Professional Documents

Culture Documents

TESDA Machining NC II Self-Assessment Guide

Uploaded by

Ferdinand De La FuenteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TESDA Machining NC II Self-Assessment Guide

Uploaded by

Ferdinand De La FuenteCopyright:

Available Formats

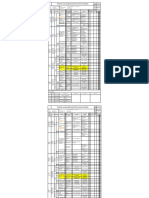

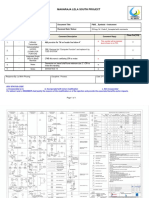

TESDA-OP-QSO-02-F07 TESDA-OP-QSO-02-F07

Rev.No.00-03/01/17 Rev.No.01-03/01/17

Reference No. MCG Reference No. MCG

to be filled out by the Processing Officer to be filled out by the Processing Officer

UNIQUE LEARNERS IDENTIFIER (ULI): UNIQUE LEARNERS IDENTIFIER (ULI):

- - - - - - - -

to be filled – out by the Processing Officer to be filled – out by the Processing Officer

SELF ASSESSMENT GUIDE SELF ASSESSMENT GUIDE

Qualification: MACHINING NC II Qualification: MACHINING NC II

Perform bench work (Basic and Complex) Perform bench work (Basic and Complex)

Turn workpiece (Basic and Intermediate) Turn workpiece (Basic and Intermediate)

Units of Competency Covered: Units of Competency Covered:

Mill workpiece (Basic and Intermediate) Mill workpiece (Basic and Intermediate)

Grind workpiece (Basic and Complex) Grind workpiece (Basic and Complex)

Instruction: Instruction:

Read each of the questions in the left-hand column of the chart. Read each of the questions in the left-hand column of the chart.

Place a check in the appropriate box opposite each question to indicate your answer. Place a check in the appropriate box opposite each question to indicate your answer.

Can I? YES NO Can I? YES NO

Wear PPE and observe safety procedures Wear PPE and observe safety procedures

Interpret drawings and sketches Interpret drawings and sketches

Know the different types and mechanical properties of engineering materials Know the different types and mechanical properties of engineering materials

Determine sequence of operations Determine sequence of operations

Calculate and set machine speed and feed Calculate and set machine speed and feed

Select and mount, aligned/centered and clamped workpiece Select and mount, aligned/centered and clamped workpiece

Select and set up cutting tools Select and set up cutting tools

Perform benchwork (e.g. laying out, chipping, filing, drilling, reaming, lapping, deburring, and Perform benchwork (e.g. laying out, chipping, filing, drilling, reaming, lapping, deburring, and

honing) honing)

Perform turning operations to produce components (e.g. facing and straight turning; cutting grooves; Perform turning operations to produce components (e.g. facing and straight turning; cutting grooves;

drilling and boring; knurling; cutting tapers by offsetting tailstock or using taper turning attachment; drilling and boring; knurling; cutting tapers by offsetting tailstock or using taper turning attachment;

and internal and external Vee and acme threads) and internal and external Vee and acme threads)

Perform milling operations to produce components (e.g. drilling, boring, reaming and spot-facing Perform milling operations to produce components (e.g. drilling, boring, reaming and spot-facing

holes; milling blocks, shoulder, parallel and angled faces; milling slots and keyways; milling holes; milling blocks, shoulder, parallel and angled faces; milling slots and keyways; milling

circular/radial slots; milling internal and external radii; milling splines and grooves; milling serrations circular/radial slots; milling internal and external radii; milling splines and grooves; milling serrations

on cylindrical workpiece; milling ratchets, spur gear and rack and plain bevel gear) on cylindrical workpiece; milling ratchets, spur gear and rack and plain bevel gear)

Perform grinding operations to produce components (e.g. grinding parallel and square surfaces, Perform grinding operations to produce components (e.g. grinding parallel and square surfaces,

angles, internal and external radii, tapers and recesses) angles, internal and external radii, tapers and recesses)

Check and measure workpiece using precision measuring instruments Check and measure workpiece using precision measuring instruments

Observe housekeeping Observe housekeeping

I agree to undertake assessment in the knowledge that information gathered will only be used for professional development purposes and I agree to undertake assessment in the knowledge that information gathered will only be used for professional development purposes and

can only be accessed by concerned assessment personnel and my manager/supervisor. can only be accessed by concerned assessment personnel and my manager/supervisor.

Date: ___________________________________ Date:

___________________________________

Candidate’s Name & Signature Candidate’s Name & Signature

Evaluated by: Evaluated by:

JOHNNY B. MATERUM

_______________________________ Qualified for Assessment JOHNNY B. MATERUM

_______________________________ Qualified for Assessment

AC Manager AC Manager

Not yet Qualified for Assessment Not yet Qualified for Assessment

Date: Date:

You might also like

- Process SheetDocument8 pagesProcess SheetSuraj RawatNo ratings yet

- Corrosion-Resistant Plastic Composites in Chemical Plant Design (Mallinson, John H) PDFDocument589 pagesCorrosion-Resistant Plastic Composites in Chemical Plant Design (Mallinson, John H) PDFGautam100% (1)

- 04 - Muse Ed - SR-02-0-PCB - 090327Document48 pages04 - Muse Ed - SR-02-0-PCB - 090327Moises PerelloNo ratings yet

- Boq Smartfren Med0169 - Simpang EmpatDocument2 pagesBoq Smartfren Med0169 - Simpang EmpatAlbert HamonanganNo ratings yet

- Job Safety Analysis Peondasi BangunanDocument14 pagesJob Safety Analysis Peondasi BangunanWahyu FebriantoNo ratings yet

- 2 - Sag-New Format MnciDocument1 page2 - Sag-New Format MnciFerdinand De La FuenteNo ratings yet

- Load Device Ecw-L220User ManualDocument28 pagesLoad Device Ecw-L220User ManualTadeo BenegusengaNo ratings yet

- Final Job Plan Install Genset Last RevisionDocument2 pagesFinal Job Plan Install Genset Last RevisionAditya Permana PutraNo ratings yet

- Monthly Details For The Month of October'21: Industrial Relation DepartmentDocument14 pagesMonthly Details For The Month of October'21: Industrial Relation DepartmentVFS GRASIMNo ratings yet

- 18 LDC MTS Inspector Posts Advt Details Application Form IFB GoaDocument10 pages18 LDC MTS Inspector Posts Advt Details Application Form IFB GoaANJANEYULUNo ratings yet

- Student Lab Work AssessmentDocument5 pagesStudent Lab Work AssessmentZul HaswalNo ratings yet

- EMAG Tutorial 2 - Coil Wrapped On Steel Core PDFDocument43 pagesEMAG Tutorial 2 - Coil Wrapped On Steel Core PDFSatadal DashNo ratings yet

- Subject Distribution For EVen Term 2022-23Document1 pageSubject Distribution For EVen Term 2022-23Ravi EngineerpatelNo ratings yet

- AF-SテレコンバーターTC-14E II/TC-17EII/TC-20E II: Nikon CorporationDocument12 pagesAF-SテレコンバーターTC-14E II/TC-17EII/TC-20E II: Nikon CorporationGeorgi GeorgievNo ratings yet

- AF-SテレコンバーターTC-14E II/TC-17EII/TC-20E II: Nikon CorporationDocument12 pagesAF-SテレコンバーターTC-14E II/TC-17EII/TC-20E II: Nikon CorporationGeorgi GeorgievNo ratings yet

- Tc20e II PDFDocument12 pagesTc20e II PDFGeorgi GeorgievNo ratings yet

- Rev 02Document3 pagesRev 02Suraj RawatNo ratings yet

- POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS (PFMEADocument3 pagesPOTENTIAL FAILURE MODE AND EFFECTS ANALYSIS (PFMEAaslamNo ratings yet

- Page 1 of 9Document9 pagesPage 1 of 9अभिषेक मिश्राNo ratings yet

- Page 1 of 9Document9 pagesPage 1 of 9Pratima MondalNo ratings yet

- Process Sheet: Part No.: Hub 1500629 (Annexure 1 To PCP 1500629E CP-08)Document5 pagesProcess Sheet: Part No.: Hub 1500629 (Annexure 1 To PCP 1500629E CP-08)Suraj RawatNo ratings yet

- West Bengal State Council of Technical & Vocational Education and Skill Development (Technical Education Division)Document44 pagesWest Bengal State Council of Technical & Vocational Education and Skill Development (Technical Education Division)Biswadeep Roy ChoudhuryNo ratings yet

- Process Sheet: Rev. No. 01 (19/10/2015)Document6 pagesProcess Sheet: Rev. No. 01 (19/10/2015)Suraj RawatNo ratings yet

- Pemurnian Rubrik Amali DEE30043 Sesi 2 TkiniDocument2 pagesPemurnian Rubrik Amali DEE30043 Sesi 2 TkiniIris HamzahNo ratings yet

- Mitsubishi Programmable Logic Controller AD51H-BASIC Programming ManualDocument688 pagesMitsubishi Programmable Logic Controller AD51H-BASIC Programming ManualTom SiriNo ratings yet

- ER_ModelDocument33 pagesER_Modelrajputajay0821No ratings yet

- BIOCHEMISTRY Course ListDocument10 pagesBIOCHEMISTRY Course Listthe598695No ratings yet

- EVAL-INAMP-ICF-RMZ User GuideDocument8 pagesEVAL-INAMP-ICF-RMZ User GuidehavocNo ratings yet

- FORM MASTER DATA MATERIAL 13 Mar 20 EMRDocument2 pagesFORM MASTER DATA MATERIAL 13 Mar 20 EMRM Iqbal AdmanNo ratings yet

- Sony BKM-14L BVM Auto Setup Probe Operation and Maintenance ManualDocument8 pagesSony BKM-14L BVM Auto Setup Probe Operation and Maintenance ManualJohnNo ratings yet

- MH - 6 Maintenance Manual For SelfejectorDocument98 pagesMH - 6 Maintenance Manual For Selfejectoralin_popovici_12No ratings yet

- Self-Assessment Guide: Hcsfho207-1009 Pho1O¿Iaphy !FLC I Hcspho207-1009 Photcg Aphy NC IiDocument2 pagesSelf-Assessment Guide: Hcsfho207-1009 Pho1O¿Iaphy !FLC I Hcspho207-1009 Photcg Aphy NC IiRonald ValenzuelaNo ratings yet

- HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U: Service ManualDocument22 pagesHVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U: Service ManualAndriamitantana ChristianNo ratings yet

- BA299FEN Liquicap M Fti 51 52 OMDocument80 pagesBA299FEN Liquicap M Fti 51 52 OMcassindromeNo ratings yet

- Comp B 60 DLDA Term Work Shashank RaiDocument51 pagesComp B 60 DLDA Term Work Shashank Raishashank raiNo ratings yet

- PDF Session Plan Carpentry Nc2 DLDocument3 pagesPDF Session Plan Carpentry Nc2 DLYeng LugtuNo ratings yet

- Boq Form 863275Document40 pagesBoq Form 863275kazisajib2021No ratings yet

- YEAR1Document22 pagesYEAR1ITI JammuNo ratings yet

- 1465270-Ir6570 SeriesDocument36 pages1465270-Ir6570 SeriesandiNo ratings yet

- GM Process SheetDocument4 pagesGM Process SheetSuraj RawatNo ratings yet

- Pearson Guarani Operator Training Certificate - GuilhermeDocument1 pagePearson Guarani Operator Training Certificate - GuilhermeFica a DicaNo ratings yet

- BN MLS 21 PTSC 307404 - Rev03 P&ID Symbols InstrumentDocument3 pagesBN MLS 21 PTSC 307404 - Rev03 P&ID Symbols InstrumentcitramuaraNo ratings yet

- Olympus IMT-2 Microscope - Service ManualDocument36 pagesOlympus IMT-2 Microscope - Service ManualMahnaz BakhshiNo ratings yet

- Brochure Wave NG ENGDocument2 pagesBrochure Wave NG ENGSamastha Nair SamajamNo ratings yet

- Daily Progress Drumshell 03.01.23Document3 pagesDaily Progress Drumshell 03.01.23kehlmathias07No ratings yet

- 610 Omn E-RomanianDocument315 pages610 Omn E-Romaniancristian godeanuNo ratings yet

- Jsa - Shut Down & Tie inDocument6 pagesJsa - Shut Down & Tie inLia Shagara82No ratings yet

- Overall Efficiency ExampleDocument1 pageOverall Efficiency Exampletru luu viNo ratings yet

- Qualifications Pack - Occupational Standards For Mining IndustryDocument37 pagesQualifications Pack - Occupational Standards For Mining IndustryChandan Chaman0% (1)

- Experiment No. 2Document5 pagesExperiment No. 2Ubair Javaid 16 (Game Play)No ratings yet

- Fitter-Ring-SpinningDocument54 pagesFitter-Ring-Spinninggizex2013No ratings yet

- S-090100-02FRM Daily Job Order (ENGINE) - SampleDocument4 pagesS-090100-02FRM Daily Job Order (ENGINE) - SampleasasasapoNo ratings yet

- 7-Tia Micro1 07e Bin OperatDocument23 pages7-Tia Micro1 07e Bin OperatFernando LeonNo ratings yet

- Lokesh Machines Ltd. Practical Skill Evaluation ReportDocument15 pagesLokesh Machines Ltd. Practical Skill Evaluation ReportSrihari Babu PeddiNo ratings yet

- 3574.07 Daily Report Period 20210428Document9 pages3574.07 Daily Report Period 20210428Irwan J. GuloNo ratings yet

- Kot Pindi Das Interchange Drainage & Erosion WorksDocument1 pageKot Pindi Das Interchange Drainage & Erosion WorksengrmasgharNo ratings yet

- Qualifications Pack - Occupational Standards For Textile SectorDocument44 pagesQualifications Pack - Occupational Standards For Textile SectorFarhana KabirNo ratings yet

- Basic Operation AL-840Document31 pagesBasic Operation AL-840Environ PrintersNo ratings yet

- Work System DesignDocument51 pagesWork System Designadarsh vemaliNo ratings yet

- The Control of Pinhole and Crack Defect On The Surface of Cold Heading Steel BilletDocument8 pagesThe Control of Pinhole and Crack Defect On The Surface of Cold Heading Steel Billetsantosh0301No ratings yet

- List of Explosion Proof EquipmentDocument75 pagesList of Explosion Proof EquipmentsandeepNo ratings yet

- Content Just in Time Backflush AccountingDocument1 pageContent Just in Time Backflush AccountingPANELA, Jericho F.No ratings yet

- ASTM B26-18 Aluminum-Alloy-Sand-CastingsDocument14 pagesASTM B26-18 Aluminum-Alloy-Sand-Castings오덕환Oh DuckhwanNo ratings yet

- BRC Brick ReinforcementDocument28 pagesBRC Brick ReinforcementantoninoNo ratings yet

- Report View of APDocument50 pagesReport View of APNURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- BTM Catalog Tog L Loc Tooling (Non 940)Document36 pagesBTM Catalog Tog L Loc Tooling (Non 940)Abrão GarciaNo ratings yet

- Scona TSPP 10213 GB TDS (En)Document2 pagesScona TSPP 10213 GB TDS (En)bsjaNo ratings yet

- QP A001 enDocument12 pagesQP A001 enzzzaNo ratings yet

- The Use of DRI in A Consteel® EAF Process: Iron and Steel Technology February 2015Document10 pagesThe Use of DRI in A Consteel® EAF Process: Iron and Steel Technology February 2015Alina StoroshchukNo ratings yet

- PI 024050 Agrifluid HT Plus ENDocument2 pagesPI 024050 Agrifluid HT Plus ENDex DexNo ratings yet

- E.2.2 Sheet Metal WorkingDocument18 pagesE.2.2 Sheet Metal WorkingMesfin SisayNo ratings yet

- Tapioplast: PropertiesDocument3 pagesTapioplast: PropertiesRoshni PattanayakNo ratings yet

- AIMOL Cement IndustryDocument57 pagesAIMOL Cement IndustryAdrianNo ratings yet

- APT Catalogo 2020Document46 pagesAPT Catalogo 2020Ivan HuertaNo ratings yet

- Company Contact Details ListDocument24 pagesCompany Contact Details Listmini nikNo ratings yet

- Akadi Products Business ProfileDocument17 pagesAkadi Products Business ProfileJayaprakash DNo ratings yet

- DS21Document3 pagesDS21vsdfsd258No ratings yet

- Walter Prototype Product Handbook Threading Walter ToolsDocument124 pagesWalter Prototype Product Handbook Threading Walter ToolsChristian MedelNo ratings yet

- Iso 9606-3-1999Document31 pagesIso 9606-3-1999NickolayNo ratings yet

- Naaz IndustriesDocument3 pagesNaaz IndustriesBV SafetyNo ratings yet

- TeksDocument1 pageTeksAjeng SafridaNo ratings yet

- Aluminum Profiles ALURAPID 167mm For Channel Letters - Partners LTDDocument2 pagesAluminum Profiles ALURAPID 167mm For Channel Letters - Partners LTDSalem SaleemNo ratings yet

- AE8603 Composite Materials and StructuresDocument3 pagesAE8603 Composite Materials and StructuresmuthugpalavesaNo ratings yet

- 30 Questions ESP Final Oral Test Part 1Document2 pages30 Questions ESP Final Oral Test Part 1lam lêNo ratings yet

- 400SS Field Glazed Installation ManualDocument75 pages400SS Field Glazed Installation ManualAmin SalahNo ratings yet

- M50 Energy Ver1 11-2007Document266 pagesM50 Energy Ver1 11-2007GAMM2003No ratings yet

- Dynamic Air ClassifiersDocument3 pagesDynamic Air Classifierskensley oliveiraNo ratings yet

- Cryogenic Hardening TreatmentDocument13 pagesCryogenic Hardening Treatmentkedar sharmaNo ratings yet