Professional Documents

Culture Documents

PQAP

Uploaded by

MAngesh GadeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQAP

Uploaded by

MAngesh GadeCopyright:

Available Formats

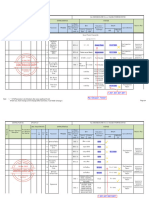

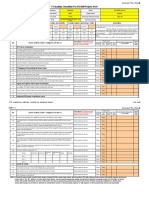

PRODUCT QUALITY ASSURANCE PLAN (For Final Inspection)

DATE (Org) :___10-02-05

PART NO. :0108EF0370N PART NAME : AIR EXTRACTOR ASSY OUTER DC RH / LH C.L. : A SUPPLIER : __VEPL______ DATE (Rev) : 4-11-05 (1)

IDENTIFICATION CODE FOR A) SUPPLIER DT004 B) MFG DATE __YES C) INSPECTOR YES

1.CUSTOMER 4.FINAL INSPECTION

2.CONCERNED ENGG. PARAMETER 3.CONTROL METHOD DURING PROCESS 5.REMARK

EXPECTATION METHOD FREQ.

MATERIAL PP (SP179) (WSK-M4777-A5) Dark Grey Inword Inspection &TC TESTING Every Lot ----

APPEARANCE &

FUNCTIONAL No Moisture mark on surface.

No Short Moulding

Free From Glass marks

Free From weld line marks

No cold material

Free From loose flashes/burrs As per operation no 20 & 40 in Visual 100% ----------

As per limit sample. Product Dimension Control Plan

As per limit sample.

Free From Flow marks

Free from

Burr,Warpage,Pits,flash,sharp

edges,sink marks etc

Inner surface should free from Dirt,

Dust, and other Material

On inner surface & Clearly visible

FITMENT

Dim Specification

DIMENSION

CD(Locators) 112.5 ±0.5 mm CMM &

Every Lot ---------

CD(Locators) 280.60.±0.8 mm As per operation no 20 & 40 in Relation Gauge

Dist from refferance to Locator CD 50.9±0.3 mm Product Dimension Control Plan / Checking Fixture

Distance 53.5±0.5

Functional Testing

Tighting Torque 3 NM Torque Tester Every Six Months ---------

PULL LOAD 80-110 kgf UTM

PACKING QA Lable / Sticker to confirm packing , Qty. &

outer packing of corrugated box , No dimensional distortion in transportation Product Visual Every Lot ---------

SUPPLIER SHALL SEND PREDESPATCH INSPECTION REPORT WITH EACH LOT & WHICH SHOULD COVER ALL CUSTOMER EXPECTATIONS &

CONCEREND ENGG. PARAMETERS.

SIGNATURE OF APPROVING AUTHORITY : ________________________ SIGNATURE OF SUPPLIER : _______________

DATE : __________________ DATE : ____________

You might also like

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- Building a Successful Board-Test StrategyFrom EverandBuilding a Successful Board-Test StrategyRating: 4 out of 5 stars4/5 (1)

- 9-Material Treacibility PDFDocument64 pages9-Material Treacibility PDFmamounsdNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDocument4 pagesEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashNo ratings yet

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Perma - CCC - Insulation IR04Document7 pagesPerma - CCC - Insulation IR04Amro MetwallyNo ratings yet

- Spotcheck SKD S2 Developer AerosolDocument2 pagesSpotcheck SKD S2 Developer AerosolInspectorNo ratings yet

- UMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentFrom EverandUMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentNo ratings yet

- Drilling String InspectionDocument7 pagesDrilling String Inspectionrais ridha100% (2)

- QAP General For Ref.Document2 pagesQAP General For Ref.AMIT SHAHNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- 1.FPC BNG 06 F 0101 Certificate of Gauge InspectionDocument3 pages1.FPC BNG 06 F 0101 Certificate of Gauge InspectionSunil GowdaNo ratings yet

- Controlplan enDocument1 pageControlplan enRaquel MungcalNo ratings yet

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkNo ratings yet

- Motor Itp For Package ItemsDocument1 pageMotor Itp For Package ItemsZulfequar R. Ali KhanNo ratings yet

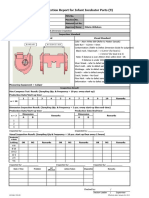

- In-Process Inspection Report For Infant Incubator Parts9Document1 pageIn-Process Inspection Report For Infant Incubator Parts9Hilario AlinabonNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Qap TataDocument5 pagesQap TataDesign VardhNo ratings yet

- Control Plan For Zinc Flake CoatingDocument3 pagesControl Plan For Zinc Flake Coatingx y100% (1)

- FM - MKT - 02 Quality Control Process ChartDocument4 pagesFM - MKT - 02 Quality Control Process Chartbarja subarjaNo ratings yet

- MT Inspection Record Form For Compressor Rotor: 05-TR-RCDDocument3 pagesMT Inspection Record Form For Compressor Rotor: 05-TR-RCDHimanyu RafiqNo ratings yet

- DSQR - RaltechDocument10 pagesDSQR - RaltechHimanshu MishraNo ratings yet

- Lembar 1Document1 pageLembar 1saepudin 40No ratings yet

- Control (Quality) PlanDocument1 pageControl (Quality) PlanRabia ZulqarnainNo ratings yet

- In-Process Inspection Report For Infant Incubator Parts2Document2 pagesIn-Process Inspection Report For Infant Incubator Parts2Hilario AlinabonNo ratings yet

- Hardness Testing ProcedureDocument6 pagesHardness Testing Procedurevaradaraj n sharmaNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- Process Inspection ExampleDocument6 pagesProcess Inspection ExampleJayant Kumar JhaNo ratings yet

- Satellite Speed CertificateDocument2 pagesSatellite Speed CertificateZafar YabNo ratings yet

- MPS 143Document14 pagesMPS 143krishnamartial8269No ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- Agreement of Inspection (Aoi) : SL No Parameters Frequency Applicable / Not ApplicableDocument3 pagesAgreement of Inspection (Aoi) : SL No Parameters Frequency Applicable / Not ApplicableSakthi VelNo ratings yet

- Ge Sill PFD PDFDocument1 pageGe Sill PFD PDFRavikumar BojjaNo ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- CMR For 2gs Am CrackDocument7 pagesCMR For 2gs Am CrackKumaravelNo ratings yet

- Painting of Structure Piping Equipment 22Document5 pagesPainting of Structure Piping Equipment 22Saurabh Kumar VermaNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Inspection Plan - Link Plate - (Am-2 Chain)Document3 pagesInspection Plan - Link Plate - (Am-2 Chain)pradeepasalunkeNo ratings yet

- 4-Lembar Pengesahan PengujiDocument163 pages4-Lembar Pengesahan PengujiNico Achmad ZulviansyahNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Document10 pagesNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Kon D000Document1 pageKon D000MohitNo ratings yet

- Air Comp 4 Inspection Report Mall of EgyptDocument4 pagesAir Comp 4 Inspection Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- QM C 7.1 Ab 0001 LDocument3 pagesQM C 7.1 Ab 0001 LalokrajamanNo ratings yet

- Inspection and Test PlanDocument2 pagesInspection and Test PlanAbdullahNo ratings yet

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Document20 pagesNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Epm Venue Go2Document5 pagesEpm Venue Go2rubyhall bio-medicalNo ratings yet

- Egy Final Report No. 1 TersaDocument22 pagesEgy Final Report No. 1 TersaKadry Nabil HegazyNo ratings yet

- Rcomcdmagsmumtsexp - bhr-131 - Karhariya - Nemhans - Ti Quality Check ListDocument12 pagesRcomcdmagsmumtsexp - bhr-131 - Karhariya - Nemhans - Ti Quality Check Listarun KumarNo ratings yet

- Pdir B0y46408Document1 pagePdir B0y46408Shankar JadhavNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- 4.1. Flow Proses Mur M12 A192 2HDocument2 pages4.1. Flow Proses Mur M12 A192 2Hcahayabp. isoNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Field Quality Plan: BusbarsDocument3 pagesField Quality Plan: BusbarsSourav RanaNo ratings yet

- Coustomer Complaint Status F-QA-18Document1 pageCoustomer Complaint Status F-QA-18MAngesh GadeNo ratings yet

- PM TrainingDocument97 pagesPM TrainingMAngesh GadeNo ratings yet

- Eng PC MD 281934-4 Z (339975)Document4 pagesEng PC MD 281934-4 Z (339975)MAngesh GadeNo ratings yet

- KK PillarDocument117 pagesKK PillarMAngesh Gade100% (1)

- Visual LabelDocument2 pagesVisual LabelMAngesh GadeNo ratings yet

- QM PillarDocument49 pagesQM PillarMAngesh GadeNo ratings yet

- JH TrainingDocument218 pagesJH TrainingMAngesh GadeNo ratings yet

- Use At: Cupboard Checklist Paste Internal On Right Hand Side Font Size: 1 12 Text: VW Headline OT-Book Size of Paper: A4Document11 pagesUse At: Cupboard Checklist Paste Internal On Right Hand Side Font Size: 1 12 Text: VW Headline OT-Book Size of Paper: A4MAngesh GadeNo ratings yet

- Curriculum Vitae: Career ObjectiveDocument2 pagesCurriculum Vitae: Career ObjectiveMAngesh GadeNo ratings yet

- JH PPT 18.12.20Document46 pagesJH PPT 18.12.20MAngesh Gade0% (1)

- Essdee Industries: Problem Date:-4M Area Change Point Change Details IPP Followed Why Changed Man DepartmentDocument1 pageEssdee Industries: Problem Date:-4M Area Change Point Change Details IPP Followed Why Changed Man DepartmentMAngesh GadeNo ratings yet

- 7WDocument1 page7WMAngesh GadeNo ratings yet

- Air System Sizing Summary For NIVEL PB - Zona 1Document1 pageAir System Sizing Summary For NIVEL PB - Zona 1Roger PandoNo ratings yet

- List ToolingDocument10 pagesList Toolingyohanes adi saputroNo ratings yet

- Knowledge /28 Application / 22 Thinking / 12 Communication / 9Document8 pagesKnowledge /28 Application / 22 Thinking / 12 Communication / 9NmNo ratings yet

- International Travel Insurance Policy: PreambleDocument20 pagesInternational Travel Insurance Policy: Preamblethakurankit212No ratings yet

- Design of CEB BuildingDocument20 pagesDesign of CEB BuildingVishalya Nipuni Lankeshi100% (1)

- LINEAR INDUCTION MOTOR 6981660.ppsxDocument56 pagesLINEAR INDUCTION MOTOR 6981660.ppsxFalley FasterNo ratings yet

- No Client Too Far: Flexible Antenna Options TDMA GPS Sync ClientDocument2 pagesNo Client Too Far: Flexible Antenna Options TDMA GPS Sync ClientFelix MartinezNo ratings yet

- O Solitude! If I Must With Thee Dwell by John Keats: SonnetDocument6 pagesO Solitude! If I Must With Thee Dwell by John Keats: SonnetshettyNo ratings yet

- Lec22 Mod 5-1 Copper New TechniquesDocument24 pagesLec22 Mod 5-1 Copper New TechniquesAaila AkhterNo ratings yet

- DUPIXENT Doctor Discussion GuideDocument4 pagesDUPIXENT Doctor Discussion GuideTAP THANH CHAUNo ratings yet

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument2 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpCarlos AvalosNo ratings yet

- 3rd Stage ComplicationsDocument84 pages3rd Stage ComplicationsDream100% (1)

- Syllabus (402050B) Finite Element Analysis (Elective IV)Document3 pagesSyllabus (402050B) Finite Element Analysis (Elective IV)shekhusatavNo ratings yet

- 基礎居合講座Document33 pages基礎居合講座任平生100% (1)

- Radiation Formula SheetDocument5 pagesRadiation Formula SheetJakeJosephNo ratings yet

- ReagentsDocument12 pagesReagentsKimscey Yvan DZ SulitNo ratings yet

- Equipment in The NICUDocument7 pagesEquipment in The NICUGheDine PeracionNo ratings yet

- Charles Haanel - The Master Key System Cd2 Id1919810777 Size878Document214 pagesCharles Haanel - The Master Key System Cd2 Id1919810777 Size878Hmt Nmsl100% (2)

- Worksheet - Labeling Waves: NameDocument2 pagesWorksheet - Labeling Waves: NameNubar MammadovaNo ratings yet

- Buckthorpe Etal 23 Optimising Early Stage ACL Rehab ProcessDocument24 pagesBuckthorpe Etal 23 Optimising Early Stage ACL Rehab ProcessCole VincentNo ratings yet

- Marxism and The Oppression of Women Lise VogelDocument259 pagesMarxism and The Oppression of Women Lise VogelMoises SaavedraNo ratings yet

- Manual de Electronica HardbookDocument970 pagesManual de Electronica HardbookninoferNo ratings yet

- MAP V6.3: Reference ManualDocument106 pagesMAP V6.3: Reference ManualGkou DojkuNo ratings yet

- 3592 Operator GuideDocument103 pages3592 Operator GuideNaim GhattasNo ratings yet

- Tyba S4 Syntax PDFDocument107 pagesTyba S4 Syntax PDFIndahNo ratings yet

- Lesson Notes Lecture 14Document5 pagesLesson Notes Lecture 14Quantum SaudiNo ratings yet

- Chapter 4 Occupational Safety Hazards in Food Service OperationsDocument14 pagesChapter 4 Occupational Safety Hazards in Food Service OperationsStraichea Mae TabanaoNo ratings yet

- Excretory Products and Their EliminationDocument13 pagesExcretory Products and Their Eliminationaravind kishanNo ratings yet

- Bitsat Paper 5Document19 pagesBitsat Paper 5pranka5240100% (1)

- Ah 1000Document1 pageAh 1000Zafir SihabuddinNo ratings yet