Professional Documents

Culture Documents

Qap B7M - 2HM

Uploaded by

JJ VAPIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qap B7M - 2HM

Uploaded by

JJ VAPICopyright:

Available Formats

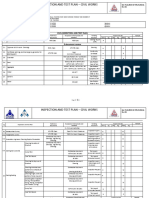

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-002 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B7M/ SA-194 GR 2HM BOLTING MATERIAL

A. Scope : This Inspection and test plan covers the minimum testing requirements for SA-193 Gr B7M/

SA-194 Gr 2HM bolting material

B. Reference Docs : Standard- ASME BPVC sec IIA- SA-193 Gr B7M/ SA-194 Gr 2HM / PO/PR/ Job specifications

and approved documents.

Inspection & Test Requirements for Manufacturer

Scope of

Reference inspection

Sl Characteristics/ Type Quantum of

Stage/ Activity standard/ Record

No of check check Supplie

Acceptance Norms TPIA

r

Test H H

Marking and ASME BPVC sec IIA-

Raw material certificate,

1 correlation with test 100% SA193 Gr B7M/ SA

inspection inspection

certificate 194 Gr 2HM

report

Chemical composition ASME BPVC sec IIA- R R

one sample Inspection

/ Macro/ Mechanical SA193 Gr B7M/ SA

per heat report

Raw material Properties 194 Gr 2HM

2

inspection ASME BPVC sec IIA- H H

Inspection

Spectro analysis 100% SA193 Gr B7M/ SA

report

194 Gr 2HM

Inspection R R

Heat treatment cycle ASME BPVC sec IIA- report/

100%

3 Heat treatment (time and SA193 Gr B7M/ SA Heat

temperature) 194 Gr 2HM treatment

charts

Thread Rolling, ASME BPVC sec IIA- H H

In Process Inspection

4 Forging Of Nuts, 100% SA193 Gr B7M/ SA

Inspection report

Machining 194 Gr 2HM

Heat of R R

material/ ASME BPVC sec IIA-

Selection of Inspection

5 Test piece marking Heat SA193 Gr B7M/ SA

samples report

treatment 194 Gr 2HM

charge/size

As per PO/ASME H H

Nondestructive BPVC sec IIA- SA193 Inspection

6 Hardness Testing 100%

testing Gr B7M/ SA 194 Gr report

2HM / ASME Sec V

Mechanical properties ASME BPVC sec IIA- R R

Destructive One sample Inspection

7 YS, UTS, RA, SA193 Gr B7M/ SA

testing per heat report

Elongation ,Proof Load 194 Gr 2HM

As per PO/ASME H H

BPVC sec IIA- SA193

Positive material

Gr B7M/ SA 194 Gr

8 PMI identification (only for 100% PMI report

2HM

AS & SS components)

As Per EIL Spec. 6-

81-0001

Visual marking, colour 100% by As per PO/ H H

coding and supplier and Stamping Of Inspection

9 Final inspection

dimensional check, at random Accepted Bolting report

Final Stamping by TPIA Material

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 2 of 4

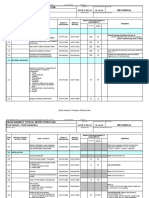

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-002 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B7M/ SA-194 GR 2HM BOLTING MATERIAL

Scope of

Reference inspection

Sl Characteristics/ Type Quantum of

Stage/ Activity standard/ Record

No of check check Supplie

Acceptance Norms TPIA

r

100% by H H

Verification of

Coating (If supplier and As per PO / PR / Inspection

10 galvanized coating &

Applicable) at 10% by Applicable Standard report

galvanizing thickness

TPIA

Test W W

Verification of

certificate

material test As per PO / PR /

Documentation (EN 10204

11 certificate, test report, 100% Material

& Release 3.2),

inspection reports & specification

Reports,

Issue of Release Note

IRN

Inspection & Test Requirements for Traders /Stockist

Reference Scope of

Sl Characteristi

Quantum standard and inspection

N Stage / Activity cs / Type of Record

of check Acceptance

o check Supplier TPIA

norms

ASME BPVC sec

MTC review for the physical

IIA- SA193 Gr

1 and chemical test, heat Verify MTC 100% Mill TC R R

B7M/ SA 194 Gr

treatment, NDT

2HM

Physical co-relation of MTC ASME BPVC sec

Verify Heat Mill TC & TPI

Heat no./Batch no. to the Each Heat IIA- SA193 Gr

2 no./Batch no. Inspection P RW

fasteners under scope of No. / Lot B7M/ SA 194 Gr

to the MTC report

supply. 2HM

Chemical

composition /

One ASME BPVC sec

Macro/

Sample selection & Check Sample IIA- SA193 Gr

3 Mechanical Test report H W

Testing per Heat / B7M/ SA 194 Gr

Properties/In

Per Size 2HM

ternal

soundness

100% by

ASME BPVC sec

Dimensional checking supplier Dimensional

Measuremen IIA- SA193 Gr

4 (including Threads Check by and at inspection P RW

t B7M/ SA 194 Gr

GO-NOGO gauge) 10% by report

2HM.

TPIA

Visible

surface

defect / 100% by ASME BPVC sec

Visual inspection and

Corrosion. supplier IIA- SA193 Gr Internal

Verification of Marking of

5 and at B7M/ SA 194 Gr Inspection P RW

Material spec./ Grade /

Verification 10% by 2HM / Std. engg. report

Heat No. / Lot No. / Size etc.

with respect TPIA Practice / PO

to Test

Certificate

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 3 of 4

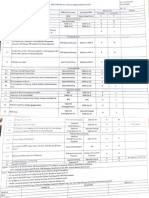

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-002 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B7M/ SA-194 GR 2HM BOLTING MATERIAL

Reference Scope of

Sl Characteristi

Quantum standard and inspection

N Stage / Activity cs / Type of Record

of check Acceptance

o check Supplier TPIA

norms

Positive

100% by

material As per PO/ ASME

supplier

identification BPVC sec IIA-

6 PMI and at PMI report P RW

(only for AS & SA193 Gr B7M/

10% by

SS SA 194 Gr 2HM

TPIA

components)

Verification

of galvanized

P.O./ Std. engg. Inspection

7 Coating (If Applicable) coating & Each item H RW

practice Report

galvanizing

thickness

Separate

TPIA stamping on all stamping for the

Each item Inspection

8 certified items of the Verification whole lot and for H H

of PO Report

inspected lot under the PO. the actual

witnessed items.

Verification

of Inspection As per PO / PR / Test

9 Documentation & Release Reports, MTC 100% Material certificate -- H

& Issue of specification Reports, IRN

Release Note

Legend

H - Hold (Do not proceed without approval), P-Perform, RW - Random Witness (As specified or 10% (min.1 No. of

each size and type of Bulk item), R-review, W-Witness (Give due notice, work may proceed after scheduled date).

Notes

1. This ITP contains the minimum inspection requirements. Vendor to comply all other requirements (if any) as per PO / PR.

2. In case of raw material supplied by sub suppliers/vendors; chemical composition / Macro/ Mechanical Properties/internal

soundness/ spectro analysis shall be performed by them and shall be witnessed by supplier as mentioned in Sl No-2

2. Hardness for studs/nuts shall be in range of 200-235 BHN (Max limit shall be 235 BHN). Hardness for nut shall be in the range of

159 to 235 BHN. ( Sample nut after Heat treatment shall be min 159 BHN)

3. Raw material or finished fastener macro etch examination to be verified by TPIA

4. B7M bolt and 2HM nuts metallurgy must be punched on both ends of the studs and at the two end faces of nuts on both ends of

the studs and at two locations on the nuts.

5. All bolts shall be properly lubricated prior to dispatch/ supplying

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 4 of 4

You might also like

- Inspection and Test Plan For Gas Turbine PDFDocument5 pagesInspection and Test Plan For Gas Turbine PDFreza ebrahimi100% (1)

- Quality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular LimitedDocument2 pagesQuality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular Limitedamit rajputNo ratings yet

- LPT ReportDocument2 pagesLPT ReportAnonymous OEUUoKHYR100% (1)

- Project Report On Paint ManufacturingDocument7 pagesProject Report On Paint ManufacturingEIRI Board of Consultants and PublishersNo ratings yet

- Qap B7 - 2HDocument4 pagesQap B7 - 2HJJ VAPINo ratings yet

- Qap B16Document4 pagesQap B16JJ VAPINo ratings yet

- Tube CS179 - MPSDocument3 pagesTube CS179 - MPSgaurangNo ratings yet

- Quality Assurance Plan FastnersDocument1 pageQuality Assurance Plan FastnersSuKHjiT SiNGhNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- WM65AJN200Document4 pagesWM65AJN200Shasin SolankiNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- With Strainer, Piston QapDocument1 pageWith Strainer, Piston QapajmainNo ratings yet

- Inspection and Test Plan For Gas TurbineDocument5 pagesInspection and Test Plan For Gas TurbineLiu YangtzeNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- Tubacex-Prakash 10650T1 QapDocument3 pagesTubacex-Prakash 10650T1 Qaprabiprasad.iispl.comletedNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocument2 pagesPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Civil Inspection and Test PlanDocument5 pagesCivil Inspection and Test PlanWalid AmdouniNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- QAP Roofing SheetDocument3 pagesQAP Roofing SheetAMRIT PAL SINGHNo ratings yet

- Airodyn TI P610 05 enDocument5 pagesAirodyn TI P610 05 enKa.P. SivagnanamNo ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Piping Class Especificacion de Tuberias 2Document1 pagePiping Class Especificacion de Tuberias 2dimolinaNo ratings yet

- Satip F 001 01Document3 pagesSatip F 001 01Ansar Ali VemmullyNo ratings yet

- Inspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)Document2 pagesInspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)iwan NugrohoNo ratings yet

- MPS TemplateDocument4 pagesMPS TemplategaurangNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- ITEM: Carbon Steel Seamless PipesDocument3 pagesITEM: Carbon Steel Seamless Pipesmanoj thakkarNo ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- ValveDocument6 pagesValvetharmarajuNo ratings yet

- Anexo 4 - Dimensionamiento PSV-7004 1Document2 pagesAnexo 4 - Dimensionamiento PSV-7004 1JairoVidalNo ratings yet

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- 1206-1906 QapDocument2 pages1206-1906 QapSambit NayakNo ratings yet

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocument6 pagesAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Inspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok ADocument7 pagesInspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok AMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- STD QapDocument141 pagesSTD QapSURAJ PRSADNo ratings yet

- Sample Quality Assurance Plan For Cs FlangesDocument2 pagesSample Quality Assurance Plan For Cs FlangesKaran BhanotNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- 07 - Apollo - Iocl - Actuator GTV - R1Document1 page07 - Apollo - Iocl - Actuator GTV - R19893203028No ratings yet

- Itp S8 CivilDocument12 pagesItp S8 CivilAnonymous G3jRndEbVNo ratings yet

- Gas Sampling Device Comem GSD: Data SheetDocument4 pagesGas Sampling Device Comem GSD: Data SheethecjavpaNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- IndexDocument11 pagesIndexAbderahmane BoubendirNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- PT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)Document3 pagesPT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)lailatul kodriNo ratings yet

- Term Work Machine GuardingDocument41 pagesTerm Work Machine GuardingSonika SinghNo ratings yet

- Liner Running, Setting & Cementing ProceduresDocument43 pagesLiner Running, Setting & Cementing Proceduresarez muhammedNo ratings yet

- HRS VS CRSDocument6 pagesHRS VS CRSHumberto GalvezNo ratings yet

- PVC Catalogue CNDocument2 pagesPVC Catalogue CNKiên PhùngNo ratings yet

- OTE Outotec Fluidization Technology Eng WebDocument16 pagesOTE Outotec Fluidization Technology Eng WebmumblexNo ratings yet

- Material Groups: ISCAR Catalog DirectoryDocument14 pagesMaterial Groups: ISCAR Catalog DirectorygielNo ratings yet

- TWI Training CSWIP 3.1 PlateDocument8 pagesTWI Training CSWIP 3.1 PlateSepthian DS100% (2)

- Unit III - Heat TreatmentDocument62 pagesUnit III - Heat TreatmentHarsha MallaNo ratings yet

- Data Sheet For Barred Tee 010719Document1 pageData Sheet For Barred Tee 010719Heru Agung SetyantoNo ratings yet

- Coagulation and Flocculation TankDocument2 pagesCoagulation and Flocculation Tankzarith sofeaNo ratings yet

- CoatingsDocument13 pagesCoatingsJIDEOLUWAYEMINo ratings yet

- Piping Class TecnaDocument135 pagesPiping Class Tecnajulia.garciaNo ratings yet

- CHE61203 Pollution ControlDocument44 pagesCHE61203 Pollution ControlPorkkodi SugumaranNo ratings yet

- Open End Wrench: Product Features ProfilesDocument3 pagesOpen End Wrench: Product Features ProfileskasanaNo ratings yet

- Different Shaper Machine Accessories and AttachementsDocument3 pagesDifferent Shaper Machine Accessories and AttachementsJaymark BebatNo ratings yet

- ZCC LNKT CuttersDocument8 pagesZCC LNKT Cutterspushpak lamjaneNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- SEC-I - Physics Workshop Skill Sample Questions With AnswersDocument20 pagesSEC-I - Physics Workshop Skill Sample Questions With AnswersMousam ChakraborttyNo ratings yet

- Elements of Mechanical EngineeringDocument3 pagesElements of Mechanical EngineeringHarish Murthy60% (5)

- Daggerz Brand Construction FastenersDocument3 pagesDaggerz Brand Construction FastenersmurdicksNo ratings yet

- DrawingDocument12 pagesDrawingOmar AbdullahNo ratings yet

- Electric Resistance WeldingDocument8 pagesElectric Resistance WeldingCrystal ElliottNo ratings yet

- Dummy 1 inDocument4 pagesDummy 1 inDurvis RomeroNo ratings yet

- Module 2 - 1Document45 pagesModule 2 - 1Biswajit LME016No ratings yet

- Welding Qualification Certification: Weld QualityDocument31 pagesWelding Qualification Certification: Weld QualityHussain ElboshyNo ratings yet

- SMS at - A - Glance - 2013EDocument16 pagesSMS at - A - Glance - 2013ESUNILNo ratings yet

- Tall Oil SoapsDocument23 pagesTall Oil SoapsMehmet Aydin100% (2)