Professional Documents

Culture Documents

Qap B16

Qap B16

Uploaded by

JJ VAPIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qap B16

Qap B16

Uploaded by

JJ VAPICopyright:

Available Formats

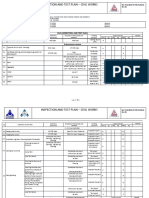

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-006 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B16 SA-194 GR 7 BOLTING MATERIAL

A. Scope : This Inspection and test plan covers the minimum testing requirements for SA-193 Gr B16

/SA-194 Gr7 bolting material

B. Reference Docs : Standard- ASME BPVC Sec IIA SA193/ ASME BPVC Sec IIA SA194/ AES-3562/ PO/PR/ Job

specifications and approved documents.

Inspection & Test Requirements for Manufacturers

Scope of

Reference inspection

Sl Characteristics/ Type Quantum of

Stage/ Activity standard/ Record

No of check check

Acceptance Norms Supplier TPIA

Test

Marking and ASME BPVC sec IIA-

Raw material certificate,

1 correlation with test 100% SA193 Gr B16/ SA H R

inspection inspection

certificate 194 Gr 7

report

Chemical composition

ASME BPVC sec IIA-

/ Macro/ Mechanical one sample Inspection

SA193 Gr B16/ SA H R

Properties/internal per heat report

Raw material 194 Gr 7

2 soundness

inspection

ASME BPVC sec IIA-

Inspection

Spectro analysis 100% SA193 Gr B16/ SA H R

report

194 Gr 7

Inspection

Heat treatment cycle ASME BPVC sec IIA- report/

3 Heat treatment (time and 100% SA193 Gr B16/ SA Heat H R

temperature) 194 Gr 7 treatment

charts

Thread Rolling, ASME BPVC sec IIA-

In Process Inspection

4 Forging Of Nuts, 100% SA193 Gr B16/ SA H _

Inspection report

Machining 194 Gr 7

Each HT Lot/ ASME BPVC sec IIA-

Selection of Inspection

5 Test piece marking Each Heat SA193 Gr B16/ SA H W

samples report

No/ Size 194 Gr 7

As per PO/ASME

Each HT Lot/

Nondestructive Surface and internal BPVC sec IIA- SA193 Inspection

6 Each Heat H RW

testing imperfections Gr B16/ SA 194 Gr 7 report

No/ Size

/ ASME Sec V

Mechanical properties Each HT Lot/ ASME BPVC sec IIA-

Destructive Inspection

7 YS, UTS, RA, Each Heat SA193 Gr B16/ SA H H

testing report

Elongation ,Proof Load No/ Size 194 Gr 7

Positive material As per PO/ASME

8 PMI identification (only for 100% BPVC sec IIA- SA193 PMI report P RW

AS & SS components) Gr B16/ SA 194 Gr 7

Visual marking, color

coding and 100% by As per PO/

dimensional check, supplier and Stamping Of Inspection

9 Final inspection H H

Final Stamping, grade at 10% by Accepted Bolting report

punch check, TPIA Material

lubrication

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 2 of 4

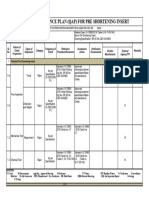

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-006 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B16 SA-194 GR 7 BOLTING MATERIAL

Scope of

Reference inspection

Sl Characteristics/ Type Quantum of

Stage/ Activity standard/ Record

No of check check

Acceptance Norms Supplier TPIA

100% by

Verification of

Coating (If supplier and As per PO / PR / Inspection

10 galvanized coating & H RW

Applicable) at 10% by Applicable Standard report

galvanizing thickness

TPIA

Test

Verification of

certificate

material test As per PO / PR /

Documentation (EN 10204

11 certificate, test report, 100% Material H H

& Release 3.2),

inspection reports & specification

Reports,

Issue of Release Note

IRN

Inspection & Test Requirements for Traders /Stockist

Reference Scope of

Sl Characterist Quantu

standard and inspection

N Stage / Activity ics / Type of m of Record

Acceptance

o check check Supplier TPIA

norms

ASME BPVC sec

MTC review for the physical

IIA- SA193 Gr

1 and chemical test, heat Verify MTC 100% Mill TC R R

B16/ SA 194 Gr

treatment, NDT

7

Physical co-relation of MTC ASME BPVC sec

Verify Heat Mill TC & TPI

Heat no./Batch no. to the Each Heat IIA- SA193 Gr

2 no./Batch no. Inspection P RW

fasteners under scope of No. / Lot B16/ SA 194 Gr

to the MTC report

supply. 7

Chemical

composition /

One ASME BPVC sec

Macro/

Sample selection & Check Sample IIA- SA193 Gr

3 Mechanical Test report H W

Testing per Heat / B16/ SA 194 Gr

Properties/In

Per Size 7

ternal

soundness

100% by

ASME BPVC sec

Dimensional checking supplier Dimensional

Measuremen IIA- SA193 Gr

4 (including Threads Check by and at inspection P RW

t B16/ SA 194 Gr

GO-NOGO gauge) 10% by report

7/ P.O.

TPIA

Visible

surface

defect / 100% by ASME BPVC sec

Visual inspection and

Corrosion. supplier IIA- SA193 Gr Internal

Verification of Marking of

5 and at B16/ SA 194 Gr Inspection P RW

Material spec./ Grade /

Verification 10% by 7 / Std. Engg. report

Heat No. / Lot No. / Size etc.

with respect TPIA Practice / PO

to Test

Certificate

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 3 of 4

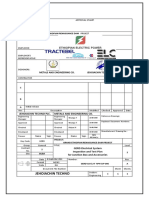

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-006 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B16 SA-194 GR 7 BOLTING MATERIAL

Reference Scope of

Sl Characterist Quantu

standard and inspection

N Stage / Activity ics / Type of m of Record

Acceptance

o check check Supplier TPIA

norms

Positive

100% by

material As per PO/ ASME

supplier

identification BPVC sec IIA-

6 PMI and at PMI report P RW

(only for AS & SA193 Gr B16/

10% by

SS SA 194 Gr 7

TPIA

components)

Verification

of galvanized

P.O./ Std. Engg. Inspection

7 Coating (If Applicable) coating & Each item H RW

practice Report

galvanizing

thickness

Separate

TPIA stamping on all stamping for the

Each item Inspection

8 certified items of the Verification whole lot and for H H

of PO Report

inspected lot under the PO. the actual

witnessed items.

Verification

of Inspection As per PO / PR / Test

9 Documentation & Release Reports, MTC 100% Material certificate -- H

& Issue of specification Reports, IRN

Release Note

Legend

H - Hold (Do not proceed without approval), P-Perform, RW - Random Witness (As specified or 10% (min.1 No. of

each size and type of Bulk item), R-review, W-Witness (Give due notice, work may proceed after scheduled date).

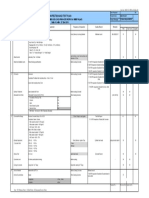

Notes

1. This ITP contains the minimum inspection requirements. Vendor to comply all other requirements (if any) as per PO / PR.

2. In case of raw material supplied by sub suppliers/vendors; chemical composition / Macro/ Mechanical Properties/internal

soundness/ spectro analysis shall be performed by them and shall be witnessed by supplier as mentioned in Sl No-2

3. Hardness for studs/nuts shall be in range of 253-319 BHN.

4. As per AES-3562, magnetic particle inspection has to be carried out on 10% of each heat on finished bolts (1 number minimum and

maximum 20 numbers per size) in accordance with ASTM-E-709. (This is a supplementary requirement and shall not apply unless

specified in the PO)

5. Raw material or finished fastener macro etch examination to be verified by TPIA

6. B16 bolt and Gr7 nuts metallurgy must be punched on both ends of the studs and at the two end faces of nuts on both ends of the

studs and at two locations on the nuts.

7. All bolts shall be properly lubricated prior to dispatch/ supplying

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 4 of 4

You might also like

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Inspection and Test Plan For Gas Turbine PDFDocument5 pagesInspection and Test Plan For Gas Turbine PDFreza ebrahimi100% (1)

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Biogeochemical Cycles Powerpoint Quiz Game With Answer Key For Educators - Download Powerpoint at Www. Science PowerpointDocument104 pagesBiogeochemical Cycles Powerpoint Quiz Game With Answer Key For Educators - Download Powerpoint at Www. Science PowerpointRyan MurphyNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- ITP For Process PipingDocument4 pagesITP For Process PipingSebastian RajeshNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Inspection and Test Plan For Gas TurbineDocument5 pagesInspection and Test Plan For Gas TurbineLiu YangtzeNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- DLP G10 Q3 WEEK 1 Day3Document7 pagesDLP G10 Q3 WEEK 1 Day3Cathy MoronioNo ratings yet

- Inspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)Document2 pagesInspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)iwan NugrohoNo ratings yet

- Winmostar tutorial: Gromacs Vapor Pressure・Surface TensionDocument12 pagesWinmostar tutorial: Gromacs Vapor Pressure・Surface TensionEliasSMonteiroFilhoNo ratings yet

- Inspection and Test Plan-Geo-Technical Works C002Document3 pagesInspection and Test Plan-Geo-Technical Works C002Furqan0% (1)

- Qap B7 - 2HDocument4 pagesQap B7 - 2HJJ VAPINo ratings yet

- Qap B7M - 2HMDocument4 pagesQap B7M - 2HMJJ VAPINo ratings yet

- Civil Inspection and Test PlanDocument5 pagesCivil Inspection and Test PlanWalid AmdouniNo ratings yet

- WM65AJN200Document4 pagesWM65AJN200Shasin SolankiNo ratings yet

- Quality Assurance Plan FastnersDocument1 pageQuality Assurance Plan FastnersSuKHjiT SiNGhNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- With Strainer, Piston QapDocument1 pageWith Strainer, Piston QapajmainNo ratings yet

- Pre Shortening Insert QAPDocument1 pagePre Shortening Insert QAPtibindas2463No ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Danem Engineering Works - WLL.: Quality Control & Inspection Test PlanDocument11 pagesDanem Engineering Works - WLL.: Quality Control & Inspection Test PlanRejoy babyNo ratings yet

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- TSP Adaptation Project No: Q3510: Inspection and Test Plan of Shop Fabricated Stainless Steel TanksDocument2 pagesTSP Adaptation Project No: Q3510: Inspection and Test Plan of Shop Fabricated Stainless Steel TanksfbellimamNo ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- GERD-02-EL-R-RPH-CIP-006-A-Inspection-and-Test-Plan-for-Junction Box and AccessoriesDocument4 pagesGERD-02-EL-R-RPH-CIP-006-A-Inspection-and-Test-Plan-for-Junction Box and AccessoriesmohammedNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- Process Audit ChecklistDocument5 pagesProcess Audit Checklistarun pandiyanNo ratings yet

- ITP HMMI Project RC Works - (003) - EditedDocument1 pageITP HMMI Project RC Works - (003) - EditedVivit Cllu StiaNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Qap Reciever TanksDocument6 pagesQap Reciever Tanksyamunaengg2011No ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocument6 pagesAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNo ratings yet

- Valve Requirement - 301-302Document2 pagesValve Requirement - 301-302Hemant NimaseNo ratings yet

- 12" - XMA-XAP - ITP Pipeline XRay PEPDocument3 pages12" - XMA-XAP - ITP Pipeline XRay PEPharrys manaluNo ratings yet

- 379-380-ZUG-Secondary Air Duct-PLTU Alor 2x3 MWDocument8 pages379-380-ZUG-Secondary Air Duct-PLTU Alor 2x3 MWMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Inspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok ADocument7 pagesInspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok AMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- Inspection and Test Plan: AcceptanceDocument4 pagesInspection and Test Plan: AcceptanceHengNo ratings yet

- Piping Class Especificacion de Tuberias 2Document1 pagePiping Class Especificacion de Tuberias 2dimolinaNo ratings yet

- Itp Monde NissinDocument27 pagesItp Monde NissinAnthony FernandezNo ratings yet

- Tube CS179 - MPSDocument3 pagesTube CS179 - MPSgaurangNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- ATTACHMENTDocument10 pagesATTACHMENTAgus SuriptoNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- ValveDocument6 pagesValvetharmarajuNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- Dana Sabah, CVDocument2 pagesDana Sabah, CVh7j42nt2b9No ratings yet

- Recommended Reading List For Civil EngineeringDocument1 pageRecommended Reading List For Civil EngineeringKho Chin NganNo ratings yet

- S-Scen001tp Environmental ScienceDocument8 pagesS-Scen001tp Environmental ScienceJoris YapNo ratings yet

- Study Questions Death SalesmanDocument3 pagesStudy Questions Death SalesmanmygirlmykyahoocomNo ratings yet

- All Aluminium Alloy ConductorsDocument2 pagesAll Aluminium Alloy ConductorsNeeraj AgarwalNo ratings yet

- Sustainable Marine Structures - Volume 04 - Issue 02 - July 2022Document61 pagesSustainable Marine Structures - Volume 04 - Issue 02 - July 2022Bilingual PublishingNo ratings yet

- I & Ii Class Intso Level - 1 Syllabus (23-24)Document1 pageI & Ii Class Intso Level - 1 Syllabus (23-24)Nirranjan JNo ratings yet

- Evolution Activity Choice BoardDocument1 pageEvolution Activity Choice Boardapi-515442701No ratings yet

- Yang 2010Document10 pagesYang 2010Li DongyueNo ratings yet

- The Swamp DwellersDocument1 pageThe Swamp DwellersMd Tazbir100% (1)

- Exercise Sheet-3Document2 pagesExercise Sheet-3pauline chauveauNo ratings yet

- The Waveshaper Effect On Ta-MS Multiliner Explosive Formed Pojectile With Tantalum As Penetrator and Mild Steel As Stabilization BaseDocument10 pagesThe Waveshaper Effect On Ta-MS Multiliner Explosive Formed Pojectile With Tantalum As Penetrator and Mild Steel As Stabilization BaseDani SaadNo ratings yet

- Design With PurposeDocument2 pagesDesign With PurposeSaleZNo ratings yet

- Recent Excavations at Tell Fadous Kfarab PDFDocument12 pagesRecent Excavations at Tell Fadous Kfarab PDFElias ZiadeNo ratings yet

- Most Important Question EnglishDocument65 pagesMost Important Question Englishbadasswhoseyourdad2009No ratings yet

- Prpc324 Module 7Document48 pagesPrpc324 Module 7raiNo ratings yet

- Eng Corpse Cart Balefire BrazierDocument1 pageEng Corpse Cart Balefire BrazierParvus Ares100% (1)

- HS United States History Reconstruction To TodayDocument415 pagesHS United States History Reconstruction To TodayAlejandra DoldNo ratings yet

- Sikuli DetailedDocument105 pagesSikuli Detaileddinakaran83100% (3)

- Ecology Class Notes - Biogeochemical Cycle (Nutrient Cycle) : December 2019Document15 pagesEcology Class Notes - Biogeochemical Cycle (Nutrient Cycle) : December 2019farNo ratings yet

- Activity 1 Objectives of Science EducationDocument2 pagesActivity 1 Objectives of Science EducationYu ErinNo ratings yet

- Post-Treatment Effects of Multiple Sclerosis (MS) On The Executive and Memory Functions Ofcommercial Pilots in The UAEDocument7 pagesPost-Treatment Effects of Multiple Sclerosis (MS) On The Executive and Memory Functions Ofcommercial Pilots in The UAEInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Trivia:: Formula Is, Used To Determine The DistanceDocument4 pagesTrivia:: Formula Is, Used To Determine The DistanceIan Caminero BarteNo ratings yet

- Engineers, Part B: Journal of Engineering Proceedings of The Institution of MechanicalDocument16 pagesEngineers, Part B: Journal of Engineering Proceedings of The Institution of Mechanicalvipul mishraNo ratings yet

- Activity No 2 - PHENOLDocument4 pagesActivity No 2 - PHENOLpharmaebooks100% (4)

- POST Newspaper For 28th of March, 2015Document112 pagesPOST Newspaper For 28th of March, 2015POST NewspapersNo ratings yet

- Question: Find The Inductance Per Phase Per KM of Double Circuit 3phDocument4 pagesQuestion: Find The Inductance Per Phase Per KM of Double Circuit 3phMuhammad abdur rehmanNo ratings yet