Professional Documents

Culture Documents

PIS - Jackfruit Processing - 1 Pager Sent

Uploaded by

Niemar AbaloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIS - Jackfruit Processing - 1 Pager Sent

Uploaded by

Niemar AbaloCopyright:

Available Formats

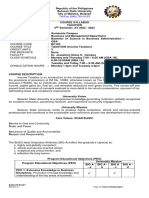

Name of Program Agency Contact Details

Industry Cluster Enhancement (ICE Department of Trade and Industry 0915-932-1582

Program)

RAPID Growth Project Department of Trade and Industry 0927-455-0104

Support on Planting materials (Grafted Department of Agriculture Regional Field

EVIARC) Office 8 0926-112-4196

DOST-SET-UP Department of Science and Technology 0921-315-5671

Regional Office 8

Agricultural Competitive Enhancement Land Bank of the Philippines (053)-832-7743

fund

PRE-INVESTMENT STUDY: COMMON SERVICE FACILITY

FOR JACKFRUIT PROCESSING

INTRODUCTION

Jackfruit, scientifically known as Artocarpus heterophyllius and locally known as “langka” or “Nangka” has been one of the

favorite fruits for consumption produced locally and widely in the Philippines.

In Eastern Visayas, the EVIARC Sweet Variety has been known for its quality and sweetness, less latex content and high thick edible

meat. The demand for this particular variety has been high for the purposes of processing particularly for vacuum-frying, dehydrating

and for depulping. Currently, the jackfruit industry in the Eastern Visayas is growing. Existing products includes vacuum-fried jackfruit,

dehydrated jackfruit, fresh frozen depulped jackfruit, jackfruit tarts and jackfruit juice. Major markets include “Pasalubong Centers”,

large retailers and direct consumers.

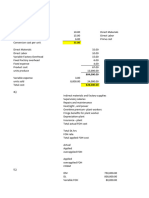

1. List

1. List

of of Tools/ Equipment

Machine/ Equipment and Tools Requirement 4. 4.

Indirect Material

Indirect Labor Requirement

Particular Unit Cost Quantity Total Annual Particular Unit Cost Quantity Total

Depreciation

Land 100,000.00 1 lot 100,000.00 Water 22.8 2.2 Cubic Meter 50.16

Building 400,000.00 1 unit 400,000.00 13333.33 Zonrox 28 4.4 Bottles 123.20

Dehydrator 400,000.00 1 unit 400,000.00 16000

Machine Dishwashing 250 1.1 Bottles 275.00

Moisture 115,000.00 1 unit 115,000.00 4600 Liquid

Analyzer Electricity 12 1440.923 kWh 17,291.08

pH Meter 50,000.00 1 unit 50,000.00 2000 Hairnet 350 1.32 box 462.00

Water Activity 90,000.00 1 unit 90,000.00 3600 Mask 150 2.64 boxes 396.00

Meter

LPG 790 1.48 Tank 1,171.73

Force Drop 15,000.00 1 unit 15,000.00 600

Oven Maintenance 1081.33 1 Month 1,081.33

Packaging and 500,000.00 1 unit 500,000.00 50000 Depreciation 9011.11 1 Month 9,011.11

Labelling

Machine Total 28,780.28

Stainless 50,000.00 1 lot 50,000.00 2000

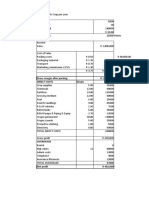

Table 5. Investment Requirement

Continuous 40,000.00 1 unit 40,000.00 8000 5. Total Project Cost

Band Sealer

Refractometer 20,000.00 1 unit 20,000.00 4000 Particular Total Sources

Equity Others

Analytic 20,000.00 1 unit 20,000.00 4000

Sources

Balance

2. List of Material Fixed Assets 1,800,000.0 720,000.0 1,080,000.0

0 0 0

Particular Unit Quantity Total Sources

Working Capital 157,989.61 157,989.61

Cost Materials

Matured 1232 22,176 Local Labor

Jackfruit 18.00 kilograms .00 Farmers Indirect Cost

Cooking 39.6 44,352 Cebu and Total Project Cost 1,957,989.61 877,989.61 1,080,000.00

Oil 1,120.00 containers .00 Local Cost Sharing 100% 45% 55%

Distributors Percentage

Total 66,528.00

6. Investment and Risk Analysis

3. Labor Requirement

Particular Rate Quantity Total

Investment Analysis

Production 7,700.00 4 Personnel 30,800.00 Payback Period- 4 months and 30 days

workers Average Net Profit Margin- 73%

Quality controller 7,700.00 1 Personnel 7,700.00 Internal Rate of Return- 286%

Production 7,700.00 1 Personnel 7,700.00 Simple Return on Investment- 290%

supervisor

Plant operators 7,700.00 2 Personnel 15,400.00 Socio Economic Impact

Total 61,600.00 Average Annual Income of Php 5,600,000.00

Personnel and laborers will be benefited thru salaries

The other value chain actors including logistics, other

raw material suppliers, retailers and distributors will also

benefit from this investment

You might also like

- Coffee Common Service Facility Boosts Local IndustryDocument2 pagesCoffee Common Service Facility Boosts Local IndustryNiemar AbaloNo ratings yet

- PIS - Coco Charcoal Briquette - 1 Page PresentationDocument1 pagePIS - Coco Charcoal Briquette - 1 Page PresentationNiemar AbaloNo ratings yet

- Financials AquaDocument7 pagesFinancials Aquajennifer bajoNo ratings yet

- Project Profile On Manufacturing of Palm PlateDocument9 pagesProject Profile On Manufacturing of Palm PlateGangaraboina Praveen MudirajNo ratings yet

- Fruit Juice Business PlanDocument7 pagesFruit Juice Business PlanOni SundayNo ratings yet

- Model Project ProfilesDocument7 pagesModel Project Profilesnitin pNo ratings yet

- Specifications of Equipmentand MaterialsDocument9 pagesSpecifications of Equipmentand MaterialsNHASSER PASANDALANNo ratings yet

- Fixed Capital and Working Capital BreakdownDocument4 pagesFixed Capital and Working Capital BreakdownNasiru029No ratings yet

- Master PDFDocument4 pagesMaster PDFNasiru029No ratings yet

- Sba AssignmentDocument8 pagesSba AssignmentjuniordelossantospenasNo ratings yet

- Fortified Rice IntroductionDocument14 pagesFortified Rice IntroductionkamalNo ratings yet

- ACN 202 Final ReportDocument10 pagesACN 202 Final ReportMohammed Nahiyan MollahNo ratings yet

- Term Report On Case Study: Farr Ceramics Production Division: A Budgetary AnalysisDocument11 pagesTerm Report On Case Study: Farr Ceramics Production Division: A Budgetary AnalysisShah Sadman HamidNo ratings yet

- FARM PLANNING AND DECISION - MAKING Final2Document16 pagesFARM PLANNING AND DECISION - MAKING Final2Ronelene GatoNo ratings yet

- Mafacga Procplan - WFP 9.21.17Document14 pagesMafacga Procplan - WFP 9.21.17ramiscaljancolinNo ratings yet

- Labong Ice CreamDocument15 pagesLabong Ice Creamdelacruzmarklloyd14No ratings yet

- Financial AssumptionsDocument15 pagesFinancial AssumptionsAngelica VinasNo ratings yet

- 7.1. Budgets Fo-WPS OfficeDocument1 page7.1. Budgets Fo-WPS OfficeAdam ZahoroNo ratings yet

- Acn 202Document10 pagesAcn 202Mohammed Nahiyan MollahNo ratings yet

- PIS - Jackfruit Production SentDocument1 pagePIS - Jackfruit Production SentNiemar AbaloNo ratings yet

- Manufacturing of Detergent Powder & CakeDocument2 pagesManufacturing of Detergent Powder & Cakeramu_uppadaNo ratings yet

- Projected Cost and ReturnDocument5 pagesProjected Cost and ReturnLeo EsmabeNo ratings yet

- Model Project ProfilesDocument6 pagesModel Project ProfilesSafir AhmedNo ratings yet

- Project Report To Set Up 10,000 Vanaraja Parents: SL - No. Particulars Total For 10,000Document5 pagesProject Report To Set Up 10,000 Vanaraja Parents: SL - No. Particulars Total For 10,000sohalsingh1No ratings yet

- Breakeven Point Analysis: Fix CostDocument7 pagesBreakeven Point Analysis: Fix CostKankanNguyenNo ratings yet

- Sanitary Land Fill Components 2000sq.m, at Brgy. PanansanganDocument5 pagesSanitary Land Fill Components 2000sq.m, at Brgy. PanansanganGayeGabrielNo ratings yet

- PT Go Green Indonesia - ReportDocument32 pagesPT Go Green Indonesia - ReportDenny SumantriNo ratings yet

- Marketing ChecklistDocument3 pagesMarketing ChecklistphilkoyosNo ratings yet

- Wilkerson ABC at CapacityDocument1 pageWilkerson ABC at CapacityTushar DuaNo ratings yet

- Financial Aspects Fixed Capital Working Capital Cost ProductionDocument3 pagesFinancial Aspects Fixed Capital Working Capital Cost Productionbiswajit1989285No ratings yet

- Intensive Tilapia Fish Farming Business PlanDocument10 pagesIntensive Tilapia Fish Farming Business PlanSaurav LamichhaneNo ratings yet

- Jacuzzi Bill of QuantitiesDocument2 pagesJacuzzi Bill of QuantitiesConstant Marlon CordialNo ratings yet

- Davao Del Norte - AlegroDocument51 pagesDavao Del Norte - AlegroJChris EsguerraNo ratings yet

- DismantleDocument4 pagesDismantlejepss1No ratings yet

- Sample Estimate With EquipmentsDocument27 pagesSample Estimate With EquipmentsHerwin AsuncionNo ratings yet

- Book 1Document15 pagesBook 1AmanuelNo ratings yet

- Gross Margin After Packing R 1,125,000 Direct Costs R/SQMDocument5 pagesGross Margin After Packing R 1,125,000 Direct Costs R/SQMTildonNo ratings yet

- COST ANALYSIS OF 3 PRODUCTS ACROSS 3 TERRITORIESDocument9 pagesCOST ANALYSIS OF 3 PRODUCTS ACROSS 3 TERRITORIESFAJAR Syahrulhaj ILMIYATULLOHNo ratings yet

- BOQ1Document7 pagesBOQ1Milo NuggetsNo ratings yet

- Chapter - V OriginalDocument15 pagesChapter - V OriginalBernadeth CiprianoNo ratings yet

- Particulars Units Unit Cost (RS) Total Cost (RS)Document3 pagesParticulars Units Unit Cost (RS) Total Cost (RS)ginish12No ratings yet

- PROJECT NAME: BROILER PRODUCTION (80,000 Birds - Capacity) LocationDocument26 pagesPROJECT NAME: BROILER PRODUCTION (80,000 Birds - Capacity) Locationapi-19753598No ratings yet

- Wilkerson Company Break Even Analysis for Multi-product SituationDocument5 pagesWilkerson Company Break Even Analysis for Multi-product SituationYAKSH DODIANo ratings yet

- Analisa Harga Satuan: Mobilisasi Dan Demobilisasi AlatDocument20 pagesAnalisa Harga Satuan: Mobilisasi Dan Demobilisasi AlatEva Siska SiregarNo ratings yet

- Production of Oxalic AcidDocument2 pagesProduction of Oxalic AcidnoviNo ratings yet

- Project Profile on Starting a Bakery BusinessDocument4 pagesProject Profile on Starting a Bakery BusinessKomma RameshNo ratings yet

- Project On Curry PowderDocument8 pagesProject On Curry PowderSrj SoorajNo ratings yet

- Financial PlanDocument13 pagesFinancial Planseleen16yahoo.comNo ratings yet

- Financial CisDocument17 pagesFinancial CisBritney Anne H. PasionNo ratings yet

- 16 Destinbrass - Solution-EnG YtcAIvEG2FDocument12 pages16 Destinbrass - Solution-EnG YtcAIvEG2Fshubhangi.jain582No ratings yet

- Midterm Cost Acctg CompilationDocument21 pagesMidterm Cost Acctg CompilationLesterAntoniDeGuzmanNo ratings yet

- FinancialDocument7 pagesFinancialMark RamosNo ratings yet

- Term Report On Case Study: Farr Ceramics Production Division: A Budgetary AnalysisDocument10 pagesTerm Report On Case Study: Farr Ceramics Production Division: A Budgetary AnalysisImranul GaniNo ratings yet

- Sattva Paints F-Plan FinalDocument44 pagesSattva Paints F-Plan FinalShrushti MehtaNo ratings yet

- Production Requirements For Combine Warehouse (Variable Cost) Production Requirements For Combine Warehouse (Fixed Cost) SR - NoDocument4 pagesProduction Requirements For Combine Warehouse (Variable Cost) Production Requirements For Combine Warehouse (Fixed Cost) SR - NoJoginder ChhikaraNo ratings yet

- Central University of Haryana: Project On Bakery ProductsDocument5 pagesCentral University of Haryana: Project On Bakery ProductsGovind JaatNo ratings yet

- Report EconomicoDocument10 pagesReport EconomicoMartin Torres RuedaNo ratings yet

- PANEER: A VERSATILE DAIRY PRODUCTDocument7 pagesPANEER: A VERSATILE DAIRY PRODUCTbuila ANo ratings yet

- Citra Dewi - 4112001008 - AM 4A Pagi - Study Case Chapter 4Document16 pagesCitra Dewi - 4112001008 - AM 4A Pagi - Study Case Chapter 4Citra DewiNo ratings yet

- Local Media7004600918096391891-3Document2 pagesLocal Media7004600918096391891-3Niemar AbaloNo ratings yet

- Raven Kay TDocument1 pageRaven Kay TNiemar AbaloNo ratings yet

- Cover LetterDocument1 pageCover LetterNiemar AbaloNo ratings yet

- 1 - Info Sheet English - Doc2Document7 pages1 - Info Sheet English - Doc2Niemar AbaloNo ratings yet

- Cbis CoverageDocument21 pagesCbis CoverageNiemar AbaloNo ratings yet

- M and E Planning WorkshopDocument1 pageM and E Planning WorkshopNiemar AbaloNo ratings yet

- BCP Roadmap LIFEDocument2 pagesBCP Roadmap LIFENiemar AbaloNo ratings yet

- Kakaw Chocolate Drink Incorporated MTCDocument6 pagesKakaw Chocolate Drink Incorporated MTCNiemar AbaloNo ratings yet

- PIS CacaoDocument2 pagesPIS CacaoNiemar AbaloNo ratings yet

- PIS - Jackfruit Production SentDocument1 pagePIS - Jackfruit Production SentNiemar AbaloNo ratings yet

- Suc CompreDocument1 pageSuc CompreNiemar AbaloNo ratings yet

- PIS - Coffee - Production - 1 - PGR SentDocument1 pagePIS - Coffee - Production - 1 - PGR SentNiemar AbaloNo ratings yet

- Republic Act No. 11210Document4 pagesRepublic Act No. 11210TinersNo ratings yet

- TriaDocument15 pagesTriasadeqNo ratings yet

- 04 - Slums and Informal Settlements: Study of Its Cause and EffectsDocument6 pages04 - Slums and Informal Settlements: Study of Its Cause and EffectsJC DoloritoNo ratings yet

- IPN Mexico School Marketing Strategy SWOT AnalysisDocument5 pagesIPN Mexico School Marketing Strategy SWOT AnalysisPedro ArroyoNo ratings yet

- 39 Different Types of Candlesticks PatternsDocument47 pages39 Different Types of Candlesticks Patternspritesh.tiwariNo ratings yet

- Alaska Milk Corporation - GroupWork 0928Document10 pagesAlaska Milk Corporation - GroupWork 0928Saxon D PinlacNo ratings yet

- Large Scale Behavioural Change: Viral Change™ Leandro HerreroDocument22 pagesLarge Scale Behavioural Change: Viral Change™ Leandro Herrerooscar moraNo ratings yet

- Specifications: Notes On The SpecificationsDocument2 pagesSpecifications: Notes On The SpecificationsSagar AcharyaNo ratings yet

- Case DigestsDocument48 pagesCase DigestsHazel Reyes-AlcantaraNo ratings yet

- SECRETS OF SELLING SUCCESSDocument30 pagesSECRETS OF SELLING SUCCESSventvmNo ratings yet

- Tata Motors Group Corporate Presentation 2023Document46 pagesTata Motors Group Corporate Presentation 2023Vikram KatariaNo ratings yet

- Bruh KitchenDocument1 pageBruh KitchenNur HanyNo ratings yet

- Accenture Ready Set Scale PDFDocument48 pagesAccenture Ready Set Scale PDFKristo SootaluNo ratings yet

- Ummary of Study Objectives: 96 The Recording ProcessDocument5 pagesUmmary of Study Objectives: 96 The Recording ProcessYun ChandoraNo ratings yet

- Specialized Expertise: Established Knowledge, Guiding You ThroughDocument6 pagesSpecialized Expertise: Established Knowledge, Guiding You ThroughOmar GuillenNo ratings yet

- Process Interaction: Plutofab Engineers Private LimitedDocument1 pageProcess Interaction: Plutofab Engineers Private LimitedRahul MenchNo ratings yet

- BF2 - AnswerDocument34 pagesBF2 - AnswerCherielee FabroNo ratings yet

- The Millionaire Real Estate InvestorDocument434 pagesThe Millionaire Real Estate InvestorKhafre Gold50% (2)

- FAR 1 - Journal EntriesDocument3 pagesFAR 1 - Journal EntriesAnime LoverNo ratings yet

- Business Development ServicesDocument10 pagesBusiness Development ServicesHaile SilasieNo ratings yet

- Pay Slip Details for Siddharth in September 2022Document1 pagePay Slip Details for Siddharth in September 2022SiddharthNo ratings yet

- Crisis Management Final Examination: "PT. Freeport Indonesia Big Gossan Collapsed"Document16 pagesCrisis Management Final Examination: "PT. Freeport Indonesia Big Gossan Collapsed"PavelBondarNo ratings yet

- BC 103. Taxation IncomeDocument8 pagesBC 103. Taxation Incomezekekomatsu0No ratings yet

- Startup Evolution Curve Excerpt 2017-05-31Document193 pagesStartup Evolution Curve Excerpt 2017-05-31LEWOYE BANTIENo ratings yet

- Chapter: Percentage Class WorkDocument6 pagesChapter: Percentage Class WorkRajat GuptaNo ratings yet

- Review of Literature on Solid Waste Management Methods and ImpactsDocument10 pagesReview of Literature on Solid Waste Management Methods and ImpactsIvy Joy UbinaNo ratings yet

- Assurance Certificate LevelDocument76 pagesAssurance Certificate Levelrubel khan100% (4)

- Contract of AgencyDocument2 pagesContract of Agencyjonel sembranaNo ratings yet

- Consent LetterDocument1 pageConsent LetterSai KiranNo ratings yet

- GENERALLY ACCEPTED ACCOUNTING PRINCIPLES Chapter - 3Document3 pagesGENERALLY ACCEPTED ACCOUNTING PRINCIPLES Chapter - 3RitaNo ratings yet