Professional Documents

Culture Documents

Reinforcedself Support

Uploaded by

TREE OF LIFECopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reinforcedself Support

Uploaded by

TREE OF LIFECopyright:

Available Formats

Reinforced Self-Support BHBP/BHAP/BKMP/BKTP

Product Description

• REINFORCED SELF-SUPPORT cable is a solid insulated, double-jacketed, armored, self-supporting aircore design intended for aerial installations where hazards

from squirrel attack, tree limb abrasion or lightning exist. The undulated, shielded, jacketed core is covered with a flooded steel armor, laid parallel to a flooded

steel support member and jacketed in an integral extrusion to form a “figure-8” configuration. The steel strand member is readily available for gripping, pulling

and tensioning using standard methods and hardware.

Physical Description

• CONDUCTORS: Solid annealed copper in 19, 22, 24 and 26 AWG. • SHIELD & INNER JACKET: A corrugated, 8-mil aluminum tape is applied

• INSULATION: Conductors are insulated with solid polyolefin in distinctive longitudinally over the core wrap. A linear low-density polyethylene inner

colors to facilitate pair identification. jacket helps protect the core and shield against mechanical damage and

• CORE ASSEMBLY: Individual conductor dimensions are tightly controlled to ingress of moisture.

limit resistance unbalance of the paired conductors. Pair twist lays and the • ARMOR: A corrugated bare 6-mil steel tape is applied longitudinally over

the inner jacket. The inner and outer surfaces of the steel are flooded.

BELL OSP COPPER

relative placement of the pairs are designed to minimize crosstalk and meet

capacitance unbalance limits. In 25 pair cables, the pairs are combined into • SUPPORT MEMBER: A 1/4 inch, 7-strand Extra High-Strength (EHS)

a cylindrical core. In cables of 50 pairs and more, multiples of 25 pair groups galvanized steel member, fully flooded for corrosion protection, serves

are assembled to form the final cable core. Each group is identified by color as the support member and is an integral part of the sheath.

coded non-hygroscopic binders. To eliminate strain on the conductors, the • OUTER JACKET: A black, linear low-density polyethylene provides a tough,

core assembly is undulated to provide sufficient slack during installation. flexible, protective covering that withstands exposure to sunlight, atmos-

• CORE WRAP: A complete covering of a non-hygroscopic dielectric material pheric temperatures and stresses expected in standard installations.

protects the core and helps provide core-to-shield dielectric strength. • JACKET MARKINGS: Information such as manufacturer’s identification, pair

count AWG, product identification, sequential footage and a telephone

handset is printed at 2 ft. intervals on the cable jacket.

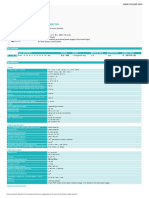

Electrical Specifications

Average Mutual Capacitance at 1000 Hz

Total Number of Pairs nF/mile nF/km

12 or less 83 ± 7 52 ± 4

Over 12 83 + 4 - 5 52 ± 2

Conductor Minimum Insulation Max Average Attenuation* Max Conductor Resistance Dielectric Strength

Size Resistance @ 68°F @ 68°F (20°C) Resistance @ 68°F Unbalance DC Potential – Volts

772 kHz Ohms/sheath Maximum Minimum

gigohm/ gigohm/ Individual Cdr. to Cdr. to

AWG mm mile km dB/kft dB/km mile km Ave % Pair % Cdr. Grnd.

19 0.90 1.0 1.6 3.3 10.8 45 28.0 1.5 5.0 5,000 10,000

22 0.64 1.0 1.6 4.7 15.4 91 56.5 1.5 5.0 4,000 10,000

24 0.50 1.0 1.6 5.9 19.4 144 89.5 1.5 5.0 3,000 10,000

26 0.40 1.0 1.6 7.4 24.3 232 144.2 1.5 5.0 2,400 10,000

Minimum Near End Crosstalk (NEXT) at 150 kHz 772 kHz Capacitance Unbalance Pair to Pair

P.S.WUNEXT mean (dB) 58 47 Pairs Maximum Individual Maximum RMS

P.S.WUNEXT worst pair (dB) 53 42 pF/kft pF/km pF/kft pF/km

Minimum Far End Crosstalk at 150 kHz 12 or less 80 145 — —

more than 12 80 145 25 45

Conductor size (AWG) 19 22 24 26

P.S. ELFEXT mean (dB/kft) 65 63 63 61 Capacitance Unbalance Pair to Ground

P.S. ELFEXT worst pair (dB/kft) 59 57 57 57 Pairs Maximum Individual Maximum Average

pF/kft pF/km pF/kft pF/km

Minimum Far End Crosstalk at 772 kHz

12 or less 800 2625 — —

Conductor size (AWG) 19 22 24 26 more than 12 800 2625 175 574

P.S. ELFEXT mean (dB/kft) 51 49 49 47

P.S. ELFEXT worst pair (dB/kft) 45 43 43 43

*For cables of 12 pairs or less, the maximum average attenuation may be increased by 10% over the values shown.

96 Toll Free 800.551.8948 — Fax 770.657.6807

superioressex.com

Reinforced Self-Support BHBP/BHAP/BKMP/BKTP

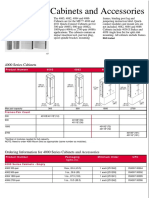

Part Numbers and Physical Characteristics

Part # Pair Count Nom. Cable Only O.D. Nom. Overall O.D. Approx. Weight Standard Length Approx. Shipping Weight Standard Reel Size

in (mm) in (mm) lbs/kft (kg/km) ft (m) lbs (kg) Steel

BHBP– 19 AWG (0.90 mm)

20-026-20 6 0.83 (21) 1.31 (33) 377 (562) 10000 (3050) 4552 (2067) 420

20-031-20 25 1.18 (30) 1.66 (42) 631 (940) 5000 (1530) 3937 (1787) 420

20-034-20 50 1.39 (35) 1.87 (47) 953 (1420) 3300 (1010) 3927 (1783) 420

BHAP – 22 AWG (0.64 mm)

20-062-20 25 0.87 (22) 1.33 (34) 455 (675) 10000 (3050) 4200 (1905) 420

20-065-20 50 1.05 (27) 1.51 (38) 625 (930) 7500 (2290) 4465 (2025) 420

20-069-20 100 1.30 (33) 1.76 (45) 940 (1400) 5000 (1530) 4475 (2029) 420

BKMP – 24 AWG (0.50 mm)

20-097-20 25 0.83 (21) 1.29 (33) 400 (595) 10000 (3050) 4345 (1971) 420

20-100-20 50 0.94 (24) 1.40 (36) 510 (760) 10000 (3050) 5445 (2469) 420

20-104-20 100 1.13 (29) 1.59 (40) 715 (1065) 5000 (1530) 4145 (1880) 420

20-108-20 200 1.42 (36) 1.88 (48) 1120 (1665) 4000 (1220) 4995 (2265) 420

BKTP – 26 AWG (0.40 mm)

20-132-20 25 0.69 (18) 1.15 (29) 335 (500) 13300 (4060) 4850 (2200) 420

BELL OSP COPPER

20-135-20 50 0.80 (20) 1.26 (32) 410 (610) 10000 (3050) 4645 (2107) 420

20-139-20 100 0.97 (25) 1.43 (36) 560 (835) 8000 (2440) 4955 (2247) 420

20-143-20 200 1.21 (31) 1.67 (42) 810 (1205) 5000 (1530) 4670 (2118) 420

20-145-20 300 1.35 (34) 1.81 (46) 1045 (1555) 3300 (1010) 4110 (1864) 420

TECH TIP

Sag and Tension guidelines for these products are available online:

http://www.superioressex.com/techinfo/sag-tension.htm

Standards Compliance:

Telcordia GR-421-CORE; ANSI/ICEA S-85-625-2002

Toll Free 800.551.8948 — Fax 770.657.6807

superioressex.com 97

You might also like

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Adp NmsDocument1 pageAdp NmsTREE OF LIFENo ratings yet

- Part II PDFDocument28 pagesPart II PDFAdrian OprisanNo ratings yet

- Hawke CableGland 501 453 RAC Compression V6Document2 pagesHawke CableGland 501 453 RAC Compression V6Ing ZenerNo ratings yet

- TDS 1n32wakhs V0R2Document1 pageTDS 1n32wakhs V0R2Anissa SiliaNo ratings yet

- Cable Siemon-SFTP CAT7A PDFDocument2 pagesCable Siemon-SFTP CAT7A PDFRenzo GuizadoNo ratings yet

- NK Cables Antenna Line ProductsDocument52 pagesNK Cables Antenna Line ProductsAndreyNo ratings yet

- Ac2xy F Na2xyDocument3 pagesAc2xy F Na2xyLombrea AdrianNo ratings yet

- Gaon Cable's Guide to Medium Voltage Cable CharacteristicsDocument18 pagesGaon Cable's Guide to Medium Voltage Cable Characteristicsphyo7799100% (2)

- Teletronik Drop Cables Catalogue PDFDocument19 pagesTeletronik Drop Cables Catalogue PDFAleksandar TasicNo ratings yet

- Heizka Catalogue Cat6 24awg Utp 2Document2 pagesHeizka Catalogue Cat6 24awg Utp 2votinh20687No ratings yet

- Completed Datasheet For RS 485 Cat 6 Amor CableDocument4 pagesCompleted Datasheet For RS 485 Cat 6 Amor Cablelam266No ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- Prysmian Esp Cable DW 205 R PDFDocument2 pagesPrysmian Esp Cable DW 205 R PDFJava Cable Center50% (2)

- 2C + EDocument2 pages2C + Eraviroj SOMVADEENo ratings yet

- Siemon Category 6a S FTP Cable International - Spec SheetDocument3 pagesSiemon Category 6a S FTP Cable International - Spec SheetELECTRICAL ENGINEERNo ratings yet

- Ficha Técnica Cable SFTP ISO FA (7A) Siemon Ref. 9T7L4-E10Document3 pagesFicha Técnica Cable SFTP ISO FA (7A) Siemon Ref. 9T7L4-E10Sergio VargasNo ratings yet

- siemon-tera-e12-cable-international_spec-sheetDocument2 pagessiemon-tera-e12-cable-international_spec-sheetinghoc2022No ratings yet

- Feeder CatalogDocument30 pagesFeeder CatalogAhmed ShabanNo ratings yet

- Datasheet 510 2 Pair 24 Awg Overall Foil Braid Shielded Cable For Eia Rs 232422Document2 pagesDatasheet 510 2 Pair 24 Awg Overall Foil Braid Shielded Cable For Eia Rs 232422hairol anuarNo ratings yet

- NCB C6sgryr 305Document1 pageNCB C6sgryr 305andrei.iooNo ratings yet

- NYCWYDocument1 pageNYCWYacarisimovicNo ratings yet

- 4414-6 Core 18 AWG Shielded Multi Conductor CableDocument1 page4414-6 Core 18 AWG Shielded Multi Conductor CableSriparthanNo ratings yet

- Solution 6 Utp Cable-InternationalDocument2 pagesSolution 6 Utp Cable-InternationalJose Miguel Hurtado GonzslesNo ratings yet

- SC Fire Resistant Catalogue 2020Document16 pagesSC Fire Resistant Catalogue 2020Phua Shang YangNo ratings yet

- Nexans Türkiye End.Tic Aş Tuzla Factory Technical SpecificationDocument2 pagesNexans Türkiye End.Tic Aş Tuzla Factory Technical SpecificationJason SecretNo ratings yet

- Ts-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMDocument2 pagesTs-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMmohd darusNo ratings yet

- HT Cables - Leading China Cable ManufacturerDocument18 pagesHT Cables - Leading China Cable ManufacturerSIMON S. FLORES G.100% (1)

- Line Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWDocument3 pagesLine Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWSadiqNo ratings yet

- Application Product Construction Technical Data: 2D ViewDocument1 pageApplication Product Construction Technical Data: 2D ViewseenudesignNo ratings yet

- 153/RAC/L: Cable Gland Selection TableDocument2 pages153/RAC/L: Cable Gland Selection TableManikandan ShriNo ratings yet

- Siemon Category 6a F FTP Cable Ls0h International Spec SheetDocument2 pagesSiemon Category 6a F FTP Cable Ls0h International Spec SheetJosue Reyes GironNo ratings yet

- GXL CablesDocument1 pageGXL CablesVijay KarthikeyanNo ratings yet

- EuroCable General CatalogueDocument34 pagesEuroCable General CatalogueRadio Parts100% (6)

- WTEC 35KV MV Cable LLDPE Rev S 20160226Document5 pagesWTEC 35KV MV Cable LLDPE Rev S 20160226carloNo ratings yet

- SGT CableDocument1 pageSGT CableVijay KarthikeyanNo ratings yet

- Ficha Técnica CABLE ERP SOUTHWIREDocument3 pagesFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNo ratings yet

- Aberdare Cable Selection ChartDocument18 pagesAberdare Cable Selection ChartEdwin Cob Guri100% (1)

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- Datasheet Armoured Cable PVC SheathedDocument9 pagesDatasheet Armoured Cable PVC SheathedDave KousudhanNo ratings yet

- Federal Kabel 2C14Document2 pagesFederal Kabel 2C14medtsl.cppNo ratings yet

- Partex CatalogDocument199 pagesPartex CatalogjamilNo ratings yet

- Soft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesDocument10 pagesSoft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesStuxnetNo ratings yet

- 交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆Document3 pages交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆jiahuanhe2023No ratings yet

- Multi-Flex® (RV-K) : DescriptionDocument3 pagesMulti-Flex® (RV-K) : DescriptionpurriagaNo ratings yet

- AIRFIELD LIGHTING CABLEDocument1 pageAIRFIELD LIGHTING CABLEantonio estradaNo ratings yet

- Cable L3Document2 pagesCable L3Riccardo AdamiNo ratings yet

- Category 6 UTP CableDocument5 pagesCategory 6 UTP CableJeff ChoyNo ratings yet

- Multi Core Unarmoured Shaped Conductor - XLPE InsulatedDocument1 pageMulti Core Unarmoured Shaped Conductor - XLPE InsulatedMohamed InshafNo ratings yet

- Kabel Katalog Airfield LightingDocument10 pagesKabel Katalog Airfield LightingHimawan Sigit NugrohoNo ratings yet

- Co Axial CableDocument9 pagesCo Axial Cablemsiddique295No ratings yet

- Hot oil resistant thin-wall 150°C automotive engine harness wireDocument2 pagesHot oil resistant thin-wall 150°C automotive engine harness wirefatimaNo ratings yet

- SC - Low Voltage Catalogue - Aluminium - 2020Document18 pagesSC - Low Voltage Catalogue - Aluminium - 2020ooi.impacNo ratings yet

- XLPE Insulated Power Cable Halogen Free PVC SheathedDocument3 pagesXLPE Insulated Power Cable Halogen Free PVC SheathedAlexandru AritonNo ratings yet

- Volition Fibre in - Out CableDocument6 pagesVolition Fibre in - Out CableGlen BastesNo ratings yet

- Leader Cable - 132kVDocument8 pagesLeader Cable - 132kVTeo Yi LinNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- Flame Retardant Instrumentation Data CablesDocument60 pagesFlame Retardant Instrumentation Data CablesSongkunhua SongNo ratings yet

- TDS Shielded Twisted Pair 1P Fire Rated 0.6 - 1KV 002Document1 pageTDS Shielded Twisted Pair 1P Fire Rated 0.6 - 1KV 002Ian RustNo ratings yet

- 3M Heavy Duty Pedestal Cabinet 4086Document1 page3M Heavy Duty Pedestal Cabinet 4086TREE OF LIFENo ratings yet

- Cop 02 enDocument2 pagesCop 02 enTREE OF LIFENo ratings yet

- 4000 CabinetsDocument4 pages4000 CabinetsTREE OF LIFENo ratings yet

- ColorcodesDocument2 pagesColorcodesTREE OF LIFENo ratings yet

- ScotchlokDocument12 pagesScotchlokTREE OF LIFENo ratings yet

- Total Access 600 - 750 - 850 - 900 Amphenol Cable Color CodeDocument2 pagesTotal Access 600 - 750 - 850 - 900 Amphenol Cable Color CodeTREE OF LIFENo ratings yet

- ECE 3113 Introduction Into RF Circuit Design: Lecture Notes For A-Term 2019Document9 pagesECE 3113 Introduction Into RF Circuit Design: Lecture Notes For A-Term 2019kenNo ratings yet

- Analyze small signal parameters of CC amplifierDocument5 pagesAnalyze small signal parameters of CC amplifierAafaqIqbalNo ratings yet

- SunPower P19 Product Data SheetDocument2 pagesSunPower P19 Product Data SheetUrfan AshrafNo ratings yet

- International Journal of Heat and Mass Transfer: Matej Kranjc, Anze Zupanic, Damijan Miklavcic, Tomaz JarmDocument7 pagesInternational Journal of Heat and Mass Transfer: Matej Kranjc, Anze Zupanic, Damijan Miklavcic, Tomaz JarmOthman Ben CheikhNo ratings yet

- Classifying Amplifiers by Configuration and OperationDocument8 pagesClassifying Amplifiers by Configuration and OperationElaine BicolNo ratings yet

- MBRB 2545CT - Diodo SchottkyDocument6 pagesMBRB 2545CT - Diodo SchottkyTiago LeonhardtNo ratings yet

- Scania Bodybuilder ElectricsDocument16 pagesScania Bodybuilder ElectricsJack Norhy100% (1)

- 1A Bipolar Linear Regulator AMS1117 Technical Reference GuideDocument7 pages1A Bipolar Linear Regulator AMS1117 Technical Reference GuideFelipe silva santanaNo ratings yet

- 35 MM - 1 Relay 8A OUR3 Part Number 88867103Document6 pages35 MM - 1 Relay 8A OUR3 Part Number 88867103Ri Cha RdNo ratings yet

- Chapter 3 Dec 50143Document29 pagesChapter 3 Dec 50143Kohilan VenugopalNo ratings yet

- PT Schneider Indonesia 630kVA Transformer SpecsDocument2 pagesPT Schneider Indonesia 630kVA Transformer SpecsArdi NalNo ratings yet

- Coil Press Machine CP-400Document6 pagesCoil Press Machine CP-400Mikhail YudhiantaraNo ratings yet

- GPU - SinePower PDFDocument4 pagesGPU - SinePower PDFrocaoNo ratings yet

- CM8600A CcmicDocument16 pagesCM8600A CcmicGheorghe MihaiNo ratings yet

- Analog Electronics Lab ManualDocument49 pagesAnalog Electronics Lab ManualReddyvari VenugopalNo ratings yet

- Engineering Physics Multiple Choice Questions on Polarization of LightDocument44 pagesEngineering Physics Multiple Choice Questions on Polarization of LightNikhil SatbhaiNo ratings yet

- EPLAN Bentec 3524942Document9 pagesEPLAN Bentec 3524942reda BoutiNo ratings yet

- 5 DielectricsDocument71 pages5 DielectricsJudy JanaNo ratings yet

- Omega Lighting-Erco Monopoll & Varipoll Linear Cylindrical Systems Catalog 10-86Document44 pagesOmega Lighting-Erco Monopoll & Varipoll Linear Cylindrical Systems Catalog 10-86Alan MastersNo ratings yet

- Lifestyle v35 PDFDocument63 pagesLifestyle v35 PDFJerry Cavalcante LidianeNo ratings yet

- Comparison of PAM-4 and NRZ Signaling for 10-12 Gbps StandardsDocument27 pagesComparison of PAM-4 and NRZ Signaling for 10-12 Gbps StandardsBarry BarnettNo ratings yet

- Vishay Siliconix: Product SummaryDocument7 pagesVishay Siliconix: Product SummaryTango SierraNo ratings yet

- Capacitive Coupling of Gate Signals PDFDocument7 pagesCapacitive Coupling of Gate Signals PDFVincent KorieNo ratings yet

- Svm123a DC1000Document113 pagesSvm123a DC1000Sgly ZemogNo ratings yet

- Layout Solns 3Document12 pagesLayout Solns 3VIKRAM KUMARNo ratings yet

- Confidential Information. Not To Be Used in Any Way Detrimental To PowellDocument3 pagesConfidential Information. Not To Be Used in Any Way Detrimental To PowellYogesh MittalNo ratings yet

- SK 3239.118 Toptherm Fan-And-Filter UnitsDocument5 pagesSK 3239.118 Toptherm Fan-And-Filter UnitsLOI HONo ratings yet

- Final Applied Physics Lab ManualDocument57 pagesFinal Applied Physics Lab ManualHuma MalikNo ratings yet

- Reactive Power Compensation Using A Voltage Source GeneratorDocument10 pagesReactive Power Compensation Using A Voltage Source GeneratorkubikNo ratings yet

- Aluminum Vs Copper in TrafoDocument6 pagesAluminum Vs Copper in TrafosamuraivickyNo ratings yet