Professional Documents

Culture Documents

2 - Sag-New Format Mnciii

Uploaded by

Ferdinand De La FuenteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 - Sag-New Format Mnciii

Uploaded by

Ferdinand De La FuenteCopyright:

Available Formats

TESDA-OP-QSO-02-F07

TESDA-OP-QSO-02-F07 Rev.No.01-03/01/17

Rev.No.00-03/01/17

Reference No. MCG 1 9 1 3 1 4 2 5 9 0 0 0 0

Reference No. MCG 1 9 1 3 1 4 2 5 9 0 0 0 0

to be filled out by the Processing Officer

to be filled out by the Processing Officer

UNIQUE LEARNERS IDENTIFIER (ULI):

UNIQUE LEARNERS IDENTIFIER (ULI):

- - - -

- - - -

to be filled – out by the Processing Officer

to be filled – out by the Processing Officer

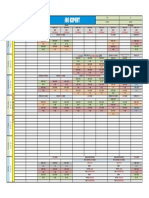

SELF ASSESSMENT GUIDE

SELF ASSESSMENT GUIDE

Qualification: MACHINING NC III

Qualification: MACHINING NC III

Project: SHAFT WITH HELICAL GEAR

Project: SHAFT WITH HELICAL GEAR

Instruction:

Instruction: Read each of the questions in the left-hand column of the chart.

Read each of the questions in the left-hand column of the chart. Place a check in the appropriate box opposite each question to indicate your answer.

Place a check in the appropriate box opposite each question to indicate your answer.

Can I? YES NO

Can I? YES NO

Determine job requirement (A written work plan listing the operation is required)

Determine job requirement (A written work plan listing the operation is required) Perform bench work

Perform bench work Perform turning operation

Perform turning operation o Turn diameters using steady rest

o Turn diameters using steady rest o Turn eccentric diameters

o Turn eccentric diameters o Perform deep hole drilling and boring

o Perform deep hole drilling and boring o Turn internal shape and surface (cylinder, chamfer, groove, radii)

o Turn internal shape and surface (cylinder, chamfer, groove, radii) o Turn internal tapers

o Turn internal tapers o Cut internal threads: square, ACME, and multi-start

o Cut internal threads: square, ACME, and multi-start o Bore hole on stationary workpiece

o Bore hole on stationary workpiece o Part off

o Part off Perform milling operation

Perform milling operation o Observe housekeeping

o Observe housekeeping o Mill helical gears

o Mill helical gears o Mill bevel gears

o Mill bevel gears o Mill ratchet ,gears, sprockets using differential indexing

o Mill ratchet ,gears, sprockets using differential indexing o Perform spiral milling

o Perform spiral milling o Mills feature from established locations

o Mills feature from established locations Check / Measure workpiece using limit gages; comparators; Gage block; Gear tooth vernier caliper;

Check / Measure workpiece using limit gages; comparators; Gage block; Gear tooth vernier caliper; micrometers; Balls; Precision rollers

micrometers; Balls; Precision rollers Perform grinding operation

Perform grinding operation o Select grinding wheels and accessories

o Select grinding wheels and accessories o Grinding parallel and square surfaces

o Grinding parallel and square surfaces o Grinding to an angle surface

o Grinding to an angle surface o Grinding to radii

o Grinding to radii o Grinding to cut off parts

o Grinding to cut off parts Measures dimensions

Measures dimensions Check surface texture

Check surface texture

I agree to undertake assessment in the knowledge that information gathered will only be used for professional development purposes and

I agree to undertake assessment in the knowledge that information gathered will only be used for professional development purposes and can only be accessed by concerned assessment personnel and my manager/supervisor.

can only be accessed by concerned assessment personnel and my manager/supervisor.

___________________________________ Date:

___________________________________ Date: Candidate’s Name & Signature

Candidate’s Name & Signature

Evaluated by:

Evaluated by: JOHNNY B. MATERUM

_______________________________ Qualified for Assessment

JOHNNY B. MATERUM

_______________________________ Qualified for Assessment AC Manager

AC Manager Not yet Qualified for Assessment

Not yet Qualified for Assessment Date:

Date:

You might also like

- 2 - Sag-New Format MnciiDocument1 page2 - Sag-New Format MnciiFerdinand De La FuenteNo ratings yet

- 0 EJ EJ: Sample Answer Sheet: Reading and Use of EnglishDocument5 pages0 EJ EJ: Sample Answer Sheet: Reading and Use of EnglishPavia AlessioNo ratings yet

- TRINITY Viola - Grade5Document11 pagesTRINITY Viola - Grade5pedrohpv009No ratings yet

- Time Table 12.12.2023 To 17.12.2023 RevisedDocument5 pagesTime Table 12.12.2023 To 17.12.2023 RevisedatharvaNo ratings yet

- Notification Application FormDocument10 pagesNotification Application FormAnil BagharNo ratings yet

- Role of The NCO - Africa Military Legal Conference 2010Document11 pagesRole of The NCO - Africa Military Legal Conference 2010U.s. Africa CommandNo ratings yet

- BS Evening Challan Spirng 2024Document139 pagesBS Evening Challan Spirng 2024Zainullah KhanNo ratings yet

- Main Arena Plan Beach HandballDocument1 pageMain Arena Plan Beach Handballpradito ala perdanaNo ratings yet

- 25th Sept'WEDNESDAY 26th Sept'THURSDAY 27th Sept'FRIDAY 28th Sept'SATURDAY 29th Sept'SUNDAY 30th Sept'Mon 24th Sept'TUESDAYDocument4 pages25th Sept'WEDNESDAY 26th Sept'THURSDAY 27th Sept'FRIDAY 28th Sept'SATURDAY 29th Sept'SUNDAY 30th Sept'Mon 24th Sept'TUESDAYRohan SoodNo ratings yet

- I Legends: Note:: & VLGVDocument1 pageI Legends: Note:: & VLGVthe conquerorNo ratings yet

- KLASA 10-3 Pasqyra Vjetore 22-23Document7 pagesKLASA 10-3 Pasqyra Vjetore 22-23Rodi MucekuNo ratings yet

- Inspection Form Check List For Electric DCS: Checked By: Checked By: Checked byDocument1 pageInspection Form Check List For Electric DCS: Checked By: Checked By: Checked byBoni SpiNo ratings yet

- Failure Accumulation ChartDocument1 pageFailure Accumulation ChartAndrei BancescuNo ratings yet

- Amguhan Es q1 Percentage of Passer 2021Document1 pageAmguhan Es q1 Percentage of Passer 2021Baybay TaekwondoNo ratings yet

- LC Anul 1: ! Practica de TIB Va Fi Stabilita Impreuna Cu Coordonatorul de GrupaDocument3 pagesLC Anul 1: ! Practica de TIB Va Fi Stabilita Impreuna Cu Coordonatorul de GrupaIacob RoxanaNo ratings yet

- Time Table 07.11.2023 To 12.11.2023Document5 pagesTime Table 07.11.2023 To 12.11.2023Shaurya JainNo ratings yet

- Spray MachineDocument51 pagesSpray MachineKỳ PhamNo ratings yet

- 0530-DWG-BSC-40-006 AC DC Termination Rev02ADocument1 page0530-DWG-BSC-40-006 AC DC Termination Rev02ALuis Marín DíazNo ratings yet

- 2 - Sag-New Format MnciDocument1 page2 - Sag-New Format MnciFerdinand De La FuenteNo ratings yet

- TimetableDocument1 pageTimetablerajpersonalNo ratings yet

- Mkg-Xxftechlib/1T/05: T It It B QDocument40 pagesMkg-Xxftechlib/1T/05: T It It B QJhantu MazumderNo ratings yet

- Viewer (v5.7.000)Document1 pageViewer (v5.7.000)Faisal freakNo ratings yet

- ENVD 2115: Spring 2020 Assignment WS 1Document2 pagesENVD 2115: Spring 2020 Assignment WS 1scu915No ratings yet

- Ariel Feedback ReportDocument19 pagesAriel Feedback ReportFenias BoaneNo ratings yet

- Item AnalysisDocument43 pagesItem AnalysisLevi Lico PangilinanNo ratings yet

- Incomers A D Buscoupler: NotesDocument1 pageIncomers A D Buscoupler: Notesganesh kumarNo ratings yet

- C II EM 4000 A - GD - Tunnel - LayoutDocument1 pageC II EM 4000 A - GD - Tunnel - Layoutskgp raiNo ratings yet

- Manpower Histogram Rev 1 Dt. 04.04.2017Document1 pageManpower Histogram Rev 1 Dt. 04.04.2017Abdulsalam YousifNo ratings yet

- Triumph Maintenance Chart 6k Mile Service IntervalDocument1 pageTriumph Maintenance Chart 6k Mile Service IntervalalexNo ratings yet

- Issa Ins TXTB en A4 Cover 1904Document68 pagesIssa Ins TXTB en A4 Cover 1904La MunteniNo ratings yet

- Yamaha MD8SDocument115 pagesYamaha MD8Selm rcNo ratings yet

- 18mar 24marDocument1 page18mar 24marjivipen905No ratings yet

- DSSSB Previous Year Paper PGT SanskritDocument39 pagesDSSSB Previous Year Paper PGT SanskritVeekeshGupta0% (2)

- Matriz de Priorización de Proyectos: Importancia Dueño de Proceso Proyecto Asignado ADocument10 pagesMatriz de Priorización de Proyectos: Importancia Dueño de Proceso Proyecto Asignado Ajamerz razethNo ratings yet

- In-Process - Urine Bag Pouch Sealing - 6Document8 pagesIn-Process - Urine Bag Pouch Sealing - 6Hilario AlinabonNo ratings yet

- 04Document1 page04Samuel RamonesNo ratings yet

- 5 - Grafico Costo-TiempoDocument1 page5 - Grafico Costo-TiempotgNo ratings yet

- Weekly Report - 25 June 2021 PDFDocument4 pagesWeekly Report - 25 June 2021 PDFDan HathurusingheNo ratings yet

- Site Development Plan: Ar. Rey Vincent Dalaguan, Uap, RMP Student Housing Angelica J. BalasabasDocument20 pagesSite Development Plan: Ar. Rey Vincent Dalaguan, Uap, RMP Student Housing Angelica J. BalasabasangelicaNo ratings yet

- SHS Template 4 SECONDARY With QR Code School 1Document12 pagesSHS Template 4 SECONDARY With QR Code School 1PatzAlzateParaguyaNo ratings yet

- Music PaperDocument20 pagesMusic PaperYaminikrishna KariNo ratings yet

- Maintenance Manual: Daito SeikiDocument70 pagesMaintenance Manual: Daito SeikiIlham 011No ratings yet

- SAG - HEO (Hydraulic Excavation) NC IIDocument1 pageSAG - HEO (Hydraulic Excavation) NC IIKira RajadaNo ratings yet

- Owner's Manual: Multitrack MD RecorderDocument115 pagesOwner's Manual: Multitrack MD RecorderSamuel GarzaNo ratings yet

- Now Available Now Available Now Available Now Available: The Philippines' Only Shipping and Transport GuideDocument12 pagesNow Available Now Available Now Available Now Available: The Philippines' Only Shipping and Transport GuidePortCallsNo ratings yet

- 2 Storey - AR 02Document1 page2 Storey - AR 02Sam SamNo ratings yet

- Divisi UserDocument12 pagesDivisi UserMuhammad Irfan Nur RasyidNo ratings yet

- Planning - Realisasi ProduksiDocument19 pagesPlanning - Realisasi ProduksighozalisiregarNo ratings yet

- CD17Document166 pagesCD17HNo ratings yet

- Amna Ahmer MorDocument1 pageAmna Ahmer Morninjah2rrarrrNo ratings yet

- The Secret Treasure: Bert Appermont Frank Van BaelenDocument32 pagesThe Secret Treasure: Bert Appermont Frank Van Baelensofia canoNo ratings yet

- Individual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiDocument8 pagesIndividual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiNida Viojan AbasoloNo ratings yet

- Daily Time Record Daily Time Record: Ilagan, Kimberly M. Ilagan, Kimberly MDocument1 pageDaily Time Record Daily Time Record: Ilagan, Kimberly M. Ilagan, Kimberly MJadeNo ratings yet

- MT Ipcrf 2022 2023 CCSDocument20 pagesMT Ipcrf 2022 2023 CCSIrene GarciaNo ratings yet

- Formato de Calificaciones BachilleratoDocument11 pagesFormato de Calificaciones BachilleratolilianaNo ratings yet

- Pancang CausewayDocument9 pagesPancang CausewayMulyaniNo ratings yet

- At Lesson Plan 04 01 2024Document2 pagesAt Lesson Plan 04 01 2024api-718935591No ratings yet

- Upper Kotmale Field VisitDocument6 pagesUpper Kotmale Field VisitIsuru Kasthurirathne50% (2)

- Sm-Volkswagen Tdi 3.0l v6 Diesel Marine Engine Service Repair ManualDocument29 pagesSm-Volkswagen Tdi 3.0l v6 Diesel Marine Engine Service Repair ManualAlberto60% (5)

- PROBLEMSDocument3 pagesPROBLEMSEl- Tally0% (3)

- Assignment 1Document2 pagesAssignment 1Borhan ShaikatNo ratings yet

- TP48200A-H15A8 Outdoor Power System Datasheet For Enterprise 01-20130507Document2 pagesTP48200A-H15A8 Outdoor Power System Datasheet For Enterprise 01-20130507Zaheer Ahmed TanoliNo ratings yet

- Section 12 - CarbSteel - tcm266-27348Document79 pagesSection 12 - CarbSteel - tcm266-27348muthukumaranNo ratings yet

- Mechanical Behaviour of Materials Model Question Paper PDFDocument2 pagesMechanical Behaviour of Materials Model Question Paper PDFSachi Dhanandam100% (1)

- Lashcon Gripper WLL 1000 On Deck Only ChainsDocument1 pageLashcon Gripper WLL 1000 On Deck Only ChainsJackNo ratings yet

- Bobcat 226 yDocument19 pagesBobcat 226 yEduardoNo ratings yet

- Z Transform 2 of 3Document18 pagesZ Transform 2 of 3Gilbert SigalaNo ratings yet

- LD5530 1CH 65W Demo Board Test ReportDocument20 pagesLD5530 1CH 65W Demo Board Test ReportAdilson BogadoNo ratings yet

- Chapter 19 OchemII QuizDocument13 pagesChapter 19 OchemII QuizPriyanka SaxenaNo ratings yet

- Week 4 - Fiber Optics and Waveguides - Solutions PDFDocument4 pagesWeek 4 - Fiber Optics and Waveguides - Solutions PDFmokhaladNo ratings yet

- Raghuveer Singh CVDocument7 pagesRaghuveer Singh CVSandeepNo ratings yet

- Altium PCB Layout Tutorial 2Document31 pagesAltium PCB Layout Tutorial 2oemarbc100% (3)

- Aofd2 r2Document387 pagesAofd2 r2ervgNo ratings yet

- UTX MTX HVX ManualDocument82 pagesUTX MTX HVX ManualMutahirrasoolNo ratings yet

- Chapter 1 Introduction and Basic ConceptsDocument26 pagesChapter 1 Introduction and Basic ConceptsZafirahAhmadFauziNo ratings yet

- Resume Sukhchain SidhuDocument2 pagesResume Sukhchain SidhuShaun SidhuNo ratings yet

- Activity No 9. The Soil ProfileDocument2 pagesActivity No 9. The Soil ProfileGedion Dumanon Añana Jr.No ratings yet

- Bounded Bi Harmonic Weights Siggraph 2011 Compressed Jacobson Et AlDocument8 pagesBounded Bi Harmonic Weights Siggraph 2011 Compressed Jacobson Et AlEnrique GarciaNo ratings yet

- Robustness Analysis: P. Vanicek E. J. Krakiwsky M. R. CraymerDocument37 pagesRobustness Analysis: P. Vanicek E. J. Krakiwsky M. R. CraymerMul YaniNo ratings yet

- Me8392 Manufacturing Technology L T P CDocument1 pageMe8392 Manufacturing Technology L T P CERKATHIRNo ratings yet

- Rodolfo CVDocument3 pagesRodolfo CVFabian Andres Calderon HurtadoNo ratings yet

- HyperWorks 10.0 Release Notes - Solvers - RADIOSS 10Document11 pagesHyperWorks 10.0 Release Notes - Solvers - RADIOSS 10bsrkaushik1No ratings yet

- Titan Energetics Spectra2 Coiled Tubing Cutters Flyer3Document2 pagesTitan Energetics Spectra2 Coiled Tubing Cutters Flyer3faiz bugtiNo ratings yet

- 12things About 122 DevelopersDocument149 pages12things About 122 Developersanoop666rNo ratings yet

- Water DistributionDocument116 pagesWater DistributionJoshua GonzalesNo ratings yet

- Balki QM Problem Set PDFDocument50 pagesBalki QM Problem Set PDFaakaash00710No ratings yet

- Fiberlon HDDocument2 pagesFiberlon HDMohamed AmeenNo ratings yet