Professional Documents

Culture Documents

H600 CSpecs

Uploaded by

Mohammed ShifulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H600 CSpecs

Uploaded by

Mohammed ShifulCopyright:

Available Formats

H-600C Commercial Hot Tub Specs

Section Includes:

1. Hot Tub Materials

A. Shell

B. Plumbing

C. Suction/Return Fittings

2. Hot Tub Mechanical System

A. Plumbing

B. Mechanical

C. Equipment Layout

D. Optional Equipment

3. Warranty

1.1 – Hot Tub Materials

A. Shell

1. The Hot Tub shell shall be vacuum formed with 0.187” acrylic.

2. The acrylic shell shall be reinforced with two coats of fibreglass resin. The first

coat shall be a waterproof high adhesion vinyl ester. The second coat shall be a

conventional composite mix.

3. The shell shall be insulated using 2lb closed cell polyurethane foam.

4. Delineating markings shall be applied to the stair and bench edges with gel

coat.

B. Plumbing

1. Piping connected to and around the sump under the Hot Tub shall consist of

PVC (Poly-Vinyl Chloride) with Schedule 40 (ASTM D1785, CSA B137.3).

2. Piping connecting the white goods shall be PVC flex pipe (NSF 50).

3. Pipe fittings shall be PVC with Schedule 40 (ASTM D1784, ASTM D2466).

C. Suction/Return Fittings

1. There shall be five (5) hydrotherapy jets.

2. There shall be one (1) VGB compliant floor drain.

3. There shall be two (2) VGB compliant side wall suction inlets located in the

foot well.

4. There shall be one (1) Poolmiser water level controller.

5. There shall be one (1) wide mouthed skimmer (NSF listed).

6. There shall be two (2) filter returns located in the foot well.

7. There shall be two (2) air controls.

1.2 – Hot Tub Mechanical

A. Plumbing

1. Piping connecting the pump, filter and heater shall consist of 2” Schedule 40

rigid PVC (ASTM D1785, CSA B137.3).

2. Pipe fittings shall be PVC with Schedule 40 (ASTM D1784, ASTM D2466)

except when connecting directly to the heater CPVC Schedule 80 (ASTM D1784,

F441) shall be used.

3. One (1) Schedule 40 2” x ¾” reducing bushing to allow for a fresh water

connection.

4. Four (4) Schedule 40 PVC true union ball valve with EPDM seats.

B. Equipment

The basic mechanical package shall consist of:

1. One (1) 240V single phase 1/2hp filter pump with strainer (NSF listed,

UL listed)

2. One (1) 240V single phase 1.5hp jet pump with strainer (NSF listed, UL

listed).

3. One (1) 100 sq.ft Cartridge Filter (NSF listed).

4. One (1) 240V single phase 11kW Electric Heater (UL listed).

5. One (1) 2” Blue White flowmeter.

6. Two (2) Inline thermometers.

Please note that some dealers may purchase only a pre-plumbed hot tub shell

and supply their own equipment.

C. Packaged Equipment Layout

1. All equipment shall be organized, mounted and plumbed to stub outs

per the equipment layout on the hot tub drawing.

2. All equipment shall be mounted on two (2) waterproof, plastic pads.

3. Thermometers and gauges shall be provided, but not installed.

Not included: Following, but not limited to:

4. Connection piping between pre-plumbed shell and packaged

mechanical equipment.

5. Control and power wiring and electrical components.

D. Optional Equipment

The following equipment does not come standard with the hot tub mechanical package

and may be purchased/upgraded at additional cost.

1. Pumps and heater may be upgraded to 208V or 575V 3 Phase equipment

(12kW heater).

2. Chemical control system.

A. One (1) Pool Link 103 chemical controller (ETL listed).

B. One (1) probe chamber.

C. One (1) pH probe.

D. One (1) ORP probe.

E. One (1) piston style flow switch.

F. One (1) Fixed Rate Peristaltic Feed Pump for acid feed.

G. One (1) acid holding tank with lid.

H. One (1) Erosion Feeder (NSF listed).

I. One (1) ½” 120V/60Hz N/C brass solenoid valve with Viton seals.

3. Add second Fixed Rate Peristaltic Feed Pump and a chemical holding tank for

liquid sanitizer.

A. Removes Erosion Feeder

B. Removes solenoid valve.

4. Emergency push/pull switch.

A. One (1) N/O contact block.

B. One (1) N/C contact block.

C. One (1) push/pull button.

5. AV Alarm (flashing beacon with horn).

6. Low voltage spa light with install.

A. 12V Spa light (UL listed).

B. 300-watt safety transformer, 120V input to 12V output (CSA certified

for Canada and US).

7. United Electric Company B54-103 external high limit temperature switch (UL,

CSA, CE listed).

A. Adjustable from 0 to 225 F.

B. Includes stainless steel thermal well.

8. Top Mount 24” Sand Filter.

A. Includes sand.

B. 2” Variflow valve

C. Replaces 100 sq.ft cartridge filter.

9. 15-minute Countdown Timer.

10. Two (2) VA-2000S Vac-Alert SVRS units (ASME/ANSI 112.19.17 compliant).

11. Grab rail with deck flange, 33 inch.

A. One (1) 33” safety access “P” shaped grab rail.

B. Two (2) deck flanges.

C. One (1) hardware set.

12. Grab rail with anchors, 33 inch.

A. One (1) 33” safety access “P” shaped grab rail.

B. Two (2) brass rail anchors.

C. Two (2) escutcheons.

13. Hot tub hardcover.

A. 4” – 3” taper

B. Grey or brown.

14. UV Disinfection System

A. 48GPM UV Sanitizer

15. Substitute Gas or Propane Heater

A. 175,000 BTU Natural Gas Heater

B. Replaces 11KW 240V Heater

16. Rigid Plumbing

17. Additional R12 Insulation

1.3 – Hot Tub Warranty

1. Five (5) year limited warranty – shell

2. Two (2) year limited warranty – mechanical package

3. One (1) year limited warranty – labour

See full warranty for details and limitations.

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Section 21 12 00Document3 pagesSection 21 12 00Ismail MohammadNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Gs 42dhv 1pdDocument3 pagesGs 42dhv 1pdkarem el hassawyNo ratings yet

- RFQ - Hot WaterDocument8 pagesRFQ - Hot Waterrkpatel40No ratings yet

- HEP-23-02-232105 Mech Systems PipingDocument14 pagesHEP-23-02-232105 Mech Systems Pipingsenseiann.eslNo ratings yet

- SEC 226200 Laboratory Vacuum SystemDocument8 pagesSEC 226200 Laboratory Vacuum SystemAkilaJosephNo ratings yet

- 224700, Drinking Fountains and Water CoolersDocument4 pages224700, Drinking Fountains and Water Coolerssrp. mohammedNo ratings yet

- Feed Water UnitDocument2 pagesFeed Water UnitEslam ElsayedNo ratings yet

- Specifications, Scope of Work, Bid Rejection/Evaluation CriteriaDocument59 pagesSpecifications, Scope of Work, Bid Rejection/Evaluation CriteriaSOPANNo ratings yet

- 221005, Plumbing SpecialtiesDocument16 pages221005, Plumbing Specialtiessrp. mohammedNo ratings yet

- 220CDocument6 pages220Cmacanipharoldf6220No ratings yet

- MHRC2 SubmittalDocument19 pagesMHRC2 SubmittalOscar A. Jiménez ColónNo ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p21-24Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p21-24SonNguyenNo ratings yet

- HWG - Boq-1Document13 pagesHWG - Boq-1Prashant Singh ChauhanNo ratings yet

- SECTION 15520 Feedwater Equipment General 1.1Document6 pagesSECTION 15520 Feedwater Equipment General 1.1fatREVITNo ratings yet

- HVAC Guide Specifications System Fan Coil UnitDocument3 pagesHVAC Guide Specifications System Fan Coil UnitRubenSaaNo ratings yet

- BOQ Fountain Water Body (1) .XLSXBDocument6 pagesBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan60% (5)

- SECTION 15120 Piping Specialties 1.1Document18 pagesSECTION 15120 Piping Specialties 1.1Munir RasheedNo ratings yet

- 6129-205 Hot Water Systems Version ADocument18 pages6129-205 Hot Water Systems Version AP_DaviesNo ratings yet

- 224215, Commercial Plumbing FixturesDocument13 pages224215, Commercial Plumbing Fixturessrp. mohammed100% (1)

- P.O. Number: 7200018725Document6 pagesP.O. Number: 7200018725sethu1091No ratings yet

- Steam, Domestic Storage Water HeaterDocument7 pagesSteam, Domestic Storage Water Heaterbandithaguru6338No ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- 23 21 13 Iei - Hvac PipingDocument10 pages23 21 13 Iei - Hvac PipingAiman AliNo ratings yet

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Document11 pagesBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNo ratings yet

- HVAC Guide Specifications Commercial Air-Cooled Condensing UnitsDocument4 pagesHVAC Guide Specifications Commercial Air-Cooled Condensing UnitsHazemNo ratings yet

- With or Without Electric Heat MHCCW Chilled Water Ceiling ConcealedDocument34 pagesWith or Without Electric Heat MHCCW Chilled Water Ceiling ConcealedWESHIMNo ratings yet

- Particular SpecificationsDocument5 pagesParticular SpecificationsMohammed HammadNo ratings yet

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- C8 SPoolTreatmentDocument3 pagesC8 SPoolTreatmentadel agustiNo ratings yet

- SECTION 23 13 23 Above Ground Fuel Storage Tanks: Part 1 - General 1.01 Section IncludesDocument6 pagesSECTION 23 13 23 Above Ground Fuel Storage Tanks: Part 1 - General 1.01 Section IncludesTeguh SetionoNo ratings yet

- Section 15450 Plumbing Fixtures and TrimDocument9 pagesSection 15450 Plumbing Fixtures and TrimArt JamesNo ratings yet

- Hydrobursting System SpecficationDocument16 pagesHydrobursting System Specficationabdeslem mouloudjNo ratings yet

- SECTION 15640 Packaged Cooling Towers General 1.1Document7 pagesSECTION 15640 Packaged Cooling Towers General 1.1Munir RasheedNo ratings yet

- Materials and ComponentsDocument121 pagesMaterials and ComponentskishoreNo ratings yet

- Brew HouseDocument7 pagesBrew HousekolanarendrababuNo ratings yet

- Hvac-05 Air CoilsDocument3 pagesHvac-05 Air CoilsCosphiiiNo ratings yet

- Hydronic PipingDocument11 pagesHydronic PipingLjubomir DjurinNo ratings yet

- Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document12 pagesModel Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Diogenes Rafael TorresNo ratings yet

- HVAC Guide Specifications Indoor Self-Contained Air-Cooled Unit Constant Volume ApplicationDocument3 pagesHVAC Guide Specifications Indoor Self-Contained Air-Cooled Unit Constant Volume ApplicationasdthuNo ratings yet

- Ccad-Aed-Sp - G-211300 - 0 - Fre Suppression SprinklersDocument9 pagesCcad-Aed-Sp - G-211300 - 0 - Fre Suppression SprinklersArun UdayabhanuNo ratings yet

- Mechanical Draft Cooling TowerDocument6 pagesMechanical Draft Cooling TowerNoushad P HamsaNo ratings yet

- SECTION 211313 Wet Pipe Sprinkler SystemsDocument7 pagesSECTION 211313 Wet Pipe Sprinkler SystemsDanZel DanNo ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- MAC-048HE-02-L High Efficiency Air-Cooled ChillerDocument14 pagesMAC-048HE-02-L High Efficiency Air-Cooled ChillerFranz CorasNo ratings yet

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoNo ratings yet

- Elevated TanksDocument8 pagesElevated TanksChâu TúNo ratings yet

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITNo ratings yet

- At/Ut/Uss: T F, A T !Document1 pageAt/Ut/Uss: T F, A T !Jerico LlovidoNo ratings yet

- EXP 2 - Plug Flow Tubular ReactorDocument18 pagesEXP 2 - Plug Flow Tubular ReactorOng Jia YeeNo ratings yet

- Well Test Barge SpecificationDocument7 pagesWell Test Barge SpecificationDjoko TriyonoNo ratings yet

- 15570Document6 pages15570JhoNo ratings yet

- Plumbing Fixtures StandardDocument12 pagesPlumbing Fixtures StandardPamela Joyce MaddumaNo ratings yet

- Underground Fire Protection Pipes & EquipmentsDocument6 pagesUnderground Fire Protection Pipes & EquipmentsSalim BakhshNo ratings yet

- Specification For Hot Water BoilersDocument1 pageSpecification For Hot Water BoilersKarthik AnandanNo ratings yet

- Section 238126 - Mini Split System Air ConditionersDocument11 pagesSection 238126 - Mini Split System Air ConditionersChase GietterNo ratings yet

- Section 21 05 23Document6 pagesSection 21 05 23Ismail MohammadNo ratings yet

- Specification ChillerDocument28 pagesSpecification Chillermishtinil100% (1)

- SECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsDocument13 pagesSECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

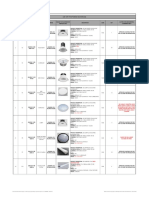

- Light Fitting ListDocument3 pagesLight Fitting ListMohammed ShifulNo ratings yet

- Underground Drainage FRT Web - tcm30-22349Document22 pagesUnderground Drainage FRT Web - tcm30-22349Mohammed ShifulNo ratings yet

- Elips Product SpecificationsDocument10 pagesElips Product SpecificationsMohammed ShifulNo ratings yet

- New Excavation Permit FormDocument5 pagesNew Excavation Permit FormMohammed ShifulNo ratings yet

- Junction Box Enclosure ListDocument2 pagesJunction Box Enclosure ListMohammed ShifulNo ratings yet

- CaptureDocument1 pageCaptureMohammed ShifulNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentMohammed Shiful0% (1)

- EEN 443: Power Distribution Research Assignment: Mohammed Riad Elchadli Mohammed Shiful Maged Al SharafiDocument4 pagesEEN 443: Power Distribution Research Assignment: Mohammed Riad Elchadli Mohammed Shiful Maged Al SharafiMohammed ShifulNo ratings yet

- Lecture 5 Power Factor ImprovementDocument54 pagesLecture 5 Power Factor ImprovementMohammed ShifulNo ratings yet

- Reconfiguration of Electric Distribution Systems: Hugh Rudnick Ildefonso Harnisch Raúl SanhuezaDocument8 pagesReconfiguration of Electric Distribution Systems: Hugh Rudnick Ildefonso Harnisch Raúl SanhuezaMohammed ShifulNo ratings yet

- A DNR and DG Sizing Simultaneously by Using EPSODocument6 pagesA DNR and DG Sizing Simultaneously by Using EPSOMohammed ShifulNo ratings yet

- A Power Distribution Network Restoration Via Feeder Reconfiguration by Using Epso For Losses ReductionDocument5 pagesA Power Distribution Network Restoration Via Feeder Reconfiguration by Using Epso For Losses ReductionMohammed ShifulNo ratings yet

- PS Tutorial Sheet 2 - 2Document3 pagesPS Tutorial Sheet 2 - 2Mohammed ShifulNo ratings yet

- 7.lect7a Two Random Variables)Document15 pages7.lect7a Two Random Variables)Mohammed ShifulNo ratings yet

- Lecture 7: Feedback: Dr. Riad KananDocument38 pagesLecture 7: Feedback: Dr. Riad KananMohammed ShifulNo ratings yet

- EEN360: Electronics Circuits Lab Assignment 1 BJT Amplifiers Frequency RespondDocument6 pagesEEN360: Electronics Circuits Lab Assignment 1 BJT Amplifiers Frequency RespondMohammed ShifulNo ratings yet

- As 1530.4-2005 PDFDocument165 pagesAs 1530.4-2005 PDFNicholas Viney100% (2)

- Nit For Vendor RefDocument263 pagesNit For Vendor RefVivek SharmaNo ratings yet

- Hyatt Regency, AmritsarDocument64 pagesHyatt Regency, AmritsarRavisankar SatheeshNo ratings yet

- Biomass StoveDocument18 pagesBiomass StoveLakshmanan ThangaveluNo ratings yet

- Shu/Shi/Shv Dishwasher Troubleshooting Tips: 5551 Mcfadden Avenue Huntington Beach, California 92649Document40 pagesShu/Shi/Shv Dishwasher Troubleshooting Tips: 5551 Mcfadden Avenue Huntington Beach, California 92649Keith Drake100% (3)

- Full ProjectDocument79 pagesFull ProjectsivachandranbNo ratings yet

- Workshop Manual Thermo Top V en WEBDocument46 pagesWorkshop Manual Thermo Top V en WEBDanMirceaNo ratings yet

- Vaillant TurboMAX PlusDocument52 pagesVaillant TurboMAX PlusPas SommeseNo ratings yet

- E160201X Manuale ES IM10 - ENGDocument32 pagesE160201X Manuale ES IM10 - ENGMinh Hiếu TrầnNo ratings yet

- Wolter Induction Fans A08.5 R2Document17 pagesWolter Induction Fans A08.5 R2KCFUNGNo ratings yet

- Dehumidifier: A Typical "Portable" Dehumidifier Can Be Moved About On Built-In CastersDocument9 pagesDehumidifier: A Typical "Portable" Dehumidifier Can Be Moved About On Built-In CastersAbhinav KumarNo ratings yet

- Lecture 3 - 4 - Boiler Mountings and AccessoriesDocument34 pagesLecture 3 - 4 - Boiler Mountings and AccessoriesFEALABREPORTSNo ratings yet

- ABBREV. Description: //tango/01053/Training/Courses/Course Library/K-Chief 700/7.3/Basic/Abbreviation ListDocument12 pagesABBREV. Description: //tango/01053/Training/Courses/Course Library/K-Chief 700/7.3/Basic/Abbreviation Listalternativblue100% (2)

- Ducting SpecificationDocument4 pagesDucting Specificationrehan khanNo ratings yet

- ARUF Series: Multi-Position, Multi-Speed Air Handler With PSC Motor 1 To 5 TonsDocument12 pagesARUF Series: Multi-Position, Multi-Speed Air Handler With PSC Motor 1 To 5 TonsStefy CarrascoNo ratings yet

- ACV Heatmaster TC enDocument68 pagesACV Heatmaster TC enОлег ВоронинNo ratings yet

- AHRICertificate CKB18CDDocument1 pageAHRICertificate CKB18CDLuis RiveraNo ratings yet

- CN Aquatherm, The One Stop Supplier For Aqua-Therm Products & Building MaterialsDocument128 pagesCN Aquatherm, The One Stop Supplier For Aqua-Therm Products & Building MaterialsYang XianjieNo ratings yet

- PT 7136 VarioDocument56 pagesPT 7136 VarioNikola ArsenovićNo ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- Technical Specification Sample SciDocument18 pagesTechnical Specification Sample SciMarvin SironNo ratings yet

- Hvac Heating Ventilation & Air Conditioning: by Amit Jha & Devendra SinghDocument29 pagesHvac Heating Ventilation & Air Conditioning: by Amit Jha & Devendra Singhjhaamit4No ratings yet

- PM Is-2082Document8 pagesPM Is-2082Raj BharaliNo ratings yet

- TS Pack Containers Reefer Trucks Final Sign Off ADocument29 pagesTS Pack Containers Reefer Trucks Final Sign Off ALuis Carlos100% (1)

- Rheem Air Handler RHSLDocument20 pagesRheem Air Handler RHSLNationalAirWarehouseNo ratings yet

- Burner Dry Out ProceduresDocument1 pageBurner Dry Out ProceduresSabarish Chandrasekaran0% (1)

- Cummins DFLB DFLC DFLE Generator Set Operator ManualDocument71 pagesCummins DFLB DFLC DFLE Generator Set Operator ManualNguyen CuongNo ratings yet

- Commissioning in DetailDocument200 pagesCommissioning in DetailmohamedovicNo ratings yet

- 0E10101 Aquatherm Green PipeDocument164 pages0E10101 Aquatherm Green Pipesaidriad71No ratings yet

- York YK Series Operation and Maintenance Form Number 160.76-EG1 - 222 - Supersedes 160.76-EG1 - 1121Document100 pagesYork YK Series Operation and Maintenance Form Number 160.76-EG1 - 222 - Supersedes 160.76-EG1 - 1121Asaad ChughtaiNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesFrom EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNo ratings yet

- Essential Building Science: Understanding Energy and Moisture in High Performance House DesignFrom EverandEssential Building Science: Understanding Energy and Moisture in High Performance House DesignRating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)