Professional Documents

Culture Documents

Op2 Rev 6

Uploaded by

AmirSyafiqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Op2 Rev 6

Uploaded by

AmirSyafiqCopyright:

Available Formats

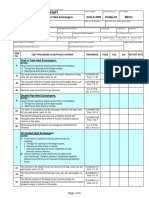

AMP REF. NO.

LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

TYPE OF INSPECTION OPERATION 2 - 100 HOURS PUB. REF. CH 05-12-02 MODEL 172SERIES MM REV 24 DATED 01-07-2021

A/C REGISTRATION 9M-DON JOB NO. LL/CAMO/DON/103

A/C SERIAL NO. 172S12493 A/C HOURS

ENGINE TYPE LYCOMING IO-360-L2A PROP TYPE MCCAULEY 1A170E/JHA7660

ENGINE S/N L-38268-51E PROP S/N APD23009

ENGINE HOURS PROP HRS

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

CHAPTER 21 - AIR CONDITIONING

1. Cold and Hot Air Hoses

Check condition, routing, and security. 120 B1.2 NIL

CHAPTER 25 - EQUIPMENT/FURNISHINGS

1. Seats Tracks and Stops

Inspect seat tracks for condition and security of installation.

211 B1.2 NIL

Check seat track stops for damage and correct location. Inspect seat

rails for cracks.

CHAPTER 28 - FUEL

1. Auxiliary (Electric) Fuel Pump

Check pump and fittings for condition, operation, security. 120 B1.2 NIL

CHAPTER 32 - LANDING GEAR

1. Main Landing Gear Wheel Fairings, Strut Fairings, and Cuffs

Check for cracks, dents, condition of paint, and correct scraper 721, 722 B1.2 NIL NOT APPLICABLE DUE TO MLG FAIRING NOT FITTED

clearance.

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 1 of

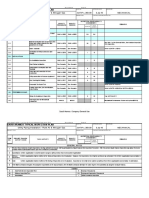

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

2. Main Gear Spring Assemblies

Check for proper routing, support, and security of attachment. 721, 722 B1.2 NIL

3. Main Landing Gear Attachment Structure

Check for damage, cracks, loose rivets, bolts and nuts and security 721, 722 B1.2 NIL

of attachment.

4. Nose Gear

Inspect torque links, steering rods, and boots for condition and

security of attachment.

Check strut for evidence of leakage and proper extension.

720 B1.2 NIL

Check strut barrel for corrosion, pitting, and cleanliness.

Check shimmy damper and/or bungees for operation, leakage, and

attach points for wear and security.

5. Nose Landing Gear Wheel Fairings

720 B1.2 NIL NOT APPLICABLE DUE TO NLG FAIRING NOT FITTED

Check for cracks, dents, and condition of paint.

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 2 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

6. Nose Gear Attachment Structure

Inspect for cracks, corrosion, or other damage and security of 720 B1.2 NIL

attachment.

7. Brakes

Test toe brakes and parking brake for proper operation. 230 B1.2 NIL

8. Brakes, Master Cylinders, and Parking Brake

Check master cylinders and parking brake mechanism for condition

224, 230 B1.2 NIL

and security. Check fluid level and test operation of toe and parking

brake

9. Tires

Check tread wear and general condition. Check for proper inflation. 720, 721, 722 B1.2 NIL

10. Wheels, Brake Discs, and Linings

Inspect for wear, cracks, warps, dents, or other damage. Check

wheel through-bolts and nuts for looseness. 721, 722 B1.2 NIL

CHAPTER 37 - VACUUM

1. Vacuum System

Inspect for condition and security. 120 B1.2 NIL

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 3 of

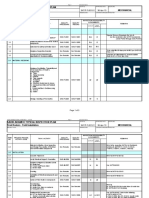

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

2. Vacuum Pumps

Check for condition and security. Check vacuum system breather 120 B1.2 NIL

line for obstructions, condition, and security.

3. Vacuum System Hoses

Inspect for hardness, deterioration, looseness, or collapsed hoses.

120 B1.2 NIL

CHAPTER 53 - FUSELAGE

1. Firewall Structure

Inspect for wrinkles, damage, cracks, sheared rivets, etc. Check cowl

210 B1.2 NIL

shock mounts for condition and security.

CHAPTER 61 - PROPELLER

1. Spinner

Check general condition and attachment.

2. Spinner, Spinner Bulkhead, and Engine Crankshaft Expansion Plug

Remove spinner, wash, and inspect for cracks and fractures. While 110 B1.2 NIL

spinner is removed, check expansion plug and area for evidence of

leakage, security of attachment, and general condition.

3. Propeller Blades

Inspect for cracks, dents, nicks, scratches, erosion, corrosion,

or other damage.

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 4 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

4. Propeller Hub

Check general condition.

5. Propeller Mounting

Check for security of installation.

110 B1.2 NIL

6. Propeller Mounting Bolts

Inspect mounting bolts and safety wire for signs of looseness.

Retorque mounting bolts as required.

Torque Wrench Tool:

PN: SN:

CHAPTER 71 - POWER PLANT

1. Cowling

Inspect for cracks, dents, other damage and security of fasteners.

2. Engine Shock Mounts, Engine Mount Structure, and Ground Straps NIL

120 B1.2

Check condition, security, and alignment.

3. Do a check of the engine mount and the oil filler tube for evidence

of contact. SB99-71-02 NOT APPLICABLE DUE TO AIRCRAFT SERIAL NUMBER

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 5 of

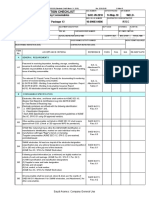

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

4. Alternate Induction Air System

Check for obstructions, operation, and security. NIL

5. Induction System

Check security of clamps, tubes, and ducting.

Inspect for evidence of leakage.

6. Induction Airbox, Valves, Doors, and Controls

Remove air filter and inspect hinges, doors, seals, and attaching

parts for wear and security. Check operation.

7. Induction Air Filter

Remove and clean. Inspect for damage and service.

8. Engine 120 B1.2 NIL

Inspect for evidence of oil and fuel leaks.

Wash engine and check for security of accessories.

9. Crankcase, Oil Sump, and Accessory Section

Inspect for cracks and evidence of oil leakage. Check bolts and nuts

for looseness and retorque as necessary. Check crankcase breather

lines for obstructions, security, and general condition.

10. Hoses, Metal Lines, and Fittings

Inspect for signs of oil and fuel leaks.

Check for abrasions, chafing, security, proper routing and support

and for evidence of deterioration.

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 6 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

11. Engine Cylinders, Rocker Box Covers, and Pushrod Housings

Check for fin damage, cracks, oil leakage, security of attachment,

and general condition.

12. Engine Metal Lines, Hoses, Clamps, and Fittings

Check for leaks, condition, and security. Check for proper routing

and support.

13. Engine Baffles and Seals NIL

Check condition and security of attachment.

14. Cylinder Compression 120 B1.2

Complete a differential compression test. If there is weak cylinder

compression.

Cyl No 1 Cyl No 2 Cyl No 3 Cyl No 4 Chapter 71, Engine -

Troubleshooting, for

/80 psi /80 psi /80 psi /80 psi

further procedures.

Compression Test Set:

PN: SN:

CHAPTER 73 - ENGINE FUEL AND CONTROL

1. Engine-Driven Fuel Pump

Check for evidence of leakage, security of attachment, and general 120 B1.2 NIL

condition.

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 7 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

2. Fuel Injection System

Check system for security and condition. Clean fuel inlet screen,

120 B1.2 NIL

check and clean injection nozzles and screens (if evidence of

contamination is found), and lubricate air throttle shaft.

3. Idle and Mixture

Run the airplane engine to determine satisfactory performance. If

Chapter 73, Fuel

required, adjust the idle rpm and fuel mixture.

120 B1.2 Injection Systems -

Maintenance Practices.

CHAPTER 74 - IGNITION

1. Dual Magnetos

Chapter 74, Ignition

Examine the external condition and for correct installation and

120 B1.2 System - Maintenance

condition of the electrical leads. Complete a check of the engine

Practices.

timing (external timing).

2. Ignition Harness and Insulators

Check for proper routing, deterioration, and condition of terminals.

120 B1.2 NIL

3. Spark Plugs

Remove, clean, analyze, test, gap, and rotate top plugs to bottom

and bottom plugs to top. 120 B1.2 NIL

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 8 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

CHAPTER 76 - ENGINE CONTROLS

1. Engine Controls and Linkage

Examine the general condition and freedom of movement

through the full range.

Complete a check for the proper travel, security of attachment,

and for evidence of wear.

Complete a check of the friction lock and vernier adjustment

for proper operation.

120

B1.2 NIL

225

Complete a check to make sure the throttle operate through their

full arc of travel. The maximum linear free play is 0.050 inch.

Complete a check to make sure the fuel mixture operate through

their full arc of travel. The maximum linear free play is 0.050 inch.

Complete a check to make sure the propeller governor arms

operate through their full arc of travel. The maximum linear free N/A DUE TO PROPELLER GOVERNOR NOT FITTED

play is 0.050 inch.

CHAPTER 78 - EXHAUST

1. Exhaust System

MAINTENANCE

PRACTICES

Inspect for cracks and security. 120 B1.2

CHAPTER 78

Special check in area of heat exchanger.

EXHAUST SYSTEM

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 9 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

CHAPTER 79 - OIL

1. Oil Cooler

Check for obstructions, leaks, and security of attachment. 120 B1.2 NIL

CHAPTER 80 - STARTING

1. Bendix Drive Starter Assembly

120 B1.2 NIL

Clean and lubricate starter drive assembly.

CHAPTER 24 - ELECTRICAL POWER

1. Alternator, Mounting Bracket, and Electrical Connections

NIL

Check condition and security.

120 B2

STANDARD PRACTICE -

Check alternator belts for condition and proper adjustment. AIRFRAME

Check belt tension. CH 24-20-00

PARA 2.B.4

Belt Tension Gauge Tool:

PN: SN: SI 1129 LATEST

REVISION

2. Main Battery

Examine the general condition and security. Complete the Chapter 12,

120 B2

applicable main battery servicing procedure. Battery - Servicing

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 10 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

3. Main Battery Box and Cables

Clean and remove any corrosion. Examine the cables for routing,

support, and security of the connections. 120 B2

4. External Power Receptacle and Power Cables

Inspect for condition and security.

120 B2 NIL

CHAPTER 37 - VACUUM

1. Gyro Filter

Inspect for condition and security.

120 B2 NIL

CHAPTER 34 - NAVIGATION

1. Pitot Tube and Stall Warning System

Examine for condition and obstructions and make sure the 510 B2 NIL

anti-ice heat operates correctly. Apply vacuum to stall warning

horn scoop assembly and make sure horn is audible.

CHAPTER 74 - IGNITION

1. Ignition Switch and Electrical Harness

Inspect for damage, condition, and security.

120 B2 NIL

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 11 of

AMP REF. NO. LLA/CAMO/AMP/C172S

LAYANG-LAYANG AEROSPACE SDN. BHD.

ISSUE 3 REVISION 1 DATE 22-AUG-2022

CAMO Approval No.: CAMO/2017/010 A/C TYPE CESSNA 172S DATE WORKSHEET ISSUED 30/12/2022

ITEM DESCRIPTION ZONES CAT. REFERENCES TECH SIGN AML SIGN AUTH. NO. DATE

CHAPTER 80 - STARTING

1. Starter and Electrical Connections 120 B2 NIL

Check security and condition of starter, electrical connection, and

cable.

Certifies that the work specified, except as otherwise specified, was carried out in accordance with CAA Malaysia Requirements and in respect to that work the aircraft/aircraft component is considered ready for

release to service.

WORKSHEETREF. NO. LLA/CAMO/AMP/C172S/WORKSHEET/OP2 REV 6 Page 12 of

You might also like

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- 100H EngineDocument3 pages100H EngineAmirSyafiqNo ratings yet

- 50H EngineDocument3 pages50H EngineAmirSyafiqNo ratings yet

- Cessna 172S Oil Change WorksheetDocument1 pageCessna 172S Oil Change WorksheetAmirSyafiqNo ratings yet

- Saudi Aramco Tank Inspection ChecklistDocument12 pagesSaudi Aramco Tank Inspection ChecklistMd ShariqueNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- SAIC-E-2005 Recvg Insp of AirCooled Heat ExchDocument5 pagesSAIC-E-2005 Recvg Insp of AirCooled Heat ExchAnonymous S9qBDVkyNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- Aramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerDocument13 pagesAramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerjerinNo ratings yet

- Job Card Package Title: SVI - A318/A319/A320/ A321 Tail Number - MSN - FSN SU-SKB - 02204 - 001Document23 pagesJob Card Package Title: SVI - A318/A319/A320/ A321 Tail Number - MSN - FSN SU-SKB - 02204 - 001moamenNo ratings yet

- Work Scope C 1 - Check Pk-Ygh Revise 1Document5 pagesWork Scope C 1 - Check Pk-Ygh Revise 1iftikhar firdausNo ratings yet

- Saudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDocument4 pagesSaudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDilshad Ahemad100% (1)

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Work Order: VN 23980529 6 - MiscellaneousDocument2 pagesWork Order: VN 23980529 6 - MiscellaneousJohn SmithNo ratings yet

- Satip e 004 01Document10 pagesSatip e 004 01Ansar Ali VemmullyNo ratings yet

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- 32-42-27-000-001-A - Removal of The BrakeDocument11 pages32-42-27-000-001-A - Removal of The BrakeYaser SahiboleNo ratings yet

- SATIP K 001 07 Refrigerant - PipingDocument2 pagesSATIP K 001 07 Refrigerant - Pipingimrankhan22100% (1)

- Chiyoda Malaysia Sdn. BHDDocument2 pagesChiyoda Malaysia Sdn. BHDmeeNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Compressed Air System Inspection Checklist: Section A - Customer DataDocument1 pageCompressed Air System Inspection Checklist: Section A - Customer DataAgus WG KucreetNo ratings yet

- SAUDCO INSPECTION CHECKLIST FOR SMALL TANKSDocument4 pagesSAUDCO INSPECTION CHECKLIST FOR SMALL TANKSAnonymous S9qBDVkyNo ratings yet

- PW1100G-JM Fan Blade Inspection GuideDocument4 pagesPW1100G-JM Fan Blade Inspection GuideKitKat ShArryNo ratings yet

- Satip A 004 04Document3 pagesSatip A 004 04Ahmed GamalNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Wellhead Desander Vessel Data Sheet for Khuft-Hawiyah Area ProjectDocument5 pagesWellhead Desander Vessel Data Sheet for Khuft-Hawiyah Area ProjectAhmed MusallamNo ratings yet

- Saudi Aramco Typical Inspection Plan: Utility Piping Installation - Plant Air & Nitrogen Gas SATIP-L-350-09 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Utility Piping Installation - Plant Air & Nitrogen Gas SATIP-L-350-09 Mechanicalkarthi51289100% (1)

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 Mechkarthi51289No ratings yet

- Pressurization of The Hydraulic Reservoirs Through The Ground ConnectorDocument5 pagesPressurization of The Hydraulic Reservoirs Through The Ground ConnectorAdrianGilRojanoNo ratings yet

- Satip y 101 01Document12 pagesSatip y 101 01spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Chapter B: Service ManualDocument6 pagesChapter B: Service ManualKINTOLOBONo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- SAUDICO Aramco cleaning inspection checklistDocument4 pagesSAUDICO Aramco cleaning inspection checklistAnonymous S9qBDVkyNo ratings yet

- Maintenance Job Card: "3DAYS - CHECK" (3DY-Ch)Document3 pagesMaintenance Job Card: "3DAYS - CHECK" (3DY-Ch)Юрий ЧерненкоNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- SAUDI ARAMCO FIRED HEATERS INSPECTION PLANDocument3 pagesSAUDI ARAMCO FIRED HEATERS INSPECTION PLANOmer aliNo ratings yet

- 028120-SPL-008 Protective Coating Riser Neoprene Rev. CDocument8 pages028120-SPL-008 Protective Coating Riser Neoprene Rev. CRokan Pipeline100% (1)

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document38 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- Satip D 109 01Document12 pagesSatip D 109 01Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Job Card: 35-11-41-400-001-A - Installation of The Crew Oxygen-Storage CylinderDocument7 pagesJob Card: 35-11-41-400-001-A - Installation of The Crew Oxygen-Storage CylinderKaushal VermaNo ratings yet

- 330 Adjustment of Pivot DoorDocument31 pages330 Adjustment of Pivot Doorhx344375No ratings yet

- RG 380e 44 Ica PDFDocument35 pagesRG 380e 44 Ica PDFsunaryaNo ratings yet

- 1c-Check Inspection Schedule..............Document36 pages1c-Check Inspection Schedule..............Jeffrey DavisNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNo ratings yet

- C Amendment 50 HRSDocument4 pagesC Amendment 50 HRSspider_apexNo ratings yet

- SATIP-P-113-03 Rev 7 FinalDocument5 pagesSATIP-P-113-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- R2 - RevADocument12 pagesR2 - RevAChirag ShahNo ratings yet

- DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015Document20 pagesDFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015KamalVirkNo ratings yet

- CNOOC Southeast Sumatra Pipeline CoatingsDocument12 pagesCNOOC Southeast Sumatra Pipeline CoatingsRokan Pipeline100% (1)

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Book BookDocument146 pagesBook BookTurpial Airlines OMAC-N 683No ratings yet

- Operational Manual AD2 API 650 Metallic Tank RO3Document102 pagesOperational Manual AD2 API 650 Metallic Tank RO3Rajesh K PillaiNo ratings yet

- Llacamo 016-01 (Man-Hour and Fod Clearance Declaration Form)Document2 pagesLlacamo 016-01 (Man-Hour and Fod Clearance Declaration Form)AmirSyafiqNo ratings yet

- Llacamo 016-01 (Man-Hour and Fod Clearance Declaration Form)Document2 pagesLlacamo 016-01 (Man-Hour and Fod Clearance Declaration Form)AmirSyafiqNo ratings yet

- Ll-Camo-Don-102 (Additional Worksheets)Document2 pagesLl-Camo-Don-102 (Additional Worksheets)AmirSyafiqNo ratings yet

- Ll-Camo-Don-100 (Worksheet Index)Document1 pageLl-Camo-Don-100 (Worksheet Index)AmirSyafiqNo ratings yet

- Layang-Layang Aerospace Maintenance Worksheet IndexDocument1 pageLayang-Layang Aerospace Maintenance Worksheet IndexAmirSyafiqNo ratings yet

- LL Camo Don 101 (Additional Worksheets)Document1 pageLL Camo Don 101 (Additional Worksheets)AmirSyafiqNo ratings yet

- Layang Layang Maintenance FormDocument2 pagesLayang Layang Maintenance FormAmirSyafiqNo ratings yet

- Scan With Mysejahtera App To Check-In: Myj NaturalleDocument1 pageScan With Mysejahtera App To Check-In: Myj NaturalleAmirSyafiqNo ratings yet

- Barnet Bread Case StudyDocument14 pagesBarnet Bread Case StudyAmirSyafiqNo ratings yet

- Tamara Residence Cabinet - Google SearchDocument1 pageTamara Residence Cabinet - Google SearchAmirSyafiqNo ratings yet

- Tamara Residence Cabinet - Google SearchDocument1 pageTamara Residence Cabinet - Google SearchAmirSyafiqNo ratings yet

- How To Use Fire ExtinguisherDocument1 pageHow To Use Fire ExtinguisherAmirSyafiqNo ratings yet

- A Review of The Occurrence Reporting System Proposed by EASA Part-145Document12 pagesA Review of The Occurrence Reporting System Proposed by EASA Part-145AmirSyafiqNo ratings yet

- A Review of The Occurrence Reporting System Proposed by EASA Part-145Document12 pagesA Review of The Occurrence Reporting System Proposed by EASA Part-145AmirSyafiqNo ratings yet

- On Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas TurbinesDocument12 pagesOn Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas Turbinescarlo83No ratings yet

- February 2023Document2 pagesFebruary 2023rohitchanakya76No ratings yet

- Proprties of MatterDocument24 pagesProprties of Matterrishithhr rajeevNo ratings yet

- Mechanical Engineering Laws (EDITED)Document25 pagesMechanical Engineering Laws (EDITED)Blaise PascalNo ratings yet

- Ex StandardsDocument1 pageEx StandardsBinu SulochananNo ratings yet

- Refrigeration Engineering: Multiple ChoiceDocument5 pagesRefrigeration Engineering: Multiple ChoiceAlfredo CondeNo ratings yet

- Ariston Shape 10l Also Elhelyezesu Villanybojler Robbantott AbraDocument4 pagesAriston Shape 10l Also Elhelyezesu Villanybojler Robbantott AbraSinkó AttilaNo ratings yet

- EE-260 Lecture 19 Synchronous Generators IntroductionDocument24 pagesEE-260 Lecture 19 Synchronous Generators IntroductionRehan BasharatNo ratings yet

- MSJ500Document1 pageMSJ500Juan Sebastian SanabriaNo ratings yet

- Machine Lab 1Document7 pagesMachine Lab 1Taha Al-sprieNo ratings yet

- Af50 550Document1 pageAf50 550thaiNo ratings yet

- 2020 Enerack Ground Solar MountDocument14 pages2020 Enerack Ground Solar MountEcosenseTechnologies GreenenergyNo ratings yet

- Ielts Reading Practice 2Document4 pagesIelts Reading Practice 2Nguyenn HonggNo ratings yet

- KIC User Manual Cooling Freezing 2023.04 - 461956039540 FinalDocument16 pagesKIC User Manual Cooling Freezing 2023.04 - 461956039540 Finallettiemulaudzi427No ratings yet

- User Manual for GHP / DC9-50A (InternationalDocument65 pagesUser Manual for GHP / DC9-50A (InternationalMateen YounasNo ratings yet

- Xenon LampDocument25 pagesXenon LampJamaica Peñaloza NatuelNo ratings yet

- Diagrama Eléctrico Soilmec sf50Document102 pagesDiagrama Eléctrico Soilmec sf50pedroandres143100% (1)

- Dr. Ibrahim Badran (C.V.) : Amman, Jordan June, 2008Document5 pagesDr. Ibrahim Badran (C.V.) : Amman, Jordan June, 2008kendoNo ratings yet

- Rates of ReactionDocument72 pagesRates of ReactionLast AliNo ratings yet

- BE142 Be42 3phase Controller Installation ManualDocument28 pagesBE142 Be42 3phase Controller Installation ManualalbeertoNo ratings yet

- Capstone Microturbine For The Oil and Gas IndustryDocument14 pagesCapstone Microturbine For The Oil and Gas IndustryJeff LNo ratings yet

- MEPCO ONLINE BILL KamiDocument1 pageMEPCO ONLINE BILL KamiMisali SchoolNo ratings yet

- 3Document1 page3Oluwadunmininu SoyinkaNo ratings yet

- Due Diligence Guidelines For CSTDocument28 pagesDue Diligence Guidelines For CSTficisid ficisidNo ratings yet

- Computers and Electrical Engineering: Fatima Abu Salah, Ahmad Harb, Mohamad K. KhawajaDocument15 pagesComputers and Electrical Engineering: Fatima Abu Salah, Ahmad Harb, Mohamad K. KhawajaOussama El BouadiNo ratings yet

- Caterpillar DCU Controller Configuration Printout (192.168.0.101Document10 pagesCaterpillar DCU Controller Configuration Printout (192.168.0.101Hamza AbdelhamidNo ratings yet

- Caterpillar c6.6 Electrical Schematic Diagnostic CodesDocument6 pagesCaterpillar c6.6 Electrical Schematic Diagnostic CodesjadliftboatsetorecordsNo ratings yet

- Loctite 567™: Technical Data SheetDocument3 pagesLoctite 567™: Technical Data SheetManikanta Sai KumarNo ratings yet

- Swirl Engineering Company Profile 081020Document17 pagesSwirl Engineering Company Profile 081020Terence LaiNo ratings yet

- Electricity bill details for April 2021Document1 pageElectricity bill details for April 2021Aditya RajNo ratings yet