Professional Documents

Culture Documents

OSHA3871

Uploaded by

SHANE ANGEL BORBE0 ratings0% found this document useful (0 votes)

13 views3 pagesOver half of injuries in commercial fishing can be prevented through good housekeeping and sanitary practices. Employers must identify hazards and address them, such as properly storing tools and gear to prevent slips, trips, and falls. Good practices include cleaning work areas, properly disposing of trash, and maintaining sanitation facilities. Workers have rights to a safe work environment and can file complaints to request inspections.

Original Description:

Osha

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOver half of injuries in commercial fishing can be prevented through good housekeeping and sanitary practices. Employers must identify hazards and address them, such as properly storing tools and gear to prevent slips, trips, and falls. Good practices include cleaning work areas, properly disposing of trash, and maintaining sanitation facilities. Workers have rights to a safe work environment and can file complaints to request inspections.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesOSHA3871

Uploaded by

SHANE ANGEL BORBEOver half of injuries in commercial fishing can be prevented through good housekeeping and sanitary practices. Employers must identify hazards and address them, such as properly storing tools and gear to prevent slips, trips, and falls. Good practices include cleaning work areas, properly disposing of trash, and maintaining sanitation facilities. Workers have rights to a safe work environment and can file complaints to request inspections.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Commercial

Fact Sheet Fishing

Safe Housekeeping and

Sanitation Practices

Workers in commercial fishing face hazardous working conditions on a daily basis that can lead to

injuries and fatalities. The most common hazards are associated with unsafe work practices and working

around moving deck machinery, rigging, or equipment, while other hazards are caused by harsh weather

conditions. Over half of the recordable injuries in commercial fishing are preventable through good

housekeeping and sanitary practices.

To protect workers on commercial fishing vessels, employers must Authority over working conditions on uninspected commercial

identify the hazards and take steps to address them. For example, fishing vessels is shared by OSHA and the U.S. Coast Guard,

improperly storing tools and fishing gear, or allowing water or fish parts with the U.S. Coast Guard being the lead agency. This fact sheet

to accumulate from processing activities increase the risk for slips, summarizes work practices and safety measures for effective

trips, and falls. The poor storage and ineffective labeling of chemicals, housekeeping and sanitation in commercial fishing operations.

cleaning solvents as well as poor maintenance of machinery and For information on OSHA’s jurisdiction of commercial fishing, see

equipment can result in worker exposure to harmful substances. Also, CPL 02-01-047, OSHA Authority Over Vessels and Facilities on

workers can be injured or killed when they are struck by equipment, or Adjacent to U.S. Navigable Waters and the Outer Continental

materials, and cargo that are stacked at unsafe heights. Shelf (OCS).

Good Housekeeping and Sanitary Practices

to Prevent Worker Injuries

• Start by cleaning up: Begin with a thorough housecleaning.

Remove all trash, accumulations of scrap, and unused materials.

• Make housekeeping an ongoing priority: Ensure workers

understand that housekeeping is a priority and that each

person is accountable for making sure that their work area

remains clean and well-kept.

• Properly dispose of trash: Provide appropriate containers

for trash and waste. Recyclables, trash, and hazardous waste

(e.g., liquids, chemicals, and soaked rags must be stored in

approved containers. Trash and waste containers must be

emptied frequently to prevent overflow.

• Keep regular and routine schedules: Sanitation facilities must

Source: OSHA

be serviced, cleaned, and stocked as needed.

BLS, 2011-2015

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

• Provide changing rooms where the work activity requires using

Generally, the applicable OSHA standards depend on the protective clothing with privacy, and separate storage for street

work activity taking place. For example, 29 CFR Part 1910, and protective clothing.

OSHA’s General Industry standard, applies to vessels

engaged in fishing or fish processing activities. When the Movement of Cargo, Ship’s Stores or Gear

vessel or its machinery undergoes servicing, the provisions

• During offloading, ensure that dunnage, hatch beams,

in 29 CFR Part 1915, OSHA’s Shipyard Employment standard,

must be followed. Also, in some cases, 29 CFR Parts 1917

tarpaulins and gear are stored at least three feet from weather

and 1918 apply when materials handling operations, such deck hatch coamings.

as loading, unloading, movement, or other handling of cargo,

ship’s stores or gear take place.

Entrance and Exit Routes

• Maintain sufficient lighting for exit routes, gangways, stairs,

and walkways.

Walking and Working Surfaces • Provide workers with a flashlight or other portable light where

• Keep surfaces clean and free of debris, protruding objects, permanent lighting is not available.

holes or loose boards, and tools. • Keep workers from entering dark holds, compartments, decks,

• Make sure equipment, materials, and cargo are stowed at safe or other spaces without a flashlight or other portable light.

heights to allow for easy reach and prevent objects from falling • Make sure exits and fire equipment are appropriately marked

on workers or causing tip or fall hazards. and easily accessible.

• Use grates or other temporary flooring where standing water

is unavoidable.

• Eliminate slippery conditions, such as snow and ice, on all

outdoor walking and working areas, or designate safe areas for

workers. Where this is not possible, employers must provide

workers with slip-resistant footwear.

• Properly stow or position hoses and electrical cords to prevent

trip hazards and damage to the hoses and cords.

• Keep heavy traffic work areas and access to vessels, cranes,

vehicles, and buildings unobstructed.

Photos by: Amy Duz — iWorkWise

Restrooms and Sanitation

• Routinely inspect areas for signs of rodents, insects, or other

vermin, and implement a control program when necessary.

• Have an adequate number of toilet facilities available close to

work locations with a means for handwashing at or adjacent

to each. Evaluation of Atmospheric Conditions

• Develop a schedule for regular servicing, cleaning, and stocking • Perform the appropriate atmospheric testing of confined

of restrooms and handwashing facilities. It is important to and enclosed spaces, such as fish holds, tanks, or cargo

evaluate the effectiveness of set frequencies and make compartments, to ensure safe entry.

adjustments as needed. • Frequently check on workers working alone in tanks or cargo

• Ensure that trash bins in eating, drinking, and break areas are compartments to ensure their safety.

emptied daily. • Dispose of flammable and combustible substances, such as

• Ensure an adequate supply of potable water is available for paint thinners, solvents, rags, scrap, and waste, or store them

drinking, worker health and personal needs, cooking, and food in covered fire-resistant containers.

preparation. All potable and non-potable water supplies must

be labeled for their designated uses.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

Workers’ Rights

Workers have the right to: their employer or OSHA. If a worker has been retaliated against

for using their rights, they must file a complaint with OSHA as

• Working conditions that do not pose a risk of serious harm.

soon as possible, but no later than 30 days.

• Receive information and training (in a language and

vocabulary the worker understands) about workplace For additional information, see OSHA’s Workers page.

hazards, methods to prevent them, and the OSHA standards

that apply to their workplace. How to Contact OSHA

• Review records of work-related injuries and illnesses. Under the Occupational Safety and Health Act of 1970, employers

• File a complaint asking OSHA to inspect their workplace if are responsible for providing safe and healthful workplaces for

they believe there is a serious hazard or that their employer their employees. OSHA’s role is to ensure these conditions for

is not following OSHA’s rules. OSHA will keep all identities America’s working men and women by setting and enforcing

confidential. standards, and providing training, education and assistance. For

• Exercise their rights under the law without retaliation, including more information, visit www.osha.gov or call OSHA at 1-800-321-

reporting an injury or raising health and safety concerns with OSHA (6742), TTY 1-877-889-5627.

This is one in a series of informational fact sheets highlighting OSHA programs, policies or standards. It does not impose any

new compliance requirements. For a comprehensive list of compliance requirements of OSHA standards or regulations, refer

DSG FS-3871 11/2017

to Title 29 of the Code of Federal Regulations. This information will be made available to sensory-impaired individuals upon

request. The voice phone is (202) 693-1999; teletypewriter (TTY) number: 1-877-889-5627.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

You might also like

- Fanuc NCGuide PMC Simulation FunctionDocument121 pagesFanuc NCGuide PMC Simulation FunctionkenNo ratings yet

- Camp Rules & RegulationsDocument4 pagesCamp Rules & RegulationsMohd AliNo ratings yet

- Confined SpaceDocument33 pagesConfined SpaceDesta WidayatNo ratings yet

- Basic Hygiene & Food Safety Training ModuleDocument43 pagesBasic Hygiene & Food Safety Training ModuleRelianceHRNo ratings yet

- UntitledDocument385 pagesUntitledDelta BravoNo ratings yet

- Unitech Metro - SAFE WORK METHOD STATEMENT - PAINTINGDocument4 pagesUnitech Metro - SAFE WORK METHOD STATEMENT - PAINTING'David TeeNo ratings yet

- Unitech Metro - SAFE WORK METHOD STATEMENT - CARPENTRYDocument3 pagesUnitech Metro - SAFE WORK METHOD STATEMENT - CARPENTRY'David Tee100% (2)

- Hazardous Material Handeling SOPDocument3 pagesHazardous Material Handeling SOPDipak ShelkeNo ratings yet

- Welcome: Created By: D.S.PAWAR Hse Officer. Mep-In Noted By: A.DASH. Qhse Manger IndiaDocument10 pagesWelcome: Created By: D.S.PAWAR Hse Officer. Mep-In Noted By: A.DASH. Qhse Manger IndiaIrvan HidanNo ratings yet

- 1270A544-032 Console v3.1Document304 pages1270A544-032 Console v3.1badr eddine100% (1)

- UF6 ManualDocument24 pagesUF6 ManualPhil Ruby Tigers0% (1)

- Brand Awareness Questionnaire SampleDocument2 pagesBrand Awareness Questionnaire SampleYogesh Sangani77% (13)

- 2.2industrail HousekeepingDocument16 pages2.2industrail HousekeepingAizm DinaniNo ratings yet

- Confined Space PresentationDocument10 pagesConfined Space PresentationNii AshiiiNo ratings yet

- University of Tennessee Religious ExemptionDocument3 pagesUniversity of Tennessee Religious ExemptionDonnaNo ratings yet

- BMP - BUSINESS-REV2016 FinalDocument8 pagesBMP - BUSINESS-REV2016 FinalOthelloBeneventiNo ratings yet

- 5 Min Safety Talk - Effective Workplace HousekeepingDocument1 page5 Min Safety Talk - Effective Workplace HousekeepingRizwan Ullah BaigNo ratings yet

- Toolbox Talks For Building and ExcavationsDocument8 pagesToolbox Talks For Building and ExcavationsbonyhermawanNo ratings yet

- House Keeping ProcedureDocument3 pagesHouse Keeping ProcedureREBAA HatemNo ratings yet

- COVID-19 Guidance For Public Pools - 5.13.20Document7 pagesCOVID-19 Guidance For Public Pools - 5.13.20jclark13010No ratings yet

- Section 26 - Housekeeping Procedures: Harper College Environmental Health & Safety Procedure ManualDocument3 pagesSection 26 - Housekeeping Procedures: Harper College Environmental Health & Safety Procedure ManualLammiifan JemalNo ratings yet

- Hygienic Practices in Slaughter HouseDocument40 pagesHygienic Practices in Slaughter Housezubair valiNo ratings yet

- Accident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionDocument81 pagesAccident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionKritesh RamnathNo ratings yet

- COVID-19 Guidance For Public Pools - 07.08.20Document7 pagesCOVID-19 Guidance For Public Pools - 07.08.20jclark13010No ratings yet

- Hazard Inventory List SampleDocument6 pagesHazard Inventory List SampleOsama ShaalanNo ratings yet

- Design o Ffood PromisesDocument31 pagesDesign o Ffood PromisesMercy WendyNo ratings yet

- How Can We Take Housekeeping As A BuisnessDocument13 pagesHow Can We Take Housekeeping As A BuisnessVikas Singh RanaNo ratings yet

- Standard Construction Safety Fatal Risk StandardsDocument32 pagesStandard Construction Safety Fatal Risk StandardsRoberto ENo ratings yet

- Site Clean Up and Decommissioning SOPDocument5 pagesSite Clean Up and Decommissioning SOPash amenNo ratings yet

- Housekeeping ProcedureDocument7 pagesHousekeeping ProcedureLwandziso DlaminiNo ratings yet

- Performance Task 5: NAME: Maria Famela B. Franco Section: ST Lorenzo RuizDocument2 pagesPerformance Task 5: NAME: Maria Famela B. Franco Section: ST Lorenzo RuizMariela FrancoNo ratings yet

- Constr Proper Housekeeping GUIDEDocument2 pagesConstr Proper Housekeeping GUIDEerinepeachNo ratings yet

- 11 Tips For Effective Workplace HousekeepingDocument4 pages11 Tips For Effective Workplace HousekeepingJr FellerNo ratings yet

- Section 02 - The Hazards of Flood Cleanup OperationsDocument22 pagesSection 02 - The Hazards of Flood Cleanup OperationsJoaquim RaimundoNo ratings yet

- PrefinalsDocument16 pagesPrefinalsMichaella Corine GonzalesNo ratings yet

- Good Manufacturing Practices (GMP) : Ftec 150 Lab Exercise 3Document44 pagesGood Manufacturing Practices (GMP) : Ftec 150 Lab Exercise 3Sharon EismaNo ratings yet

- Wait Staff SafetyDocument3 pagesWait Staff Safetyselvarangam govindarajanNo ratings yet

- Housekeeping and Material Storage: NotesDocument8 pagesHousekeeping and Material Storage: NotesBry AsuncionNo ratings yet

- Amenities On Housing SitesDocument4 pagesAmenities On Housing SitesvigneshpandiNo ratings yet

- Fajar International College Housekeeping PolicyDocument2 pagesFajar International College Housekeeping PolicyDiNozzo PosnerNo ratings yet

- Work Shop Hazards FinalDocument3 pagesWork Shop Hazards FinalAlexutza StanNo ratings yet

- Maz - PRJ - Hse - PRC 09 - Hygiene and Housekeeping Procedures 001Document4 pagesMaz - PRJ - Hse - PRC 09 - Hygiene and Housekeeping Procedures 001ghazi kallelNo ratings yet

- Safe Handling, Treatment, Transport and Disposal of Ebola-Contaminated WasteDocument6 pagesSafe Handling, Treatment, Transport and Disposal of Ebola-Contaminated WasteEhsanNo ratings yet

- Feasibility Study On Palm OilDocument4 pagesFeasibility Study On Palm OilmarilouNo ratings yet

- The Society of Food Hygiene and TechnologyDocument4 pagesThe Society of Food Hygiene and TechnologyrheriNo ratings yet

- Wiper Job For RoyalDocument2 pagesWiper Job For RoyalIlham SobriNo ratings yet

- Good Manufacturing Practices in Fish Handling: Vipul GuptaDocument17 pagesGood Manufacturing Practices in Fish Handling: Vipul GuptajoshigautaNo ratings yet

- Housekeeper Job DescriptionDocument1 pageHousekeeper Job DescriptionTrâu XjnhNo ratings yet

- 0001 - Environmental ControlDocument2 pages0001 - Environmental ControlJohn Vem BansagNo ratings yet

- Hand Washing FacilitiesDocument10 pagesHand Washing FacilitiesNaz RaNo ratings yet

- Hse Operational ControlDocument12 pagesHse Operational ControlnagaaNo ratings yet

- Hazards in Port and Docks Info SheetDocument6 pagesHazards in Port and Docks Info SheetAidanNo ratings yet

- Tcs 220Document3 pagesTcs 220yeralNo ratings yet

- Checklist For Environmental Management Within DormitoriesDocument2 pagesChecklist For Environmental Management Within DormitoriesWanping TangNo ratings yet

- Current Practices Being Used in Their Manufacturing ProcessDocument5 pagesCurrent Practices Being Used in Their Manufacturing ProcessjaredjoeNo ratings yet

- S-Lab HousekeepingDocument3 pagesS-Lab HousekeepingSimon HafeniNo ratings yet

- BitlockerDocument6 pagesBitlockerJNfotoeventsNo ratings yet

- Eyewash and Safety Shower SiDocument3 pagesEyewash and Safety Shower SiAli EsmaeilbeygiNo ratings yet

- C TASK-1 Participate in Safe Work Practices C - Task 1Document5 pagesC TASK-1 Participate in Safe Work Practices C - Task 1Mukta AktherNo ratings yet

- Sterile Preparations Chapter 13Document15 pagesSterile Preparations Chapter 13christinepaguio16No ratings yet

- HSE-307-PR Housekeeping, WorksiteDocument5 pagesHSE-307-PR Housekeeping, WorksitecobbymarkNo ratings yet

- Tool Box Talk Topic-Workplace Housekeeping & Material StackingDocument2 pagesTool Box Talk Topic-Workplace Housekeeping & Material StackingSameer PatilNo ratings yet

- 0914 ORM 20 SP Environ CleanDocument4 pages0914 ORM 20 SP Environ Cleanjuanja83No ratings yet

- Setup Animal House-1Document13 pagesSetup Animal House-1Er Purushottam Pal100% (1)

- Business Plan SampleDocument18 pagesBusiness Plan SampleSHANE ANGEL BORBENo ratings yet

- Provided by Research Papers in EconomicsDocument33 pagesProvided by Research Papers in EconomicsSHANE ANGEL BORBENo ratings yet

- Roles and Responsibilities of OfficersDocument1 pageRoles and Responsibilities of OfficersSHANE ANGEL BORBENo ratings yet

- Adevinta Legal Compliance PolicyDocument3 pagesAdevinta Legal Compliance PolicySHANE ANGEL BORBENo ratings yet

- Organizational Planning The Ladder To An Organization Success PDFDocument36 pagesOrganizational Planning The Ladder To An Organization Success PDFSHANE ANGEL BORBENo ratings yet

- Personal Narrative OutlineDocument2 pagesPersonal Narrative OutlineSHANE ANGEL BORBENo ratings yet

- HousekeepingDocument30 pagesHousekeepingSHANE ANGEL BORBENo ratings yet

- Physical EducationDocument2 pagesPhysical EducationSHANE ANGEL BORBENo ratings yet

- IHM104 SemProj AY22-23 BSTM1103 BorbeDocument23 pagesIHM104 SemProj AY22-23 BSTM1103 BorbeSHANE ANGEL BORBENo ratings yet

- Housekeeping Training Narrative Report FormatDocument3 pagesHousekeeping Training Narrative Report FormatSHANE ANGEL BORBENo ratings yet

- EVENT DOCUMENTATION TemplateDocument4 pagesEVENT DOCUMENTATION TemplateSHANE ANGEL BORBENo ratings yet

- BSTM1103 - North and Central AmericaDocument56 pagesBSTM1103 - North and Central AmericaSHANE ANGEL BORBENo ratings yet

- Local Media167776177079435867Document2 pagesLocal Media167776177079435867SHANE ANGEL BORBENo ratings yet

- Local Media605511774785482708Document6 pagesLocal Media605511774785482708SHANE ANGEL BORBENo ratings yet

- Reporter 6 Biological Hazard Part 6Document4 pagesReporter 6 Biological Hazard Part 6SHANE ANGEL BORBENo ratings yet

- HW1Document5 pagesHW1John SpartanNo ratings yet

- Math Achievement Gr11GenMathDocument3 pagesMath Achievement Gr11GenMathMsloudy VilloNo ratings yet

- Particulate Ow at The Mouth of The Soummam Watershed (Algeria)Document9 pagesParticulate Ow at The Mouth of The Soummam Watershed (Algeria)bougheraraNo ratings yet

- Database NotesDocument4 pagesDatabase NotesKanishka SeneviratneNo ratings yet

- Unit 2Document42 pagesUnit 2Kalaiselvan PunniyamoorthyNo ratings yet

- Rasi Navamsa: As Mo Ke Su Ve Mo JuDocument11 pagesRasi Navamsa: As Mo Ke Su Ve Mo JuRavan SharmaNo ratings yet

- Msds 2342Document5 pagesMsds 2342Gabo TellezNo ratings yet

- I Can Learn English 1Document100 pagesI Can Learn English 1IbetNo ratings yet

- Digital SAT Skills Insight Tool - MathDocument61 pagesDigital SAT Skills Insight Tool - MathSianitus La Tour D'AuvergneNo ratings yet

- Sow English Year 2 2023Document12 pagesSow English Year 2 2023Noramaliza GhazaliNo ratings yet

- Conjunction and Exposition Text-2Document19 pagesConjunction and Exposition Text-2keyshalaokkiNo ratings yet

- TDS - 0121 - CapaCare Classic - 201912Document5 pagesTDS - 0121 - CapaCare Classic - 201912ayviwurbayviwurbNo ratings yet

- Ferrites For Linear Appl - Properties - SnellingDocument10 pagesFerrites For Linear Appl - Properties - SnellingTom SebastianNo ratings yet

- Verilog HDL: Special ClassesDocument11 pagesVerilog HDL: Special ClassesUnique ProNo ratings yet

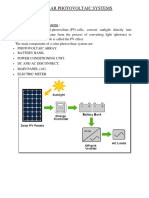

- 22661-RET Notes-UNIT 02Document25 pages22661-RET Notes-UNIT 02jayeshdeore398No ratings yet

- 344W11MidTermExamI Solution PDFDocument22 pages344W11MidTermExamI Solution PDFTrường TùngNo ratings yet

- Aciclovir 400mg and 800mg TabletsDocument2 pagesAciclovir 400mg and 800mg TabletsKalyan NandanNo ratings yet

- Dans Swing Trade StrategyDocument3 pagesDans Swing Trade StrategyDimitrios OuzounisNo ratings yet

- Jess's Heart Is Racing at 100 Miles Per Hour.Document3 pagesJess's Heart Is Racing at 100 Miles Per Hour.vexagon wallowNo ratings yet

- 1 Man Is The Crowning Glory of God's CreationDocument12 pages1 Man Is The Crowning Glory of God's CreationCaptainBreezy YeezyNo ratings yet

- Imran Index 1Document11 pagesImran Index 1api-387022302No ratings yet

- A Sensorless Direct Torque Control Scheme Suitable For Electric VehiclesDocument9 pagesA Sensorless Direct Torque Control Scheme Suitable For Electric VehiclesSidahmed LarbaouiNo ratings yet

- Arahan Dan Soalan Tugasan Jkp513e417e Sa 20222023Document4 pagesArahan Dan Soalan Tugasan Jkp513e417e Sa 20222023skblueNo ratings yet

- Exercises - PronounsDocument3 pagesExercises - PronounsTerritório PBNo ratings yet