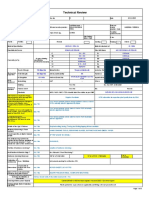

Format No.

:PDC-EPD-F16

Process Sheet Rev No. :00(03/04/15)

Issue No.:04(03/04/15)

(Annexure 1 to PCP 894172 528 CP-08)

Part No. : 894172528 GM FW Rev. No.: 03(11/05/2016) CNC Ist Set Up

Special Charecteristics

Inspector's

Operator's

Frequency for

Frequency for

DrawingB Recording in

Recording in Inspection Method for Inspector's Inspection

allooned Parameters Specifications In-Process

the log book Operator's Method for Line QC

No. Inspection

(QC-MCN-

Report (QC-

F10)

MCN-F02)

N/A Chuck Pressure ▼ 22 ± 2.0 Kg/Cm2 2/Shift Dial Indicator 2/Shift Dial Indicator

1 Inner Dia Ø 50.8 / 51.2 mm 100% SPG-74 35th PC SPG-74

Bore Gauge with Dial LC Bore Gauge with Dial LC

2 Inner Dia ▼ Ø95.000 / 95.040 mm 100% 10th PC

0.001 MSR-05-2 0.001 MSR-05-2

6 Outer Dia ▼ Ø271.30 / 271.40 mm 100% SG-32 with MSP-23 20th PC SG-32 with MSP-23

28 Depth ▼ 12.5 / 12.7 mm N/A N/A 35th PC Height Gauge

29 Depth ▼ 1.4 / 1.6 mm N/A N/A 50th PC Depth Vernier

30 Depth 6.80 / 7.20 mm 20th PC Depth Vernier 50th PC Depth Vernier

A3 Depth 14.00 / 14.10 mm N/A N/A 20th PC Depth Vernier

Operator's Specific Instructions :-

tk¡c dk ikVZ uacj gj ihl ij igyk (1st )lsVvi cukus ls igys fuEukuqlkj vafdr djs+a :-

1 o“kZ eghuk fnuk¡d # ikVZ ij mnkgj.k Lo:i

YY-15 A-M ( NO ' I ' ) 01-31 YY-M-DD-Sr. No 15-D-14-01

2 ikVZ cuus d¢ ckn mij¨Dr lkj.kh d¢ vuqlkj vkWijsVj lkbt+ ls pSd djd¢ ykWx cqd esa p<+k;s A

3

lHkh lkbt+ MªkWbax vuqlkj ik;s tkus d¢ i‘pkr~ diMs- ls cqjknk ,oa dwysaV lkQ djsa A fQj RPO yxk dj

fu/kkZfjr fcu@ isVh esa lqjf{kr #i ls j[kok;s A

Inspector's Specific Instructions :-

ykbu baLisDVj ykbu fujh{k.k djrs le; vkWijsVj dh dk;Z‘kSyh dk iw.kZr~: /;ku j[ksa v©j lqfuf‘pr djsa fd

%&

1 1½ vkWijsVj tk¡p lgh rjg ls dj jgk gS A

2½ ykWx cqd esa ,aVªh dj jgk gS A

2 vko`fr d¢ vuqlkj ikVZ pSd djsa rFkk In-Process Inspection Report (QC-MCN-F02) Hkjsa A

�Remark:- Reviewed on 03/05/2016. Rev 02 Due to change in Ring Fitment Process.

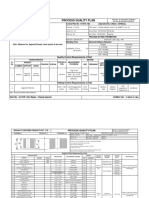

� Format No.:PDC-EPD-F16

Process Sheet

(Annexure 1 to PCP 894172 528 CP-09)

Rev No. : 00(03/04/15)

Issue No. : 04(03/04/15)

Part No. : 894172528 GM FW Rev. No.: 03(11/05/2016) CNC 2nd Set Up

Special Charecteristics

Inspector's

Operator's

Frequency for

Frequency for

DrawingB Recording in

Recording in Inspection Method for Inspector's Inspection

allooned Parameters Specifications In-Process

the log book Operator's Method for Line QC

No. Inspection

(QC-MCN-

Report (QC-

F10)

MCN-F02)

N/A Chuck Pressure ▼ 22 ± 2.0 Kg/Cm2 2/Shift Dial Indicator 2/Shift Dial Indicator

8 Outer Diameter Ø296.7 / 297.3 mm 20th PC Vernier Caliper 50th PC Vernier Caliper

31 Depth 61.9 / 62.1 mm 20th PC Depth Vernier 35th PC Depth Vernier

32 Depth 41.9 / 42.1 mm 20th PC Depth Vernier 35th PC Depth Vernier

36 Width 15.3 /15.7 mm 20th PC Micrometer 35th PC Micrometer

0.07 TIR MAX. with Ref. 100% Height Gauge with Dial LC

40 Parallelism ▼ 'C' on Ø225 mm

N/A N/A

(On Part) 0.001

50 Inne Diameter Ø234.5 / 235.5 mm N/A N/A 35th PC Vernier Caliper

Operator's Specific Instructions :-

tkWc d¢ igys (1st )lsVvi esa Mkys x;s uacj d¢ vuqlkj ykWx cqd esa ,aVªh djs+aA

1 mnkgj.k Lo:i

15-D-14-01

2 ikVZ cuus d¢ ckn mij¨Dr lkj.kh d¢ vuqlkj vkWijsVj lkbt+ pSd djd¢ ykWx cqd esa p<+k;s A

3

lHkh lkbt+ MªkWbax vuqlkj ik;s tkus d¢ i‘pkr~ diMs- ls cqjknk ,oa dwysaV lkQ djsa A fQj RPO yxk dj

fu/kkZfjr fcu@ isVh esa lqjf{kr #i ls j[kok;s A

Inspector's Specific Instructions :-

ykbu baLisDVj ykbu fujh{k.k djrs le; vkWijsVj dh dk;Z‘kSyh dk iw.kZr~: /;ku j[ksa v©j lqfuf‘pr djsa fd

%&

1 1½ vkWijsVj tk¡p lgh rjg ls dj jgk gS A

2½ ykWx cqd esa tkWc d¢ igys (1st )lsVvi esa Mkys x;s uacj d¢ vuqlkj ykWx cqd esa ,aVªh dj jgk gS A

2 vko`fr d¢ vuqlkj ikVZ pSd djsa rFkk In-Process Inspection Report (QC-MCN-F02) Hkjsa A

Remark:- Reviewed on 03/05/2016. Rev 02 Due to change in Ring Fitment Process.

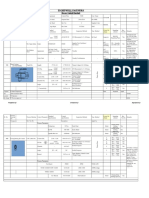

� Format No.:PDC-EPD-F16

Process Sheet

(Annexure 1 to PCP 894172 528 CP-10)

Rev No. : 00(03/04/15)

Issue No. : 04(03/04/15)

Part No. : 894172528 GM FW Rev. No.: 03(11/05/2016) VMC Set Up

Special Charecteristics

Inspector's

Frequency for

Drawing Operator's Recording in

Inspection Method for Inspector's Inspection

Ballooned Parameters Specifications Frequency for In-Process

Operator's Method for Line QC

No. Checking Inspection

Report (QC-

MCN-F02)

73 PCD Ø74.00 mm 100% Receiving Gauge-13 50th PC Receiving Gauge-13

75 PCD ▼ Ø251.00 mm 100% Receiving Gauge-09 50th PC Receiving Gauge-09

80 Drill Dia Ø13.5 mm 100% SPG-73 50th PC SPG-73

81 Tap & Pitch M8 X 1.25 100% TPG-09 50th PC TPG-09

82 Drill Dia ▼ Ø 5.974 / 5.988 mm 100% SPG-72 20th PC SPG-72

92 Depth 17.80 /18.20 mm 100% SPG-65 50th PC SPG-65

Operator's Specific Instructions :-

1 ikVZ cuus d¢ ckn mij¨Dr lkj.kh d¢ vuqlkj vkWijsVj lkbt+ pSd djsaA

2 ikVZ cuus d¢ ckn vkWijsVj viuk iap yxk;s A

3

lHkh lkbt+ MªkWbax vuqlkj ik;s tkus d¢ i‘pkr~ diMs- ls cqjknk ,oa dwysaV lkQ djsa djsa A fQj RPO

yxk dj fu/kkZfjr fcu@ isVh esa lqjf{kr #i ls j[kok;s A

Inspector's Specific Instructions :-

ykbu baLisDVj ykbu fujh{k.k djrs le; vkWijsVj dh dk;Z‘kSyh dk iw.kZr~: /;ku j[ksa v©j lqfuf‘pr djsa fd

%&

1

1½ vkWijsVj tk¡p lgh rjg ls dj jgk gS A

2½ vkWijsVj viuk iap yxk;s A

2 vko`fr d¢ vuqlkj ikVZ pSd djsa rFkk In-Process Inspection Report (QC-MCN-F02) Hkjsa A

Remark:- Reviewed on 03/05/2016. Rev 02 Due to change in Ring Fitment Process.