Professional Documents

Culture Documents

U-Frame action design according to Eurocodes

Uploaded by

VijayGokulavasan SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U-Frame action design according to Eurocodes

Uploaded by

VijayGokulavasan SCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/348269080

U-Frame action design according to Eurocodes

Article · January 2021

CITATIONS READS

0 1,349

1 author:

Ricardo Pimentel

Pell Frischmann

24 PUBLICATIONS 9 CITATIONS

SEE PROFILE

All content following this page was uploaded by Ricardo Pimentel on 06 January 2021.

The user has requested enhancement of the downloaded file.

TECHNICAL

U-Frame action design

according to Eurocodes

Ricardo Pimentel of the SCI discusses the consideration of U‐Frame action to restrain members

susceptible to flexural and lateral torsional buckling according to Eurocodes.

Introduction Structures such as portal frames[3],[4], multi-storey buildings with continuous

Buckling phenomena frequently govern the design of steel members under composite beams or arched bridges may also rely on U-frame action to provide

compression or for elements partially compressed. To achieve a good restraint against buckling.

compromise between steel tonnage and performance, discrete restraints along

the compressed member (or along the compressed part of the member) can be General advice and design principles

used. However, for certain cases, introducing restraints as part of an orthodox The stiffness of the U-frames is the key for the structural behaviour and

bracing system is not feasible and designers must use other options to achieve a design. Care must be taken not only while selecting the members sizes but

capable structural solution. The use of U-frame action offers this opportunity. also while undertaking the connections design and detailing.

Semi-rigid connections will decrease the stiffness of the U-frame, which in

U-Frame action general principles turn will decrease the stiffness of the point restraints and therefore the

The classic U-Frame action example can be found in “half-through” railway buckling resistance of the restrained elements. The joint stiffness

bridges[1],[2] or pedestrian bridges. The key concept of the U-frame action is classification can be assessed based on EN 1993-1-8[5]. The stiffness of semi-

illustrated in Figure 1a. The two longitudinal girders are subjected to a sagging rigid joints must be used while assessing the U-frame behaviour.

bending moment, which causes compression in the top flanges. At certain In addition to the stiffness of the elements forming the U-frame, the

locations along the bridge span, a continuous U-shaped frame is formed from resistance of the elements must also be checked including second order

the horizontal deck beams and vertical elements in the main girders – usually effects. Guidance on the design is provided in references [6], [7], [8] and [9].

full depth stiffeners welded to the web. There is a stiff connection between the The objective when considering U-frame action is to address the elastic

end of the deck beam and the vertical elements, so that an appropriate bending stability problem of the elements that are being restrained – typically the

stiffness between the vertical elements and the floor beams is achieved. The elastic critical buckling force for the compression element restrained by

flexural stiffness of the U-frame provides discrete spring restraints to the intermediate spring supports. Designers will then use typical buckling

compressed beam flanges. These elastic restraints increase the resistance of the resistance verifications based on buckling curves according to Eurocode 3.

girders to lateral torsional buckling. The same principle can be applied to a Even for U-frame action in composite structures, the lateral torsional

trussed solution (Figure 1b). If the vertical posts of the truss are connected to buckling resistance will still be based on the buckling curves from

the adjacent floor beam, the top compressed chords will have spring restraints, EN 1993-1-1[10] section 6.3.

which will increase the out-of-plane flexural buckling resistance of the chord.

The concepts described may be extended to other forms of construction based U-Frame action in composite structures

on the same principles. Typical UK composite practice assumes simply supported beams, which offers

Although the concept of U-frame action is often related to “half-through” a good compromise considering structural capacity, slab detailing and

railway bridges or pedestrian bridges, the concept may be also used when straightforward analysis and design. For certain cases – due to say high

designing conventional downstand composite bridge beams during the loading or atypical requirements for serviceability floor performance – a

construction stage or to prevent lateral torsional buckling of the compressed continuous solution may be utilised. The unrestrained steelwork of a

bottom flanges near the bridge internal supports. The typical configuration continuous composite beam experiences compression over the supports and

shown in Figure 1a may not suffice and bracing elements (typically forming a therefore is susceptible to local and member buckling. To avoid the

“K” shaped bracing arrangement) or haunched cross beam solutions may be unattractive practice of introducing restraints to the beam bottom flange,

provided to increase the stiffness and effectiveness of the restraints, to provide U-frame action may be considered, achieved by the combined behaviour of

an effective torsional bracing or simply to establish clear segments for the beam two adjacent parallel floor beams and the slab. The restraint to buckling is

buckling verification. based on the stiffness ks (Figure 2), which accounts for the stiffness of the

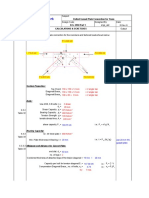

Figure 1: U-Frame action a) I-shaped girders – addressing lateral torsional buckling b) Trussed solutions – addressing flexural buckling

24 January 2021 NSC

TECHNICAL

beam web and the slab. The design is covered by Eurocode 4[11] and further beam supported by an elastic foundation, can be undertaken as follows, based

guidance on the buckling resistance of continuous composite beams can be on EN 1993-2 section 6.3.4.2 (6):

found in reference [12].

Ncrit = mNE Eq. (3)

where:

π2EI

NE = 2 , where L is the distance between rigid braces;

L

2

m= γ ≥ 1 where g = cL4/EI and c = Cd/l, in which l is the distance

π2

between U-frames.

From equation (3), the buckling length of the compressed member can be

Figure 2: U-Frame action in a continuous composite beam

obtained from:

π2EI

lcrit =

U-frame stiffness and design Ncrit

For the typical U-frame configurations such as the ones presented in Figure 1, Equation (3) assumes that the end frames are rigid, which will not be the

the stiffness Cd can be calculated from EN 1993-2[6] Table D.2 as follows: case for most practical cases. The influence of the flexibility of the supports may

be considered by replacing the variable “m” in Equation (3) by[14], [7]:

E Iv

Cd = γ

( )

hv 3 h2bqIv me =

π 0.69 2 , where X = Ce l3 0.25

3

+

2Iq ( +

2 X + 0.5 ) 2 Cd3EI

and Ce is the stiffness of the

Eq. (2) end frame according to equation (2).

The stiffness of the end supports will only have an influence in the design of

critical segments close to the supports. The influence of the stiffness of the

supports may be neglected for segments located at least 2.5 × lcrit from the

Figure 3: Generic model for U-frame stiffness calculation supports[7].

where: Design for flexural buckling according to Eurocode 3

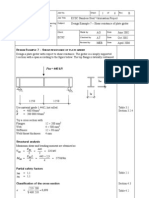

Iv is the second moment of area of the vertical stiffeners; Consider a 20 m span pedestrian bridge with two 1575 mm deep longitudinal

Iq is the second moment of area of the cross/horizontal member; warren trusses with additional vertical members as shown in Figure 4. The

ℎ is the distance between the centroid of the compressed flange and the trusses are 3 m apart and the verticals spaced at approximately 1.67 m. Five

centroid of the cross member; U-frames are provided in the structural solution: 2 end frames and 3 interior

ℎv is the distance between the centroid of the compressed flange and the top equally spaced frames (5 m between U-frames). The axial loads in the chords

of the cross member; are estimated as 550 kN at midspan. The design will be based on EN 1993-1-1

bq is the spacing of the main girders. section 6.3.2.4 (1) or EN 1993-2 6.3.4.2.

A hot finished SHS 150 × 150 × 6.3 was selected for the preliminary design,

Iv may be calculated assuming the contribution of a web width equal to ts + which gives a buckling resistance of 673 kN for a 5 m buckling length and

30 ε tw[13], where ts is the thickness of the vertical stiffener, tw is the thickness of gM1 = 1.10. The cross beams at U-frame locations have the same cross section

the web, ε = √(235 ⁄ fy,w) and fy,w is the yield strength of the web. If flange plates (SHS 150 × 150 × 6.3: I = 1220 cm⁴).

are welded to the vertical stiffeners, the inertia Iv can be calculated based on the

obtained equivalent “I” section. Higher stiffnesses can be achieved by specifying

two double “T” shaped stiffeners on each side of the main girder web, which can

each be cut from a standard “I” or “H” section. The stiffness of the connections

between cross beams and verticals may be accounted for in equation 2 by

adding the term ℎ²EIv/Sj in the denominator, where Sj is the stiffness of the

connection[2].

The assessment of U-frame stiffness may seem straightforward for the

orthodox configuration shown in Figure 3. However, for certain cases the

designer may wish to prepare a simple FE model from which the stiffness can be

calculated. The stiffness can be calculated by applying a pair of forces “F”

(Figure 3) in the U-frame, measuring the deflection at the tip of the flange and

dividing the load by the measured deflection. The stiffness (Cd) may then be

used to assess the elastic critical force of a top chord of a truss or for a

compressed flange of a beam susceptible to lateral torsional buckling. Figure 4: Trussed pedestrian bridge with 20 m span

The elastic critical buckling force can be calculated based on an analytical

approach or determined from FE models. The analytical approach, based on a The stiffness of the U-frames can be calculated as follows, using equation (2): ▸25

NSC January 2021 25

TECHNICAL

The benchmark buckling resistance of the chord assuming a buckling length

▸25 210 × 106 × 1220 × 10 -8

Cd = = 662.69 kN/m between U-frames is:

1.353 1.4252 × 3 × 1220 × 10 -8

+ π2 × 210 × 10⁶ × 1220 × 10 -8

3 2 × 1220 × 10 -8 NE,5m = = 1011.44 kN

52

A simple FE model with bar elements was completed to compare the It can be concluded that the U-frames are of benefit in restraining the chord

calculated U-frame stiffness. Rigid links were used to model the distance ℎv. if the end restraints were rigid, as the critical load (1165.44 kN) is higher in

Forces with opposite directions represent the critical mode (producing higher comparison with the value obtained (1011.44 kN) considering the distance

deflection). From the analysis results, the deflection is 1.507 mm under between U-frames for the chord buckling length.

opposing forces of 1 kN. The spring stiffness can be obtained as follows: As the end restraints are also U-frames (and therefore flexible), the values

1 calculated previously are not accurate. The flexibility of the end supports needs

Cd,FEM = = 663.57 kN/m which is very close to the value of

1.507 · 10 -3 to be considered as follows:

( )

662.69 kN/m previously calculated (See Fig. 5). 662.69 53 0.25

X= = 1.69 m

Having calculated the U-frame stiffness, the elastic critical force can be 2 662.69³ × 210 × 10⁶ × 1220 × 10-8

determined:

8277.16

Cd 662.69 me = = 14.13

c= = = 132.54 kN/m²

( 0.69

)

2

π

l 5 +

2 1.69 + 0.5

g = 132.54 × 20⁴/(210 × 10⁶ × 1220 × 10-8) = 8277.16

Ncrit = 14.13 × 63.21 = 893.50 kN

2

m= × 8277.16 = 18.44

π² The chord effective length can be back-calculated as follows:

π × 210 × 10⁶ × 1220 · 10

2 -8

NE = = 63.21 kN

20 2 π2 × 210 × 10⁶ × 1220 × 10 -8

lcrit = = 5.32 m

Ncrit = 18.44 × 63.21 = 1165.44 kN 893.50

Figure 5: U-Frame stiffness based on a simple FE model[17]

Nationwide delivery of all Structural Steel Sections

RAINHAM

Phone: 01708 522311 Fax: 01708 559024

MULTI PRODUCTS ARRIVE ON ONE VEHICLE

26 January 2021 NSC

TECHNICAL

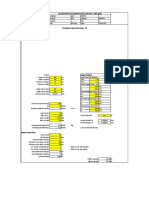

The buckling length is shown to be a little longer than the system length. More sophisticated analyses may be undertaken where the elastic critical

As an alternative approach, a FE model was also completed to evaluate the buckling load is obtained directly from 3D FE models. The designers must

elastic critical buckling load of the chord. The spring supports of 663.57 kN/m ensure that the internal bar releases and support conditions are correctly

were modelled (including end frames). The buckling shape obtained for the modelled to obtain a realistic behaviour of the structure. Such models may be

cord is represented in Figure 6. Each bar was subdivided in 10 segments for completed using bar elements or with shell elements. The elastic critical

accuracy[15],[16]. For simplicity, the axial load was considered constant along the buckling loads may differ from the more simplistic models due to the three-

chord, which is conservative. The analysis reports an elastic critical buckling dimensional structural behaviour. Shell element models can be also used to

resistance of Ncrit = 985.42 kN. more accurately obtain the U-frame stiffness as shown in Figure 5, which may

also include the stiffness of the connections. The simple model represented in

Figure 5 may also account for joint stiffness by including spring internal bar

releases at the joints.

Figure 6: Chord elastic critical buckling load - flexible supports[17]

10 FE per par. Critical multiplier: acrit = 985.42, Ncrit = 985.42 kN Design for lateral torsional buckling according to Eurocode 3

The effective length for the chord based on the FE analysis is therefore: To illustrate the process applied to an “I” beam, consider a half-through bridge

π2 × 210 × 10⁶ × 1220 × 10 -8 with a 42 m span. The main girders are spaced apart by 9 m. At a preliminary

lcrit = = 5.07 m

985.42 design stage, the top flanges were defined as 1000 × 120 mm plates, the bottom

A FE model was also completed to evaluate the impact of the axial load flanges 1500 × 70 mm and the webs 2810 × 20 mm. All plates were S460 (yield

gradient in the compressed chord. The results are shown in Figure 7. The model strength of 390 MPa for the top flange and 440 MPa for the web). The cross

with constant axial force shows a lower resistance, as the less stable end girders are spaced at 3.5 m centres along the bridge span and have a total depth

segments had a higher axial force. The analysis reports an elastic critical of 700 mm, a centroid at half depth and a major axis second moment of area of

buckling resistance of Ncrit = 1193.99 kN. 4.50 × 10⁹ mm⁴. The vertical “I”-shaped posts of the U-frame have a second

moment of area of 1.20 × 10⁹ mm⁴, which comprises a gusset of 400 × 15 mm

perpendicular to the web, an end plate of 425 × 40 mm and a web contribution

of √(235 ⁄ 440) × 30 × 20 + 15 = 453.50 mm.

Figure 7: Chord elastic critical buckling load - flexible supports with axial load gradient[17]

10 FE per par. Critical multiplier: acrit = 1193.99, Ncrit = 1193.99 kN

The new effective length for the chord based on the FE analysis is therefore:

π2 × 210 × 10⁶ × 1220 × 10 -8

lcrit = = 4.60 m

1193.99

Figure 8: Half-through bridge with plated girder worked example geometry

It can be concluded that both analytical and numerical approaches

show a good agreement. The chord member could then be checked against The challenge of the worked example is to check the main beam for lateral

EN 1993-1-1/EN 1993-2 rules for member stability using the back-calculated torsional buckling accounting for the contribution of the U-frame action

effective buckling length. provided by the cross beams and vertical stiffeners. The design will be ▸28

GRADES S355JR/J0/J2 Beams • Columns

STEEL

Channel • Angle

Flats • Uni Flats

Saw Cutting

Shot Blasting

Painting • Drilling

Head Office: 01708 522311 Fax: 01708 559024 Bury Office: 01617 962889 Fax: 01617 962921

Hot & Cold Structural

email: sales@rainhamsteel.co.uk www.rainhamsteel.co.uk Hollow Sections

Full range of advanced steel sections available ex-stock

NSC January 2021 27

TECHNICAL

▸27 undertaken based on EN 1993-1-1 section 6.3.2.4(1) / EN 1993-2 6.3.4.2. The 2. U-frame action may be used to provide elastic (spring) restraints to

process will be analogous to the one described in the previous worked example, elements which at first sight may look like an unrestrained component, such

but for this case an equivalent compression strut needs to be defined for the as a compressed chord susceptible to flexural buckling or a flange of a “I”

process. EN 1993-2 clause 6.3.4.2(7) states that the area of the equivalent strut girder susceptible to lateral torsional buckling;

may be assumed the area of the compressed flange plus 1/3 of the compressed 3. The stiffness of the connections between U-frame elements is important if

web area, accounting for the effective web area due to local plate buckling. The the stiffness of the U-frame is to be correctly calculated;

main beam cross section is class 4 under sagging bending moment due to the 4. U-frame action is used with elastic stability calculations, so that Ncrit and

slender web. The effective cross section area is represented in Figure 9. In this then l may be calculated for elements susceptible to flexural buckling.

example, the effective area of the equivalent strut is therefore Aeff = 1000 × 120 + 5. For members subject to lateral-torsional buckling, a non-dimensional

20 × (373.85 + 560.77) / 3 = 126230.80 mm². The equivalent strut out of plane slenderness lLT may be calculated.

second moment of area is based on the flange plate (ignoring the small 6. U-frame action can be accounted for by undertaking an analytical procedure

contribution of the web), which has a value of I = 1.0 × 1010 mm⁴. based on available guidance or based on a more general method using FE

According to Figure 3, the example comprises the following data: analysis; in the examples shown, a good agreement between the two

possible design routines was achieved.

Iv [mm⁴] 1.20 × 10⁹

Iq [mm⁴] 4.5 × 10⁹ References

[1] SCI P318 – Design Guide for Steel Railway Bridges, The Steel

hv[mm] 2065

Construction Institute, 2004;

h [mm] 2415

[2] SCI P185 – Guidance on best practice in steel bridge construction, The

bq[mm] 9000 Steel Construction Institute, 2015;

Cd [kN/m] 25367.74 [3] Brown, D., U-frames in bridges; New Steel Construction; 2018;

Ce [kN/m] 25367.74 [4] Horne, M. R. and Ajmani, J. L. Stability of columns supported laterally by

C [kN/m²] 7247.92 side rails International Journal of Mechanical Sciences. 11(2), 159-174.

g 10739.68 1969;

[5] BS EN 1993-1-8:2005, Eurocode 3: Design of steel structures. Design of

m 21.00

joints BSI, 2005;

X [m] 0.60

[6] BS EN 1993-2:2006, Eurocode 3. Design of steel structures. Steel bridges;

me 12.77

[7] PD 6695-2:2008, Recommendations for the design of bridges to BS EN

Ne [kN] 11749.53 1993, BSI, 2018.

Ncrit [kN] 150035.68 Figure 9 : Main beam effective area[18] [8] Hendy, C. R. and Murphy, C. J. Designers’ Guide to EN 1993-2. Eurocode

Aeff [mm²] 126230.80 3: Design of Steel Structures. Part 2: Steel bridges Thomas Telford

Publishing, London, 2007;

The normalized slenderness to calculate the lateral torsional buckling [9] SCI P 295 – Commentary on BS 5400-3: 2000 Code of practice for the

resistance of the girder can be calculated as follows – EN 1993-2 section design of steel bridges, The Steel Construction Institute, 2000;

9.3.4.2(4): [10] BS EN 1993-1-1:2005+A1:2014, Eurocode 3. Design of steel structures.

General rules and rules for buildings;

Aeff × fy 126230.80 × 390 × 10 -3

λLT = = = 0.57 [11] BS EN 1994-1-1:2004, Eurocode 4. Design of composite steel and

Ncrit 150035.68

concrete structures. General rules and rules for buildings;

As lLT > 0.20 the beam is susceptible to lateral torsional buckling. With the [12] Johnson, R. P. and Anderson, D. Designers’ Guide to EN 1994 1 1.

value of lLT , the buckling verification according to EN 1993-1-1 section 6.3 can Eurocode 4: Design of composite steel and concrete structures. Part 1.1:

be undertaken. General rules and rules for buildings, Thomas Telford Publishing,

Similar FE models could be used to evaluate the elastic critical buckling London, 2004;

resistance as described for the previous pedestrian bridge worked example. [13] BS EN 1993-1-5:2006, Eurocode 3: Design of steel structures. Plated

The calculations presented above assume that the flange is subjected to a structural elements BSI, 2006;

constant bending moment. The bending moment gradient for the segment [14] BS 5400-3:2000 Steel, concrete and composite bridges. Code of practice

under analysis may be allowed for according to EN 1993-2 section 6.3.4.2 (7) for design of steel bridges, BSI, 2006;

Note. [15] Pimentel, R., Stability and second order of steel structures: Part 1:

For the cases where the concrete deck is effectively connected to the beam fundamental behaviour; News Steel Construction; vol 27 No 3 March

webs, the stiffness Iq may be considered as the second moment of area of the 2019;

deck (see reference [12]) and Iv = tw³/12(1 − v2), where v is Poisson’s ratio[19]. [16] Pimentel, R., Stability and second order of steel structures: Part 2: design

according to Eurocode 3; New Steel Construction; vol 27 No 4 April 2019;

Conclusions [17] Autodesk Robot Structural Analysis 2020

1. U-frame action is present in many forms of construction, from single- and [18] Z4 1.0.2, CTICM

multi-storey buildings to bridges, related with steel or composite [19] SCI P360 – Stability of steel beams and columns, The Steel Construction

structures; Institute, 2011

28 January 2021 NSC

View publication stats

You might also like

- Builders Guide To TrussesDocument48 pagesBuilders Guide To TrussesSimjan D. FloresNo ratings yet

- Crash Analysis Assignment 1Document18 pagesCrash Analysis Assignment 1Duc TuNo ratings yet

- Design for Connection to Wall in 38 CharactersDocument2 pagesDesign for Connection to Wall in 38 Charactersjklo12No ratings yet

- 2015 WFCMDocument326 pages2015 WFCMCollin100% (2)

- Engineering Consultants Group: Project Name Job Ref. Calc. by Date DateDocument3 pagesEngineering Consultants Group: Project Name Job Ref. Calc. by Date DateHarjasa AdhiNo ratings yet

- Pipeline Radial Bend Forces and Anchor Block DesignDocument2 pagesPipeline Radial Bend Forces and Anchor Block DesignSaqib LaeeqNo ratings yet

- Statics (Joint Method) PDFDocument69 pagesStatics (Joint Method) PDFSteven Dominic AballeNo ratings yet

- Load Calculation For Portal Framed Shed With Wind Asce 7-10Document10 pagesLoad Calculation For Portal Framed Shed With Wind Asce 7-10msb100% (1)

- PurlinDocument13 pagesPurlinadliNo ratings yet

- Structural Analysis and Design Report GigacreteDocument50 pagesStructural Analysis and Design Report GigacreteKristel de GuzmanNo ratings yet

- Structural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchesDocument4 pagesStructural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchessitheeqNo ratings yet

- Design Manual For Structural Stainless Steel Design Example 7 enDocument6 pagesDesign Manual For Structural Stainless Steel Design Example 7 enAl7amdlellah100% (1)

- Batteries 07 00063 v2Document28 pagesBatteries 07 00063 v2ismoyoNo ratings yet

- Boat ImpactDocument5 pagesBoat ImpactStephen KokoNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationMohamed NkNo ratings yet

- Designed Job No Checked Contract Conn - No Rev 0 Date Code For Maximum Moment Mz-Case - P2Document12 pagesDesigned Job No Checked Contract Conn - No Rev 0 Date Code For Maximum Moment Mz-Case - P2kyatoor prashanthNo ratings yet

- Ground Floor Slab Design CalculationsDocument7 pagesGround Floor Slab Design CalculationsArindam RoyNo ratings yet

- PM Team Reviews Padeye Design for Loading Arm ProjectDocument10 pagesPM Team Reviews Padeye Design for Loading Arm ProjectCésar Cristóbal Pino GuzmánNo ratings yet

- Roofing Plans PDFDocument18 pagesRoofing Plans PDFAilyn TanNo ratings yet

- Auld 1979Document16 pagesAuld 1979inge ocNo ratings yet

- ShearDocument16 pagesShearyadav04_abhishekNo ratings yet

- A2-Pile Calculation - BH M1Document90 pagesA2-Pile Calculation - BH M1Priya GopalNo ratings yet

- 2020 LEC 3 Deep FoundationDocument135 pages2020 LEC 3 Deep FoundationSky FireNo ratings yet

- Section 2 - S878FU4 SOW 42 Inch Conductor Casing - Existing Topside DeckDocument246 pagesSection 2 - S878FU4 SOW 42 Inch Conductor Casing - Existing Topside DeckErnesto FariasNo ratings yet

- Ch102x51 - Moment Connection-Fm Panel PlatformDocument40 pagesCh102x51 - Moment Connection-Fm Panel PlatformPriya GopalNo ratings yet

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document23 pagesIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul Aggarwal100% (1)

- Bolted Field Splices For Steel Bridge Flexural Members OverviewDocument78 pagesBolted Field Splices For Steel Bridge Flexural Members OverviewJeisson CastilloNo ratings yet

- Sample 2Document1 pageSample 2Mustapha Rojo Sakali100% (1)

- Purlin Structure Design PDFDocument28 pagesPurlin Structure Design PDFrammohanNo ratings yet

- 000-GD-C-002 R.2 Civil & Structural DesignDocument16 pages000-GD-C-002 R.2 Civil & Structural DesignJavier PachariNo ratings yet

- MODULE 6 - (Laterally Supported Beams)Document31 pagesMODULE 6 - (Laterally Supported Beams)Tobi100% (1)

- Problems of Chapter 1: Construction DepartmentDocument2 pagesProblems of Chapter 1: Construction DepartmentAbdulaziz Mohamed100% (1)

- 17RIT-139 Baseplate and Stiffener Check R0 060418Document4 pages17RIT-139 Baseplate and Stiffener Check R0 060418pennacchiettiNo ratings yet

- Example 1: Single-Anchor Fastening Close To Two Edges of A ColumnDocument8 pagesExample 1: Single-Anchor Fastening Close To Two Edges of A Columnproteor_srlNo ratings yet

- ACP036-RP-ST-002 - Lashing Calculation Report - Rev ADocument22 pagesACP036-RP-ST-002 - Lashing Calculation Report - Rev AThomas StephenNo ratings yet

- Calculation of Crack Width As Per Is:456-2000Document4 pagesCalculation of Crack Width As Per Is:456-2000Gautam DuttaNo ratings yet

- 3 - Force Method (Analysis of Frames)Document11 pages3 - Force Method (Analysis of Frames)Mohammad AliNo ratings yet

- Effective LengthsDocument8 pagesEffective Lengthsberto2008No ratings yet

- Fischer WhitepaperDocument20 pagesFischer WhitepaperLucas MateusNo ratings yet

- Seismic Load Calculation Input Data:: (As Per The Specification, 301 Structural Loading and Forces)Document16 pagesSeismic Load Calculation Input Data:: (As Per The Specification, 301 Structural Loading and Forces)Asaru DeenNo ratings yet

- Beam Deflections and Stresses During Lifting PDFDocument10 pagesBeam Deflections and Stresses During Lifting PDFManoj KumarNo ratings yet

- 29 CFR Part 1926 Subpart E (Up To Date As of 2-08-2023)Document16 pages29 CFR Part 1926 Subpart E (Up To Date As of 2-08-2023)Amr EssamNo ratings yet

- Cantilever Diaphragm Wall, English Units (DeepEX 2015)Document14 pagesCantilever Diaphragm Wall, English Units (DeepEX 2015)yin hoe ongNo ratings yet

- Shear Verification For Shear Walls ACI 318-08Document9 pagesShear Verification For Shear Walls ACI 318-08Joseph AsfourNo ratings yet

- 11099-EnG-I-IW-PI-MR-0142-7 MR - Fire Hydrants and Fire Hose Cabinets v1Document43 pages11099-EnG-I-IW-PI-MR-0142-7 MR - Fire Hydrants and Fire Hose Cabinets v1SachinDivateNo ratings yet

- UPDATED BOQ-Temporary Facilities 14.03.2022 Abtal AlfuratDocument23 pagesUPDATED BOQ-Temporary Facilities 14.03.2022 Abtal AlfuratMohammad A. AliNo ratings yet

- 3 - Timber-Screwed Connections - Kerto ManualDocument29 pages3 - Timber-Screwed Connections - Kerto ManualJulianNo ratings yet

- 2cbd7ebb8045d471a2170aea91a0b136Document15 pages2cbd7ebb8045d471a2170aea91a0b136Tedi RustandiNo ratings yet

- EG0222032301 Solar Carport Mounting System-Area A ASCE 7-10) - 10x21Document20 pagesEG0222032301 Solar Carport Mounting System-Area A ASCE 7-10) - 10x21SalauddinAnsariNo ratings yet

- Refinery-Engineering Design Basis For Civil-IOCL-2022Document199 pagesRefinery-Engineering Design Basis For Civil-IOCL-2022SRINIVASAN TNo ratings yet

- LATEST EPPM4014 ASSG3 Case Analysis GroupingDocument36 pagesLATEST EPPM4014 ASSG3 Case Analysis GroupingSANTHIANo ratings yet

- 2023 BSSF Middle School Inter School Sports ResultsDocument31 pages2023 BSSF Middle School Inter School Sports ResultsBernewsAdminNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarNo ratings yet

- Appendix A Example 10 - Sign Structure Foundation Design: General InformationDocument14 pagesAppendix A Example 10 - Sign Structure Foundation Design: General InformationSabreena NasrinNo ratings yet

- ATT MasTec Stamped SA Capitan NM 85ft AFS1700Document41 pagesATT MasTec Stamped SA Capitan NM 85ft AFS1700kaysheph100% (1)

- 1 1Document1 page1 1jasekan.dcNo ratings yet

- Evoking 21 - Century Skills: Developing Instrument of Critical Thinking Skills and Mastery of Ecosystem ConceptsDocument15 pagesEvoking 21 - Century Skills: Developing Instrument of Critical Thinking Skills and Mastery of Ecosystem ConceptsDiyan SariNo ratings yet

- Foundation Failure and Instability of An Offshore Jecket Structure-Case StudyDocument13 pagesFoundation Failure and Instability of An Offshore Jecket Structure-Case StudyJaimurugan KNo ratings yet

- Comparision IS VS EURO PDFDocument7 pagesComparision IS VS EURO PDFRadhaKrishnanTNo ratings yet

- Chapter 9 Rigid Pavement Design) AAshto93Document64 pagesChapter 9 Rigid Pavement Design) AAshto93Thada JaemtimNo ratings yet

- Design of SlabsDocument42 pagesDesign of SlabsMuralidargouda BhagavantagoudarNo ratings yet

- Overhead Cranes Mechanical Data SheetDocument9 pagesOverhead Cranes Mechanical Data SheetMohammad AminiNo ratings yet

- Gulfpub Wo 202204Document62 pagesGulfpub Wo 202204giovanniNo ratings yet

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- T ND 000123000000000000 NRL 02301Document19 pagesT ND 000123000000000000 NRL 02301nourooziNo ratings yet

- PC162 Kingpost Marine CraneDocument2 pagesPC162 Kingpost Marine Craneo_tostaNo ratings yet

- 24 - Earthquake Codes and Design in Canada... A.C. HeidebrechtDocument34 pages24 - Earthquake Codes and Design in Canada... A.C. HeidebrechtPrashant MuleNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- Example Calculation Stability PontoonDocument1 pageExample Calculation Stability PontoonAleks VNo ratings yet

- U-Frame Action Design According To EurocodesDocument5 pagesU-Frame Action Design According To Eurocodessayak banerjeeNo ratings yet

- U-Frame - David ChildDocument6 pagesU-Frame - David ChildVijayGokulavasan SNo ratings yet

- FPL 1309ocrDocument18 pagesFPL 1309ocrVijayGokulavasan SNo ratings yet

- 84734459Document1 page84734459Sree Arvind Harish SomasundaramNo ratings yet

- New Unified Concrete Code - Irc 112-2011Document17 pagesNew Unified Concrete Code - Irc 112-2011sujupsNo ratings yet

- Finite Element AnalysisDocument3 pagesFinite Element AnalysisVijayGokulavasan SNo ratings yet

- Progressive Collapse Jon VJDocument22 pagesProgressive Collapse Jon VJVijayGokulavasan SNo ratings yet

- Indian Standard (Second Revision) : Specification For Paper SizesDocument13 pagesIndian Standard (Second Revision) : Specification For Paper SizesVijayGokulavasan SNo ratings yet

- 8' X 20' Frame: Typical Profiles & AccessoriesDocument4 pages8' X 20' Frame: Typical Profiles & AccessoriesKen SuNo ratings yet

- Fascia Frame Details: Foundation PlanDocument1 pageFascia Frame Details: Foundation PlanRod NajarroNo ratings yet

- TM5 551BDocument200 pagesTM5 551Bdamanripu30No ratings yet

- Two-Way Slab Design WorksheetDocument69 pagesTwo-Way Slab Design WorksheetJule LobresNo ratings yet

- Re-Construction of Belabo Community Clinic at Amdia Union (Ward No03 Old) in Sadar Upazila Under Narsingdi District.Document31 pagesRe-Construction of Belabo Community Clinic at Amdia Union (Ward No03 Old) in Sadar Upazila Under Narsingdi District.Shafiqul islamNo ratings yet

- Steel Roof Truss OptimizationDocument98 pagesSteel Roof Truss OptimizationNadya ChandraNo ratings yet

- Proposed 11 Unit Townhouse Ceiling EnclosureDocument6 pagesProposed 11 Unit Townhouse Ceiling EnclosureRoy Niňo Abadijos MallanaoNo ratings yet

- Canopy 37Document7 pagesCanopy 37ganesh patilNo ratings yet

- Thermal effects in fluid film bearingsDocument2 pagesThermal effects in fluid film bearingsSergeyGalkinNo ratings yet

- Front Elevation Right Side Elevation Left Side ElevationDocument1 pageFront Elevation Right Side Elevation Left Side ElevationQueenie Marie IlangosNo ratings yet

- Beam DesignDocument29 pagesBeam DesignMwengei MutetiNo ratings yet

- BridgeDocument25 pagesBridgeGokul GklNo ratings yet

- Building Weather Cathedral Stadium Dwellings Rain Heat Sunlight Wind Conservatory VerandahDocument24 pagesBuilding Weather Cathedral Stadium Dwellings Rain Heat Sunlight Wind Conservatory Verandahdudynayn100% (1)

- E. SolutionDocument4 pagesE. SolutionRICHELLE NESTORNo ratings yet

- Working Platform For Installing and Dismantling Aluminum Formwork PDFDocument9 pagesWorking Platform For Installing and Dismantling Aluminum Formwork PDFmohd zulhafizNo ratings yet

- Long Span Trusses - SalahuddinDocument11 pagesLong Span Trusses - SalahuddinSalahuddin ShaikhNo ratings yet

- Assignment 1 PDFDocument3 pagesAssignment 1 PDFJunevee AmaranteNo ratings yet

- Wood JoistDocument36 pagesWood JoistKenny SanchezNo ratings yet

- The bending moment at section x-x is:MA = -P1x + P2(L-x)= -P1x + P2L - P2x= (P2 - P1)x + P2LSo the bending moment is (P2 - P1)x + P2LDocument42 pagesThe bending moment at section x-x is:MA = -P1x + P2(L-x)= -P1x + P2L - P2x= (P2 - P1)x + P2LSo the bending moment is (P2 - P1)x + P2LTshepiso NthiteNo ratings yet

- Laboratory: Timber DesignDocument53 pagesLaboratory: Timber DesignMark Kevin C. PingolNo ratings yet