0% found this document useful (0 votes)

912 views6 pagesTraining Plan for Machining & Casting

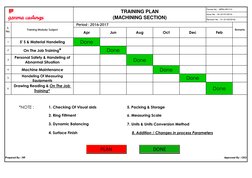

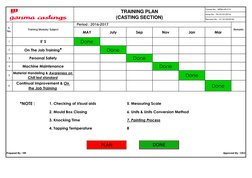

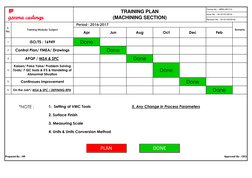

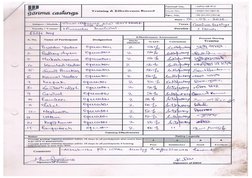

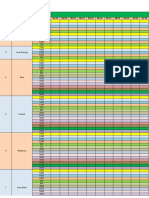

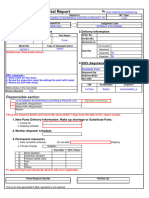

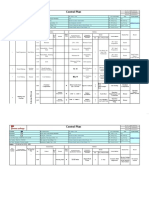

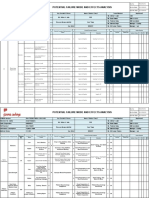

The document outlines training plans for machining and casting sections of a company for 2016-2017. It lists various training modules to be conducted each month, including 5S, machine maintenance, safety procedures, and on-the-job training. Notes at the bottom define additional topics to be covered in on-the-job training, such as tool setting, surface finish measurement, and process parameter changes. A second training plan details modules for a part number, conducted September to October 2016 and addresses operational topics by departmental staff.

Uploaded by

Suraj RawatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

912 views6 pagesTraining Plan for Machining & Casting

The document outlines training plans for machining and casting sections of a company for 2016-2017. It lists various training modules to be conducted each month, including 5S, machine maintenance, safety procedures, and on-the-job training. Notes at the bottom define additional topics to be covered in on-the-job training, such as tool setting, surface finish measurement, and process parameter changes. A second training plan details modules for a part number, conducted September to October 2016 and addresses operational topics by departmental staff.

Uploaded by

Suraj RawatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Machining Section Training Plan: Details the training schedule for the machining section, including modules like Material Handling and Machine Maintenance, with completion statuses.

- Casting Section Training Plan: Outlines the casting section's training timeline, featuring tasks such as On-The-Job Training and Machine Maintenance.

- Additional Machining Training: Presents further training plans for the machining section, including ISO/TS implementation and control plans.

- Training Modules Overview: Lists specific training modules, trainers, and remarks, indicating training focus and completion statuses.

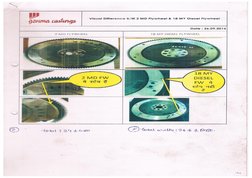

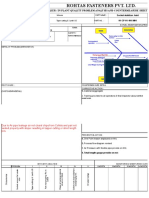

- Visual Differences in Flywheels: Compares different types of flywheels visually to identify differences pertinent to training

- Training Effectiveness Record: Records effectiveness assessments for training sessions, listing participants and feedback for improvements.