rod bore stretch Corrective actions:

tapered, hourglass shape or barrel shape that can erode the bearing material. Corrective actions: Find the origin of the abrasive particles and other

Choose bearings with sufficient crush height Corrective actions: contaminants

Corrective actions:

for the application Prevent excessive crush height Replace air filter, oil and oil filter

Corrective actions:

Select stronger (harder) bearing material Eliminate the cause of seizure Check the housing diameter Check crankshaft oil passages and all engine

Replace/redress grinding wheel Decrease oil clearance Check housing diameter for size and roundness Avoid over-torqueing the rods components. Thoroughly clean them with hot soapy

Re-grind the crankshaft Avoid running the engine at extremely high rotation speeds Tighten bolts to the specified torque value Choose more rigid connecting rods water prior to assembly.

www.kingbearings.com MRK-AM008

You might also like

- King Engine BearingsDocument1 pageKing Engine BearingsDanny BenderNo ratings yet

- Tarea deDocument3 pagesTarea deDavid UrbinaNo ratings yet

- Bearing FailuresDocument2 pagesBearing FailuresBülent BulutNo ratings yet

- Bearing Damage Analysis BDAPosterDocument1 pageBearing Damage Analysis BDAPosterCurtler PaquibotNo ratings yet

- Assembly ProblemsDocument1 pageAssembly ProblemsFahad ZebNo ratings yet

- Bearing Failure & Their Root CauseDocument19 pagesBearing Failure & Their Root CauseAntoine lazarus MaomyNo ratings yet

- DamageDocument27 pagesDamageLuiz SilvaNo ratings yet

- Crank Pin Metal BurnDocument1 pageCrank Pin Metal Burnricky pradanaNo ratings yet

- 8 StepDocument1 page8 Stepricky pradanaNo ratings yet

- Chapter 3. Typical Damages of Machine PartsDocument30 pagesChapter 3. Typical Damages of Machine PartswondimuNo ratings yet

- Bc8 Gear Box Recon. ReportDocument6 pagesBc8 Gear Box Recon. ReportRahmat Wahyu PratamaNo ratings yet

- Fluid Film Bearing Damage-1Document1 pageFluid Film Bearing Damage-1Hafiz HarunNo ratings yet

- WB - Bearings - Poster - FINAL - US SizeDocument1 pageWB - Bearings - Poster - FINAL - US SizeAditya Shiva AppallaNo ratings yet

- Fluid Film Bearing Damage Poster 1668361770Document1 pageFluid Film Bearing Damage Poster 1668361770Amna YahyaNo ratings yet

- Plain Bearing FailuresDocument7 pagesPlain Bearing FailuressourajpatelNo ratings yet

- Maintenance of Gears and Gear DrivesDocument44 pagesMaintenance of Gears and Gear Driveskapun kumar nayak100% (1)

- Boroscope Inspection CriteriaDocument6 pagesBoroscope Inspection CriteriaPhong leNo ratings yet

- Plain Bearing Failure Foreign Matter Wiping FatigueDocument1 pagePlain Bearing Failure Foreign Matter Wiping FatigueSatyabrat GaanNo ratings yet

- RCA - 05-P521A Shaft FailureDocument40 pagesRCA - 05-P521A Shaft FailureAnkit SharmaNo ratings yet

- Bearing FailureDocument41 pagesBearing FailureMr.Safety100% (2)

- Repair ManualDocument260 pagesRepair ManualAnonymous 0k1o5N60% (1)

- Maintenancetools 04Document14 pagesMaintenancetools 04siyankallar100% (1)

- Failure Analysis ExaminationDocument3 pagesFailure Analysis ExaminationNelbert SumalpongNo ratings yet

- Aim Towards Zero Failure: Fishbone Diagram and Why-Why Analysis of BFP DE Side Bearing Temperature HighDocument6 pagesAim Towards Zero Failure: Fishbone Diagram and Why-Why Analysis of BFP DE Side Bearing Temperature HighAlvin PanjaitanNo ratings yet

- Root Cause AnalysisDocument21 pagesRoot Cause AnalysisXavier JosephNo ratings yet

- 01 Friction Lubrication WearDocument10 pages01 Friction Lubrication WearJuan Carlos Espinoza FloresNo ratings yet

- Chapter2 Damage PartsDocument16 pagesChapter2 Damage Partsmolla biyadgieNo ratings yet

- CV2 TRB B Earing DamageDocument4 pagesCV2 TRB B Earing DamageAlvaroNo ratings yet

- Timken MDV2 Tapered Roller Bearing Damage - 10826Document4 pagesTimken MDV2 Tapered Roller Bearing Damage - 10826mariamalloney1730No ratings yet

- Bearing FailureDocument25 pagesBearing Failureokta saputra100% (1)

- Faulty Shock AbsorberDocument1 pageFaulty Shock AbsorberHersa Morgana Resta IndraprahastaNo ratings yet

- PUB BU P4 13485 en ISO Classification of Bearing Damages PosterDocument1 pagePUB BU P4 13485 en ISO Classification of Bearing Damages PosterAlvaro Munoz100% (1)

- Main Beaaring Inspection ReportDocument3 pagesMain Beaaring Inspection Reportasanka136No ratings yet

- Engine Bearing Failures and How To Avoid Them PDFDocument8 pagesEngine Bearing Failures and How To Avoid Them PDFCarlos RamirezNo ratings yet

- 06 Gear FailuresDocument43 pages06 Gear FailuresrudisamosirNo ratings yet

- Foreign Object Damage Uneven Wear Normal Wear: Radial and Bias TiresDocument1 pageForeign Object Damage Uneven Wear Normal Wear: Radial and Bias Tireshpulido33_390009144100% (1)

- Plate Sample Cap: Welding Process MMA (SMAW)Document14 pagesPlate Sample Cap: Welding Process MMA (SMAW)Readersmo0% (1)

- Troubleshooting For Hob DamagedDocument3 pagesTroubleshooting For Hob DamagedSundarraj NagarajNo ratings yet

- 06 - Kim Mech Seal API619Document22 pages06 - Kim Mech Seal API619AliNo ratings yet

- Timken Bearing Damage Analysis - 7352Document3 pagesTimken Bearing Damage Analysis - 7352mariamalloney1730No ratings yet

- TIMKEN-Bearing Damage AnalysisDocument3 pagesTIMKEN-Bearing Damage AnalysisAnonymous Bdt0OGhNo ratings yet

- Surface Defects in Steel ProductsDocument41 pagesSurface Defects in Steel ProductsShilaj PNo ratings yet

- Unit 7 - 5 & 15 MarksDocument10 pagesUnit 7 - 5 & 15 MarksBipul VermaNo ratings yet

- Damage Analysis Chart 2Document1 pageDamage Analysis Chart 2NuM NaNo ratings yet

- Presentation 1Document7 pagesPresentation 1kihal zohirNo ratings yet

- ENG Rep2020Document3 pagesENG Rep2020Green MichaelsNo ratings yet

- Ball BearingDocument8 pagesBall BearingEsra TrokNo ratings yet

- PFI - Guia de Falhas de MontagemDocument1 pagePFI - Guia de Falhas de MontagemROBINSON ASSADNo ratings yet

- S09 SpeDocument93 pagesS09 SpeAmore S100% (1)

- Distortion Types of DistortionDocument6 pagesDistortion Types of DistortionHarsha Vardhan MeduriNo ratings yet

- Problem-Solving Model: Identify Determine Root CauseDocument68 pagesProblem-Solving Model: Identify Determine Root CauseDin UdinNo ratings yet

- Bearing Failure and Their CausesDocument5 pagesBearing Failure and Their CausesMUHAMMAD ASRI BIN ABDUL RAHMANNo ratings yet

- PreliminaryReport 02026.4Document5 pagesPreliminaryReport 02026.4Green MichaelsNo ratings yet

- Gear Box Failure AnalysisDocument39 pagesGear Box Failure AnalysisAli Hasnain100% (1)

- Poster Fallas de RodamientosDocument1 pagePoster Fallas de RodamientosRepositorio MantenimientoNo ratings yet

- Sr. No. Item Effects Causes Functions / Requirements Failure ModeDocument6 pagesSr. No. Item Effects Causes Functions / Requirements Failure ModeAtul DahiyaNo ratings yet

- Lubrication and Oil Analysis 1698237450Document114 pagesLubrication and Oil Analysis 1698237450mariustresor997No ratings yet

- AFA Overview WearDocument7 pagesAFA Overview WearMohamed HamdallahNo ratings yet

- CMP.2001.1217 - Multi Stage Centrifugal Compressors (Final To Print)Document7 pagesCMP.2001.1217 - Multi Stage Centrifugal Compressors (Final To Print)Mahmoud AbdellatifNo ratings yet

- Turbinas de GasDocument170 pagesTurbinas de Gasjose-consueloNo ratings yet

- Bearing Protection Best Practices: 1 © 2016 - Electro Static Technology An ITW CompanyDocument58 pagesBearing Protection Best Practices: 1 © 2016 - Electro Static Technology An ITW CompanyMahmoud AbdellatifNo ratings yet

- 1689207280050Document4 pages1689207280050Mahmoud AbdellatifNo ratings yet

- Uns N06625Document1 pageUns N06625robertNo ratings yet

- Topic 3: Metal Forming & Shaping ProcessesDocument115 pagesTopic 3: Metal Forming & Shaping ProcessesA TalkNo ratings yet

- Chap 13 Dew Point CorrosionDocument8 pagesChap 13 Dew Point CorrosionGustavoNo ratings yet

- SF 0654Document4 pagesSF 0654QA LAB ISMNo ratings yet

- Djj10033 Chapter 2Document30 pagesDjj10033 Chapter 2YogenNo ratings yet

- PRISESDocument52 pagesPRISESChandra SekharNo ratings yet

- Designer PVC LaminatesDocument98 pagesDesigner PVC LaminatesDeepu VijayanNo ratings yet

- Tinplate and Tin Free SteelDocument18 pagesTinplate and Tin Free SteelMartinNo ratings yet

- Semi Solid RheocastingDocument21 pagesSemi Solid RheocastingGiacomo ZammattioNo ratings yet

- Ds-Oe-020 Data Sheet RlgobDocument2 pagesDs-Oe-020 Data Sheet RlgobviksursNo ratings yet

- 2ND Summative Test Science 4 Q1Document2 pages2ND Summative Test Science 4 Q1Kristy HernandezNo ratings yet

- Categories of Cased Hole LogsDocument11 pagesCategories of Cased Hole LogsAG YNo ratings yet

- Processing Hot-Melt Pressure-Sensitive AdhesiveDocument12 pagesProcessing Hot-Melt Pressure-Sensitive AdhesiveCaio OliveiraNo ratings yet

- G-10 For Factory Line Reference FormulationDocument1 pageG-10 For Factory Line Reference FormulationĐặng Huỳnh ĐứcNo ratings yet

- 12Cr Stats WeldingDocument27 pages12Cr Stats WeldingMark JohnsonNo ratings yet

- Mechanical Problems Associated With Surface Micromachining: Class 7Document24 pagesMechanical Problems Associated With Surface Micromachining: Class 7ShankarAthava100% (1)

- Re: AISI 1050 Steel For Injection MoldingDocument2 pagesRe: AISI 1050 Steel For Injection MoldingMaulana PanjiNo ratings yet

- List Katalog Fire Hydrant (Box)Document3 pagesList Katalog Fire Hydrant (Box)Sales1 mpicaNo ratings yet

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocument2 pagesShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa AquitanNo ratings yet

- BS EN 1759-1 (2004) - Annex C - InformativeDocument2 pagesBS EN 1759-1 (2004) - Annex C - Informativegusla7No ratings yet

- Firechem FOAM PDFDocument2 pagesFirechem FOAM PDFrkssNo ratings yet

- 2.b Poster - Ferrous Material and AlloyDocument1 page2.b Poster - Ferrous Material and AlloyChristian Dave RoneNo ratings yet

- Thermax Limited: Inspection Procedure For GalvanizingDocument14 pagesThermax Limited: Inspection Procedure For GalvanizingNsidibe Michael EtimNo ratings yet

- Ceiling PDFDocument1 pageCeiling PDFjun vincint geleraNo ratings yet

- Serma LonDocument1 pageSerma LonIrwanzNo ratings yet

- Laboratorio Nº2 Hidrometalurgia: Lixiviación en ColumnasDocument17 pagesLaboratorio Nº2 Hidrometalurgia: Lixiviación en ColumnasIsidora Martin TriviñoNo ratings yet

- Universal Wps Stainless Steel Welding Lores enDocument1 pageUniversal Wps Stainless Steel Welding Lores en19MME-S1-323 Usman Ul Hassan PirzadaNo ratings yet

- CSWIP 3.1 Course Note 2016 With Question & AnswersDocument3 pagesCSWIP 3.1 Course Note 2016 With Question & AnswersSakthi Pk100% (1)

- Kobel Co WELDING HAND BOOKDocument180 pagesKobel Co WELDING HAND BOOKans44155100% (1)

- Adhesive Coating CatalogueDocument12 pagesAdhesive Coating CatalogueZamroni KarimNo ratings yet