Professional Documents

Culture Documents

2 - Sag-New Format Mnci

Uploaded by

Ferdinand De La FuenteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 - Sag-New Format Mnci

Uploaded by

Ferdinand De La FuenteCopyright:

Available Formats

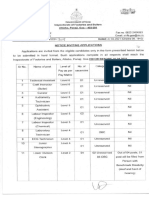

TESDA-OP-QSO-02-F07

Rev.No.00-03/01/17

Reference No. MCG 1 9 1 3 1 4 1 4 4 0 0 0 0

Reference No. MCG 1 9 1 3 1 4 1 4 4 0 0 0 0 to be filled out by the Processing Officer

to be filled out by the Processing Officer UNIQUE LEARNERS IDENTIFIER (ULI):

UNIQUE LEARNERS IDENTIFIER (ULI): - - - -

- - - - to be filled – out by the Processing Officer

to be filled – out by the Processing Officer SELF ASSESSMENT GUIDE

SELF ASSESSMENT GUIDE

Qualification: MACHINING NC I

Perform bench work (Basic)

Qualification: MACHINING NC I

Turn workpiece (Basic)

Units of Competency Covered:

Perform bench work (Basic) Mill workpiece (Basic)

Turn workpiece (Basic) Grind workpiece (Basic)

Units of Competency Covered:

Mill workpiece (Basic) Instruction:

Grind workpiece (Basic) Read each of the questions in the left-hand column of the chart.

Instruction: Place a check in the appropriate box opposite each question to indicate your answer.

Read each of the questions in the left-hand column of the chart.

Can I? YES NO

Place a check in the appropriate box opposite each question to indicate your answer.

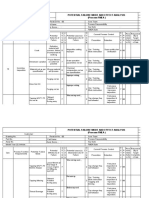

Determine job requirements (A written work plan listing the operation is required)

Can I? YES NO

Perform Bench Work

Determine job requirements (A written work plan listing the operation is required) Sawing, chiseling, filing

Perform Bench Work o Drilling, tapping, die thread cutting, reaming

Sawing, chiseling, filing o Off-hand grinding

o Drilling, tapping, die thread cutting, reaming

Perform turning operation:

o Off-hand grinding

Select and set up cutting tools

Perform turning operation: o Setup workpiece

Select and set up cutting tools o Facing and longitudinal turning

o Setup workpiece o Cutting grooves, recess, shoulders; knurls and parting off

o Facing and longitudinal turning o Perform grinding operations to produce components (e.g. grinding parallel and square

o Cutting grooves, recess, shoulders; knurls and parting off surfaces, angles, internal and external radii, tapers and recesses)

o Perform grinding operations to produce components (e.g. grinding parallel and square o Drilling, boring, counterboring and countersinking

surfaces, angles, internal and external radii, tapers and recesses) o Thread cutting V-threads: internal and externa

o Drilling, boring, counterboring and countersinking

o Cutting external taper: compound table or formed tool

o Thread cutting V-threads: internal and externa

Perform milling operation

o Cutting external taper: compound table or formed tool

o Drilling and boring

Perform milling operation

Spot facing

o Drilling and boring

o Milling slots and keyways

Spot facing o Milling serrations

o Milling slots and keyways

o Milling of vees

o Milling serrations

o Cutting off materials

o Milling of vees

o Milling circular slots

o Cutting off materials

Perform grinding operation

o Milling circular slots

o Select grinding wheels and accessories

Perform grinding operation o Grinding parallel and square surfaces

o Select grinding wheels and accessories

o Grinding to an angle surface

o Grinding parallel and square surfaces

o Grinding to radii

o Grinding to an angle surface

o Grinding to cut off parts

o Grinding to radii

Measures dimensions

o Grinding to cut off parts

Check surface texture

Measures dimensions

I agree to undertake assessment in the knowledge that information gathered will only be used for professional development purposes and

Check surface texture can only be accessed by concerned assessment personnel and my manager/supervisor.

I agree to undertake assessment in the knowledge that information gathered will only be used for professional development purposes and

can only be accessed by concerned assessment personnel and my manager/supervisor.

___________________________________ Date:

Candidate’s Name & Signature

___________________________________ Date:

Candidate’s Name & Signature Evaluated by:

Qualified for Assessment

Evaluated by: JOHNNY B. MATERUM

_______________________________

Qualified for Assessment AC Manager Not yet Qualified for Assessment

JOHNNY B. MATERUM

_______________________________ Date:

AC Manager Not yet Qualified for Assessment

Date:

TESDA-OP-QSO-02-F07

Rev.No.01-03/01/17

You might also like

- FMEA TemplateDocument28 pagesFMEA Templatekhawaja Ali100% (1)

- Welcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToDocument27 pagesWelcome To The FMEA Worksheet: This Spreadsheet Can Be Used Tolucas100% (2)

- CXC CSEC Information Technology January 2017 P2Document22 pagesCXC CSEC Information Technology January 2017 P2Jaleel Jones0% (1)

- RPMS KRA AutosavedDocument68 pagesRPMS KRA AutosavedMa'am Therese Bahandi Villanueva100% (5)

- 2 - Sag-New Format MnciiDocument1 page2 - Sag-New Format MnciiFerdinand De La FuenteNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- NSCL Recruitment 1Document9 pagesNSCL Recruitment 1thamizh555No ratings yet

- Notification NSCL Asst MT SR Trainee Other PostsDocument9 pagesNotification NSCL Asst MT SR Trainee Other Postsvineet chauhanNo ratings yet

- 18 LDC MTS Inspector Posts Advt Details Application Form IFB GoaDocument10 pages18 LDC MTS Inspector Posts Advt Details Application Form IFB GoaANJANEYULUNo ratings yet

- 2 - Sag-New Format MnciiiDocument1 page2 - Sag-New Format MnciiiFerdinand De La FuenteNo ratings yet

- Page 1 of 9Document9 pagesPage 1 of 9Pratima MondalNo ratings yet

- Page 1 of 9Document9 pagesPage 1 of 9अभिषेक मिश्राNo ratings yet

- Scientia®: Web Server For Course Planner™ - Universiti Teknologi PetronasDocument1 pageScientia®: Web Server For Course Planner™ - Universiti Teknologi PetronasHaziq MansorNo ratings yet

- Process SheetDocument8 pagesProcess SheetSuraj RawatNo ratings yet

- Welcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToDocument26 pagesWelcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToKailash PandeyNo ratings yet

- Engineering Change NoticeDocument30 pagesEngineering Change NoticeImam MansyurNo ratings yet

- MaulikDocument1 pageMaulikMaulikk PatelNo ratings yet

- Subject Distribution For EVen Term 2022-23Document1 pageSubject Distribution For EVen Term 2022-23Ravi EngineerpatelNo ratings yet

- FMEA Analysis MaintenanceDocument28 pagesFMEA Analysis MaintenanceBasit AliNo ratings yet

- Indian Army WorkshopDocument9 pagesIndian Army WorkshopAnonymous wbwmU9DSANo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Annex B Ipcr Form (New)Document2 pagesAnnex B Ipcr Form (New)Steph Dela MujerNo ratings yet

- Welcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToDocument7 pagesWelcome To The FMEA Worksheet: This Spreadsheet Can Be Used TonishantNo ratings yet

- Emergency Drill April 2022Document5 pagesEmergency Drill April 2022Zohaib TahirNo ratings yet

- Rev 02Document3 pagesRev 02Suraj RawatNo ratings yet

- Service Manual: DSC-F828Document2 pagesService Manual: DSC-F828Anonymous Lfgk6vygNo ratings yet

- Process Sheet: Rev. No. 01 (19/10/2015)Document6 pagesProcess Sheet: Rev. No. 01 (19/10/2015)Suraj RawatNo ratings yet

- Process Sheet: Part No.: Hub 1500629 (Annexure 1 To PCP 1500629E CP-08)Document5 pagesProcess Sheet: Part No.: Hub 1500629 (Annexure 1 To PCP 1500629E CP-08)Suraj RawatNo ratings yet

- Mains Cabinet BoardsDocument1 pageMains Cabinet BoardsKarthick BalakrishnanNo ratings yet

- Shining Projects - Milestone File - FY'21 - R3Document2 pagesShining Projects - Milestone File - FY'21 - R3Abhinav RaiNo ratings yet

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Document8 pagesCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarNo ratings yet

- Service Parts: Bulletin NoDocument2 pagesService Parts: Bulletin NoinqwalterNo ratings yet

- Daily Progress Drumshell 03.01.23Document3 pagesDaily Progress Drumshell 03.01.23kehlmathias07No ratings yet

- Daily Report: Embasy Renovation ProjectDocument3 pagesDaily Report: Embasy Renovation ProjectQuốc Hùng VũNo ratings yet

- 5001 Apr-19Document3 pages5001 Apr-19SUBIN EVNo ratings yet

- 2007-2008 Introduction To Business Bahacc1Document3 pages2007-2008 Introduction To Business Bahacc1C.U.Z. O.N.ENo ratings yet

- GM Process SheetDocument4 pagesGM Process SheetSuraj RawatNo ratings yet

- Boq Smartfren Med0169 - Simpang EmpatDocument2 pagesBoq Smartfren Med0169 - Simpang EmpatAlbert HamonanganNo ratings yet

- Jounral Bearing ExperimentDocument4 pagesJounral Bearing ExperimentMohsin IftikharNo ratings yet

- Commercial Bid FormDocument68 pagesCommercial Bid FormKasarachi AmadiNo ratings yet

- Final Job Plan Install Genset Last RevisionDocument2 pagesFinal Job Plan Install Genset Last RevisionAditya Permana PutraNo ratings yet

- Mahabal Manpower PlanningDocument4 pagesMahabal Manpower PlanningNitin KambleNo ratings yet

- P O S T (Post) : Ositive Perational Afety Arget Score CardDocument2 pagesP O S T (Post) : Ositive Perational Afety Arget Score CardekoimampNo ratings yet

- S-0000-13A0-101 B Specification For PaintingDocument6 pagesS-0000-13A0-101 B Specification For PaintingAgus Hendra PramujiNo ratings yet

- FMEA TemplateDocument23 pagesFMEA TemplateGurumoorthiNo ratings yet

- Fm-She-50 She Daily Report - r1Document1 pageFm-She-50 She Daily Report - r1Elfa ArrahmanNo ratings yet

- Road Name: Improvement of Narayanghat-Butwal Road Daily Work ProgramDocument1 pageRoad Name: Improvement of Narayanghat-Butwal Road Daily Work ProgramSuwash PaudelNo ratings yet

- Panel WorkshopDocument1 pagePanel WorkshopReza SyailendraNo ratings yet

- Daily Report TGL 23 Feb 23 Fab. Motor Test BenchDocument1 pageDaily Report TGL 23 Feb 23 Fab. Motor Test BenchNikmatullohNo ratings yet

- Team2B GBE KPO 4 001 00 Kaizen Template (Operations) Rev 05Document54 pagesTeam2B GBE KPO 4 001 00 Kaizen Template (Operations) Rev 05Peggy LeeNo ratings yet

- Project: Health Care Center at Ba - EydhafushiDocument25 pagesProject: Health Care Center at Ba - EydhafushiRenuka TekumudiNo ratings yet

- Adobe Scan 21-Dec-2023Document1 pageAdobe Scan 21-Dec-2023PRIYANSHU JAKHARNo ratings yet

- Monthly Details For The Month of October'21: Industrial Relation DepartmentDocument14 pagesMonthly Details For The Month of October'21: Industrial Relation DepartmentVFS GRASIMNo ratings yet

- Skill Map FormatDocument1 pageSkill Map FormatWendra HakaNo ratings yet

- 2022 2023eeDocument4 pages2022 2023eeIsmail HossainNo ratings yet

- FMEA - Design - TutorialDocument14 pagesFMEA - Design - TutorialTutis05No ratings yet

- Description: S / 4 HANA ContentDocument36 pagesDescription: S / 4 HANA ContentEnrique Israel Flores ZúñigaNo ratings yet

- FMC OffShore YZ Yard Weighting, Load Out, DeMobilization and Closing - Rev2Document5 pagesFMC OffShore YZ Yard Weighting, Load Out, DeMobilization and Closing - Rev2HELIO SANTOS JUNIORNo ratings yet

- Irussor - 2021 (Aor) 28 - 07 - 2022Document505 pagesIrussor - 2021 (Aor) 28 - 07 - 2022raja shekarNo ratings yet

- PERT View 2 - A3Document1 pagePERT View 2 - A3engrmasgharNo ratings yet

- Santa Ana Academy of Barili, Inc. H. Alquizola ST., Poblacion Barili, CebuDocument2 pagesSanta Ana Academy of Barili, Inc. H. Alquizola ST., Poblacion Barili, CebuEscabillas BenNo ratings yet

- Questions - The Story of My LifeDocument2 pagesQuestions - The Story of My Lifeapi-266661430No ratings yet

- E2030 Conceptual Framework Key Competencies For 2030Document24 pagesE2030 Conceptual Framework Key Competencies For 2030April Lei IrincoNo ratings yet

- JurnalDocument17 pagesJurnalBlank - CodeNo ratings yet

- Implementasi Metode Iqro' Dalam Pembelajaran Membaca Al-Qur'AnDocument11 pagesImplementasi Metode Iqro' Dalam Pembelajaran Membaca Al-Qur'AnCafe SastraNo ratings yet

- Women in Science WorksheetDocument2 pagesWomen in Science WorksheetJanna RickNo ratings yet

- Myers-Briggs Type Indicator (MBTI)Document15 pagesMyers-Briggs Type Indicator (MBTI)TattsunNo ratings yet

- Ness Wadia College of Commerce Pune - 1: NoticeDocument1 pageNess Wadia College of Commerce Pune - 1: NoticekushNo ratings yet

- Worksheet Homework Class3Document40 pagesWorksheet Homework Class3ashdayashdayNo ratings yet

- Grading Rubric For PowerPoint Presentation & Oral ReportingDocument2 pagesGrading Rubric For PowerPoint Presentation & Oral Reportingshiela mae ucangNo ratings yet

- Vaggione Archaeus 2002Document4 pagesVaggione Archaeus 2002CAStmNo ratings yet

- Metode Role Playing Terhadap Kemampuan Menyelesaikan Soal Cerita Matematika Siswa Tunarungu Kelas IiiDocument8 pagesMetode Role Playing Terhadap Kemampuan Menyelesaikan Soal Cerita Matematika Siswa Tunarungu Kelas IiiHaha HihiNo ratings yet

- MagnetismDocument8 pagesMagnetismsanober humairNo ratings yet

- Observation PaperDocument11 pagesObservation PaperemilytatarynNo ratings yet

- Mapeh (P.E) : Quarter 2.module NumberDocument3 pagesMapeh (P.E) : Quarter 2.module NumberJeannetteNo ratings yet

- Warragamba Dam and Township MapDocument2 pagesWarragamba Dam and Township MapRaveeNo ratings yet

- Izzat Faiz Johan: Data EngineerDocument2 pagesIzzat Faiz Johan: Data EngineerHamdani IlhamNo ratings yet

- Java Web ProgrammingDocument7 pagesJava Web ProgrammingShekhar SaudNo ratings yet

- TPN2601 Assignment 01 Student No 23450053Document5 pagesTPN2601 Assignment 01 Student No 23450053bradfordNo ratings yet

- Level 1 English, 2018Document12 pagesLevel 1 English, 2018Avneet KaurNo ratings yet

- Avid Site Team Plan 2014-2015Document7 pagesAvid Site Team Plan 2014-2015api-288788317No ratings yet

- Curriculum Interpretation and ImplementationDocument10 pagesCurriculum Interpretation and ImplementationHlatli Nia100% (1)

- Career in Marine BiologyDocument8 pagesCareer in Marine BiologyBasri IsmailNo ratings yet

- Resume Book One 2024Document38 pagesResume Book One 2024milk bearNo ratings yet

- Linguistics-Quiz and Compre-18-19 IDocument4 pagesLinguistics-Quiz and Compre-18-19 IDrishtantRaghavNo ratings yet

- Fact SheetDocument2 pagesFact Sheetapi-185962808No ratings yet

- Linux InstallationDocument55 pagesLinux InstallationAbhyudai YadavNo ratings yet

- Prof Ed Reviewer With AnswerDocument203 pagesProf Ed Reviewer With AnswerEdel Borden PaclianNo ratings yet

- Reflections - Week 2Document4 pagesReflections - Week 2api-298663101No ratings yet