Professional Documents

Culture Documents

Stub 4.3

Uploaded by

BrcakOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stub 4.3

Uploaded by

BrcakCopyright:

Available Formats

Page: 1/10

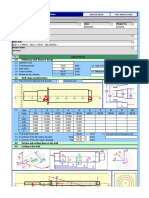

Project: Model: Prosta-greda-4.3 Sheet: 1

Cartesian 1.1 NODES

Node Reference Coordinate Node Coordinates

No. Node Type Node System X [mm] Y [mm] Z [mm] Comment

2 Standard - Cartesian 0.0 0.0 6300.0

3 Standard - Cartesian 0.0 0.0 2500.0 Supported

4 Standard - Cartesian 0.0 0.0 5400.0 Supported

5 Standard - Cartesian 0.0 0.0 4500.0

1.2 LINES

Line Line Length

No. Line Type Nodes No. L [mm] Comment

2 Polyline 4,5 900.0 Z

3 Polyline 2,4 900.0 Z

4 Polyline 5,3 2000.0 Z

1.3 MATERIALS

Matl. Modulus Modulus Poisson's Ratio Spec. Weight Coeff. of Th. Exp. Partial Factor Material

No. E [kN/cm 2] G [kN/cm 2] [-] [kN/m 3] [1/°C] M [-] Model

1 Steel S 235 | EN 10025-2:2004-11

21000.00 8076.92 0.300 78.50 1.20E-05 1.00 Isotropic Linear

Elastic

2 Aluminum EN-AW 6060 (ET,ER/B) T66 | EN 1999-1-1:2007

7000.00 2700.00 0.296 27.00 2.30E-05 1.00 Isotropic Linear

Elastic

1.7 NODAL SUPPORTS

Support Column Support Conditions

No. Nodes No. Axis System in Z uX/uX' uY/uY' uZ/uZ' X/X' Y/Y' Z/Z'

2 3 User Defined X',Y',Z'

3 2 Global X,Y,Z

1.7.10 NODAL SUPPORTS - NONLINEARITIES - SCAFFOLDING - PZ'/PHIX' PHIY',

ABSOLUTE

Support Direction Rotation [°] Coordinate 1st Node 1 Node 2 2nd Referen Member/Line

No. Type Sequence about X about Y about Z System axis No. No. axis Node No.

2 Rotated ZYX 0.00 -90.00 0.00

TO 150/50/2/2/2/2 TO 116/44/5/5/5/5

1.13 CROSS-SECTIONS

Section Matl. J [mm 4] Iy [mm 4] Iz [mm 4] Principal Axes Rotation Overall Dimensions [mm]

No. No. A [mm 2] Ay [mm 2] Az [mm 2] [°] ' [°] Width b Height h

1 TO 150/50/2/2/2/2

TO 150/44/3/3/3/3

2 1030980.3 2132645.3 378245.3 0.00 0.00 50.0 150.0

784.0 104.6 549.5

2 TO 116/44/5/5/5/5

1 1261849.4 2348740.0 476260.0 0.00 0.00 44.0 116.0

1500.0 224.9 1033.7

3 TO 150/44/3/3/3/3

2 1162683.8 2919384.0 406336.0 0.00 0.00 44.0 150.0

1128.0 123.5 818.5

1.17 MEMBERS

Mbr. Line Rotation Cross-Section Hinge No. Ecc. Div. Length

No. No. Member Type [°] Start End Start End No. No. L [mm]

4 4 Beam Angle 0.00 1 1 - - - - 2000.0 Z

5 2 Beam Angle 0.00 1 1 - - - - 900.0 Z

6 3 Beam Angle 0.00 1 1 - - - - 900.0 Z

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 2/10

Project: Model: Prosta-greda-4.3 Sheet: 1

MODEL

Node Numbering Isometric

Member Numbering 2

Cross-Section Description

M6

4

TO 150/50/2/2/2/2

M5

5

TO 150/50/2/2/2/2

3800.0

M4

TO 150/50/2/2/2/2

2.1 LOAD CASES

Load Load Case EN 1990 | CEN Self-Weight - Factor in Direction

Case Description Action Category Active X Y Z

LC1 Permanent 0.000 0.000 -1.000

LC2 Wind Wind

2.1.1 LOAD CASES

Load Load Case

Case Description Calculation Parameters

LC1 Method of analysis : Geometrically linear analysis

Method for solving system of : Newton-Raphson

nonlinear algebraic equations

Activate stiffness factors of: : Cross-sections (factor for J, Iy, I z, A, Ay, Az)

: Members (factor for GJ, EIy, EIz, EA, GA y, GAz)

LC2 Wind Method of analysis : Geometrically linear analysis

Method for solving system of : Newton-Raphson

nonlinear algebraic equations

Activate stiffness factors of: : Cross-sections (factor for J, Iy, I z, A, Ay, Az)

: Members (factor for GJ, EIy, EIz, EA, GA y, GAz)

2.5 LOAD COMBINATIONS

Load Load Combination

Combin. DS Description No. Factor Load Case

CO1 Uls 1 1.35 LC1

2 1.50 LC2 Wind

CO2 1.35*LC1 + 1.5*LC2 1 1.35 LC1

2 1.50 LC2 Wind

2.5.2 LEHR'S DAMPING DIFFERENT FOR EACH LOAD CASE

Load

Combin. Description Calculation Parameters

CO1 Uls Method of analysis : Second order analysis (P-Delta)

Method for solving system of : Picard

nonlinear algebraic equations

Options : Consider favorable effects due to tension

: Refer internal forces to deformed system for:

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 3/10

Project: Model: Prosta-greda-4.3 Sheet: 1

2.5.2 LEHR'S DAMPING DIFFERENT FOR EACH LOAD CASE

Load

Combin. Description Calculation Parameters

Normal forces N

Shear forces Vy and Vz

Moments My, Mz and MT

Activate stiffness factors of: : Materials (partial factor M)

: Cross-sections (factor for J, Iy, I z, A, Ay, Az)

: Members (factor for GJ, EIy, EIz, EA, GA y, GAz)

CO2 1.35*LC1 + 1.5*LC2 Method of analysis : Second order analysis (P-Delta)

Method for solving system of : Picard

nonlinear algebraic equations

Options : Consider favorable effects due to tension

: Refer internal forces to deformed system for:

Normal forces N

Shear forces Vy and Vz

Moments My, Mz and MT

Activate stiffness factors of: : Materials (partial factor M)

: Cross-sections (factor for J, Iy, I z, A, Ay, Az)

: Members (factor for GJ, EIy, EIz, EA, GA y, GAz)

LC1 3.2 MEMBER LOADS LC1

Reference On Members Load Load Load Reference Load Parameters

No. to No. Type Distribution Direction Length Symbol Value Unit

1 Members 6 Force Concentr. ZL True Length P -0.950 kN

A 350.0 mm

5 Members 5 Force Concentr. ZL True Length P -0.800 kN

A 100.0 mm

6 Members 4 Force Concentr. ZL True Length P -0.950 kN

A 800.0 mm

3.2/2 WIND ON ICE|WI|WI|WIND ON ICE LC1

Reference On Members Absolute Offset Relative Offset

No. to No. eY [mm] eZ [mm] y-Axis z-Axis

1 Members 6 0.0 0.0 Middle Middle

5 Members 5 0.0 0.0 Middle Middle

6 Members 4 0.0 0.0 Middle Middle

3.1 NODAL LOADS - BY COMPONENTS

LC2 - COORDINATE SYSTEM LC2: Wind

Wind On Nodes Coordinate Force [kN] Moment [kNmm]

No. No. System PX / P U PY / PV PZ / P W MX / MU MY / MV MZ / MW

1 2 0 | Global XYZ 0.823 0.000 0.000 0.000 0.000 0.000

3.2 MEMBER LOADS LC2: Wind

Reference On Members Load Load Load Reference Load Parameters

No. to No. Type Distribution Direction Length Symbol Value Unit

1 Members 6 Force Uniform z True Length p 0.600 kN/m

2 Members 4,5 Force Uniform z True Length p 0.600 kN/m

3.2/1 WIND LOADS – FWK – EXECUTION|6.2||WIND LOADS LC2: Wind

Reference On Members Absolute Offset Absolute Offset Relative Offset Relative Offset

No. to No. Mbr. Start Mbr. Start Mbr. End Mbr. End Mbr. Start Mbr. Start Mbr. End Mbr. End

eY [mm] eZ [mm] eY [mm] eZ [mm] y-Axis z-Axis y-Axis z-Axis

1 Members 6 0.0 0.0 0.0 0.0 Middle Middle Middle Middle

2 Members 4,5 0.0 0.0 0.0 0.0 Middle Middle Middle Middle

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 4/10

Project: Model: Prosta-greda-4.3 Sheet: 1

LC2: WIND

LC2 : Wind Isometric

Loads [kN/m], [kN] 0.823 2

0.600

0.600

3800.0

0.600

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 5/10

Project: Model: Prosta-greda-4.3 Sheet: 1

4.0 RESULTS - SUMMARY

Description Value Unit Comment

Load Case LC1

Sum of loads in X 0.000 kN

Sum of support reactions in X 0.000 kN

Sum of loads in Y 0.000 kN

Sum of support reactions in Y 0.000 kN

Sum of loads in Z -2.780 kN

Sum of support reactions in Z -2.780 kN Deviation 0.00%

Resultant of reactions about X 0.000 kNmm At center of gravity of model (X:0.000, Y:0.000, Z:4400.000 mm)

Resultant of reactions about Y 0.000 kNmm At center of gravity of model

Resultant of reactions about Z 0.000 kNmm At center of gravity of model

Max. displacement in X 0.0 mm

Max. displacement in Y 0.0 mm

Max. displacement in Z -0.1 mm Member No. 4, x: 2000.0 mm

Max. vector displacement 0.1 mm Member No. 4, x: 2000.0 mm

Max. rotation about X 0.00 °

Max. rotation about Y 0.00 °

Max. rotation about Z 0.00 °

Maximum member strain 0.000 mm/m Member No. 0, x: 0.0 mm

Method of analysis Linear Geometrically linear analysis

Reduction of stiffness Cross-sections, Members, Surfaces

Number of load increments 1

Number of iterations 1

Maximum value of element of stiffness matrix on 1.22E+08

diagonal

Minimum value of element of stiffness matrix on 1.E+03

diagonal

Stiffness matrix determinant 3.544E+113

Infinity Norm 2.439E+08

Load Case LC2 - Wind

Sum of loads in X 3.103 kN

Sum of support reactions in X 3.103 kN Deviation 0.00%

Sum of loads in Y 0.000 kN

Sum of support reactions in Y 0.000 kN

Sum of loads in Z 0.000 kN

Sum of support reactions in Z 0.000 kN

Resultant of reactions about X 0.000 kNmm At center of gravity of model (X:0.000, Y:0.000, Z:4400.000 mm)

Resultant of reactions about Y 1563.700 kNmm At center of gravity of model

Resultant of reactions about Z 0.000 kNmm At center of gravity of model

Max. displacement in X 10.9 mm Member No. 4, x: 0.0 mm

Max. displacement in Y 0.0 mm

Max. displacement in Z 0.0 mm

Max. vector displacement 10.9 mm Member No. 4, x: 0.0 mm

Max. rotation about X 0.00 °

Max. rotation about Y 0.53 ° Member No. 4, x: 2000.0 mm

Max. rotation about Z 0.00 °

Maximum member strain 0.000 mm/m Member No. 0, x: 0.0 mm

Method of analysis Linear Geometrically linear analysis

Reduction of stiffness Cross-sections, Members, Surfaces

Number of load increments 1

Number of iterations 1

Maximum value of element of stiffness matrix on 1.22E+08

diagonal

Minimum value of element of stiffness matrix on 1.E+03

diagonal

Stiffness matrix determinant 3.544E+113

Infinity Norm 2.439E+08

Load Combination CO1 - Uls

Sum of loads in X 4.655 kN

Sum of support reactions in X 4.655 kN Deviation 0.00%

Sum of loads in Y 0.000 kN

Sum of support reactions in Y 0.000 kN

Sum of loads in Z -3.754 kN

Sum of support reactions in Z -3.754 kN Deviation 0.00%

Resultant of reactions about X 0.00 kNmm At center of gravity of model (X:0.00, Y:0.00, Z:4400.00 mm)

Resultant of reactions about Y 2377.03 kNmm At center of gravity of model

Resultant of reactions about Z 0.00 kNmm At center of gravity of model

Max. displacement in X 16.2 mm Member No. 4, x: 200.0 mm

Max. displacement in Y 0.0 mm

Max. displacement in Z -0.1 mm Member No. 4, x: 2000.0 mm

Max. vector displacement 16.2 mm Member No. 4, x: 200.0 mm

Max. rotation about X 0.00 °

Max. rotation about Y 0.78 ° Member No. 4, x: 2000.0 mm

Max. rotation about Z 0.00 °

Maximum member strain 0.000 mm/m Member No. 0, x: 0.0 mm

Method of analysis 2nd Order Second order analysis (Nonlinear, Timoshenko)

Internal forces referred to deformed system for... N, Vy, Vz, My, Mz, M T

Reduction of stiffness Materials, Cross-sections, Members, Surfaces

Consider favorable effects of tensile forces

Divide results by CO factor

Number of load increments 1

Number of iterations 2

Maximum value of element of stiffness matrix on 1.22E+08

diagonal

Minimum value of element of stiffness matrix on 1.E+01

diagonal

Stiffness matrix determinant 5.459E+101

Infinity Norm 2.439E+08

Load Combination CO2 - 1.35*LC1 + 1.5*LC2

Sum of loads in X 4.655 kN

Sum of support reactions in X 4.655 kN Deviation 0.00%

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 6/10

Project: Model: Prosta-greda-4.3 Sheet: 1

4.0 RESULTS - SUMMARY

Description Value Unit Comment

Sum of loads in Y 0.000 kN

Sum of support reactions in Y 0.000 kN

Sum of loads in Z -3.754 kN

Sum of support reactions in Z -3.754 kN Deviation 0.00%

Resultant of reactions about X 0.00 kNmm At center of gravity of model (X:0.00, Y:0.00, Z:4400.00 mm)

Resultant of reactions about Y 2377.03 kNmm At center of gravity of model

Resultant of reactions about Z 0.00 kNmm At center of gravity of model

Max. displacement in X 16.2 mm Member No. 4, x: 200.0 mm

Max. displacement in Y 0.0 mm

Max. displacement in Z -0.1 mm Member No. 4, x: 2000.0 mm

Max. vector displacement 16.2 mm Member No. 4, x: 200.0 mm

Max. rotation about X 0.00 °

Max. rotation about Y 0.78 ° Member No. 4, x: 2000.0 mm

Max. rotation about Z 0.00 °

Maximum member strain 0.000 mm/m Member No. 0, x: 0.0 mm

Method of analysis 2nd Order Second order analysis (Nonlinear, Timoshenko)

Internal forces referred to deformed system for... N, Vy, Vz, My, Mz, M T

Reduction of stiffness Materials, Cross-sections, Members, Surfaces

Consider favorable effects of tensile forces

Divide results by CO factor

Number of load increments 1

Number of iterations 2

Maximum value of element of stiffness matrix on 1.22E+08

diagonal

Minimum value of element of stiffness matrix on 1.E+01

diagonal

Stiffness matrix determinant 5.459E+101

Infinity Norm 2.439E+08

Summary

Max. displacement in X 16.2 mm CO1, Member No. 4, x: 200.0 mm

Max. displacement in Y 0.0

Max. displacement in Z -0.1 mm CO1, Member No. 4, x: 2000.0 mm

Max. vector displacement 16.2 mm CO1, Member No. 4, x: 200.0 mm

Max. rotation about X 0.00

Max. rotation about Y 0.78 ° CO1, Member No. 4, x: 2000.0 mm

Max. rotation about Z 0.00

Other Settings:

Number of 1D finite elements 3

Number of 2D finite elements 0

Number of 3D finite elements 0

Number of FE mesh nodes 4

Number of equations 24

Internal forces referred to deformed system for...:

Max. number of iterations 100

Number of divisions for member results 10

Division of cable/foundation/tapered members 10

Number of member divisions for searching 10

maximum values

Subdivisions of FE mesh for graphical results 3

Percentage of iterations according to Picard 5 %

method in combination with Newton-Raphson

method

Options:

Activate shear stiffness of members (Ay, Az)

Activate member divisions for large deformation or

post-critical analysis

Activate entered stiffness modifications

Ignore rotational degrees of freedom

Check of critical forces of members

Nonsymmetric direct solver if demanded by

nonlinear model

Method for the system of equations Direct

Plate bending theory Mindlin

Solver version 64-bit

Precision and Tolerance:

Change default setting

4.1 NODES - SUPPORT FORCES

Node Support Forces [kN] Support Moments [kNmm]

No. LC/CO PX' PY' PZ' MX' MY' MZ'

2 LC1 0.000 0.000 -2.780 0.000 0.000 0.000

LC2 1.963 0.000 0.000 0.000 0.000 0.000 Wind

CO1 2.953 0.000 -3.754 0.000 0.000 0.000 Uls

CO2 2.953 0.000 -3.754 0.000 0.000 0.000

3* LC1 0.000 0.000 0.000 0.000 0.000 0.000

LC2 0.000 0.000 -1.140 0.000 0.000 0.000 Wind

CO1 0.000 0.000 -1.702 0.000 0.000 0.000 Uls

CO2 0.000 0.000 -1.702 0.000 0.000 0.000

Supp. LC1 0.000 0.000 -2.780

Loads LC1 0.000 0.000 -2.780

Supp. LC2 3.103 0.000 0.000

Loads LC2 3.103 0.000 0.000

Supp. CO1 4.655 0.000 -3.754

Supp. CO1 4.655 0.000 -3.754

Supp. CO2 4.655 0.000 -3.754

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 7/10

Project: Model: Prosta-greda-4.3 Sheet: 1

4.1 NODES - SUPPORT FORCES

Node Support Forces [kN] Support Moments [kNmm]

No. LC/CO PX' PY' PZ' MX' MY' MZ'

Supp. CO2 4.655 0.000 -3.754

4.12 CROSS-SECTIONS - INTERNAL FORCES

Member Node Location Forces [kN] Moments [kNmm]

No. LC/CO No. x [mm] N Vy Vz MT My Mz

Section No. 1: TO 150/50/2/2/2/2

4 LC1 5 0.0 0.992 0.000 0.000 0.000 0.000 0.000

800.0 0.975 0.000 0.000 0.000 0.000 0.000

800.0 0.025 0.000 0.000 0.000 0.000 0.000

3 2000.0 0.000 0.000 0.000 0.000 0.000 0.000

LC2 5 0.0 0.000 0.000 -0.060 0.000 -1080.000 0.000

3 2000.0 0.000 0.000 1.140 0.000 0.000 0.000

CO1 5 0.0 1.340 0.000 -0.097 0.000 -1594.680 0.000

800.0 1.321 0.000 0.616 0.000 -1385.410 0.000

800.0 0.039 0.000 0.616 0.000 -1385.400 0.000

3 2000.0 0.023 0.000 1.702 0.000 0.000 0.000

CO2 5 0.0 1.340 0.000 -0.097 0.000 -1594.680 0.000

800.0 1.321 0.000 0.616 0.000 -1385.410 0.000

800.0 0.039 0.000 0.616 0.000 -1385.400 0.000

3 2000.0 0.023 0.000 1.702 0.000 0.000 0.000

5 LC1 4 0.0 1.811 0.000 0.000 0.000 0.000 0.000

100.0 1.809 0.000 0.000 0.000 0.000 0.000

100.0 1.009 0.000 0.000 0.000 0.000 0.000

5 900.0 0.992 0.000 0.000 0.000 0.000 0.000

LC2 4 0.0 0.000 0.000 -0.600 0.000 -783.000 0.000

5 900.0 0.000 0.000 -0.060 0.000 -1080.000 0.000

CO1 4 0.0 2.454 0.000 -0.884 0.000 -1149.220 0.000

100.0 2.450 0.000 -0.798 0.000 -1233.850 0.000

100.0 1.370 0.000 -0.798 0.000 -1233.870 0.000

5 900.0 1.340 0.000 -0.097 0.000 -1594.680 0.000

CO2 4 0.0 2.454 0.000 -0.884 0.000 -1149.220 0.000

100.0 2.450 0.000 -0.798 0.000 -1233.850 0.000

100.0 1.370 0.000 -0.798 0.000 -1233.870 0.000

5 900.0 1.340 0.000 -0.097 0.000 -1594.680 0.000

6 LC1 2 0.0 2.780 0.000 0.000 0.000 0.000 0.000

350.0 2.773 0.000 0.000 0.000 0.000 0.000

350.0 1.823 0.000 0.000 0.000 0.000 0.000

4 900.0 1.811 0.000 0.000 0.000 0.000 0.000

LC2 2 0.0 0.000 0.000 -1.140 0.000 0.000 0.000

4 900.0 0.000 0.000 -0.600 0.000 -783.000 0.000

CO1 2 0.0 3.777 0.000 -1.667 0.000 0.000 0.000

350.0 3.761 0.000 -1.361 0.000 -532.270 0.000

350.0 2.479 0.000 -1.361 0.000 -532.298 0.000

4 900.0 2.454 0.000 -0.884 0.000 -1149.220 0.000

CO2 2 0.0 3.777 0.000 -1.667 0.000 0.000 0.000

350.0 3.761 0.000 -1.361 0.000 -532.270 0.000

350.0 2.479 0.000 -1.361 0.000 -532.298 0.000

4 900.0 2.454 0.000 -0.884 0.000 -1149.220 0.000

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 8/10

Project: Model: Prosta-greda-4.3 Sheet: 1

GLOBAL DEFORMATIONS uX, SUPPORT REACTIONS

LC2 : Wind Isometric

Support Reactions[kN] 2

1.963

M6

4

TO 150/50/2/2/2/2

M5

5

TO 150/50/2/2/2/2

10.9

3800.0

M4

TO 150/50/2/2/2/2

3

1.140

Factor of deformations: 35.00

Max P-X': 1.963, Min P-X': 0.000 kN

Max P-Y': 0.000, Min P-Y': 0.000 kN

Max P-Z': 0.000, Min P-Z': -1.140 kN

Max u-X: 10.9, Min u-X: 0.0 mm

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 9/10

Project: Model: Prosta-greda-4.3 Sheet: 1

RF-ALUMINUM

CA1

Design of aluminum 1.1 GENERAL DATA

members according to Members to design: All

Eurocode 9 Sets of members to design:

National Annex: CEN

Ultimate Limit State Design

Load combinations to design: CO2 1.35*LC1 + 1.5*LC2

1.2 MATERIALS

Matl. Material E- Modulus Shear Modulus Poisson's Ratio Proof Strength Max. Thickness

No. Description E [ksi] G [ksi] [-] fo [ksi] t [mm]

2 Aluminum EN-AW 6060 (ET, 10152.600 3916.020 0.300 23.206 3.0

ER/B) T66 | EN 1999-1-1:2007

TO 150/50/2/2/2/2 1.3 CROSS-SECTIONS

Sect. Matl. Cross-Section Cross-Section Max Design

No. No. Description Type Ratio Comment

1 2 TO 150/50/2/2/2/2 Box welded 0.39

1.6 EFFECTIVE LENGTHS - MEMBERS

Member Buckling Buckling About Axis y Buckling About Axis z Lateral-Torsional Buckling

No. Possible Possible k cr,y Lcr,y [mm] Possible kcr,z Lcr,z [mm] Possible kz kw Lw [mm] LT [mm]

4 1.00 2000.0 1.00 2000.0 1.0 1.0 2000.0 2000.0

5 1.00 900.0 1.00 900.0 1.0 1.0 900.0 900.0

6 1.00 900.0 1.00 900.0 1.0 1.0 900.0 900.0

2.4 DESIGN BY MEMBER

Member Location LC/CO/ Design Equation Description

No. x [mm] RC No.

4 Cross-section No. 1 - TO 150/50/2/2/2/2

800.0 CO2 0.34 1 106) Cross-section check - Bending about y-axis acc. to 6.2.5

2000.0 CO2 0.03 1 111) Cross-section check - Shear force in z-axis acc. to 6.2.6

2000.0 CO2 0.05 1 122) Cross-section check - Shear buckling acc. to 6.7.4.1 - Shear force in

z-axis

2000.0 CO2 0.05 1 124) Cross-section check - Shear buckling acc. to 6.5.5 - Shear force in

z-axis

800.0 CO2 0.34 1 141) Cross-section check - Bending and shear force acc. to 6.2.5 and

6.2.8

800.0 CO2 0.34 1 150) Cross-section check - Bending, shear force and torsion acc. to 6.7 -

Plate girders

200.0 CO2 0.39 1 171) Cross-section check - Bending, shear and axial force acc. to 6.2.9

200.0 CO2 0.39 1 180) Cross-section check - Bending, shear, axial force and torsion acc.

to 6.7 - Plate girders

5 Cross-section No. 1 - TO 150/50/2/2/2/2

0.0 CO2 0.02 1 111) Cross-section check - Shear force in z-axis acc. to 6.2.6

0.0 CO2 0.03 1 122) Cross-section check - Shear buckling acc. to 6.7.4.1 - Shear force in

z-axis

0.0 CO2 0.03 1 124) Cross-section check - Shear buckling acc. to 6.5.5 - Shear force in

z-axis

900.0 CO2 0.39 1 171) Cross-section check - Bending, shear and axial force acc. to 6.2.9

900.0 CO2 0.39 1 180) Cross-section check - Bending, shear, axial force and torsion acc.

to 6.7 - Plate girders

6 Cross-section No. 1 - TO 150/50/2/2/2/2

0.0 CO2 0.03 1 101) Cross-section check - Tension acc. to 6.2.3

0.0 CO2 0.03 1 111) Cross-section check - Shear force in z-axis acc. to 6.2.6

0.0 CO2 0.05 1 122) Cross-section check - Shear buckling acc. to 6.7.4.1 - Shear force in

z-axis

0.0 CO2 0.05 1 124) Cross-section check - Shear buckling acc. to 6.5.5 - Shear force in

z-axis

900.0 CO2 0.28 1 171) Cross-section check - Bending, shear and axial force acc. to 6.2.9

900.0 CO2 0.28 1 180) Cross-section check - Bending, shear, axial force and torsion acc.

to 6.7 - Plate girders

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

Page: 10/10

Project: Model: Prosta-greda-4.3 Sheet: 1

DESIGN RATIO

RF-ALUMINUM CA1 Isometric

Ultimate Limit State: Cross-Section Design, Stability Design

2

Max

Design Ratio [-] 0.05

0.39

0.28 4

0.00

Max : 0.39

Min : 0.00

0.39 5

0.39

3

0.05

Max Design Ratio: 0.39

RFEM 5.25.02 - General 3D structures solved using FEM www.dlubal.com

You might also like

- Advaita Vedanta and Modern ScienceDocument63 pagesAdvaita Vedanta and Modern ScienceKaushik Saha100% (1)

- Abs 0056Document17 pagesAbs 0056darrow dori100% (1)

- Stress Analysis Methods For Underground Pipe Lines Part 1 - Basic CalculationsDocument5 pagesStress Analysis Methods For Underground Pipe Lines Part 1 - Basic Calculationskumaran__k100% (3)

- Biaxial Bending in ColumnsDocument14 pagesBiaxial Bending in Columnsnvnrev100% (1)

- MItcal - Ejemplo de ClaseDocument102 pagesMItcal - Ejemplo de ClasedaagiraldogoNo ratings yet

- Schüco Fassade FW 50+ - FW 60+Document112 pagesSchüco Fassade FW 50+ - FW 60+BrcakNo ratings yet

- Allplan 2015 BasicsTutl PDFDocument269 pagesAllplan 2015 BasicsTutl PDFSirHumptyDumptyNo ratings yet

- Lateral Bracing of Beams Provided by Standing Seam Roof System Concepts and Case StudyDocument11 pagesLateral Bracing of Beams Provided by Standing Seam Roof System Concepts and Case Studyjackcan501No ratings yet

- ch4 Mechanical Properties of Wood PDFDocument46 pagesch4 Mechanical Properties of Wood PDFdan-gabiNo ratings yet

- Unbalance: Dew/Cbpm Lab/JvDocument27 pagesUnbalance: Dew/Cbpm Lab/JvNaveen ChodagiriNo ratings yet

- Stub 1.1Document9 pagesStub 1.1BrcakNo ratings yet

- Stub 3Document9 pagesStub 3BrcakNo ratings yet

- Pipe Support - Calculation ReportDocument33 pagesPipe Support - Calculation ReportIkramNo ratings yet

- 03-Conn-102 - Glass RailingDocument5 pages03-Conn-102 - Glass RailingReysan Caballero GonzalesNo ratings yet

- Duct Working LayoutDocument1 pageDuct Working LayoutAlps EngineeringNo ratings yet

- PTR90 777814Document5 pagesPTR90 777814Sgly ZemogNo ratings yet

- Frame UnitDocument27 pagesFrame UnitVN MÁY TỰ ĐỘNGNo ratings yet

- Specification For Fixed, Insulated, Hermetically Sealed Tantalum Capacitors With Solid ElectrolyteDocument5 pagesSpecification For Fixed, Insulated, Hermetically Sealed Tantalum Capacitors With Solid ElectrolytepadmanabhanNo ratings yet

- SAW Components: SAW RX 2in1 FilterDocument12 pagesSAW Components: SAW RX 2in1 Filterdiagnoz7auto7carsvanNo ratings yet

- TACT Switch TDSDocument3 pagesTACT Switch TDSHareram ShuklaNo ratings yet

- Calculo de Bus BarraDocument8 pagesCalculo de Bus BarraJohn AnguloNo ratings yet

- Part Number 22232KEJW33, Spherical Roller Bearings - Steel CageDocument4 pagesPart Number 22232KEJW33, Spherical Roller Bearings - Steel CageXiaoYaiZiZaiNo ratings yet

- Le Cle I Re Foucault Final BDocument6 pagesLe Cle I Re Foucault Final BdanyNo ratings yet

- Assignment 2: Submitt Ed by Hassan AhmedDocument11 pagesAssignment 2: Submitt Ed by Hassan AhmedHasan AhmedNo ratings yet

- Flexible Pavement DesignDocument39 pagesFlexible Pavement DesignSaurabh KumarNo ratings yet

- Material: DesignDocument26 pagesMaterial: DesignDavor IlicNo ratings yet

- ASNA2050 - Solid Rivet - Aluminium&UniversalHead PDFDocument9 pagesASNA2050 - Solid Rivet - Aluminium&UniversalHead PDFAnonymous mq0U43UsP100% (1)

- Power Scaling of Kw-Diode Lasers Optimized For Material Processing ApplicationsDocument9 pagesPower Scaling of Kw-Diode Lasers Optimized For Material Processing ApplicationsDu RoyNo ratings yet

- Craneway: Design of Crane RunwayDocument5 pagesCraneway: Design of Crane RunwayHamdi AslanNo ratings yet

- Post TensionDocument8 pagesPost Tensionedc1312No ratings yet

- Portal 1 PDFDocument21 pagesPortal 1 PDFAyodele Oluwaseyi DinaNo ratings yet

- Connector: 0.5mm Pitch/connectors For FPCDocument2 pagesConnector: 0.5mm Pitch/connectors For FPCJoão Paulo Da S NogueiraNo ratings yet

- Radio SIAE (Dia 0,6 M)Document8 pagesRadio SIAE (Dia 0,6 M)indra_uhuiiNo ratings yet

- E ACH1Document2 pagesE ACH1JamesNo ratings yet

- Part Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialGỗ MộcNo ratings yet

- Navi Mumbai Metro Line 1: Mast Calculation - Panchanand DepotDocument3 pagesNavi Mumbai Metro Line 1: Mast Calculation - Panchanand DepotAnkit AgarwalNo ratings yet

- MICROJDocument12 pagesMICROJalexanderNo ratings yet

- RECOM Rev BDocument1 pageRECOM Rev Be.montgomeryNo ratings yet

- WL24Document23 pagesWL24alex robinNo ratings yet

- 2D Plane Strain PlasticityDocument4 pages2D Plane Strain PlasticitySebastiao SilvaNo ratings yet

- Detail 02 L Vinkel Var 1Document14 pagesDetail 02 L Vinkel Var 1BrcakNo ratings yet

- SurlokPlusRighAnglePlug3 6Document47 pagesSurlokPlusRighAnglePlug3 6ayesNo ratings yet

- Innershield NS-3M: Welding Positions Key FeaturesDocument2 pagesInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoNo ratings yet

- Pg240128a DisplayDocument1 pagePg240128a Displaybancadasol03No ratings yet

- 1500 SLC DS-1Document2 pages1500 SLC DS-1Soup PongsakornNo ratings yet

- Catalog Low Voltage Armour Cable XLPE CableDocument39 pagesCatalog Low Voltage Armour Cable XLPE Cableteguh prasetyoNo ratings yet

- Description of The ProjectDocument8 pagesDescription of The ProjectCompass GreenNo ratings yet

- Examples of ConductorsDocument16 pagesExamples of ConductorsJubert PerezNo ratings yet

- Part Number 22211KEJW33, Spherical Roller Bearings - Steel CageDocument4 pagesPart Number 22211KEJW33, Spherical Roller Bearings - Steel CageXiaoYaiZiZaiNo ratings yet

- Resistencia 680Document3 pagesResistencia 680Rafael Román García-sec DNo ratings yet

- Supreme Kabel NYYDocument2 pagesSupreme Kabel NYYIntanNo ratings yet

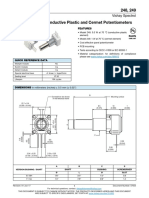

- 248, 249 1/2" (12.7 MM) Conductive Plastic and Cermet PotentiometersDocument20 pages248, 249 1/2" (12.7 MM) Conductive Plastic and Cermet PotentiometersRahmat Nur IlhamNo ratings yet

- WL21Document11 pagesWL21alex robinNo ratings yet

- SJ Mepla Calculation Protocol: Geometry:: Project: 03-Jlt Case-3 - Wl-1.72Kpa Back Support 03-04-2024Document9 pagesSJ Mepla Calculation Protocol: Geometry:: Project: 03-Jlt Case-3 - Wl-1.72Kpa Back Support 03-04-2024alex robinNo ratings yet

- WL02Document9 pagesWL02alex robinNo ratings yet

- SJ Mepla Calculation Protocol: Geometry:: Project: 03-Jlt Case-3 - Wl-1.72Kpa Back Support 03-04-2024Document10 pagesSJ Mepla Calculation Protocol: Geometry:: Project: 03-Jlt Case-3 - Wl-1.72Kpa Back Support 03-04-2024alex robinNo ratings yet

- Project Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16Document21 pagesProject Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16kheang amgNo ratings yet

- Program Discerption & VerificationDocument45 pagesProgram Discerption & VerificationMohammed Haitham ElShafieNo ratings yet

- ZJYS81 - CanCommon Mode FiltersDocument2 pagesZJYS81 - CanCommon Mode Filters40818248No ratings yet

- 120 X 120 X 38 MM SERIES: Dimensions DrawingDocument1 page120 X 120 X 38 MM SERIES: Dimensions DrawingrseheNo ratings yet

- Rf/Pulse Transformers: Electrical Specifications @25 CDocument1 pageRf/Pulse Transformers: Electrical Specifications @25 CzakreaNo ratings yet

- Kajian Teknis Untuk Perubahan Kabel Feeder Trafo To LVMDPDocument4 pagesKajian Teknis Untuk Perubahan Kabel Feeder Trafo To LVMDPHendrias ari sujarwoNo ratings yet

- Magnet Selection Homogenous Field Application Note MelexisDocument8 pagesMagnet Selection Homogenous Field Application Note MelexisCelis CedeñoNo ratings yet

- Analisys Panel Support Arah PendekDocument150 pagesAnalisys Panel Support Arah PendekWANSNo ratings yet

- Antenna Product Specifications: SLU1278S6Document8 pagesAntenna Product Specifications: SLU1278S6camilo andres ToroNo ratings yet

- Componon S4-0 80Document5 pagesComponon S4-0 80Никита КуратовNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Detail 02 L Vinkel Var 1Document14 pagesDetail 02 L Vinkel Var 1BrcakNo ratings yet

- Post-Installed Rebar Connections Technical Information ASSET DOC LOC 5018489Document77 pagesPost-Installed Rebar Connections Technical Information ASSET DOC LOC 5018489BrcakNo ratings yet

- Industrial Profiles 2018 Bros enDocument28 pagesIndustrial Profiles 2018 Bros enBrcakNo ratings yet

- List of Standards in SerbiaDocument51 pagesList of Standards in SerbiaBrcakNo ratings yet

- Allplan TutorialDocument330 pagesAllplan TutorialOana ScutarasuNo ratings yet

- GmizavciDocument19 pagesGmizavciBrcakNo ratings yet

- GmizavciDocument19 pagesGmizavciBrcakNo ratings yet

- 16.zidovi 3.SP. List4-Spec - ArmDocument1 page16.zidovi 3.SP. List4-Spec - ArmBrcakNo ratings yet

- Krek Revit 2014Document1 pageKrek Revit 2014BrcakNo ratings yet

- 001-LIM 20mmDocument1 page001-LIM 20mmBrcakNo ratings yet

- Instalacija Tower Build 1350 I ArmCAD-A Build 1763 Na Win 7 x64 UltimateDocument2 pagesInstalacija Tower Build 1350 I ArmCAD-A Build 1763 Na Win 7 x64 UltimateNikola Zecevic100% (2)

- Monarplan FMDocument1 pageMonarplan FMBrcakNo ratings yet

- tg53 Model PDFDocument1 pagetg53 Model PDFBrcakNo ratings yet

- Tg53 ModelDocument1 pageTg53 ModelBrcakNo ratings yet

- Nads Adic 1 - 1Document2 pagesNads Adic 1 - 1BrcakNo ratings yet

- Instructions For Europass CVDocument12 pagesInstructions For Europass CVKasia KowalskaNo ratings yet

- 2foundation Moments Hydraulics and CM Self Study QuestionsDocument40 pages2foundation Moments Hydraulics and CM Self Study QuestionsAngel TeyNo ratings yet

- Thermal MCQDocument42 pagesThermal MCQRanjeet KumarNo ratings yet

- Week II FlotationDocument23 pagesWeek II FlotationAamir SirohiNo ratings yet

- Introduction To SensorsDocument17 pagesIntroduction To SensorsHossam AbdelmoneimNo ratings yet

- Netting Analysis of Composite Pressure VesselsDocument3 pagesNetting Analysis of Composite Pressure VesselsPratyu Ch100% (1)

- Types of Fluid FlowDocument7 pagesTypes of Fluid FlowVinoth PandiNo ratings yet

- SHM Full NotesDocument11 pagesSHM Full Notessrashtikumariclass9No ratings yet

- Development Length - Difference Between Development Length and Lap LengthDocument6 pagesDevelopment Length - Difference Between Development Length and Lap LengthFeraidoon zamani najiNo ratings yet

- Principles of Foundation Design D.BDocument4 pagesPrinciples of Foundation Design D.BDavid BaltazaryNo ratings yet

- Lecture-2 Module-1 Structural Analysis-IIDocument26 pagesLecture-2 Module-1 Structural Analysis-IIHira WahabNo ratings yet

- Magnetism (Solved Ex. & Exciese)Document22 pagesMagnetism (Solved Ex. & Exciese)Chandradeep MandalNo ratings yet

- Hydrostatic Force On Plane SurfacesDocument3 pagesHydrostatic Force On Plane SurfaceskarthikNo ratings yet

- SimXpert R3.2 Motion Workspace GuideDocument262 pagesSimXpert R3.2 Motion Workspace GuidepaulkastleNo ratings yet

- Diseño de Maquinas - Estabilidad 2Document451 pagesDiseño de Maquinas - Estabilidad 2Rodrii RoblesNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- CHAPTER 4 - Theory of FailureDocument38 pagesCHAPTER 4 - Theory of FailureMadiha ZaimuriNo ratings yet

- Vortex Drop ShaftDocument9 pagesVortex Drop ShaftMarco PazNo ratings yet

- Strain Rate and Temperature Effects On Tensile Properties of Monocrystaline Cu6Sn5 by Molecule Dynamic SimulationDocument4 pagesStrain Rate and Temperature Effects On Tensile Properties of Monocrystaline Cu6Sn5 by Molecule Dynamic SimulationMd Sihan KhanNo ratings yet

- MSC Mechanical BUET-All QuestionsDocument13 pagesMSC Mechanical BUET-All QuestionsTahsin IbtidaNo ratings yet

- Bluebook (EN1993 1 1, HyperBeam, 17 Dec 2013)Document138 pagesBluebook (EN1993 1 1, HyperBeam, 17 Dec 2013)Peyman MznNo ratings yet

- Tutorial 5 FluentDocument56 pagesTutorial 5 FluentCrisner ToicenNo ratings yet

- Hydrodynamic Characteristics of Twin-Rudders at Small Attack AnglesDocument13 pagesHydrodynamic Characteristics of Twin-Rudders at Small Attack Anglesebey_endunNo ratings yet

- Friction Coefficient in PipesDocument16 pagesFriction Coefficient in PipesVanessa AyalaNo ratings yet

- M1 As-Level Past PaperDocument6 pagesM1 As-Level Past PaperTimur ChirkovNo ratings yet