Professional Documents

Culture Documents

Basic Civil Engineering - 4

Basic Civil Engineering - 4

Uploaded by

visanuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Civil Engineering - 4

Basic Civil Engineering - 4

Uploaded by

visanuCopyright:

Available Formats

TRADITIONAL MATERIALS 9

Then the cylinder is rotated at a speed of 30 to 33 rpm for specified number of times (500 to 1000). Then

the aggregate is removed and sieved on 1.7 mm. IS sieve. The weight of aggregate passing is found.

Then Los Angeles value is found as

Weight of aggregate passing through sieve

= × 100.

Original weight

The following values are recommended for road works:

For bituminous mixes – 30%

For base course – 50%

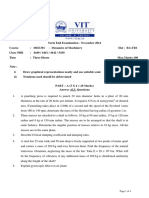

(iv) Impact Test: The resistance of stones to impact is found by conducting tests in impacting

testing machine (Fig. 1.2). It consists of a frame with guides in which a metal hammer weighing 13.5 to

15 kg can freely fall from a height of 380 mm.

Lifting

handle

Hammer of weight

132—137 N

100 mm dia Vertical guide

350 mm

bar

Cup 102 mm Dia

and height 50 mm

Circular base

Fig. 1.2. Aggregate impact testing machine

Aggregates of size 10 mm to 12.5 mm are filled in cylinder in 3 equal layers; each layer being

tamped 25 times. The same is then transferred to the cup and again tamped 25 times. The hammer is

then allowed to fall freely on the specimen 15 times. The specimen is then sieved through 2.36 mm

sieve. Then,

W2

Impact value =

W1

where W2 = weight of fines

W1 = original weight.

The recommended impact values for various works are:

(i) for wearing course >/ 30%

You might also like

- The Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Document6 pagesThe Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Dilshan0% (1)

- Transitions Between Two-Body and Three-Body Abrasive Wear InfluenceDocument10 pagesTransitions Between Two-Body and Three-Body Abrasive Wear InfluenceSamuel Berger VeltenNo ratings yet

- Tile Abrasion Lab ManualDocument8 pagesTile Abrasion Lab ManualAshish VermaNo ratings yet

- Experiment No. 2 Object-To Determine The Impact Value of Course AggregateDocument4 pagesExperiment No. 2 Object-To Determine The Impact Value of Course AggregateShivang VivekNo ratings yet

- Aggregate Impact TestsDocument12 pagesAggregate Impact TestsPavan BurraNo ratings yet

- Test of AggregateDocument24 pagesTest of AggregatePriyank BhimaniNo ratings yet

- Testing of AggregatesDocument6 pagesTesting of AggregatesMegelJoshuaRamiterreNo ratings yet

- Chapter 1 - Aggregate: SurfaceDocument3 pagesChapter 1 - Aggregate: SurfaceAmit KumarNo ratings yet

- Aggregate Lab ManualDocument24 pagesAggregate Lab ManualnikhilNo ratings yet

- Civil Engineering Material TestingDocument8 pagesCivil Engineering Material TestingprashmceNo ratings yet

- 18CV34 ArcDocument176 pages18CV34 ArcJose RappaiNo ratings yet

- Aggregate Impact ValueDocument5 pagesAggregate Impact ValuezahinNo ratings yet

- ACV TFV and AIVDocument7 pagesACV TFV and AIVBernard KitosiNo ratings yet

- Chapter 4-Bulk Deformation ProcessesDocument38 pagesChapter 4-Bulk Deformation ProcessesG. Dancer GhNo ratings yet

- Reference: BS: 812: 1975 (Part 1,2,3) "Methods For Sampling and Testing of Mineral Aggregates, Sands and Fillers"Document32 pagesReference: BS: 812: 1975 (Part 1,2,3) "Methods For Sampling and Testing of Mineral Aggregates, Sands and Fillers"Jubayer HassanNo ratings yet

- Aggregate Impact Value TestDocument15 pagesAggregate Impact Value Testmd khajaNo ratings yet

- 8 Stresses in BeamDocument6 pages8 Stresses in BeamAnkit SinghNo ratings yet

- TorsionDocument27 pagesTorsionVIPUL KOTHANo ratings yet

- Transportation LabDocument23 pagesTransportation LabSiddharth kumar SinghNo ratings yet

- Aggregate Impact Value TestDocument2 pagesAggregate Impact Value TestWasif RiazNo ratings yet

- Stress and StrainDocument73 pagesStress and StrainKarthikeyan MunirajNo ratings yet

- 2 Los-Angeles AbrasionDocument6 pages2 Los-Angeles AbrasionUmer KhanNo ratings yet

- Orascom 70 Ton T Block Lifting PlanDocument3 pagesOrascom 70 Ton T Block Lifting PlanIslam ShaheenNo ratings yet

- 6-A, B) Impact Test On Aggregate, Crushing Test On AggregateDocument5 pages6-A, B) Impact Test On Aggregate, Crushing Test On Aggregatevijay2293No ratings yet

- Torsional Yield FormulaDocument13 pagesTorsional Yield Formulamillenial troopersNo ratings yet

- 081B52EFAC704D5AB58072B74C443C48Document3 pages081B52EFAC704D5AB58072B74C443C48yashvantNo ratings yet

- 3.2.2 Basic Tests On AggregatesDocument3 pages3.2.2 Basic Tests On AggregatesannNo ratings yet

- Tests On BricksDocument19 pagesTests On BricksrashmarsvNo ratings yet

- Aggregate Impact Value TestDocument10 pagesAggregate Impact Value Testneeraja medapatiNo ratings yet

- Testing On AggregatesDocument12 pagesTesting On AggregatesNakul Kumar NishuNo ratings yet

- Rahul 20221410112 ILSS 3-Point Bending Test Exp4Document9 pagesRahul 20221410112 ILSS 3-Point Bending Test Exp4NCS RAHULNo ratings yet

- Aggregate Impact ValueDocument5 pagesAggregate Impact ValuemuralidharanNo ratings yet

- Design of Water TankDocument30 pagesDesign of Water TankDeepthi ReddyNo ratings yet

- Material Testing Lab: Sr. No. Specifications Unit Price in RsDocument3 pagesMaterial Testing Lab: Sr. No. Specifications Unit Price in Rsrahul srivastavaNo ratings yet

- Experiment No. 3 - Determination of Aggregate Impact Value: Objective: TheoryDocument3 pagesExperiment No. 3 - Determination of Aggregate Impact Value: Objective: TheoryKanishka SarkarNo ratings yet

- 05 - Todd Swinderman - Belt Wear Fron Loading and Belt CleaningDocument42 pages05 - Todd Swinderman - Belt Wear Fron Loading and Belt Cleaningluis martinezNo ratings yet

- Highway Engg Lab ExperimentsDocument9 pagesHighway Engg Lab Experimentskamalkumarbal77No ratings yet

- MOS Lab ReportDocument25 pagesMOS Lab ReportTalha MustafaNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValueAmira Ab RahmanNo ratings yet

- Elasticity and Hooke's LawDocument26 pagesElasticity and Hooke's LawSinaga PhilipNo ratings yet

- Material TestingDocument22 pagesMaterial Testing22Patil RiyaNo ratings yet

- Problems: Problem 1 Problem 2Document2 pagesProblems: Problem 1 Problem 2Lily Margareth ArrietaNo ratings yet

- Method B7 - The Determination of The Treton Impact Value of Aggregate.Document3 pagesMethod B7 - The Determination of The Treton Impact Value of Aggregate.GUO LEI100% (1)

- Vdocuments - MX - Pressure Vessel SafetyDocument21 pagesVdocuments - MX - Pressure Vessel SafetyMuhammad AkramNo ratings yet

- Abrasion TestDocument7 pagesAbrasion TestMohd SyahrulizamNo ratings yet

- Concrete and Highway Lab Manual SDMCET PDFDocument66 pagesConcrete and Highway Lab Manual SDMCET PDFMufassil KardiguddNo ratings yet

- Pile Hammer Weight PDFDocument2 pagesPile Hammer Weight PDFMohd Azual JaafarNo ratings yet

- Pile Hammer PDFDocument2 pagesPile Hammer PDFMohd Azual JaafarNo ratings yet

- Tutorial 5 FrictionDocument5 pagesTutorial 5 FrictionAjwad HaziqNo ratings yet

- Strength of Material Lab Manual: Mechanical Engineering Second Year Section B, B - 2Document27 pagesStrength of Material Lab Manual: Mechanical Engineering Second Year Section B, B - 2Satvik YelluriNo ratings yet

- Hooke Law BasicDocument27 pagesHooke Law BasicSinaga PhilipNo ratings yet

- Statement:: To Determine The Uniaxial Compressive Strength of Rocks Using L-Type & N-Type Schmidt Rebound HammerDocument6 pagesStatement:: To Determine The Uniaxial Compressive Strength of Rocks Using L-Type & N-Type Schmidt Rebound Hammerusama elalaouiNo ratings yet

- Fig. 1: Lab Vane Shear ApparatusDocument2 pagesFig. 1: Lab Vane Shear ApparatusKishanNo ratings yet

- Lecture 3 TorsionDocument24 pagesLecture 3 TorsionJacob BaltazarNo ratings yet

- MMEN 326 - Combined Benidng and TorsionDocument15 pagesMMEN 326 - Combined Benidng and TorsionchegedennNo ratings yet

- Hardness Testing and Impact Testing of MaterialsDocument32 pagesHardness Testing and Impact Testing of MaterialsMUUTHUKRISHNAN100% (4)

- Chapter 13 Lecture - Rolling ProcessDocument66 pagesChapter 13 Lecture - Rolling Processabd altwierNo ratings yet

- Concrete Testing: Non-DestructiveDocument46 pagesConcrete Testing: Non-DestructivekevalNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Design Construction Manual2002 - 10Document1 pageDesign Construction Manual2002 - 10visanuNo ratings yet

- Bentonite 1Document1 pageBentonite 1visanuNo ratings yet

- Communication Skills Basics - 6Document1 pageCommunication Skills Basics - 6visanuNo ratings yet

- Basic Civil Engineering - 8Document1 pageBasic Civil Engineering - 8visanuNo ratings yet

- Bentonite 4Document1 pageBentonite 4visanuNo ratings yet

- Communication Skills Basics - 7Document1 pageCommunication Skills Basics - 7visanuNo ratings yet

- Communication Skills Basics - 1Document1 pageCommunication Skills Basics - 1visanuNo ratings yet

- Design Construction Manual2002 - 6Document1 pageDesign Construction Manual2002 - 6visanuNo ratings yet

- Basic Civil Engineering - 15Document1 pageBasic Civil Engineering - 15visanuNo ratings yet

- Bentonite 6Document1 pageBentonite 6visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 2Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 2visanuNo ratings yet

- Communication Skills Basics - 2Document1 pageCommunication Skills Basics - 2visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 3Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 3visanuNo ratings yet

- Bentonite 3Document1 pageBentonite 3visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 4Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 4visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 3Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 3visanuNo ratings yet

- Bentonite 2Document1 pageBentonite 2visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 1Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 1visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 1Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 1visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 3Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 3visanuNo ratings yet

- Basic Civil Engineering - 13Document1 pageBasic Civil Engineering - 13visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 6Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 6visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 4Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 4visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 2Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 2visanuNo ratings yet

- ANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 5Document1 pageANALYSIS & DESIGN - Chen, Duan, Bridge Engineering Handbook, (CRC 1999) - 5visanuNo ratings yet

- Basic Civil Engineering - 11Document1 pageBasic Civil Engineering - 11visanuNo ratings yet

- Basic Civil Engineering - 14Document1 pageBasic Civil Engineering - 14visanuNo ratings yet

- Basic Civil Engineering - 9Document1 pageBasic Civil Engineering - 9visanu100% (1)

- Basic Civil Engineering - 10Document1 pageBasic Civil Engineering - 10visanuNo ratings yet

- Basic Civil Engineering - 12Document1 pageBasic Civil Engineering - 12visanuNo ratings yet