Professional Documents

Culture Documents

202517C-0000-JSD-1300-010-A - Piping Support

Uploaded by

Hasan arif KısaalioğluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

202517C-0000-JSD-1300-010-A - Piping Support

Uploaded by

Hasan arif KısaalioğluCopyright:

Available Formats

T.

EN NUMBER

Revision Page

Project № Unit Number Document Type Mat./Work Code Serial Number

A 1/33

202517C 0000 JSD 1300 010

ETI BAKIR

ISSUED FOR REVIEW

JOB SPECIFICATION FOR DESIGN

PIPING SUPPORT

Jaume Morales-Llobet

Andrea Di-Perna

Juan Benitez-Infante 2022.04.04 12:57:49

2022.04.04 12:54:24 +02'00' 2022.04.04

+02'00' 13:14:06+02'00'

A 04.04.2022 IFR - Issued for Review J. BENITEZ J. MORALES A. DI PERNA

REV. DATE ISSUE PURPOSE WRITTEN BY: CHECKED BY: APPROVED BY:

REVISIONS OF THE DOCUMENT

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 2/33

Job Specification for design – Piping support

HOLD LIST

HOLD N° SECTION DESCRIPTION

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 3/33

Job Specification for design – Piping support

HISTORICAL REVISION CHANGE DETAILS

LOCATION OF

REV. BRIEF DESCRIPTION OF CHANGE

CHANGE

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 4/33

Job Specification for design – Piping support

TABLE OF CONTENTS

INDEX

1. PURPOSE OF THE DOCUMENT ................................................................................................................ 7

2. REFERENCE DOCUMENTS ....................................................................................................................... 7

2.1 Codes Requirements ............................................................................................................................ .... 7

2.2 DEFINITIONS AND ABBREVIATIONS................................................................................................. .... 7

2.3 Project Reference Documents .............................................................................................................. .... 8

2.4 Order of Precedence ............................................................................................................................. .... 8

3. terminology ................................................................................................................................................. 8

3.1 Support Components Classification ...................................................................................................... .... 8

3.1.1 ... Primary support ........................................................................................... 8

3.1.2 ... Secondary support ........................................................................................... 8

3.2 Line Classification ................................................................................................................................. .... 8

3.2.1 ... Classified hot line ........................................................................................... 8

3.2.2 ... Classified cold line ........................................................................................... 9

4. STRUCTURE OF THE PIPING SUPPORTS COLLECTION ...................................................................... 9

4.1 Standard Piping Support Collection for Hot Lines ................................................................................ .... 9

4.2 Special Piping Support.......................................................................................................................... .... 9

4.3 Civil Special Piping Support .................................................................................................................. .... 9

5. LIMIT OF LIABILITY .................................................................................................................................. 10

5.1 Engineering ........................................................................................................................................... .. 10

6. BASIC DESIGN Criteria ............................................................................................................................ 11

6.1 General Criteria ..................................................................................................................................... .. 11

6.2 Loads and Loading Conditions ............................................................................................................. .. 12

6.2.1 ... Lines with stress calculation note ......................................................................................... 12

6.2.2 ... Lines without stress calculation note ......................................................................................... 12

6.3 Supports Displacements ....................................................................................................................... .. 14

6.4 Design Temperature for Support Components ..................................................................................... .. 14

6.5 Structural Attachments between Piping and Supports ......................................................................... .. 14

6.5.1 ... General rules ......................................................................................... 14

6.5.2 ... Pipe shoes ......................................................................................... 15

6.5.3 ... Trunnions ......................................................................................... 15

6.5.4 ... Protection shield ......................................................................................... 16

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 5/33

Job Specification for design – Piping support

6.6 Structural Attachments Between Supports and Structures .................................................................. .. 17

6.6.1 ... On concrete frames or structures ......................................................................................... 17

6.6.2 ... On steel structures and beams ......................................................................................... 17

6.6.3 ... On paving ......................................................................................... 17

6.6.4 ... Unpaved area ......................................................................................... 17

6.7 PIPE SPANS ......................................................................................................................................... .. 18

6.7.1 ... Metallic pipes spans ......................................................................................... 18

6.7.2 ... Glass Reinforced Plastic Pipes ......................................................................................... 18

7. GENERAL SUPPORTS DESIGN for the project ..................................................................................... 18

7.1 Support for Classified Hot Lines ........................................................................................................... .. 18

7.1.1 ... General rules for diameter lines higher or equal than dn 50 ............................................................ 18

7.1.2 ... General rules for diameter lines lower than dn 50 ........................................................................... 18

7.1.3 ... Carbon Steel lines without P.W.H.T and Low Temperature Carbon Steel lines.............................. 19

7.1.4 ... Stainless Steel and Nickel Alloy lines: AISI 304L, AISI 316(L), AISI 321, Super Duplex, 254Mo,

Alloy 625 (Incoloy) and Alloy 825 (Inconel) ......................................................................................... 19

7.1.5 ... Internal Cement or PTFE lined lines ......................................................................................... 20

7.1.6 ... Non-metallic lines ......................................................................................... 20

7.1.7 ... Existing lines ......................................................................................... 21

8. SPECIFIC SUPPORTS DESIGN ............................................................................................................... 21

8.1 Pressure Safety Valves ......................................................................................................................... .. 21

8.2 Iron Round Rods ................................................................................................................................... .. 21

8.3 Tie Rods Hangers ................................................................................................................................. .. 21

8.4 Variable and Constant Spring Hangers ................................................................................................ .. 22

8.5 Rigid Struts............................................................................................................................................ .. 22

8.6 Shock Absorbers or Snubbers. ............................................................................................................. .. 22

8.7 Sliding Plates ........................................................................................................................................ .. 22

8.8 Heat Isolation Block .............................................................................................................................. .. 23

8.9 Typical Installation Assemblies ............................................................................................................. .. 23

8.9.1 ... Structural attachments and design between Supports and Vessels................................................ 23

8.9.2 ... Supports near pumps, centrifugal compressors or turbines ............................................................ 23

8.9.3 ... Powder transfer lines ......................................................................................... 23

8.10 Lines Submitting to Water Hammer or Slug Events ............................................................................. .. 24

8.11 Tubing ................................................................................................................................................... .. 24

8.12 TEA and CAT lines ............................................................................................................................... .. 24

9. Support Materials ..................................................................................................................................... 24

9.1 Miscellaneous Support Material ............................................................................................................ .. 24

9.2 Supports Components .......................................................................................................................... .. 25

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 6/33

Job Specification for design – Piping support

9.3 Material certificates ............................................................................................................................... .. 25

ATTACHMENT 1 : PROTECTION SHIELD....................................................................................................... 26

ATTACHMENT 2 : PRINCIPLES FOR CLASSIFIED HOT LINES DN < 50. .................................................... 27

ATTACHMENT 3 : HEIGHT PIPE SHOE FOR CLASSIFIED HOT LINES ....................................................... 28

ATTACHMENT 4 : TYPICAL ARRANGEMENTS ON PAVING ........................................................................ 30

ATTACHMENT 5 : TYPICAL FOR PUMP AND HEAT EXCHANGER ............................................................. 31

ATTACHMENT 6 : GUTTER FOR tEA AND CAT LINES ................................................................................. 32

ATTACHMENT 7 : PIPE SHOE ......................................................................................................................... 33

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 7/33

Job Specification for design – Piping support

1. PURPOSE OF THE DOCUMENT

Present Job Specification for Piping Support Design 202517C-0000-JSD-1300-010 intends to specify basic

data, rules and documentation for the Design of Pipe Supports on ETI BAKIR New Phosphoric acid plant Project.

The Site is located in Samsun, Turkey.

Piping Support design is in Mechanical/Piping contractor scope. Compliance and/or deviations from the present

JSD shall be agreed between Mechanical/Piping contractor and ETI BAKIR.

2. REFERENCE DOCUMENTS

2.1 CODES REQUIREMENTS

Piping supports shall be designed, installed, fabricated and erected in complete accordance with the most recent

edition of the following reference codes:

DOCUMENT DOCUMENT TITLE

REFERENCE

ASME B31.3 Process Piping

MSS SP58 Pipe Hangers and Supports - Materials, Design and Manufacture

MSS SP69 Pipe Hangers and Support - Selection and Application

MSS SP89

Pipe Hangers and Supports - Fabrication and Installation

Practice

2.2 DEFINITIONS AND ABBREVIATIONS

Unless stated otherwise, words in capital letters have the same meaning as in the CONTRACT. The following

terms used in this document have the definition defined in table below:

TERM DEFINITION

LICENSOR TECHNIP ENERGIES

COMPANY ETI BAKIR

The following abbreviations used in this document have the meaning defined in table below:

ABBREVIATION MEANING

May

Is to be understood as giving a freedom of choice

Shall

Is to be understood as mandatory

Should

Is to be understood as strongly recommended

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 8/33

Job Specification for design – Piping support

2.3 PROJECT REFERENCE DOCUMENTS

The following listed specifications shall be used in conjunction with this specification:

202517C-000-CN-0007-0001 Basis of Design

202517C -0000-JSD-1300-002 Plant Layout and Piping Design

202517C -0000-JSD-1300-008 Piping Stress Analysis

202517C -0000-JSD-1300-021 Piping Classes Summary

202517C -0000-JSD-1300-022 Piping Classes Detailed

2.4 ORDER OF PRECEDENCE

In case of conflict between codes, rules, specifications and standards the following order of precedence shall

be considered:

International codes and standards referenced into this specification

This specification and other TECHNIP ENERGIES specifications

Owner’s specification referenced into this specification

Supplier’s specifications

Industrial association standards referenced into this specification

Any conflict between the above documents shall be brought to the COMPANY’s attention and a written

clarification shall be obtained before proceeding to the manufacture or to any work.

3. TERMINOLOGY

3.1 SUPPORT COMPONENTS CLASSIFICATION

3.1.1 PRIMARY SUPPORT

Primary supports include all components which are directly connected to pipe (welded or clamped).

For example: pipe shoe, clamp, rod hanger, trunnion, etc…

3.1.2 SECONDARY SUPPORT

Secondary supports are those devices which connect the primary support to the main steel or to the ground, for

supporting pipe or group of pipes.

For example: cantilever support, ‘U’ frame, etc… These are covered in Standard Piping Support Collection under

structural supports series (SB).

3.2 LINE CLASSIFICATION

3.2.1 CLASSIFIED HOT LINE

Classified hot supports are installed on lines working under temperature between -29°C and 650°C.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 9/33

Job Specification for design – Piping support

3.2.2 CLASSIFIED COLD LINE

Classified cold supports are installed on lines working under temperature between -29°C and -45ºC.

4. STRUCTURE OF THE PIPING SUPPORTS COLLECTION

Standard supports collections are those commonly used in petrochemical plants: this range concerns all

supports on lines up to DN 1500/ 60”.

For lines above DN 1500/60”, special supports shall be designed.

4.1 STANDARD PIPING SUPPORT COLLECTION FOR HOT LINES

The Standard Piping Supports Collection for classified “HOT” lines is subdivided into subcollection according to

technical design criteria. Each subcollection is called “Series”. The complete Standard Piping Supports Hot

Collection is composed by the following supports series :

WELDED SUPPORTS SERIES STC 1391-00

CLAMPED SUPPORTS SERIES STC 1392-00

HANGER & ITEMIZED SUPPORTS SERIES STC 1393-00

STRUCTURAL SUPPORTS SERIES STC 1394-00

SMALL DIAMETER SUPPORTS STC 1395-00

The collection structure will be detailed in :

PIPING STANDARD SUPPORTS HOT COLLECTION (STC-1390-00)

An overall view of the standard piping supports hot collection will be detailed in :

STANDARD CONSTRUCTION DRAWINGS SYNOPTICS SUPPORTS SERIES – HOT COLLECTION (STC-

1390-01).

4.2 SPECIAL PIPING SUPPORT

The special auxiliary piping supports are designed when the standard supports are not suitable.

The special supports are the supports which are not covered by the Standard Piping Support Collection and are

to be designed taking into account the configuration and load data by piping designer / support designer and

stress engineer. Special supports correspond to individual figures that need special design and a dedicated

drawing.

The use of special supports shall be minimized.

A single special support can be used as often as necessary in similar situations. In this case, the drawing of the

special support shall present, if necessary, the list of isometrics concerned and , for the calculated lines, the

number of the calculation note as well as the mark of the node.

Hot special pipe supports should be designated and listed independently of standard support collections in

special pipe support collection listed in NM-1360-100.

4.3 CIVIL SPECIAL PIPING SUPPORT

In cases of large support dimensions or supports subjected to loads exceeding the limits set in the standards, a

detailed design of these supports is going to be transferred to the Civil department for its calculation and detailed

design, to ensure its stability and its integration into the whole metal structure of the project.

These supports are called C-SPS (Civil Special Pipe Support) and basically characterized by:

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 10/33

Job Specification for design – Piping support

▪ Vertical and/or horizontal dimensions greater than 2 meters or exceed the limits set in the standards.

▪ Vertical loads greater than 2000 kg. or horizontal loads greater than 500 kg.

▪ For construction feasibility and cost reasons it is preferable to include them in the supply of the metal structure

contractor.

▪ Supports that convey loads on to the pavement and must be constructed a concrete slab with or without

plate to support them by civil works contractor.

5. LIMIT OF LIABILITY

5.1 ENGINEERING

As per Technip’s scope, estimated Support position will be indicated in the isometric without type detail, only as

a identification mark for all lines with a diameter equal to DN65 and above.

Mechanical/Piping subcontractor will be in charge of study and design all Piping Supports for all lines (primary,

secondary and special supports).

TABLE 1 : LIMIT OF LIABILITY

Pipe

Type of supports Support Description

Diameter

Pipe clips, pads and Supports selected and designed during detail

gussets on vessel engineering phase by Mechanical/Piping subcontractor.

Supports selected and designed on site during

< DN 65 construction phase by piping sub-contractor; always

All except above based on the optimized use of Technip Energies

supports collections:

STC-1390-00/01 & STC-1395-00.

Estimated Support position will be indicated in the

isometric without type detail, only as a identification

mark.

≥ DN 65 All

Primary and secondary Supports selected and designed

during detail engineering phase by Mechanical/Piping

subcontractor.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 11/33

Job Specification for design – Piping support

6. BASIC DESIGN CRITERIA

The following design rules are applicable to standard and special piping supports.

6.1 GENERAL CRITERIA

Maximum spacing of supports shall be defined in Piping Standard Supports, refer to document

STC-1390-00.

Use of standard piping supports as per Technip Energies collection shall be maximized in order

to limit the number of support types.

All the components of supports elements in contact with or directly welded onto the piping

(welded pipe shoe, protection shield, clamps and bracket, U-bolts, when applicable) shall be

from the same material grade or metallurgy as the supported pipe.

All insulated lines including lines with personal insulation shall be on shoes in any position

(horizontal or vertical).

Except in the case of anchors, all the pipe shoes shall rest on a round iron, diameter 20 mm,

welded to the structure or embedded in the concrete foundations.

Temporary pipe supports may be used only for load conditions encountered during : erection,

hydrostatic testing, long term maintenance work, and repairs. The temporary service of such

supports shall be clearly indicated on the calculation note to ensure their removal upon

completion.

Piping subject to frequent dismantling for standard maintenance (e.g. lines connected to heat

exchangers) or for operative requirements (e.g. installation of blind flanges) shall be provided

with supports for pipe erected and pipe dismantled positions. It shall be clearly indicated on

piping isometric drawings whether a given support is for use under all line conditions or only for

the dismantled condition.

Secondary structural support members shall be designed on the basis of contract standards for

structural steel construction, see document STC-1390-00.

Protection shields on the pipe shall have a vent/drain hole (unblocked) in its lower part. Filled

with grease or mastic material for service temperature lower than 300°C.

Resting supports located in proximity to pumps, turbines or compressors shall be of adjustable

type (see attachment 5).

For non-insulated stainless steel lines, a stainless steel flat bar shall be placed at each steel

beam under the line (see WE04 from STC-1391-00 series) in case no protection shield is

supplied at that point.

If piping is subjected to dynamic stresses, it shall be necessary to evaluate the feasibility of using

damping supports.

Supports shall be designed and installed to warrant free thermal expansion of pipes and to avoid

sagging and strain on equipment (according to allowable loads).

Supports shall be designed to take into account stress analysis conditions as per JSD-1300-008.

Spring hangers, rigid struts or shock absorbers, shall be defined by stress engineer (data sheets

with loads, movements, and so on) and submitted to purchase.

Two phases flow lines will have special support consideration (see paragraph 8.10).

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 12/33

Job Specification for design – Piping support

Pipe supports connected to columns, vessels and heat exchangers shall not cause undue local

or overall stresses on such equipment. Admissible forces and moments shall be determined

according to the Pressure Vessel & Heat Exchangers and Mechanical Department or with

supplier acceptance.

Support close to strain sensitive equipment (e.g. turbines, compressors…) shall consider loads

limitations as specified in the related Standard, Code or Equipment Manufacturer.

As a rule, auxiliary pipe supports shall be connected to reinforced concrete structures by welding

to an embedded plate into the concrete or by expansion anchor bolts.

Pipe Supports type ``clamp´´ shall be used for Pipe lines with CS+PTFE material.

Special attention with FSQR requirements when designing pipe supports. Depending on the

FSQR risk zone, particular supports design considerations shall be implemented.

6.2 LOADS AND LOADING CONDITIONS

6.2.1 LINES WITH STRESS CALCULATION NOTE

Refer to calculation note for considered cases and loads applied to the support.

6.2.2 LINES WITHOUT STRESS CALCULATION NOTE

Supports shall be designed to withstand loads transmitted under the permanent and occasional conditions.

6.2.2.1 PERMANENT AND TEMPORARY LOADS

Pressure effect (internal or external).

Weight of the piping, insulation and in-line components (valves, flanges,…).

Weight of the fluid transported during normal operation.

Pressure thrust when pipe mechanical unity is interrupted, for example by an expansion joint.

Thermal loads due to friction during effective or potential sliding contact between pipe and

support.

Hydrostatic test loads.

6.2.2.2 OCCASIONAL LOADS

Wind loads [see 202517C -0000-JSD-1300-08]

Seismic loads [see 202517C -0000-JSD-1300-08]

Snow loads [see 202517C -0000-JSD-1300-08]

Safety valve loads [see 202517C -0000-JSD-1300-08]

Unless specified otherwise in local or contractual standards, load conditions, loads and admissible stress

increase shall be as indicated in the following TABLE 2.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 13/33

Job Specification for design – Piping support

TABLE 2 : LOADS ON PIPING SUPPORTS

INCREASE OF THE

ALLOWABLE STRESS

CONDITION LOADS

FOR SUPPORT

MATERIAL

1) Weight of support

2) Weight of erected pipe

12.5% increase

3) Snow and/or ice loads when incidental

Erection

loads are

4) Wind loads applied separately in two

considered

normal directions. Use of one load or other

shall depend on which gives worst

condition when summed to loads 1, 2, 3

1) Weight of support

12.5% increase

2) Weight of pipe during testing when incidental

Testing

3) Snow loads loads are

considered

4) 50% of wind loads applied separately in

two normal direction (two load cases)

1) Weight of support

2) Weight of pipe during service

3) Load due to particular operating conditions

e.g. hammering, opening of safety valves

(*), unrestrained expansion joints 12.5% increase

when incidental

Operating 4) Snow and/or ice loads

loads are

5) Thermal loads considered

6) Wind or seismic loads applied separately

in two or three normal directions. Use of

one load or other shall depend on which

gives worst condition when summed to

loads 1, 2, 3, 4, 5

(*) Loads due to opening of safety valves shall be determined according to API RP 520 “Recommended

practice for the Design and Installation of pressure-Relieving system in refineries”

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 14/33

Job Specification for design – Piping support

6.3 SUPPORTS DISPLACEMENTS

Supports displacements should consider the various temperature conditions that may occur during operating,

start up, shut down :

Design temperature of the line

According to the site climatic data :

o Minimum ambient temperature : [see 202517C -0000-JSD-1300-08]

o Maximum ambient temperature : [see 202517C -0000-JSD-1300-08]

o Solar temperature : [see 202517C -0000-JSD-1300-08]

Steam out temperature if specified

Steam or electrical tracing for traced lines without circulation

For lines alternatively cold or hot, support design shall take into account the range of the total displacement.

6.4 DESIGN TEMPERATURE FOR SUPPORT COMPONENTS

The temperature to be considered in the design of supports shall be the greatest of the temperature defined in

paragraph 6.3.

At a minimum, all support components shall be designed for a temperature equal to 80°C for components

within and outside the insulation (note that TECHNIP ENERGIES Piping Supports Hot Collection STC-1390,

covers a temperature range from -29 to 342 ºC).

For operating Tº larger or equal to 250 ºC, an isolation block must be used.

6.5 STRUCTURAL ATTACHMENTS BETWEEN PIPING AND SUPPORTS

6.5.1 GENERAL RULES

•Generally pipe shoes will be welded types.

•When used, stanchions on elbows shall be minimum length from B.O.P (bottom of pipe), junction to

pavement will be of pedestal type with support base plate at ground or beam structure.

•Welded support borders shall be at least 50 mm of joining welded of pipes, bend, flange, etc...

•All components shall be welded to pipe by continuous fillet weld except other imposition. Angle

welding thickness shall be 0,8 time plate or frame thickness if not indicated. In all cases, the welding

will be carried out in accordance with the welding book.

•Pipe attachments, welded directly or clamped to the main pipe shall be same quality as pipe

specification material (incl. material certificate). It shall be specified on the piping isometrics if specific

requirements is required such as heat treatment or shop welding.

•All elements integrally welded to the pipes, such as reinforced pads, shall be drilled in order to

evacuate the gas produced during welding (see attachment 1)

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 15/33

Job Specification for design – Piping support

6.5.2 PIPE SHOES

▪ All lines insulated (hot insulation or personal protection) (all DNs) shall be installed on pipe shoe.

▪ Non-insulated lines shall rest directly on support / structure profile without pipe shoe.

▪ For the following Non-insulated lines case, pipe shoe will be required:

- Slope lines: Adjustable pipe shoes shall be used to suit the slope or shimmed to suit for smaller

dimensions. Where necessary, drawings shall be marked as `SHIM TO SUIT´.

- Lines DN600 and above Pipe shoe

▪ Insulated lines shall be supported on Pipe shoes to ensure that the outside diameter of the insulation clears

the supporting steel.

▪ Insulated lines with Personnel Protection shall be supported on Pipe shoes during the isolated pipe section. In

pipe parts without insulation shall rest directly con supports.

6.5.2.1 PIPE SHOE LENGTH

As a general rule, the shoe length is defined as follows :

Pipe shoe length will be 300 mm for thermal expansion below to 75 mm.

Pipe shoe length will be 500 mm for thermal expansion from 75mm to 150 mm.

For thermal expansion over 150 mm , pipe shoe length will be increased by 100 mm step.

The overall length of the shoe will not have to be lower than 2 times the total displacement

(increased of 200mm)

Refer to paragraph 6.3 for the calculation of the thermal expansion.

6.5.2.2 PIPE SHOE HEIGTH

The height of the pipe shoe will be defined according to Attachment 3, PIPE SHOE HEIGHT.

6.5.2.3 SHOES FOR GLASS REINFORCED PLASTIC PIPES

All uninsulated and insulated lines shall rest directly on Pipe shoes.

6.5.3 TRUNNIONS

Trunnions will have an overture at the extreme site or a vent hole according to the Technip

piping support standards.

Trunnions will be as short as possible in order to minimize tensions and bending effects.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 16/33

Job Specification for design – Piping support

6.5.4 PROTECTION SHIELD

6.5.4.1 CRITERIA

Piping reinforcement shall be provided at the support points as per the following rules :

horizontal lines for DN ≥ 200,

vertical lines for DN ≥ 100,

lines connected to rotating machines (vibration conditions) whatever the diameter.

Thin pipe walls. Pipe is considered thin-walled when :

72 with 𝐷 = outside diameter and 𝑆 = corroded thickness

Additional criteria for the installation of a protection shield are indicated in paragraph 7 (according to line

material, heat treatments or type of support).

6.5.4.2 DESIGN

Refer to attachment 1.

Protection shields welded to the pipe shall:

Have a length at least 100mm longer than element to be welded on it (pipe shoe, profile).

For pipe shoes have a length at least equal to 400mm.

Cover a third of the circumference of the piping

Systematically have a air hole (unblocked) in its lower part, filled with grease or mastic

material for service temperatures less than 300°C,

Be welded onto the piping by a continuous weld

Lines with thickness below 12.7 mm :

Protection shields are considered as cut from the pipe and shall be same quality as pipe

specification material (incl. material certificate).

Protection shields thickness shall be as per pipe schedule.

Lines with thickness higher or equal to 12.7 mm :

The thickness of the protection shield shall be 12.7 mm.

Protection shield shall be same quality as pipe specification material. Protection shield shall

be cut from pipe class material or equivalent (incl. material certificate).

It shall be specified on the piping isometrics if specific requirements is required such as heat

treatment or shop welding.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 17/33

Job Specification for design – Piping support

6.6 STRUCTURAL ATTACHMENTS BETWEEN SUPPORTS AND STRUCTURES

6.6.1 ON CONCRETE FRAMES OR STRUCTURES

Insert plates will be provided on concrete beams or columns.

When insert plates may not be provided, a support plate will be fixed by chemical anchor

bolts.

Insert plate dimension shall be compatible with the loads and displacements of the support

to avoid contact support / concrete.

For small bore pipes, supports can be clamped on concrete columns.

6.6.2 ON STEEL STRUCTURES AND BEAMS

As a general rule, piping supports shall be fixed to structure by welds. In some particular

cases, piping supports shall be connected to metallic structures by bolted gussets.

On platform, supports will be limited in loads. Support’s plate will be clamped or bolted on

grating (generally small bore lines).

On grating, supports will be forbidden for lines with a diameter higher or equal to DN 50. For

lines with a diameter lower than 2”, the total loads of the supports will be limited to 500N/m².

In a general way, the support must be chosen to avoid the drilling of an element of the main

steel (including beam of pipe racks and main beam of structure).

The temperature at the contact point between the piping support and the structure will not

exceed 180°C.

If a new structure for a support is welded or installed to an existing structure or profile, the

area where profiles of the new structure are going to be welded or installed will be cleaned

up removing fireproofing, painting and rust, if so. The aim of these tasks is to prepare the

metal surface for new proper weldings in existing structure.

6.6.3 ON PAVING

The allowable primary loads for support on paving without reinforcement or foundation is

equal to 20 kN. If calculated loads are higher than allowable loads, they shall be submitted

to the Civil Work Department by the Support Leader for approval.

Base support plates will be fixed to paving by means of chemical anchor bolts (see

attachment 4 type A) except for supports whose loads justify reinforcement, or foundation

with anchor bolts and insert plates by Civil Work Department (see attachment 4 type B).

A pedestal is provided on concrete slab areas. The minimum height is fixed at 50 mm. Thus

the elevation, for the support, is +100 050 at the high point of pavement. In the retention

areas, if the supports must be above the height of retention, the height of the pedestal will

be adapted consequently.

Pedestal on paving shall be in the scope of work of Civil Work Department (see attachment

4).

6.6.4 UNPAVED AREA

Generally support are embedded in ground and civil work department will provide such

supports.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 18/33

Job Specification for design – Piping support

In other cases for lower loads (tracing manifolds, utilities lines, drains system,....), supports

will be provided by field during construction. In these cases concrete will be poured in a

plastic protection in excavation.

6.7 PIPE SPANS

6.7.1 METALLIC PIPES SPANS

Pipe spans shall conform to charts given at STC-1390-00.

As a limit in the hydro test condition (e.g. insulated pipe full of water), the pipe shall not deflect

more than 12.5 mm. Maximum deflection admissible according to Technip Energies piping support

standards.

6.7.2 GLASS REINFORCED PLASTIC PIPES

Pipe spans supports span shall be as per the Manufacturer’s Data and applicable Codes and

Standards. To be defined after award of contractor.

7. GENERAL SUPPORTS DESIGN FOR THE PROJECT

7.1 SUPPORT FOR CLASSIFIED HOT LINES

7.1.1 GENERAL RULES FOR DIAMETER LINES HIGHER OR EQUAL THAN DN 50

All insulated lines will be on pipe shoes. Refer to attachment 3 for height pipe shoe.

Non-insulated lines shall rest directly on support / structure profile without pipe shoe.

7.1.2 GENERAL RULES FOR DIAMETER LINES LOWER THAN DN 50

All insulated lines will be on pipe shoes.

Insulated small bore lines (except personal protection), running on pipe racks or pipe ways

and traced small bore line will be on shoes. On vertical lines, support will pass through the

insulation (see attachment 3 fig. V). Only when u-bolts are allowed. Below in this paragraph,

it is defined the criteria for u-bolts.

Traced small bore line will be on shoes all the time. Refer to attachment 3 for height pipe

shoe.

If possible, lines with a DN equal to 40 and smaller may use common supports.

Tracing lines from compact manifolds may be insulated and supported together.

Lines shall be guided at each support point, except some cases where it is necessary to

allow lateral displacement for thermal expansion. For example at change of direction after a

long running pipe, the support near the elbow shall be without guide.

Typical installations: see attachment 3 for hot lines.

For tubing lines, particular attention shall be paid for supporting any instrument (ex:

manometer) or fitting (ex: control valve).

For vertical lines, vertical guides shall be used. Space between guides shall be equal to

horizontal span of similar continuous running pipe.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 19/33

Job Specification for design – Piping support

For sloping piping, the maximum span between two adjacent supports shall be established

so that center line deflection does not exceed 1/3 of the difference of elevation between the

supports.

Where valves or by-pass are present, piping shall be supported to facilitate operations and/or

dismantling.

No gusseting/stiffeners are needed on small bore branch tapping (<DN50) where nipolets

are used (in line with GS RC PVA 102-00, paragraph 7.5). Exceptions shall be considered

for special requests, particular applications or for vibrating services under conditions

indicated in the following table (taken from TOTAL GS mentioned):

TABLE 3 : APPLICATION TABLE FOR GUSSETS IN VIBRATING SERVICES

7.1.3 CARBON STEEL LINES WITHOUT P.W.H.T AND LOW TEMPERATURE CARBON STEEL LINES

7.1.4 STAINLESS STEEL AND NICKEL ALLOY LINES: AISI 304L, AISI 316(L), AISI 321, SUPER DUPLEX, 254MO,

ALLOY 625 (INCOLOY) AND ALLOY 825 (INCONEL)

Pipe shoes will be welded on a protection shield of the same material than pipe, in case of

anchor supports (STOP) and in vertical pipelines where pipe shoes or shape legs are resting

or guiding on steel structure.

When a protection shield is welded between pipe and support components, these

components (ribs, stanchions, plates, bars,…) could be on carbon steel. Just for economic

reasons, preferably they shall be on carbon steel.

In case of guide supports and rest supports in horizontal pipelines clamped type support is

used. The clamp shall be made of stainless steel A240-304 or equivalent material than the

pipe (see doc. STC-1390-100, SECTION 4).

When it is used protection shield shall be shop welded to the main pipe and other

components welded on site for all diameters.

On stops and anchors shoes will be welded on pipe with a protection shield. It is used “

clamp-type” with lugs on pipe according to loads and pipe thickness if there is not physical

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 20/33

Job Specification for design – Piping support

space to install a welded pipe shoe. Protection shield shall be of the same material than the

pipe and other components could be on carbon steel. Just for economic reasons, preferably

they shall be on carbon steel.

When a protection shield is welded on the main pipe and the support components are on

carbon steel (ribs, stanchions, plates, bars, profiles…), proceed sand blasting and painting

them before welding them on the protection shield.

When a stainless steel clamp is installed on the main pipe, proceed sand blasting and

painting support components on carbon steel (ribs, stanchions, plates, bars, profiles…)

before welding them to the clamp.

Take special attention on welding procedures of this materials, since if weldings are done

incorrectly, there will be corrosion problems in the future.

7.1.5 INTERNAL CEMENT OR PTFE LINED LINES

N.A.

7.1.6 NON-METALLIC LINES

• Clamped supports (see ATTACHMENT ) will be used.

• For clamped supports which work as anchors or «guide stop» a GRP ring will be laminated on

both sides from DN250 to DN700. Rings dimensions will be according to GRP Supplier Standard.

GFK rings according to material class.

• Pipe clamp include a soft band (neoprene, EPDM, NBR or similar) between pipe and support.

• Plastic lines DN50 and above shall be on clamped type pipe shoe.

• Valve loads must be considered by using valves supports.

7.1.6.1 GRP PIPE

GRP piping lines will be supported with the purpose of confirm the pipe routing and

validate the correct supportation of the line according to the GRP Vendor guidelines and

to this Job Specification.

Pipe properties, support design like inside diameter of the clamp and supports span shall

be as per the manufacturer’s data and applicable codes and standards.

Supported IFD Isometric will be sent to GRP Vendor for comments and checking. The

validation shall be confirmed by GRP Supplier in order the obtain the Responsibility

regarding the support position, piping routing, support details and support

function/configuration. After GRP Supplier comments are implemented, IFC Isometric will

be issued.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 21/33

Job Specification for design – Piping support

7.1.7 EXISTING LINES

Pipe shoe to be included only when an existing line is modified and when a new structure is

added.

If a pipeline modification involves another pipeline, which is not going to be modified and a

new support for the non-modified pipeline is required to fulfil allowable pipe support spacing,

clamp type supports are going to be allowed in all kind of materials, including carbon steel.

8. SPECIFIC SUPPORTS DESIGN

8.1 PRESSURE SAFETY VALVES

Pipes connected to pressure safety valves (PSV) inlet and discharge shall be supported as close as possible

to the PSV, and follow :

Anchor at discharge Transversal guide at discharge

+ OR +

Weight support at inlet Anchor at inlet

Block with 2 directions acting support (weight support hold down)

Supports without gap

Support shall be designed to withstand the static and dynamic loads.

Refer to JSD 1300 008 for dynamic loads to be applied.

8.2 IRON ROUND RODS

In case iron rounds rods are requested by the client. Civil department is the responsible to include this element

in all the structures and racks.

For existing structures or racks no Iron Rods will be included, in order to keep Center Line/BOP of existing

lines with no modifications.

8.3 TIE RODS HANGERS

Tie rod hangers may be used when resting shoes are not realizable and according to stress

analysis imposition to reduce friction loads on horizontal lines.

Tie rod hangers with thermally insulated piping are prohibited without using a thermal

isolation device between the pipe and the hanger attachment.

Tie rods are designed to work under traction forces, they shall never be subjected to

compression.

Minimum length of tie rod shall be calculated so that angle between cold position and hot

position does not exceed 3°. Length of tie rod shall be at least 15 times the pipes horizontal

movement.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 22/33

Job Specification for design – Piping support

Tie rods shall be adjustable by using a turnbuckle when they’re installed on pipes 2” and

above.

Tie rods connection ends (pipe side and structural side) have to be made by adapted items

as : welded gussets, eye nuts, clevis, pipe or beam clamps. Attachments by ball joints are

prohibited due to the risk of the ball joints jamming

Safe loads for threaded hanger rods shall be based on the root area of the threads and

allowable stress of the material (refer to paragraph 9.1).

8.4 VARIABLE AND CONSTANT SPRING HANGERS

The rules indicated in the paragraph relevant to the tie rods shall apply to variable and

constant spring hangers (i.e. length of tie-rod considered as distance between two hinges).

Spring hangers shall be used when advised by piping stress department. Nevertheless,

spring hangers shall be avoided by means of particular layout.

Spring hangers shall be used when piping connected to equipment and structures cannot

withstand load variations and movements resulting from the use of rigid support.

Spring hangers shall not be considered as a solution when the predicted spring travel from

the cold position to the operating position (vertical) is five (5) mm or lower, except on sensitive

mechanical and rotating machines (turbines, compressors, pumps, etc.) where overloads

are limited by a Code or manufacturer limits.

As a general rule, variable spring supports will be used when load variation between cold

position and operating position is not exceeding 20%. Over this limitation Constant Spring

supports will be preferred.

8.5 RIGID STRUTS

Rigid struts shall be used for absorption of shocks in the event of unscheduled load at stress

analysis request to protect sensitive equipment.

Rigid strut may be also used as stop or guide of the piping system when standard welded

lugs are unrealizable.

Rigid struts are articulated on each side and loads reversible.

8.6 SHOCK ABSORBERS OR SNUBBERS.

Shock absorbers or snubbers installation can only be required by stress analysis.

These devices are designed to allow piping thermal displacements but allow to block sudden

displacements given by hammering or seismic studies.

Snubber’s piston rod shall be connected to the pipe attachment side while its body shall be

connected to the structure.

8.7 SLIDING PLATES

Low friction plates shall be used when advised by piping stress group or Civil Work department.

The effect of friction shall be calculated based on the following :

Surfaces Friction factor

Steel to steel [see JSD 1300-08]

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 23/33

Job Specification for design – Piping support

Stainless steel to PTFE [see JSD 1300-08]

PTFE to PTFE shall not be used.

Anti-friction sliding plates will be PTFE (or similar fluorocarbon resins) on stainless steel with suitable surface

finish.

As a general rule, sliding plates shall not work under loads higher than 70 DaN/Cm², and temperature on contact

surface higher than 120°C.

The minimum length of the sliding section shall be at least equal to three times the maximum displacement value

of the piping at the considered point.

8.8 HEAT ISOLATION BLOCK

HH01 → Top>400 °C

8.9 TYPICAL INSTALLATION ASSEMBLIES

8.9.1 STRUCTURAL ATTACHMENTS AND DESIGN BETWEEN SUPPORTS AND VESSELS

Clips for classified “HOT” vessel supports, for lines DN 50 to 600, have to be defined by

Vessel Contractor according with piping designer’s information indicated in gussets data

sheets (level, load, angle position, standard shape in junction with gusset).

For line’s diameter or loads out of support standard ranges, definition of attachments on

vessels and support structure design will be defined by Civil Work Department.

All pipe clips, pads and gussets on vessels shall be defined for all pipes regardless of line

diameter including utilities lines, tracing lines or instruments lines when necessary.

For reused single clips of equipment, single bracket support design with GUIDE+HOLD

DOWN or STOP+GUIDE+HOLD DOWN is going to be accepted for vertical pipelines .

8.9.2 SUPPORTS NEAR PUMPS, CENTRIFUGAL COMPRESSORS OR TURBINES

Supports installed on piping close to nozzle connection of pumps, centrifugal compressors or turbines, shall be

adjustable type to make alignment easier. Their position shall continue to support fully the pipe work while spool

piece is disconnected during maintenance.

The lines, connected to a pump, shall be supported on the ground to avoid the use of spring boxes placed on

structure in an cantilevered position on pipe racks. This support configuration ensures an easier protection of

nozzle.

8.9.3 POWDER TRANSFER LINES

Powder transfer lines shall be supported with guides close enough one to each other to avoid vibrations. Each

straight run of powder transfer lines shall once be rigidly restrained in axial direction. All guides are required

without gap.

Strong support as rigid strut or special support type or heavy support type shall be used. Each support must be

set with reinforced pads where pipe support shoes and double trunnions are permanently welded to the piping.

An additional dynamic load must be added to static load in longitudinal axis at each support if any and must be

taken into account for the support design.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 24/33

Job Specification for design – Piping support

8.10 LINES SUBMITTING TO WATER HAMMER OR SLUG EVENTS

Refer to JSD-1300-008 for the lines submitting to dynamic loads due to water hammer or slug events.

8.11 TUBING

Lines belonging to “TUBING” class shall have a maximum horizontal or vertical span of 1200 mm, otherwise, if

it is not possible, these lines shall be supported by means of gutters (see attachment 6).

8.12 TEA AND CAT LINES

TEA and CAT lines shall be supported by means of gutters. To avoid mechanical impact damage in all places

where there is a possibility to hit these lines, a protective device shall be provided (see attachment 6)

9. SUPPORT MATERIALS

9.1 MISCELLANEOUS SUPPORT MATERIAL

Piping supports materials shall be selected according to those listed in ASME B31.3

Appendix A or according to those foreseen in equivalent codes (DIN/EN). Refer to Project

Standard for details description of materials to be used.

Piping supports materials shall not be used at temperatures that are not backed by Design

Codes giving allowable stress value.

The design temperature of support members in direct contact with pipe wall shall be assumed

as equal to the temperature of the pipe carried fluid. The design temperature of support

members not in direct contact with pipe and located outside line insulation shall be assumed

as equal to ambient temperature or 1/3 the temperature of the pipe carried fluid, whichever

is higher.

Attachments welded directly to the pipe as open profiles, reinforcing saddles or protection

shields, shall be of appropriate chemical composition according to welding requirements,

according to 202517C -0000-STC-1390-100, SECTION 4.

Unless otherwise specified, the heat treatments required for the supports welded directly to

the process piping components are to be according to 202517C -0000-STC-1390-100,

SECTION 5.

Note: Even if not required for process and/or metallurgic requirements, the post weld heat treatment shall be

executed according to the prescriptions shown in the SECTION 5 of 202517C -0000- STC-1390-100.

All dimensions are in mm. unless otherwise indicated.

Elevations are referred to the same conventional elevation assumed for the plant except if

clearly specified for tangent or welding reference lines.

Angles are in degrees, and are measured in a clock wise direction starting from conventional

north of the plant.

Threads shall be metric system unless otherwise indicated.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 25/33

Job Specification for design – Piping support

9.2 SUPPORTS COMPONENTS

Components to be used for fabrication of pipe supports will be described in 202517C -0000-

STC-1390-100.

If other shape types are used for delivery reasons, supplier shall advise Technip for

agreement and shall have to adjust standards to these materials.

Forged pieces and clamps are given only for information and may be adapted according to

a supplier catalogue, however when specified, admissible loads shall be respected

independently of supplier.

Bolting shall consist of bolt and nut, unless otherwise indicated.

Chemical anchor bolts shall be used for piping supports on pavement except those defined

by Civil Work Department.

Protection shields are considered as cut from pipe.

Pipe elements for supports welded on main pipe (including reinforced saddles, protection

pads and profiles) will be, except specific information on support isometric data sheet, as

piping classes used in this plant and taken into account with piping MTO (but are not

indicated on isometrics bill of material).

Pipe elements for supports not welded on main pipe may be from standard schedule or

equivalent except specific requirements due to stresses or loads.

Clamps are considered as flat bar, and they shall be the same material or equivalent than

the pipe according to 202517C-0000-STC-1390-100, SECTION 4. Other plates may be from

steel sheets.

9.3 MATERIAL CERTIFICATES

For support components, a type 2.2 certificate according to EN 10204 or ISO 10474 is sufficient if

they are assembled on pads or protection shields.

The supply principle for support elements such as commercial profiles (T, H, UPN, IPN, …)

delivered with a type 2.2 certificate intended to be assembled by welding on a component

subjected to pressure should be validated by the Notified Body.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 26/33

Job Specification for design – Piping support

ATTACHMENT 1 : PROTECTION SHIELD.

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 27/33

Job Specification for design – Piping support

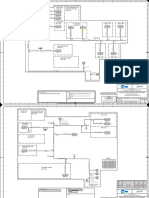

ATTACHMENT 2 : PRINCIPLES FOR CLASSIFIED HOT LINES DN < 50.

LINE DN ≤ 40

15 ≤ DN ≤ 40

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 28/33

Job Specification for design – Piping support

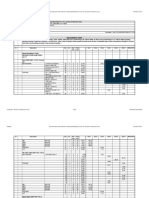

ATTACHMENT 3 : HEIGHT PIPE SHOE FOR CLASSIFIED HOT LINES

Tracing lines : All diameters

Line ranges :

PIPE DIAM. INSULATION THICKNESS PIPE SHOE HEIGHT /

(in) (mm) PROTECTION SHIELD

(mm)

All insulation thickness except Lines on pipe rack or

1” to 1 ½ “

personal protection sleeper: 100

No pipe shoe is required

Protection shield thickness

shall be considered if

2” to 18” Without insulation (3)

required by stress analysis

or

if De/s > 72 (2)

No pipe shoe is required

20” to 24” Without insulation (3) Protection shield thickness

shall be considered

Without insulation or insulation

26” and larger 100 (1)

for personal protection (3)

26” and larger With insulation 200 (1)

2” to 24” ≤ 60 100 (1)

2” to 24” 60 < INS. THK. < 110 150 (1)

2” to 24” 110 < INS. THK. < 150 200 (1)

(1) : ALSO VALID FOR LINE WITH SLIDING PLATE ( INSULATED OR NOT ).Warning, height

including sliding components

(2) De: external pipe diameter, S: pipe thickness corroded

(3) For operating temperature > 180 °C a 100 mm height pipe shoe shall be required

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 29/33

Job Specification for design – Piping support

FOR LINE WITH SLOPE, MINIMUM HEIGHT PIPE SHOE WILL BE 100 mm AND ≈300 mm

AS MAXIMUM FOR RANGE DN 50 TO 600 (EXCEPT TECHNICAL IMPOSITION)

SLOPE

300 mm

100 mm

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 30/33

Job Specification for design – Piping support

ATTACHMENT 4 : TYPICAL ARRANGEMENTS ON PAVING

( Paved area without foundation )

( Paved or unpaved area with foundation )

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 31/33

Job Specification for design – Piping support

ATTACHMENT 5 : TYPICAL FOR PUMP AND HEAT EXCHANGER

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 32/33

Job Specification for design – Piping support

ATTACHMENT 6 : GUTTER FOR TEA AND CAT LINES

COVER (1)

(in accessible area)

GUTTERS

(1)

FASTENING

(1)

(1) supplied and installed by piping constructeur.

GUTTERS FOR TEA AND CAT LINES

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

T.EN NUMBER Revision Page

202517C-0000-JSD-1300-010 A 33/33

Job Specification for design – Piping support

ATTACHMENT 7 : PIPE SHOE

A-WELDED PIPE SHOES

B- CLAMPED PIPE SHOES

For:

▪ Stainless steel lines

▪ Carbon Steel + PTFE lines

▪ Carbon Steel and as with PWHT

▪ GFK / PVC+GFK / PP+GFK / PVDF+GFK / PVC-U+GFK lines

This document and the information it contains is confidential and can be used only with the written authorization of CLIENT.

CONFIDENTIAL – Do not disclose without authorization

You might also like

- How To Create A Reinforcing Pad in Branch Table PDFDocument1 pageHow To Create A Reinforcing Pad in Branch Table PDFnirgaNo ratings yet

- TEM-En-001-00 - Spring Support Data SheetDocument2 pagesTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreNo ratings yet

- Practice 000 250 2020 Date 11feb00 Page 1 of 4Document6 pagesPractice 000 250 2020 Date 11feb00 Page 1 of 4mengelito almonteNo ratings yet

- VEL MS 2003b PDFDocument28 pagesVEL MS 2003b PDFCenk Yağız ÖzçelikNo ratings yet

- 03SA0S04Document5 pages03SA0S04Jhonny RinconesNo ratings yet

- PNSMV026Document26 pagesPNSMV026Philippe AlexandreNo ratings yet

- Check Valve Nozzle Non - SlamDocument16 pagesCheck Valve Nozzle Non - SlamPatricio AcuñaNo ratings yet

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationDocument32 pages202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluNo ratings yet

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationDocument32 pages202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluNo ratings yet

- AB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersDocument1 pageAB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersTrung NguyenNo ratings yet

- 1.0 Scope: Welding of Carbon Steel PipingDocument3 pages1.0 Scope: Welding of Carbon Steel PipingandhucaosNo ratings yet

- AP-NozzleTutorial R01 PDFDocument31 pagesAP-NozzleTutorial R01 PDFbalumagesh1979No ratings yet

- C2 - RevADocument16 pagesC2 - RevAChirag ShahNo ratings yet

- Insulation Schedule With Mto FOR Main Process Plant: Project SpecificationDocument18 pagesInsulation Schedule With Mto FOR Main Process Plant: Project SpecificationcakhokheNo ratings yet

- 6-44-0005 Rev 7Document446 pages6-44-0005 Rev 7MDhana SekarNo ratings yet

- Tubing: Tubing Selection Tubing Handling Gas Service Tubing Installation Types of TubingDocument16 pagesTubing: Tubing Selection Tubing Handling Gas Service Tubing Installation Types of TubingsandeshmusaleNo ratings yet

- Onis Brochure GB 2015Document16 pagesOnis Brochure GB 2015r_chulinNo ratings yet

- Mechanical Piping and FittingsDocument19 pagesMechanical Piping and FittingsPinak ProjectsNo ratings yet

- Class M1C2Document10 pagesClass M1C2SalimNo ratings yet

- Nioec SP 00 05 PDFDocument8 pagesNioec SP 00 05 PDFamini_mohiNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- LS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Document6 pagesLS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Kreshna Wisnu BrataNo ratings yet

- ASTM F 1718 - 99Document7 pagesASTM F 1718 - 99Oh No PotatoNo ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- General Notice For AG Piping Layout - TSA - RADocument35 pagesGeneral Notice For AG Piping Layout - TSA - RAkienhg96No ratings yet

- 50B10 Standard Assembly LibraryDocument78 pages50B10 Standard Assembly Libraryishu vohraNo ratings yet

- 6 44 0005 A2Document25 pages6 44 0005 A2S.selvakumarNo ratings yet

- SPREADSHEETS SERIES No. 0009S - 2Document4 pagesSPREADSHEETS SERIES No. 0009S - 2Emma DNo ratings yet

- 8-1200-31 Pipe Class IndexDocument11 pages8-1200-31 Pipe Class IndexWilson ramirez zuniniNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- Oxygen Piping Hazards and Customer Engineering ApproachDocument67 pagesOxygen Piping Hazards and Customer Engineering ApproachKom Nak100% (1)

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Document2 pagesDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrNo ratings yet

- Acc. Valves in - To PED N Air Sepa On The Ba Aration Un Asis of AD Nits D 2000Document4 pagesAcc. Valves in - To PED N Air Sepa On The Ba Aration Un Asis of AD Nits D 2000sriramNo ratings yet

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDocument8 pagesISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezNo ratings yet

- 1.0 Scope: Special Requirements For Equipment Purchased For Gaseous Oxygen ServiceDocument13 pages1.0 Scope: Special Requirements For Equipment Purchased For Gaseous Oxygen ServiceandhucaosNo ratings yet

- RPS MMR Piping ClassDocument42 pagesRPS MMR Piping ClassKathia Espinoza RojasNo ratings yet

- Agip-15801 Pip Mec SDSDocument64 pagesAgip-15801 Pip Mec SDSFAUSTO SAMPIETRONo ratings yet

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresNo ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingabdo samadNo ratings yet

- ECS 3-12-5 Compact and Extended Body Steel Gate and Globe ValvesDocument8 pagesECS 3-12-5 Compact and Extended Body Steel Gate and Globe ValvesFlorin Daniel AnghelNo ratings yet

- Nawcpf Msbi NCPF 000 Me LST 31139 c01 Tie in ListDocument5 pagesNawcpf Msbi NCPF 000 Me LST 31139 c01 Tie in ListnizardsouissiNo ratings yet

- Piping Engineering: Marathon Petroleum Co. Project Specific AddendumDocument17 pagesPiping Engineering: Marathon Petroleum Co. Project Specific AddendumChirag ShahNo ratings yet

- 175-Ir022501, (850146), 07.12.2017Document2 pages175-Ir022501, (850146), 07.12.2017Rami ELLOUMINo ratings yet

- Floating and Trunnion Ball Valves PDFDocument15 pagesFloating and Trunnion Ball Valves PDFAlienshowNo ratings yet

- Block and Bleed ValveDocument36 pagesBlock and Bleed ValveTochukwu OnuohaNo ratings yet

- 1280a4-8230-Sp-0001 Rev F3Document18 pages1280a4-8230-Sp-0001 Rev F3Stephen LowNo ratings yet

- 2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev ADocument8 pages2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev ANguyễn ThựcNo ratings yet

- E1N SpecDocument6 pagesE1N SpecprathameshNo ratings yet

- Monolithic Isolating Joint DatasheetDocument3 pagesMonolithic Isolating Joint DatasheetEpwe100% (1)

- JD 007 Part 5 Mechanical Specifications R02Document466 pagesJD 007 Part 5 Mechanical Specifications R02debu332100% (1)

- Lateral DimensionsDocument1 pageLateral DimensionsaravindhcamNo ratings yet

- 7-12-0033 Rev 4Document1 page7-12-0033 Rev 4cynideNo ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- 5D Bends Combine RFQDocument376 pages5D Bends Combine RFQMuhammad Ghufran KhanNo ratings yet

- Swagelok Needle ValvesDocument12 pagesSwagelok Needle Valvesnegg 348No ratings yet

- Udhe 2.standardsDocument1 pageUdhe 2.standardsom dhamnikarNo ratings yet

- Pneumatic, Piston Type: Needle Valve ActuatorsDocument20 pagesPneumatic, Piston Type: Needle Valve Actuatorsarif fadhillahNo ratings yet

- TVA Flowmeter-Technical InformationDocument2 pagesTVA Flowmeter-Technical InformationRandy PalmaNo ratings yet

- Iso 21457-2010Document7 pagesIso 21457-2010empireamsyarNo ratings yet

- Using Economic Indicators to Improve Investment AnalysisFrom EverandUsing Economic Indicators to Improve Investment AnalysisRating: 3.5 out of 5 stars3.5/5 (1)

- 12 M KonveyörDocument36 pages12 M KonveyörHasan arif KısaalioğluNo ratings yet

- m-4 ReportDocument47 pagesm-4 ReportHasan arif KısaalioğluNo ratings yet

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluNo ratings yet

- Boru Bant3Document46 pagesBoru Bant3Hasan arif KısaalioğluNo ratings yet

- System Information Idler Set DataDocument48 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- System Information Cross Sectional LoadingDocument62 pagesSystem Information Cross Sectional LoadingHasan arif KısaalioğluNo ratings yet

- 12 (B 100) Metre KonveyörDocument30 pages12 (B 100) Metre KonveyörHasan arif KısaalioğluNo ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- em 00000 27280 001Document20 pagesem 00000 27280 001Hasan arif KısaalioğluNo ratings yet

- Es 00000 27280 002Document21 pagesEs 00000 27280 002Hasan arif KısaalioğluNo ratings yet

- m-1 ReportDocument58 pagesm-1 ReportHasan arif KısaalioğluNo ratings yet

- m-2 ReportDocument62 pagesm-2 ReportHasan arif KısaalioğluNo ratings yet

- Ee 00000 27280 001Document25 pagesEe 00000 27280 001Hasan arif KısaalioğluNo ratings yet

- Ee 00000 27281 001Document10 pagesEe 00000 27281 001Hasan arif KısaalioğluNo ratings yet

- Slury Sump Calculation ReportDocument2 pagesSlury Sump Calculation ReportHasan arif KısaalioğluNo ratings yet

- 6 KM 2 BoosterDocument62 pages6 KM 2 BoosterHasan arif KısaalioğluNo ratings yet

- Critical Shaft SpeedDocument3 pagesCritical Shaft SpeedkitofanecoNo ratings yet

- 107071-RP-P0005-40443-001 Request For Budgetary QuotationDocument9 pages107071-RP-P0005-40443-001 Request For Budgetary QuotationHasan arif KısaalioğluNo ratings yet

- 107071-RP-P0005-40440-001 Form of AcknowledgementDocument1 page107071-RP-P0005-40440-001 Form of AcknowledgementHasan arif KısaalioğluNo ratings yet

- 15 M3 Tank ReportDocument41 pages15 M3 Tank ReportHasan arif KısaalioğluNo ratings yet

- Vs 99 01Document1 pageVs 99 01Hasan arif KısaalioğluNo ratings yet

- Kule 03-04 Arası KonveyorDocument34 pagesKule 03-04 Arası KonveyorHasan arif KısaalioğluNo ratings yet

- Vs 50 20Document1 pageVs 50 20Hasan arif KısaalioğluNo ratings yet

- 202517C-0000-STC-1390-0001-A - Piping Standart SupportsDocument184 pages202517C-0000-STC-1390-0001-A - Piping Standart SupportsHasan arif KısaalioğluNo ratings yet

- ETI BAKIR P&IDs Mark-Up 29-11-2022Document47 pagesETI BAKIR P&IDs Mark-Up 29-11-2022Hasan arif KısaalioğluNo ratings yet

- 202517C-0000-JSD-1300-022-A - Piping Class DetailedDocument70 pages202517C-0000-JSD-1300-022-A - Piping Class DetailedHasan arif KısaalioğluNo ratings yet

- Conveyor Pulley Design Conveyor Pulley DesignDocument2 pagesConveyor Pulley Design Conveyor Pulley DesignHasan arif KısaalioğluNo ratings yet

- H Series: Reference: Selection No# 84487Document8 pagesH Series: Reference: Selection No# 84487Hasan arif KısaalioğluNo ratings yet

- CupTester Type F - Maintenance PackyardDocument2 pagesCupTester Type F - Maintenance Packyardandrei20041No ratings yet

- Reinforcement Steel FormatDocument18 pagesReinforcement Steel FormatRASCON BUILDNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument36 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Book 1Document16 pagesBook 1ernarendersainiNo ratings yet

- Construction Specifications - Civil: Expand Dhahran Residential Community Residential Area - Package - 6Document261 pagesConstruction Specifications - Civil: Expand Dhahran Residential Community Residential Area - Package - 6mdabdulhadi88No ratings yet

- Hospital ArchiDocument1 pageHospital ArchiGrace Orilla RavarraNo ratings yet

- Drilling and Blasting Activities at Senakin Mine ProjectDocument18 pagesDrilling and Blasting Activities at Senakin Mine ProjectSlamet SetyowibowoNo ratings yet

- LRFD-Manual de PuenteDocument883 pagesLRFD-Manual de PuenteLaura ChomoNo ratings yet

- LP16 Drawing Symbols and SignsDocument4 pagesLP16 Drawing Symbols and SignsGlenn Fortades SalandananNo ratings yet

- Partial Replacement of Fine Aggregate With Marble Waste Powder in Cement Concrete.Document36 pagesPartial Replacement of Fine Aggregate With Marble Waste Powder in Cement Concrete.Harihara Priyadharshan100% (2)

- Ubgmsw 20 M - 2Document3 pagesUbgmsw 20 M - 2abdullah_23320666No ratings yet

- Evaluasi Tebal Perkerasan Oprit Jembatan Bawas Dengan Menggunakan Manual Desain Perkerasan JALAN NO. 02/M/BM/2013Document7 pagesEvaluasi Tebal Perkerasan Oprit Jembatan Bawas Dengan Menggunakan Manual Desain Perkerasan JALAN NO. 02/M/BM/2013elmanpangalinanNo ratings yet